PQR

Diunggah oleh

naseema1100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

160 tayangan2 halamanprocedure qualification

Judul Asli

pqr

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniprocedure qualification

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

160 tayangan2 halamanPQR

Diunggah oleh

naseema1procedure qualification

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

L

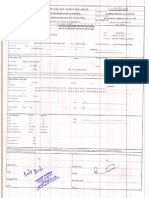

P. O . B o x 88 17, B Ui lding # D Y34 Tel : +971 4 3243888

In si d e D ubai Ship Docking Yard F a x : +971 4 324 3682

A I J ad a f , D ubai

E m a il : te sti n g @ lo nesta r- la b. c o m

U n ited Arab Emira t e s

Website: w w w . l o nestar- Ia b .co m

PROCEDURE QUALIFICATION RECORD (PQR)

PQR # ; SLM/PQR/OO5/09 I

DAlE ; 24-DECEMBER-2009 ; SHEET 1 0F 2

wPs # I SLMIWPS/OO5/09 I

REV# ; 0 I CODE (S) i AWS 0 1.1

WELDER(s) NAME , MR. BISWANATH SARKAR I WELDERSIDENTIFICAn ON(S) W21

WELDING PROCESS FCAW I TYPE/MODE

l

SEMI AUTOMATIC

JOINT DES IGN

TEST COUPON -I THK 20mm

6 o ~ s ,

JOll\'T DES IGN Single 'V ' G ro ove

-.~ / /

GROOVEANGLE 60 ( 5')

ROOT Giu' 2. 5mm

ROOT FACE 2mm

RETAINE RS NIA

\ _4

0 mm }'I

t

~ ~

RANGE QUALIFIED 5 m m to u nlimited

2.5 mm

BAS METAL PRE HEAT

MATERIAL SPECIFICATION EN 10025, S275JR METHOD 1 NIA

P NUMBER 1 TEMPERATURE i 50C If ambient less than 10 C

TEST COUPONTHICKNESS 20mm INTERPASS , 250 C

TEST COUPONDIAMETER NA MEASUREMENT Temole SLick

FILLER METALS PWHT

SPECIFICATION i SFAA5.20 HEATINGMETHOD N/A

CLASS ; E7 1T HEATINGRATE, MAXIMUM, 0 0 N/A

FILLER METAL NUMBER ! F6 SOAK TEMPERATURE. c I N/A

ANALYSIS NUMBER (A) i 1 HOLDING TIME N/A

FILLERMETAL SIZE (DIA) ; 1.2mm COOLINGRATE MAXIMUM, 'c NI A

POS ITIO NS SH IELDI NG GAS

GROOVEPOSITION ; 3G GA S I - ! CO2

PROGRESSION ; Up Hill TYPE I - I Active

!

TECHNIQUE MIXTURE

I

-

I

99.9%

TRAVEL SPEED I RANGE 1.12mm to 1.24mm min/ sec FLOWRATE

:

I - !

15/ 20 CF H

STRINGI WEAVE Bot h N/ A N/A

PURGINGDURATION

I I

SINGLEI MULTIPASS Mu lti Pa ss ELECTRI CAL

SINGLEI MULTIELECTRODE Single POLARITY DCEP

MAX WELDTHICK(ANY PASS) 5mm CURRENT

!

DC

INTERPASSCLEANING Gflndi ng & Wi re Brushi ng CURRENTRANGE

i

150- 250 AMP

I

PEENING N/A VOLTAGE RANGE

!

20 -30 VOLT

I

TUNGSTEN ELECTRODE SIZE N/A OTHER

!

N/A

I

GENERAL

ENVIRONMENTAL CONDITIONS AMBIENTDAY liGHT 35 c

MILL CERTIFICATE I Att ached NDT REPORT RT ! LTS R IOPORT# 2077 8

MECHANICAL TEST REPORTS t.onest ar Report # 40 115 PWHTREPORT NIA

I

HARONESS S URVEY I N/A RECORD PARAMSCHART : N/A

NDT- RP T- 1613-P OR- Stars Line Met all ic Pag e 1 of 2

Otner L.Occ l i v;}S Abu DllCibl Ajma n C.. ' :,", Oat a

P.O. Box 8817 , Building # DY34 Tel : +971 4 324 3888

Insi de Dub ai Ship Dockin g Yard Fax: +971 .<I, 324 3682

AI .Jadaf, Dubai

Email : testing@lonest ar-lab.com

United Arab Emirates

Website: www.lonesta r-Iab.com

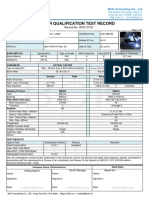

PROCEDURE QUALIFICATION RECORD

PQR# SLM/PQR/OOS/O9 DATE 24-December-2009 SHEET 2 0F2

: I ! I :

