CBR Soil Testing Method

Diunggah oleh

meelauk86Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CBR Soil Testing Method

Diunggah oleh

meelauk86Hak Cipta:

Format Tersedia

Pavements Engineering Branch

TEST METHOD

WA 141.1

DETERMINATION OF THE CALIFORNIA BEARING RATIO OF A SOIL: STANDARD LABORATORY METHOD FOR A REMOULDED SPECIMEN

SCOPE This Standard sets out the procedure for the determination of the California Bearing Ratio (CBR) of a soil when compacted and tested in the laboratory. The method is applicable to finegrained and medium-grained soils, as defined in Test Method WA 105.1.

REFERENCED DOCUMENTS Australian Standards AS 1152 AS 2103 AS 2193 Specification for test sieves Dial gauges and dial test indicators Methods for calibration and grading of force-measuring systems of testing machines

WA Test Methods WA 105.1 Preparation of Disturbed Soil and Granular Pavement Material Samples for Testing. Soil and Granular Pavement Material Moisture Content: Convection Oven Method. Soil and Granular Pavement Material Moisture Content: Microwave Oven Method. Dry Density/Moisture Content Relationship: Standard Compaction Fine and Medium Grained Soils Dry Density/Moisture Content Relationship: Modified Compaction Fine and Medium Grained Soils

WA 110.1

WA 110.2

WA 132.1

WA 133.1

DEFINITIONS Laboratory moisture ratio the ratio of the moisture content of the specimen to the optimum moisture content of the material as determined on material prepared in accordance with Procedure 1.4, expressed as a percentage. Laboratory density ratio the ratio of the dry density of the specimen to the maximum dry density of the material as determined on material prepared in accordance with Procedure 1.4, expressed as a percentage.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 1 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

APPARATUS 1. Steel penetration piston with a 49.6 0.1 mm diameter over the length of penetration. The length of the piston will depend upon the number of surcharges and the depth of penetration required. Loading machine equipped with (a) A moveable head or base capable of travelling at a uniform (not pulsating) rate of 1 0.2 mm/min for use in forcing the penetration piston into the specimen; and A force-measuring device meeting the accuracy and repeatability requirements of AS 2193 Grade C testing machines for the range of forces used in the test. The force-measuring device shall be also capable of indicating seating loads of approximately 50 N and 250 N.

2.

(b)

NOTE: The indicator points of the force-measuring device at the seating loads of approximately, but not greater than, 50 N (for expected CBR values equal to or less than 30) and 250 N (for expected CBR values greater than 30) need not necessarily meet the Grade C requirements of AS 2193 but should be displayed as definite numbers or marks.

3.

Cylindrical metal mould (Figure 1) of known volume with an internal diameter 152 1 mm, height 178 1 mm and wall thickness of at least 5 mm, provided with a metal extension collar and a perforated metal baseplate. Steel spacer disc (Figure 2) of 150 0.5 mm diameter and 61 0.25 mm high, fitted with a removable handle for lifting the disc from the mould. Compaction apparatus complying with the requirements of WA 132.1 or WA 133.1, as applicable. Metal stem and perforated plate with a mass of 1.00 0.025 kg (Figure 3). Metal surcharges, with each surcharge having a mass of 2.25 0.025 kg, a diameter of 150 0.5 mm and with a centre hole of 55 1.0 mm diameter (Figure 4).

NOTE: During penetration the surcharge in contact with the soil should meet the tolerances as specified. Other surcharges may be slotted and may be outside the tolerances provided the total surcharge mass is within the required tolerances and there is no contact with the side of the mould and the penetration piston.

4.

5.

6. 7.

8.

Two displacement measuring devices, e.g. dial gauges capable of measuring the expected range of travel, graduated to 0.01 mm and meeting the accuracy and repeatability requirements of AS 2103. Sieve, 19 mm and, if required, a 4.75 mm sieve, complying with AS 1152. Balance of at least 15 kg capacity readable to 1 g, or less, with a limit of performance (F) of not more than 4.0 g, at the 95% Confidence Level. Jack, lever, frame or other suitable device, which may be used for extruding specimens from the cylinder (optional).

9. 10.

11.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 2 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 3 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

12.

