pr1175 1176

Diunggah oleh

akitaleJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

pr1175 1176

Diunggah oleh

akitaleHak Cipta:

Format Tersedia

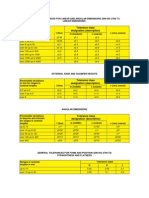

GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED BY PRESS WORKING FROM SHEET METAL AND SHEAR FROM METAL

PLATES

1. General dimensional tolerances for parts formed by press working from sheet metal

Table 1. General dimensional tolerance of blanking

Basic size step 6 or less Over Over Over Over 6 to 30 to 120 to 30 incl. 120 incl. 400 incl. Grades Grade A 0.05 0.1 0.15 0.2 0.3 0.5 Grade B 0.1 0.2 0.3 0.5 0.8 1.2 Grade C 0.3 0.5 0.8 1.2 2 3 Over Over Over Over Unit:mm

TECHNICAL DATA

Excerpt from JIS B 0408/0410(1991)

GENERAL DIMENSIONAL TOLERANCE

1. General dimensional tolerance of cutting

Degree

TECHNICAL DATA

Excerpt from JIS B 0405/0419(1991)

JIS B 0408

-1991

JIS B 0405 -1991

Unit:mm Basic size step

Table 2. adimensional tolerance of bending and drawing

Basic size step 6 or less 6 to 30 to 120 to 30 incl. 120 incl. 400 incl. Grades Grade A 0.1 0.2 0.3 0.5 0.8 1.2 Grade B 0.3 0.5 0.8 1.2 2 3

Unit:mm Grade C 0.5 1 1.5 2.5 4 6

Length dimensional tolerance (excluding chamfered parts)

0.5 ( 1 ) to 3 incl. Over 3 to 6 incl. Over 6 to 30 incl. Over 30 to 120 incl. Over 120 to 400 incl. Tolerance f m c v Fine Medium Coarse Very coarse 0.05 0.1 0.2 0.05 0.1 0.3 0.5 0.1 0.2 0.5 1 0.15 0.3 0.8 1.5 0.2 0.5 1.2 2.5 0.3 0.8 2 4 0.5 1.2 3 6 Over 400 to 1000 incl. Over 1000 to 2000 incl.

Symbol

Explanation

Over 2000 to 4000 incl.

2 4 8

400 to 1000 incl.

400 to 1000 incl.

Over 1000 to 2000 incl. JIS B 0405 respectively.

Over 1000 to 2000 incl. JIS B 0405 respectively.

Note: Grade A, B and C are equal to tolerance grade f, m and c of

Note: Grade A, B and C are equal to tolerance grade m, c and v of

Note 1) ( :Tolerance for standard dimensions of less than 0.5mm shall be specified individually.

2. General tolerances for parts formed by shear from metal plates

Table 1. General dimaensional tolerance of cut width

Board thickness t) ( Basic size step t 1.6 Grade A 30 or less Over Over Over 30 to 120 to 120 incl. 400 incl. 0.1 0.2 0.3 0.5 0.8 1.2 Grade B 0.3 0.5 0.8 1 1.5 2 1.6< t3 Grades Grade A 0.3 0.4 0.5 0.8 1.2 Grade B 0.5 0.8 1.2 2 2.5 Grade A 0.8 1 1.5 2 3 Grade B 1.2 1.5 2 3 4 3< t6

JIS B 0410

-1991

Unit:mm 6< t12 Grade A Grade B 1.5 2 2.5 3 4 Unit:mm Board thickness t) ( 1.6< t3 Grades 3< t6 Grade A 0.5 0.8 1.5 2 3 Grade B 0.8 1.5 2 3 5 Unit:mm Board thickness t) ( 3< t6 Grades 6< t12 Grade A Grade B 1.5 2 3 6 10 6< t12 Grade A Grade B 1.5 2 3 4 6

2. Length dimensional tolerance in chamfered parts 3. Tolerance of angle dimension (corner roundness or chamfer dimension)

Unit:mm Degree 0.5 ( 1 ) to 3 incl. Basic size step Over 3 to 6 incl. Tolerance f m Fine Medium Coarse Very coarse 0.2 0.5 1 Over 6 Degree Symbol Explanation f m c 0.4 1 2 v Fine Medium Coarse 10 or less Shorter side of corner

Over 10 to 50 incl. Over 50 to 120 incl. Over 120 to 400 incl.