ME CHANI CAL TEST RESULTS

TENSIL E TEST S (LONESTAR SAM PLE# 400/4849 1 )

SIZE AREA TENSILESTRENGTH TENSILE

SAMPLE ID FRACTURELOCATION

(mm) ISa, mrn) Dsi (MPa) LOAD(lbs)

TT 1 20 .08 x 19.01 381.72 437 166,978 PARENT METAL

TT 2 20.05 x 19.35 387.97 434 168,346 PARENT METAL

BEND TESTS

SAMPLE 10 TYPE DlAMETERMM ANGL E RESULT

SB 1 S IDEBEND 381 180 PASSED

SB2 S IDEBEND 381 180 PASSED

SB 3 S IDEBEND 381 180 PASSED

SB 4 S IDE BEND 381 180 PASSED

CHARPYI MPACT

N/A

IV1}I, CRO EXAMINATI ON/HA RDNESS VA LUES

N/A

NOTE S:

WE CERTIFY THAT THE STATEMENTS OF THS RECORD ARE CORRECT AND THAT THE TEST WELDS

WERE PREP ARED, WE LDE D AND TESTED IN ACCORDANCE W ITH THE REQUIREMENTS OF THE CODE

STATE D A BOVE.

Line Met alli c Page 2 of 2

UK/IS, C'..o1T1T71 rz;i

o l

v Legal terms and condiuons on the reverse of this sheet

Anda mungkin juga menyukai

- Sany Grader Parts ManualDokumen436 halamanSany Grader Parts ManualJohnson Lee93% (14)

- PQRDokumen2 halamanPQRHoangBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- TEFC vs WPII Motors in Harsh Petrochemical EnvironmentsDokumen3 halamanTEFC vs WPII Motors in Harsh Petrochemical EnvironmentsJhonatan OyolaBelum ada peringkat

- WpsDokumen2 halamanWpsnaseema1100% (1)

- WPS PQR CompressedDokumen5 halamanWPS PQR CompressedBalaje MantravadiBelum ada peringkat

- WPS-PQR ListDokumen1 halamanWPS-PQR ListSandra SandersBelum ada peringkat

- WPS PQR PDFDokumen23 halamanWPS PQR PDFtomj9104Belum ada peringkat

- Larsen & Toubro Minerals & MetalsDokumen2 halamanLarsen & Toubro Minerals & MetalsneerajBelum ada peringkat

- P. WpsDokumen14 halamanP. WpsIsmiArdyBelum ada peringkat

- Joints (Qw-402) DetailsDokumen3 halamanJoints (Qw-402) DetailsNaqqash SajidBelum ada peringkat

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Dokumen3 halamanBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONBelum ada peringkat

- Wps & PQR and Weld Map and Test PlanDokumen67 halamanWps & PQR and Weld Map and Test PlanmarghoobBelum ada peringkat

- Report on Welding Procedure Specifications for Single V-Groove JointsDokumen15 halamanReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- WPS - 023Dokumen10 halamanWPS - 023MAT-LION0% (1)

- CALTECH ENGINEERING PQR PROCEDUREDokumen8 halamanCALTECH ENGINEERING PQR PROCEDURESrikant GanjiBelum ada peringkat

- Procurement Services: Industry & Facilities DivisionDokumen6 halamanProcurement Services: Industry & Facilities DivisionVikas Mani TripathiBelum ada peringkat

- PQR For 32 MM PlateDokumen1 halamanPQR For 32 MM PlateMuhammed MubeenBelum ada peringkat

- Sabari Engineering PQRDokumen3 halamanSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- WPS 204 NewDokumen6 halamanWPS 204 Newarockiyathass100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDokumen6 halamanWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Form Wps JBL09-2011Dokumen2 halamanForm Wps JBL09-2011fawad aliBelum ada peringkat