Metal tripod, if swell is to be measured to support the dial gauge or displacement measuring device for measuring the amount of swell during soaking (see Figure 5). Setting piece, if swell is to be measured and the tripod or displacement measuring device is removed from the mould during the test, to set the reading on the dial gauge or measuring device attached to the metal tripod prior to each reading in the swell test. Water tank or container capable of maintaining water at a level above the moulds, during soaking. Other apparatus such as a mixing bowl, straightedge, filter paper and dishes.

13.

14.

15.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 4 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

PROCEDURE 1 1.1 PREPARATION OF THE TEST INCREMENT Using the 19 mm sieve, sieve a representative sample of the soil prepared in accordance with the procedure prescribed in Test Method WA 105.1. Determine the percentage of material retained on the sieve. Only the material passing the 19 mm sieve is to be used for the test.

NOTES: 1 The removal of small amounts of stone retained on the 19 mm sieve will affect the CBR obtained only by amounts comparable with experimental error involved in measuring CBR. The exclusion of a large portion of stone coarser than 19 mm (such as is present, for example, in a gravel of 75 mm maximum size) may have a major effect on CBR compared with that obtainable with the soil as a whole, and on the optimum moisture content. There is at present no generally accepted method of testing, or of calculation, for dealing with this difficulty in comparing laboratory CBR test results with CBR values obtained in the field. If it is specified that the same percentage of coarse material (passing the 53 mm and retained on the 4.75 mm sieves) in the test sample as in the original field sample is to be maintained, the material retained on the 19 mm sieve may be replaced by an equal portion by mass of the materials passing the 19 mm sieve and retained on the 4.75 mm sieve. It is important that the maximum dry density and optimum moisture content used to determine the laboratory density ratio and laboratory moisture ratio be determined on the material passing the 19 mm sieve which is the same as that used to determine the CBR value. If material retained on the 19 mm sieve is replaced by an equal portion by mass of materials passing the 19 mm sieve, the values determined on material without the replacement are not applicable. The percentage by mass of material retained on the 19 mm sieve and whether it was excluded or replaced should be included in the report. 2 Material, which has been compacted previously in the laboratory, should not be re-used, as breakdown of the material during compaction can lead to misleading results.

1.2

Obtain by riffling or quartering the sieved material, representative test increments for determining maximum dry density, optimum moisture content and CBR. Determine the maximum dry density and optimum moisture content in accordance with Test Method WA 132.1or WA 133.1, as applicable Determine the hygroscopic moisture content ( wH ) on an additional two test increments in accordance with either Test Method WA 110.1 or WA 110.2. Select the dry density ( d ) / moisture content ( wC ) condition at which the test increments are to be moulded. Thoroughly mix two test increments with a suitable amount of potable water to bring the test increment to the required moisture content. Calculate the required mass of water (m WR ) using the following equations:

1.3

1.4

1.5

1.6

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 5 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

Calculate the dry mass of the test increment using the equation:

DM TI = WM TI 100 100 + w H

where DMTI WMTI WH

= dry mass of test increment in grams = wet mass of test increment in grams = hygroscopic moisture content as a percentage

Calculate the total mass of water required to bring the test increment to the desired moisture content using the equation:

mW = where mW wc DMTI

w c DM TI 100 = total mass of water to bring test increment to the required moisture content in grams = moisture content at compaction as a percentage = dry mass of test increment in grams

Calculate the mass of hygroscopic water in the test increment using the following equation:

mH = wH DM TI 100

where

mH wH DMTI

= mass of hygroscopic water in grams = hygroscopic moisture content as a percentage = dry mass of test increment in grams

Calculate the mass of water to be added to bring the test increment to the desired moisture content using the equation:

m WR = m W m H

where mWR mW mH = mass of water to be added to the test increment in grams = total mass of water in test increment in grams = mass of hygroscopic water in test increment in grams

1.7

Cure the test increment for an adequate period depending upon the soil type. Record the duration of curing.