Unit:mm

Over 400

Symbol Explanation

Tolerance 1B 1B 30 30 1B 2B 20 30 1B 10 15 30 5 10 20

400 to 1000 incl.

Over 1000 to 2000 incl. Over 2000 to 4000 incl.

c v

Very coarse 3B

Table 2. General tolerance of straightness

Nominal length on cut dimension 30 or less Over Over Over 30 to 120 to 120 incl. 400 incl. 0.1 0.2 0.3 0.5 0.8 1.2 t1.6 Grade A Grade B 0.2 0.3 0.5 0.8 1.2 2

Note 1) ( :Tolerance for standard dimensions of less than 0.5mm shall be specified individually.

4. General tolerance of perpendicularity

JIS B 0419 -1991

Unit:mm Nominal length on shorter side Degree 100 or less

Over 100 to 300 incl. Over 300 to 1000 incl. Over 1000 to 3000 incl.

Grade A 0.2 0.3 0.5 0.8 1.2

Grade B 0.3 0.5 1 1.5 2.5

400 to 1000 incl.

Perpendicularity tolerance H K L 0.2 0.4 0.6 0.3 0.6 1 0.4 0.8 1.5 0.5 1 2

Over 1000 to 2000 incl. Over 2000 to 4000 incl.

Table 3. General tolerance of perpendicularity

Nominal length on shorter side Grade A 30 or less Over Over Over 30 to 120 to 120 incl. 400 incl. 0.3 0.8 1.5 3 6 t 3 Grade B 0.5 1.2 3 6 10

5. General tolerance of straightness and flatness

JIS B 0419 -1991

Unit:mm Nominal area Degree 10 or less Over 10 to 30 incl. Over 30 to 100 incl. Over 100 to Over 300 to Over 1000 to 300 incl. 1000 incl. 3000 incl.

Grade A 0.5 1 2 4 6

Grade B 0.8 1.5 3 6 10

Straightness and flatness tolerance H K L 0.02 0.05 0.1 0.05 0.1 0.2 0.1 0.2 0.4 0.2 0.4 0.8 0.3 0.6 1.2 0.4 0.8 1.6

400 to 1000 incl.

Over 1000 to 2000 incl. Over 2000 to 4000 incl.

1175

1176

Anda mungkin juga menyukai

- General Tolerances DIN ISO 2768Dokumen2 halamanGeneral Tolerances DIN ISO 2768Vasil Gospodinov79% (24)

- Standard Machining Tolerance JIS B 0405Dokumen6 halamanStandard Machining Tolerance JIS B 0405fsijestBelum ada peringkat

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDokumen17 halamanDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoBelum ada peringkat

- Splines: Side Splines For Soft Holes in Fittings-Sae J499aDokumen4 halamanSplines: Side Splines For Soft Holes in Fittings-Sae J499aSanjay C BhattBelum ada peringkat

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDokumen7 halamanFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganBelum ada peringkat

- General Tolerance - IsO 2768-mH (DIN 7168) (JIS B 0419)Dokumen3 halamanGeneral Tolerance - IsO 2768-mH (DIN 7168) (JIS B 0419)olive_poa100% (3)

- Standard Machining ToleranceDokumen1 halamanStandard Machining ToleranceDenny Ilyas AttamimiBelum ada peringkat

- General Tolerances To DIN ISO 2768 T1 and T2Dokumen2 halamanGeneral Tolerances To DIN ISO 2768 T1 and T2manageieBelum ada peringkat

- Ss-Iso 2768-1Dokumen1 halamanSs-Iso 2768-1Smile ManBelum ada peringkat

- 6885 1Dokumen1 halaman6885 1ajeshBelum ada peringkat

- Gage Calibration IDokumen2 halamanGage Calibration Imanha3Belum ada peringkat

- Cutting With BroachDokumen5 halamanCutting With BroachJori Kristian RidayatBelum ada peringkat