- WPS PQR 12 PDFDokumen9 halamanWPS PQR 12 PDFVinay YadavBelum ada peringkat

- WPQDokumen1 halamanWPQChava TejaBelum ada peringkat

- WPS PQR-08Dokumen8 halamanWPS PQR-08Ranjan KumarBelum ada peringkat

- WPS RegisterDokumen2 halamanWPS RegisterdaveswinburneBelum ada peringkat

- Optimized Title for Welspun MPQT ReportDokumen84 halamanOptimized Title for Welspun MPQT ReportAlam MD SazidBelum ada peringkat

- Welder Job Clearance Card: Nesma/TanmiaDokumen8 halamanWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarBelum ada peringkat

- QW-482 Suggested Format For Welding ProcDokumen2 halamanQW-482 Suggested Format For Welding Procsachin0% (1)

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Dokumen4 halamanProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabBelum ada peringkat

- Wps Mma PipeDokumen2 halamanWps Mma PipeDimitris NikouBelum ada peringkat

- SMAW DuniDokumen4 halamanSMAW DuniMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- MTC Sample Dia 36 Inch Heat 639914 4130Dokumen2 halamanMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarBelum ada peringkat

- T.C.L. Co. - Test & Control LaboratoriesDokumen2 halamanT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταBelum ada peringkat

- AWS D1.1 Structural Steel TolerancesDokumen8 halamanAWS D1.1 Structural Steel Tolerancesمهندس ايهاب الفقي البرعصيBelum ada peringkat

- Welder Operators Qualification TestDokumen2 halamanWelder Operators Qualification Testlokifarad100% (1)

- W-55 PLATE ID CARDDokumen6 halamanW-55 PLATE ID CARDKrishnan TnBelum ada peringkat

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKAnonymous Ij6VfaBelum ada peringkat

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen8 halamanQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanBelum ada peringkat

- CV Mechanical Engineer with Extensive Experience in Oil & Gas ProjectsDokumen3 halamanCV Mechanical Engineer with Extensive Experience in Oil & Gas Projectshamza brahmiBelum ada peringkat

- WPQ Template (Asme Ix) No LogoDokumen4 halamanWPQ Template (Asme Ix) No LogorcpretoriusBelum ada peringkat

- Visual Inspection ReportDokumen2 halamanVisual Inspection ReportAlfian ImaduddinBelum ada peringkat

- Mill Test Certificate: Customer Name/Address StampDokumen1 halamanMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluBelum ada peringkat

- Industry & Facilities Inspection ReportDokumen10 halamanIndustry & Facilities Inspection Reportkbpatel123Belum ada peringkat

- P Q R - 005Dokumen2 halamanP Q R - 005Courtney DukeBelum ada peringkat

- Varilla B7 3-8 X 144 MT (B7)Dokumen1 halamanVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoBelum ada peringkat

- 03 WPS CS 1Dokumen3 halaman03 WPS CS 1mohammadBelum ada peringkat

- Welding Procedure Specification For GTAW & GMAWDokumen4 halamanWelding Procedure Specification For GTAW & GMAWanh thoBelum ada peringkat

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- Flange 10 & 12 InchDokumen2 halamanFlange 10 & 12 InchreniBelum ada peringkat

- Saudi Aramco WPS Procedure ApprovalDokumen7 halamanSaudi Aramco WPS Procedure ApprovalAkansha SharmaBelum ada peringkat

- Proposed Welding Procedure Specification (PWPS) : REV:A3Dokumen1 halamanProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakBelum ada peringkat

- AMRITA ENGINEERING WORKS PQRDokumen3 halamanAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyBelum ada peringkat

- WPQ WeldCanada PDFDokumen1 halamanWPQ WeldCanada PDFAhmad DanielBelum ada peringkat

- Wps Sp14 Reva PDFDokumen9 halamanWps Sp14 Reva PDFravi00098Belum ada peringkat

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDokumen11 halamanCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONBelum ada peringkat

- Welder Job Clearance Card Saudi AramcoDokumen3 halamanWelder Job Clearance Card Saudi AramcoMohamed Reda Hussein SengarBelum ada peringkat

- Welder Qualification Test Record for NDBDokumen1 halamanWelder Qualification Test Record for NDBAli HammoudaBelum ada peringkat