NOTE: It is important that the water is thoroughly mixed into and uniformly distributed through the soil since inadequate mixing gives rise to variable results. It is desirable to keep the soil in a sealed container to allow the water to become more uniformly distributed through the soil before compaction. For materials of low plasticity and high permeability prepared in a moist condition close to optimum moisture content, little or no curing is required, but if the soil is dry and contains heavy clay, up to 7 days curing prior to compaction may be required. The more cohesive a soil, the more time required for moisture to infiltrate and equilibrate. All soils should be cured for a minimum of 2 hours.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 6 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

PREPARATION OF THE TEST SPECIMEN

2.1

Calculate the desired wet density of the test specimen using of the following equation:

=

where wC 2.2

d (100 + w C )

100

= desired wet density of test specimen in t/m = dry density of test specimen in t/m = moulding moisture content of the test specimen as a percentage

Calculate the wet mass of each layer that is to be compacted in the mould using the equation:

mL = m TS No. of layers

where

mL mTS

= wet mass of soil per layer in grams = wet mass of test specimen in grams

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

MAIN ROADS Western Australia 04/12588

Page 7 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

2.3

Determine the mass of the mould (m1).

NOTE: For convenience weighing of the mould may include the baseplate. If so all subsequent procedures and calculations should be modified.

2.4

Insert the spacer disc, clamp the mould (with the extension collar attached) to the baseplate and place a filter paper on top of the spacer disc. Immediately prior to compaction thoroughly mix the cured soil and determine the moisture content (w1) of a representative fraction of the test portion in accordance with Test Method WA 110.1. Compact the specimen uniformly in the mould to the specified laboratory density ratio as follows: (a) Standard compactive effort in three layers so that the compacted height of the soil is 39 mm to 44 mm in the first layer, 78 mm to 83 mm in the second layer and 117 mm to 122 mm in the third layer. Modified compactive effort in five layers so that the compacted height of the soil in the mould is 21 mm to 26 mm in the first layer, 45 mm to 50 mm in the second layer, 67 mm to 72 mm in the third layer, 92 mm to 97 mm in the fourth layer and 117 mm to 122 mm in the fifth layer. Discard specimens that do not meet these requirements.

2.5

2.6

(b)

NOTE: Unless otherwise specified, specimens should be compacted with a laboratory density ratio of 100 percent and a laboratory moisture ratio of 100 percent. This will require 53 blows of the rammer per layer. Where specimens are compacted at other than a laboratory density ratio of 100% and a laboratory moisture ratio of 100% the minimum number of blows per layer, using either the standard or modified compaction hammers, shall be nine (9) blows. The blows shall be distributed as follows: eight (8) blows around the perimeter of the specimen (with minimal overlap) and one (1) blow in the centre of the layer. In all cases, the laboratory moisture ratio should be within 5.0 percent of the specified moisture ratio and laboratory density ratio should be within 1.0 percent of the specified density ratio, respectively.

2.7 2.8

Free the material from around the inside of the collar and carefully remove the collar. While the baseplate is still attached, trim the surface of the compacted specimen level with the top of the mould by means of a straightedge. Use smaller sized material to patch any holes developed in the surface from removal of coarse material during trimming (see also Test Methods WA 132.1 or WA 133.1). Remove the perforated baseplate, spacer disc and filter paper, and determine the mass of the mould plus compacted soil (m2).

2.9

2.10 Place a filter paper on the perforated baseplate, invert the mould plus the compacted soil and place it on the baseplate. Clamp the baseplate to the mould with the compacted soil in contact with the filter paper. 2.11 If soaking is not required, perform the penetration test (Procedure 4).

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 8 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

SOAKING THE TEST SPECIMEN

3.1 3.2

Determine the mass of the baseplate plus mould plus specimen (m3). Place the stem and perforated plate on the compacted soil specimen in the mould and apply surcharges of 4.5 kg. Apply any additional surcharges, if specified.

NOTE: Surcharges may be applied to simulate the confining effects of the overlying material layers (see Figure 7).

3.3

If measurement of swell is required proceed as follows: (a) If the tripod or measuring gauge is to be removed from the mould during soaking, set the reading on the measuring device against the setting piece. Record the initial reading before soaking (h1) using the metal tripod and displacement measuring device. Mark the points of contact of the tripod with the mould.

(b)

3.4

Immerse the surcharged specimen in water, allow free access of water to the top and the bottom of the specimen. Allow the specimen to soak for 4 days, or for the specified soaking period. Maintain the water level above the mould during this period.

NOTE: A shorter soaking period is permissible for soils that take up moisture readily, provided tests have shown that the shorter period does not affect the results. Some specifiers require longer soaking periods. If shorter or longer soaking periods are used they are to be adhered to and reported.