- SAE J1926, MS 16142 - CuttersDokumen11 halamanSAE J1926, MS 16142 - CutterspbsurfBelum ada peringkat

- Totime BTA DRILLDokumen5 halamanTotime BTA DRILLTOTIME (DEREK HIROSAKA)Belum ada peringkat

- Thread TolerancesDokumen8 halamanThread TolerancesLê Xuân HiệpBelum ada peringkat

- Gears, Splines, and Serrations: Unit 24Dokumen8 halamanGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Hob Seminar (English)Dokumen26 halamanHob Seminar (English)RizwanAliBelum ada peringkat

- Din 7168Dokumen1 halamanDin 7168Anderson SantosBelum ada peringkat

- Hollow Bars (ISO2938)Dokumen8 halamanHollow Bars (ISO2938)suku maranBelum ada peringkat

- Gear CorrectionDokumen17 halamanGear CorrectionMurugesanBelum ada peringkat

- Circlip Dimensions PDFDokumen71 halamanCirclip Dimensions PDFBoobalan ShriBelum ada peringkat

- Gears - Engineering InformationDokumen138 halamanGears - Engineering InformationGiang T LeBelum ada peringkat

- Helical Spring LockwashersDokumen4 halamanHelical Spring LockwashersjoseocsilvaBelum ada peringkat

- Kisssoft Tut 007 E BearingsDokumen12 halamanKisssoft Tut 007 E BearingsIkshit JainBelum ada peringkat

- Quick Knurling CatalogueDokumen28 halamanQuick Knurling CatalogueMilos Lazovic100% (1)

- BS 970Dokumen5 halamanBS 970aezeadBelum ada peringkat

- Technical Catalogue Bearings NBCDokumen109 halamanTechnical Catalogue Bearings NBCBhusarapu Srinivas50% (2)

- Nps - NPSM - NPSC TapsDokumen1 halamanNps - NPSM - NPSC TapsCarlos Murguia PerezBelum ada peringkat

- Metal Table JISDokumen1 halamanMetal Table JISNakkolopBelum ada peringkat

- Spring PinsDokumen3 halamanSpring PinsalphadingBelum ada peringkat

- BoilerTubes - TechnitubeDokumen24 halamanBoilerTubes - TechnitubeMMPAPBelum ada peringkat

- Thread EngagementDokumen15 halamanThread Engagementsumeetsaini88Belum ada peringkat

- ISO Tolerances For FastenersDokumen2 halamanISO Tolerances For Fastenersganeshl08Belum ada peringkat

- List of DIN Standards - 2006-04-20 PDFDokumen4 halamanList of DIN Standards - 2006-04-20 PDFSerggie TabanaoBelum ada peringkat

- SKF Ball ScrewDokumen40 halamanSKF Ball Screwsav33Belum ada peringkat

- Bs 4235 1 1972 Specification For Metric Keys and Keyways Parallel and Taper Keys PDFDokumen26 halamanBs 4235 1 1972 Specification For Metric Keys and Keyways Parallel and Taper Keys PDFHithayathulla KhanBelum ada peringkat

- Metric DIN 127 SpecDokumen5 halamanMetric DIN 127 SpecmahfuzBelum ada peringkat

- ISO 2768 TolerancesDokumen2 halamanISO 2768 TolerancesJan Van de Velde100% (2)

- Fed STD H28 20BDokumen30 halamanFed STD H28 20BL FBelum ada peringkat

- Thread RollingDokumen2 halamanThread RollingManoj MathewBelum ada peringkat

- Surface Roughness by Different Processing MethodsDokumen1 halamanSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Us 12e pr1265 PDFDokumen1 halamanUs 12e pr1265 PDFAzis AbdBelum ada peringkat

- ToleranceDokumen9 halamanTolerancemarkom123Belum ada peringkat

- Worldsupport Standards14.Php ActioDokumen3 halamanWorldsupport Standards14.Php ActioSteel Zevallos PitzuhaBelum ada peringkat

- Thikness TolerenceDokumen5 halamanThikness TolerencemuneeshwaraperumalBelum ada peringkat