- Lithika - 001Dokumen1 halamanLithika - 001Harkesh RajputBelum ada peringkat

- MTC - Astm A36 - Jis400 - Q235Dokumen2 halamanMTC - Astm A36 - Jis400 - Q235nayeemBelum ada peringkat

- Technoweld PQR Welding Procedure Single Run Fillet Joint AS3678 Gr350 GMAW 2FDokumen5 halamanTechnoweld PQR Welding Procedure Single Run Fillet Joint AS3678 Gr350 GMAW 2FAdiBelum ada peringkat

- UT inspection of round rod finds no issuesDokumen1 halamanUT inspection of round rod finds no issuessaravanan_c1Belum ada peringkat

- Maxi-Jolly Chain Length CalculationDokumen3 halamanMaxi-Jolly Chain Length Calculationnaseema1Belum ada peringkat

- Buttweld FittingsDokumen3 halamanButtweld FittingsAshok Kumar100% (1)

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDokumen7 halamanPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1Belum ada peringkat

- Piping System Installation Page 4 Thru 8Dokumen5 halamanPiping System Installation Page 4 Thru 8naseema1Belum ada peringkat

- Seamless Welding Fittings-DataDokumen24 halamanSeamless Welding Fittings-DataeASMEBelum ada peringkat

- Kaiflex MasterSpecificationDokumen8 halamanKaiflex MasterSpecificationnaseema1Belum ada peringkat

- (AL Shabab) : Painting Procedure P-04Dokumen12 halaman(AL Shabab) : Painting Procedure P-04Omar Nabil80% (5)

- Viewing and Interpretation of RadiographsDokumen30 halamanViewing and Interpretation of RadiographsNatrajiBelum ada peringkat

- Weld Fitting DimensionsDokumen5 halamanWeld Fitting DimensionsteguheafBelum ada peringkat

- Sproule WR 1200 Perlite TDSDokumen2 halamanSproule WR 1200 Perlite TDSnaseema1Belum ada peringkat

- Travel Speed Calculator: Calculate Welding Speed in mm/minDokumen2 halamanTravel Speed Calculator: Calculate Welding Speed in mm/minMohammad ElhedabyBelum ada peringkat

- Itp For Storge TankDokumen23 halamanItp For Storge Tanknaseema1Belum ada peringkat

- Kooltherm PipeDokumen8 halamanKooltherm Pipenaseema1Belum ada peringkat

- Kaiflex Specification DomesticDokumen5 halamanKaiflex Specification Domesticnaseema1Belum ada peringkat

- ProcedureDokumen11 halamanProcedurePoonam AshwinBelum ada peringkat

- InsulationDokumen4 halamanInsulationnaseema1Belum ada peringkat

- Pipe, Duct and Equipment InsulationDokumen6 halamanPipe, Duct and Equipment Insulationnaseema1Belum ada peringkat

- Insulation InspectionsDokumen1 halamanInsulation Inspectionsnaseema1Belum ada peringkat

- Pipe and Equipment Insulation 0910Dokumen14 halamanPipe and Equipment Insulation 0910naseema1Belum ada peringkat

- U.I.P. System: Submittal DataDokumen2 halamanU.I.P. System: Submittal Datanaseema1Belum ada peringkat

- r1Dokumen3 halamanr1naseema1Belum ada peringkat

- Insulation InspectionsDokumen1 halamanInsulation Inspectionsnaseema1Belum ada peringkat

- Post WeldDokumen4 halamanPost Weldnaseema1Belum ada peringkat

- Kooltherm PipeDokumen8 halamanKooltherm Pipenaseema1Belum ada peringkat

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDokumen1 halamanMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Belum ada peringkat

- Jhl1 5 RepairDokumen2 halamanJhl1 5 Repairnaseema1Belum ada peringkat

- UAS Engineering & Ship Repair ServicesDokumen1 halamanUAS Engineering & Ship Repair Servicesnaseema1Belum ada peringkat

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- B - 8.8 - ZSS006 STD Spec For Piping Flushing Testing InspectionDokumen9 halamanB - 8.8 - ZSS006 STD Spec For Piping Flushing Testing Inspectionnaseema1Belum ada peringkat

- Norsok L-004-CR Ror OgDokumen29 halamanNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- Spectroxepos Xep03: Verbrauchsmaterial Und Verschleißteile Consumables and Wear PartsDokumen26 halamanSpectroxepos Xep03: Verbrauchsmaterial Und Verschleißteile Consumables and Wear Partsamin adimiBelum ada peringkat