3.5

After soaking is completed and if the measurement of swell is required proceed as follows prior to removal of the specimen from the water: (i) If the tripod or measuring device has been removed from the mould during soaking, set the reading on the measuring device against the setting piece so that it is the same as that used in Step 3.3 (a). Place the tripod on the points of contact marked in Step 3.3 (b) and record the reading after soaking (h2).

(ii)

3.6

Remove the specimen from the water and tilt the specimen to remove the surface water. Return the mould to the vertical position and allow the specimen to drain downward for 15 minutes. Do not disturb the surface of the specimen during the removal of water. Remove the surcharges, stem and perforated plate and determine the mass of the baseplate plus mould plus specimen (m4). Perform the penetration test (Procedure 4) as soon as practicable ensuring the specimen does not dry out.

3.7

3.8

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 9 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

PENETRATION TEST

4.1

Place the 2.25 kg annular surcharge on the soil surface and then place the mould plus specimen plus baseplate in the loading machine. Seat the penetration piston with the smallest possible load, not exceeding 50 N for expected CBR values equal to or less than 30 and 250 N for expected CBR values greater than 30. Apply surcharges as required. Unless otherwise specified the surcharge mass shall be 4.5 kg. If the specimen was soaked, apply surcharges equivalent in mass to those applied during soaking.

NOTES: 1 This initial load is required to ensure satisfactory seating of the piston and is considered as the zero load when plotting the load-penetration curve. Surcharges may be applied to simulate the confining effects of the overlying material layers (see Figure 7).

4.2

Read, or set to zero, the force-measuring device and the displacement measuring device used to measure penetration. The penetration measured shall be that of the piston relative to the mould (Note).

NOTE: The dial gauge should be mounted such that no other displacements in the equipment influence the actual measured penetration.

4.3

Apply the load with a constant rate of penetration of 1 0.2 mm/min. Record load readings at penetrations of 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 7.5, 10.0 and 12.5 mm.

NOTES: 1 With manually operated loading devices, it may be necessary to take load readings at closer intervals to control the rate of penetration. The test may be terminated after 7.5 mm penetration if the penetration is proceeding without any increase or decrease, in the load.

4.4

Remove the soil from the mould and determine the moisture content of the top 30 mm layer (w30) and that of the entire depth (including the top 30 mm) of the specimen (wr) in accordance with Test Method WA 110.1.

CALCULATIONS

Calculate the following: 1. Plot the load-penetration curve (see Figure 6). When the load-penetration curve is concave upward initially (because of surface irregularities or other causes) adjust the zero point as shown in Figure 6, curve 3. If the correction is greater than 2 mm the loadpenetration curve shall be presented in the test report. Read from the load-penetration curve, corrected if required, the force value in kN at penetrations of 2.5 mm and 5.0 mm and calculate the bearing ratio for each by dividing by 13.2 kN and 19.8 kN, respectively, and multiplying by 100. Record the greater value of the calculated values as the CBR of the material. 3. Calculate the dry density of the specimen before soaking (pd) from the following equation:

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

2.

MAIN ROADS Western Australia 04/12588

Page 10 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

d =

m m1 1 x 2 w V1 1 + 1 100

Where

d = dry density of the specimen, in grams per cubic centimetre

m2 = mass of the mould plus compacted soil, in grams m1 = mass of the mould, in grams V1 = volume of the specimen before soaking, in cubic centimetres (volume of the mould less the volume occupied by the disc) w1 = moisture content of the material immediately prior to compaction

4.

If the specimen is compacted to a density ratio other than 100 per cent, calculate the laboratory density ratio (LDR) of the specimen from the following equation:

LDR =

d

MDD

x100

Where

LDR

= laboratory density ratio, in percent = dry density of the specimen, in grams per cubic centimetre

MDD = maximum dry density of the soil, in grams per cubic centimetre

5.

If the specimen is compacted with a moisture ratio other than 100 percent, calculate the laboratory moisture ratio (LMR) of the specimen from the following equation:

LMR =

w1 x100 OMC

Where

LMR w1

= laboratory moisture ratio, in percent = moisture content of the soil immediately prior to compaction, in percent

OMC = optimum moisture content of the soil, in percent

6.

If the swell is to be measured, calculate the swell (S) from the following equation:

S=

h2 h1 x100 117

Where

S h2 h1

= the swell of the specimen, in percent = the reading after soaking, in millimetres = the reading before soaking, in millimetres

7.