- Acceptence Criteria IMTEDokumen12 halamanAcceptence Criteria IMTEdanaka007100% (1)

- Standard EN10029Dokumen4 halamanStandard EN10029Florin JipaBelum ada peringkat

- Jis G4051Dokumen7 halamanJis G4051tnchsgBelum ada peringkat

- Structural Tolerances Bs4 - 2004Dokumen4 halamanStructural Tolerances Bs4 - 2004Anonymous 8bH7sXpcEHBelum ada peringkat

- BS en 10219 (Tolerances) Dimensional-TolerancesDokumen1 halamanBS en 10219 (Tolerances) Dimensional-TolerancesBFEVietnamBelum ada peringkat

- Jis B 0419Dokumen1 halamanJis B 0419Wee Yaw LimBelum ada peringkat

- Tata Steel Bulb Flats BroDokumen11 halamanTata Steel Bulb Flats BroMd. Rafique HassanBelum ada peringkat

- Tolerante Table Groase Laminate La Cald EN 10029-2011 PDFDokumen2 halamanTolerante Table Groase Laminate La Cald EN 10029-2011 PDFDaniel C.Belum ada peringkat

- Parkers: BS EN 10258: 1997Dokumen3 halamanParkers: BS EN 10258: 1997JagankumarBelum ada peringkat

- Tolerances FabDokumen1 halamanTolerances FabAnwarBelum ada peringkat

- Tolerances For Stainless Steel Flat BarsDokumen1 halamanTolerances For Stainless Steel Flat BarsOvidiu ChertesBelum ada peringkat

- Jis B 08265 000 000 2010 Cor 2 201312 e CHDokumen11 halamanJis B 08265 000 000 2010 Cor 2 201312 e CHdhBelum ada peringkat

- By: Hlux Strategy: Repeat 4 Rounds: Turn # Level: 28 0 Boost Level: 28 0 Boost Level: 30 0 Boost RemarksDokumen1 halamanBy: Hlux Strategy: Repeat 4 Rounds: Turn # Level: 28 0 Boost Level: 28 0 Boost Level: 30 0 Boost RemarkstnchsgBelum ada peringkat

- HLux Strategy PDFDokumen1 halamanHLux Strategy PDFtnchsgBelum ada peringkat

- Power Screw: Square Threads Acme ThreadsDokumen9 halamanPower Screw: Square Threads Acme ThreadstnchsgBelum ada peringkat

- BN 621Dokumen3 halamanBN 621tnchsgBelum ada peringkat

- Linear Actuators Accelerate Motion-System Design: What's InsideDokumen1 halamanLinear Actuators Accelerate Motion-System Design: What's InsidetnchsgBelum ada peringkat

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDokumen34 halamanBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessestnchsgBelum ada peringkat

- Grinding WheelsDokumen26 halamanGrinding Wheelsznovak77Belum ada peringkat

- Mould+Steel+1 2316 (ESR)Dokumen3 halamanMould+Steel+1 2316 (ESR)tnchsgBelum ada peringkat

- Intro To Machine Vision SlidesDokumen49 halamanIntro To Machine Vision Slidestnchsg100% (3)

- 1 VR6470LVM (VR6272) (E)Dokumen44 halaman1 VR6470LVM (VR6272) (E)tnchsgBelum ada peringkat

- ISO 4026 DIN 913: GewindestifteDokumen3 halamanISO 4026 DIN 913: GewindestiftetnchsgBelum ada peringkat

- Measurement GC 600e71 GB WW 1065-4Dokumen70 halamanMeasurement GC 600e71 GB WW 1065-4tnchsgBelum ada peringkat

- M Cubed Thermal Management Materials WebDokumen2 halamanM Cubed Thermal Management Materials WebtnchsgBelum ada peringkat

- CeramicsDokumen39 halamanCeramicsAlok MahadikBelum ada peringkat

- Inch Fastener Standards 8th Edition PreviewDokumen18 halamanInch Fastener Standards 8th Edition Previewtnchsg50% (4)

- Jis G4051Dokumen7 halamanJis G4051tnchsgBelum ada peringkat

- S 275Dokumen3 halamanS 275tnchsgBelum ada peringkat