- IX Exercise Rev 02 PDFDokumen11 halamanIX Exercise Rev 02 PDFweerasinghekBelum ada peringkat

- Get TRDocDokumen238 halamanGet TRDocShev PanushkinBelum ada peringkat

- Water Wasser: PN 10... 25 DN 300, 500, 600, 800Dokumen3 halamanWater Wasser: PN 10... 25 DN 300, 500, 600, 800AhmedRamadanBelum ada peringkat

- Sobek Endurance ToolsDokumen14 halamanSobek Endurance ToolsAhmet KöseleciBelum ada peringkat

- HR2470TDokumen3 halamanHR2470TRosângela O. Santos0% (1)

- Hyster j2 2 3 5xnDokumen12 halamanHyster j2 2 3 5xnBraveBoy JalloBelum ada peringkat

- 320D & 320D L Excavator Hydraulic System SchematicDokumen15 halaman320D & 320D L Excavator Hydraulic System SchematicchanlinBelum ada peringkat

- Terminal Blocks ABBDokumen36 halamanTerminal Blocks ABBalishaikh12Belum ada peringkat

- PFEIFER Tension Rod System: Data Sheet CollectionDokumen16 halamanPFEIFER Tension Rod System: Data Sheet Collectioncerbu_bass_cdcBelum ada peringkat

- Fatigue AnalysisDokumen46 halamanFatigue Analysisnitesh_n284050% (4)

- CVEN 444 Structural Concrete Design Structural System OverviewDokumen40 halamanCVEN 444 Structural Concrete Design Structural System OverviewAhmed EwisBelum ada peringkat

- Archimedes PrincipleDokumen4 halamanArchimedes Principleraviteja036Belum ada peringkat

- 1411 1502 PDFDokumen60 halaman1411 1502 PDFAlejandro RagoBelum ada peringkat

- Gastec Qa 198Dokumen24 halamanGastec Qa 198CristianBelum ada peringkat

- SAE350 AND 450-SAE, - F3L-912 DEUTZ Engine Welders: Parts List TitlesDokumen18 halamanSAE350 AND 450-SAE, - F3L-912 DEUTZ Engine Welders: Parts List TitlesCarlos IrabedraBelum ada peringkat

- Thern Ta2 Air Winch PressDokumen2 halamanThern Ta2 Air Winch PressKiat LimBelum ada peringkat

- BQ Rmu PlinthDokumen3 halamanBQ Rmu Plinthaqeel_al_triniBelum ada peringkat

- Porosity or PermeabilityDokumen30 halamanPorosity or PermeabilitytabibkarimBelum ada peringkat

- AE-SB-05 Seismic Loads - How They Relate To Cooling TowersDokumen1 halamanAE-SB-05 Seismic Loads - How They Relate To Cooling TowerspamelaBelum ada peringkat

- Behavior and Analysis of Curved and Skewed Steel Girder BridgesDokumen14 halamanBehavior and Analysis of Curved and Skewed Steel Girder Bridgestrabajosic100% (1)

- MIG Welding: A Seminar Report On byDokumen12 halamanMIG Welding: A Seminar Report On bybmkaleBelum ada peringkat

- Rigid Pavement Thesis 3Dokumen12 halamanRigid Pavement Thesis 3san htet aungBelum ada peringkat

- 2011, Ongoing Aspects in Geotechnical Engineering, O. Leibniz, S. Semprich, K. Gell PDFDokumen135 halaman2011, Ongoing Aspects in Geotechnical Engineering, O. Leibniz, S. Semprich, K. Gell PDFVasile BudaBelum ada peringkat

- Edge Effects in Thin Film DelaminationDokumen15 halamanEdge Effects in Thin Film DelaminationAdamRaczBelum ada peringkat

- Corner Cast in Place AnchorDokumen7 halamanCorner Cast in Place Anchorwaweng22Belum ada peringkat

- Power Transformer Design, Manufacturing and TestingDokumen19 halamanPower Transformer Design, Manufacturing and TestingAbd ALRahmanBelum ada peringkat

- Helicoil ChartDokumen14 halamanHelicoil ChartSURYAKUMAR MANEBelum ada peringkat