If the specimen has been soaked and if required, calculate the mass of dry soil in the specimen (m5) from the following equation:

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

MAIN ROADS Western Australia 04/12588

Page 11 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

m5 =

m2 m1 w 1 + 1 100

Where

m5 = mass of dry soil in the specimen, in grams m2 = mass of mould plus compacted soil, in grams m1 = mass of mould, in grams w1 = moisture content of the soil immediately prior to compaction, in percent

8.

If the specimen has been soaked and if required, calculate the moisture content of the specimen after soaking (ww) from the following equation:

ww = w1 +

Where

m4 m3 x100 m5

ww = moisture content of the specimen after soaking, in percent w1 = moisture content of the soil immediately prior to compaction, in percent m4 = mass of mould baseplate plus mould plus specimen after soaking in grams m3 = mass of mould baseplate plus mould plus specimen before soaking, in grams m5 = mass of dry soil in the specimen, in grams

9.

If the specimen has been soaked and, if required, calculate the volume of the specimen after soaking (V2) from the following equation:

100 + S V2 = V1 100

Where

V2 = the volume of the specimen after soaking, in cubic centimetres V1 = the volume of the specimen before soaking, in cubic centimetres (volume of the mould less the volume occupied by the disc) S

= the swell of the specimen, in percent

10.

If the specimen has been soaked, and if required, calculate the specimen dry density after soaking (pda) from the following equation:

da =

Where

m5 V2

da

m5 V2

= dry density of the specimen after soaking, in grams per cubic centimetre = mass of dry soil in the specimen, in grams = the volume of the specimen after soaking, in cubic centimetres Document Number 71-04-141-1 Page 12 of 19

Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

MAIN ROADS Western Australia 04/12588

Pavements Engineering Branch

TEST METHOD

WA 141.1

11.

Calculate the following moisture contents as a percentage of optimum moisture content (determined in accordance with Test Method WA 132.1 or WA 133.1). Moisture content (w1) of the specimen prior to compaction Moisture content (w30) of the top 30 mm layer after testing Moisture content (w r) of the entire specimen after testing

12.

If appropriate, calculate the following dry densities as a percentage of maximum dry density (determined in accordance with Test Method WA 132.1 or WA 133.1). Dry density of specimen before soaking Dry density of the specimen after soaking

REPORTING

Report the following: 1. CBR of the specimen to the nearest value, in percent as follows: CBR percent <5 5 to 20 20 to 50 > 50 2. 3. Report value to the nearest 0.5 1 5 10

The penetration at which the CBR was determined, in millimetres. The laboratory moisture content and the moisture ratio at which the specimen was compacted, to the nearest 0.01 and 0.1 percent respectively. The laboratory dry density and dry density ratio, at which the specimen was compacted, to the nearest 0.001 t/m and 0.1 percent respectively. The moisture content and moisture ratio of the top 30 mm of the specimen after penetration, to the nearest 0.01 and 0.1 percent respectively. (a) (b) (c) The swell of the specimen after soaking to the nearest 0.5 percent. The dry density ratio of the specimen after soaking, in percent. The moisture content and moisture ratio of the entire depth of the specimen, after penetration, to the nearest 0.01 and 0.1 percent respectively.

4.

5.

6.

The percentage by mass of the material retained on the 19 mm sieve and whether it was excluded from the test or crushed to material that passes the 19 mm sieve and is retained on the 4.75 mm sieve. The mass of surcharges applied.

7.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 13 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

8.

The compactive effort used to compact the specimen in terms of the number of layers, the number of blows per layer and the mass of the rammer. The period of soaking. Identification and description of sample. The load-penetration curve, if the correction to the test curve is greater than 2 mm. The number of this Test Method; WA 141.1. The maximum dry density to the nearest 0.001 t/m and the optimum moisture content of the specimen to the nearest 0.1%.

9. 10. 11. 12. 13.

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 14 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 15 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

REVISION STATUS RECORD OF THIS ISSUE Page No. Section Revision Description / Reference

3.5

prior to removal of the specimen from the water inserted at the end of the first sentence. Insertion made to clarify when measurement for swell is made. Remove the specimen from the water and added to the beginning of the first sentence. Added the word mass to read

3.6

11

Calculations 3

m2 = mass of the mould plus compacted soil, in grams

Previously the line read

m2 = of the mould plus compacted soil, in grams

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 16 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 17 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 18 of 19

Pavements Engineering Branch

TEST METHOD

WA 141.1

MAIN ROADS Western Australia 04/12588

Document Number 71-04-141-1 Determination of the California Bearing Ratio of a Soil: Standard Laboratory Method for a Remoulded Specimen Issue 28 August 2006

Page 19 of 19

Anda mungkin juga menyukai

- SRDK Cryocooler Service Manual: For Service Personnel OnlyDokumen151 halamanSRDK Cryocooler Service Manual: For Service Personnel OnlyOtávio PagnoncelliBelum ada peringkat

- Quarterly Reports: Presented by ICE SouthwestDokumen10 halamanQuarterly Reports: Presented by ICE SouthwestRuben Rodriguez PargaBelum ada peringkat

- Ice Ipd PDF FreeDokumen60 halamanIce Ipd PDF FreeNur JumatBelum ada peringkat

- Project Closure Report - New Adelaide Hospital ProjectDokumen23 halamanProject Closure Report - New Adelaide Hospital ProjectSahilBelum ada peringkat

- CDC UP Quality Management Plan TemplateDokumen9 halamanCDC UP Quality Management Plan TemplatePriyanka GargBelum ada peringkat

- BOBS Standards Catalogue - June 2014Dokumen131 halamanBOBS Standards Catalogue - June 2014King Ken Molefane0% (1)

- 3.3 Pile CapDokumen16 halaman3.3 Pile CapEnrike GarciaBelum ada peringkat

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDokumen44 halamanOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Belum ada peringkat

- TG1 Scala Dynamic Cone Penetrometer Cone CalibrationDokumen4 halamanTG1 Scala Dynamic Cone Penetrometer Cone Calibrationanthony100% (1)

- t209 PDFDokumen12 halamant209 PDF094-STEVEN EDWARD WINDARTO100% (1)

- Annalysis of Sediments of MahaoyaDokumen13 halamanAnnalysis of Sediments of MahaoyaBhathiya AthurupaneBelum ada peringkat

- GROUP 2 SLOPE FAILURE IN UKM BANGIDokumen41 halamanGROUP 2 SLOPE FAILURE IN UKM BANGIMunirohBaharinBelum ada peringkat

- ICAR Rheometer: Eric Koehler W.R. Grace & CoDokumen34 halamanICAR Rheometer: Eric Koehler W.R. Grace & CoHafiezul HassanBelum ada peringkat

- Advanced RC Week2Dokumen41 halamanAdvanced RC Week2haloBelum ada peringkat

- Concrete and Concrete Structures: Modular Concepts India PVT LTDDokumen24 halamanConcrete and Concrete Structures: Modular Concepts India PVT LTDArunKumar ChandrasekarBelum ada peringkat

- VTU PHD Guidelines 2013Dokumen11 halamanVTU PHD Guidelines 2013Harish ReddyBelum ada peringkat

- ICAR Rheometer Users ManualDokumen24 halamanICAR Rheometer Users ManualJAVIER ANDRADE MARTINEZBelum ada peringkat

- Presentation For Third Party Quality Surveillance Work: - Sertech ConsultantsDokumen26 halamanPresentation For Third Party Quality Surveillance Work: - Sertech Consultantsrajivbhargava88Belum ada peringkat

- Concrete Pipe Deflection LimitsDokumen18 halamanConcrete Pipe Deflection LimitsAhmed KarimBelum ada peringkat

- Week 5 - Intro Design and Analysis of Shallow FoundationDokumen33 halamanWeek 5 - Intro Design and Analysis of Shallow FoundationMUSLIHAH AQILAH MUSAFFENDY100% (1)

- Test Materials Apparatus GuideDokumen42 halamanTest Materials Apparatus GuideEllen Rose NovoBelum ada peringkat

- Department of Construction Sessional Examination (Spring Semester)Dokumen9 halamanDepartment of Construction Sessional Examination (Spring Semester)Harry LaiBelum ada peringkat

- CSC Orion Programme PDFDokumen24 halamanCSC Orion Programme PDFnsureshbabuBelum ada peringkat

- Install Guide Spunlite Poles 2015Dokumen6 halamanInstall Guide Spunlite Poles 2015Balaji PalaniBelum ada peringkat

- IGS Paper Q 291Dokumen4 halamanIGS Paper Q 291RoshanRSVBelum ada peringkat

- Strength of Materials Laboratory ManualDokumen33 halamanStrength of Materials Laboratory ManualRock Man100% (1)

- Presentation On Reinforcing Detailing of R.CDokumen16 halamanPresentation On Reinforcing Detailing of R.CbertazcorpBelum ada peringkat

- AS1304Dokumen1 halamanAS1304Jef LeBelum ada peringkat

- C 293 - 00 Qzi5my0wma - PDFDokumen3 halamanC 293 - 00 Qzi5my0wma - PDFMarceloBelum ada peringkat

- Loading Tests On PilesDokumen3 halamanLoading Tests On PilesRajesh KhadkaBelum ada peringkat

- PAKISTAN ENGINEERING COUNCIL EPE SYLLABUSDokumen5 halamanPAKISTAN ENGINEERING COUNCIL EPE SYLLABUSTaimur AkhtarBelum ada peringkat

- Method Statement - Soil InvestigationDokumen10 halamanMethod Statement - Soil InvestigationKamal Deo ShahBelum ada peringkat

- HSD Mechanical Technology and Construction ProceduresDokumen17 halamanHSD Mechanical Technology and Construction ProceduresbienndcBelum ada peringkat

- Civil Engineering Structure Lab ReportDokumen13 halamanCivil Engineering Structure Lab ReportasyrafBelum ada peringkat

- ALDAR Sustainablity Report 2009Dokumen81 halamanALDAR Sustainablity Report 2009Scott KramerBelum ada peringkat

- Pull Out Testing Methodology Ultimate Load Tests For Rebar DowelsDokumen3 halamanPull Out Testing Methodology Ultimate Load Tests For Rebar DowelsHenry FlorendoBelum ada peringkat

- Aisi 4340Dokumen3 halamanAisi 4340santoshBelum ada peringkat

- GUIDE CONCRETEDokumen28 halamanGUIDE CONCRETEAfzaalUmairBelum ada peringkat

- Project Management Professional (PMP) - General - Part IDokumen27 halamanProject Management Professional (PMP) - General - Part Iguava58Belum ada peringkat

- Draft Pren 15383: European Standard Norme Européenne Europäische NormDokumen55 halamanDraft Pren 15383: European Standard Norme Européenne Europäische NormGigiBelum ada peringkat

- Discussion Bending MomentDokumen4 halamanDiscussion Bending MomentLoga SaserBelum ada peringkat

- General Specification For Civil Engineering Works (GS), 2006 Edition - Guidance NoteDokumen374 halamanGeneral Specification For Civil Engineering Works (GS), 2006 Edition - Guidance NoteZaireen Azmee67% (3)

- Astm c131 06 LaavDokumen4 halamanAstm c131 06 LaavRasya FiezaBelum ada peringkat

- Presentation Template Civil Structural Inspection1Dokumen68 halamanPresentation Template Civil Structural Inspection1sayafrands6252Belum ada peringkat

- Rebar Cut & Bend WorkDokumen6 halamanRebar Cut & Bend Workajit karandikarBelum ada peringkat

- Welded Wire Reinforcement WWM WWR Common SizesDokumen2 halamanWelded Wire Reinforcement WWM WWR Common Sizesgullipalli100% (1)

- Steel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeDokumen6 halamanSteel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeРумен ДрагановBelum ada peringkat

- KDACI New V1 PDFDokumen30 halamanKDACI New V1 PDFVasaBelum ada peringkat

- Retaining Walls DesignDokumen17 halamanRetaining Walls DesignSidny GoncalvesBelum ada peringkat

- Eng R Midterm ExamDokumen15 halamanEng R Midterm ExamMotim So0% (1)

- Submittal Log SheetDokumen3 halamanSubmittal Log SheetAhmad HusnainBelum ada peringkat

- Route To CEng IMechEDokumen17 halamanRoute To CEng IMechEMAZIAH BINTI MOHAMAD FKMBelum ada peringkat

- AstmDokumen6 halamanAstmQaiser Khan100% (1)

- Survey Position Determination MethodsDokumen18 halamanSurvey Position Determination MethodsMohamedBelum ada peringkat

- Common questions about beam-slab analysisDokumen10 halamanCommon questions about beam-slab analysisRonald ReynoldsBelum ada peringkat

- NDECIDokumen6 halamanNDECIRishaalRamBelum ada peringkat

- MEng / BEng Environmental Engineering, Coventry UniversityDokumen10 halamanMEng / BEng Environmental Engineering, Coventry UniversitySuresh SurendranBelum ada peringkat

- Instability of Slender Concrete Deep BeamDokumen12 halamanInstability of Slender Concrete Deep BeamFrederick TanBelum ada peringkat

- CBR TEST PARAMETERSDokumen13 halamanCBR TEST PARAMETERSsmart.engineerBelum ada peringkat

- ASTM D 2167-94 Standard Test Method For Density and Unit Weight of Soil in Place by The Rubber Balloon MethodDokumen6 halamanASTM D 2167-94 Standard Test Method For Density and Unit Weight of Soil in Place by The Rubber Balloon MethodPablo Antonio Valcárcel VargasBelum ada peringkat

- Pressuremeter Testing: Methods and InterpretationDari EverandPressuremeter Testing: Methods and InterpretationPenilaian: 5 dari 5 bintang5/5 (2)

- Course OutlineDokumen14 halamanCourse OutlineTony SparkBelum ada peringkat

- How To Install GmtsarDokumen24 halamanHow To Install GmtsardedetmixBelum ada peringkat

- ReleDokumen3 halamanRelevitor4santos_6Belum ada peringkat

- V8fr-Ii V8r7-IiDokumen1 halamanV8fr-Ii V8r7-Iiaeroseb1Belum ada peringkat

- SBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811Dokumen1 halamanSBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811vitor marianoBelum ada peringkat

- TDS2000 Rig Systems DiagramsDokumen13 halamanTDS2000 Rig Systems DiagramsBaskar KannaiahBelum ada peringkat

- False Ceiling Construction Details PDFDokumen2 halamanFalse Ceiling Construction Details PDFAlexis17% (6)

- VisiLogic Software Manual-LadderDokumen158 halamanVisiLogic Software Manual-LadderEduardo Vasquez CastroBelum ada peringkat

- Murray Loop Test To Locate Ground Fault PDFDokumen2 halamanMurray Loop Test To Locate Ground Fault PDFmohdBelum ada peringkat

- Dewatering SystemDokumen124 halamanDewatering SystemSpyros NannosBelum ada peringkat

- LMDQDokumen601 halamanLMDQMohd Azamuddin Mohd SaifullizanBelum ada peringkat

- Department of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryDokumen7 halamanDepartment of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryTauQeer ShahBelum ada peringkat

- Determining The Redundancy FactorDokumen6 halamanDetermining The Redundancy FactorEdris Salehi GolsefidiBelum ada peringkat

- Velp ZX3 Vortex PDFDokumen5 halamanVelp ZX3 Vortex PDFarodassanchez0% (1)

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDokumen8 halamanNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETBelum ada peringkat

- Smart Access 1105Dokumen12 halamanSmart Access 1105Gerson Freire De Amorim FilhoBelum ada peringkat

- Manual Service Aoc - E943fwskDokumen51 halamanManual Service Aoc - E943fwskEduardo BentoBelum ada peringkat

- Gps VulnerabilityDokumen28 halamanGps VulnerabilityaxyyBelum ada peringkat

- Fire Risk AssessmentDokumen13 halamanFire Risk Assessmentteuku zulfikarBelum ada peringkat

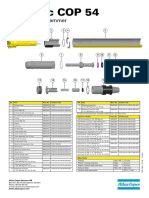

- 9853 1239 01 - COP 54 Service Poster - LOWDokumen1 halaman9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasBelum ada peringkat

- Memory Map and Address DecodingDokumen9 halamanMemory Map and Address DecodingGhozi AlBelum ada peringkat

- Pen Holder SHSDokumen16 halamanPen Holder SHSabhijeetbose1Belum ada peringkat

- An Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDokumen8 halamanAn Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDewi FitriyaniBelum ada peringkat

- Catálogo King LaiDokumen144 halamanCatálogo King LaiJason Salas FloresBelum ada peringkat

- The Z-Transform: Introduction and DerivationDokumen16 halamanThe Z-Transform: Introduction and DerivationAnanth SettyBelum ada peringkat

- Thinking ForthDokumen311 halamanThinking ForthCristianBelum ada peringkat

- W 7570 enDokumen276 halamanW 7570 enthedoors89Belum ada peringkat

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDokumen3 halamanSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)