Process Control Servo System SD 1664 Stepper Motor Training Unit

Diunggah oleh

Carlos RamirezDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Process Control Servo System SD 1664 Stepper Motor Training Unit

Diunggah oleh

Carlos RamirezHak Cipta:

Format Tersedia

Process Control and Servo Systems

SD 1664 Stepper Motor Training Unit

SD 1664 is a unit for training and teaching stepper motor applications. The stepper motor has many applications where it is very useful and economic but unfortunately it has a lot of "side effects" which are a problem. SD 1664 teaches how to overcome problems like frequency resonance, loss of pulses and overshots.

SD 1664 Specication

* * * Max pulse frequency 1200 Hz Max torque 160 Ncm Three modes 1. Continues 2. Count 3. Single step * Two types of drive systems, unipolar and bipolar. Both types of drives are used in CNC-machines, etc. The controller has several facilities such as on/off, half/full step and clockwise / counter clockwise rotation. In continuous mode (1) the motor runs with a speed according to speedref potentiometer. The frequency can be measured at a testpoint. In count mode (2) it is possible to preset number of revolutions, ramping times and maximum speed. In single step mode (3) the rotor rotates one step for each push on the push button. The equipment includes : Control Unit Stepper Motor Module Two ywheels with different moment of inertia Comprehensive Laboratory Manual General Data Dimension: Weight: Control Unit 500 x 340 x 300 mm 12 kg Stepper Motor Module 300 x 190 x 120 mm 5 kg

SD 1664 Experiments

1 2 3 4 5 6 7 8 9 10 11 Torque characteristics / Speed Pull in / pull out torque Pull in / pull out rate Holding torque Max pull in rate Max pull out rate Max working torque Start range Slew range Bipolar drive Unipolar drive

Supply voltage: 220 - 240 V AC 50 - 60 Hz 1-phase

13

Anda mungkin juga menyukai

- 080544R - Stepper Motor and DriversDokumen8 halaman080544R - Stepper Motor and DriversAnuruddha WijerathneBelum ada peringkat

- Dynamometer For E-Bikes According To New EPAC/EMC Standard: FeaturesDokumen12 halamanDynamometer For E-Bikes According To New EPAC/EMC Standard: FeaturesenekomBelum ada peringkat

- PDF Created With Pdffactory Trial VersionDokumen16 halamanPDF Created With Pdffactory Trial VersionRubenBelum ada peringkat

- LG Surucu Ig5Dokumen16 halamanLG Surucu Ig5uyung_mustofaBelum ada peringkat

- LG VFD Drive ManualDokumen16 halamanLG VFD Drive ManualrnkmipBelum ada peringkat

- 1104a 4g 34t Type Governor Manual Zt147 01 PDFDokumen54 halaman1104a 4g 34t Type Governor Manual Zt147 01 PDFFaserphi Sac100% (2)

- DY3E Three-Phase Compound Step Motor Driver User ManualDokumen20 halamanDY3E Three-Phase Compound Step Motor Driver User ManualZoran ŠiručkaBelum ada peringkat

- C604 AttachmentpaperDokumen32 halamanC604 AttachmentpaperWander GomesBelum ada peringkat

- Robotic LabDokumen20 halamanRobotic Lab037 Amit SemwalBelum ada peringkat

- BIOBASE Table-Type Low Speed Centrifuge BKC-TL4II User Manual 202009Dokumen14 halamanBIOBASE Table-Type Low Speed Centrifuge BKC-TL4II User Manual 202009Gustavo QuispeBelum ada peringkat

- Driver For Improving The Positioning Accuracy of Step MotorsDokumen11 halamanDriver For Improving The Positioning Accuracy of Step MotorsAvanish VermaBelum ada peringkat

- I G5Dokumen16 halamanI G5MoustaffaBelum ada peringkat

- Stepper IntroDokumen60 halamanStepper IntroAshok More100% (1)

- Image Processing of Sidescan SonarDokumen7 halamanImage Processing of Sidescan SonarAlex NicksonBelum ada peringkat

- TecoDokumen94 halamanTecoNgọc ÁnhBelum ada peringkat

- Servo Drive - KT SeriesDokumen8 halamanServo Drive - KT Seriesgabriel_domin0% (2)

- Joystick Control of Stepper Motor Using ArduinoDokumen7 halamanJoystick Control of Stepper Motor Using ArduinoDany Mathew100% (2)

- Vibration TesterDokumen2 halamanVibration TesterRohit ChawlaBelum ada peringkat

- Samsung AC Servo System 2009 4Dokumen40 halamanSamsung AC Servo System 2009 4Frank M C100% (1)

- YCKT-Balancing Machine CEMBDokumen7 halamanYCKT-Balancing Machine CEMBNguyễn Quốc PhượngBelum ada peringkat

- QuadDokumen55 halamanQuadVgokulGokulBelum ada peringkat

- Tacómetro Óptico y Mecánico SKFDokumen108 halamanTacómetro Óptico y Mecánico SKFValidaciones VicarBelum ada peringkat

- Stepper Motor: Operation and TheoryDokumen1 halamanStepper Motor: Operation and TheoryrambetsBelum ada peringkat

- Antenna ServoDokumen3 halamanAntenna ServoamarnathavulaBelum ada peringkat

- SFDEN 006 005 - FD11controllerDokumen19 halamanSFDEN 006 005 - FD11controllerChris HendersonBelum ada peringkat

- SFDEN 006 008 - FD11controller PDFDokumen22 halamanSFDEN 006 008 - FD11controller PDFkhophimhdBelum ada peringkat

- G3Dokumen8 halamanG3viernes06Belum ada peringkat

- Syphon Energies Solar Cleaning RobotDokumen5 halamanSyphon Energies Solar Cleaning RobotDheeraj DarjiBelum ada peringkat

- Esp-2000 BSDokumen6 halamanEsp-2000 BSByron LopezBelum ada peringkat

- Self Balancing Robot Using PidDokumen21 halamanSelf Balancing Robot Using Pidline follower robotBelum ada peringkat

- Inverter Varispeed F7A (KAE-S616-55F)Dokumen98 halamanInverter Varispeed F7A (KAE-S616-55F)Miguel LinaresBelum ada peringkat

- Stepper Motor ControlDokumen11 halamanStepper Motor ControlMerian Mercado100% (1)

- 3 G 3 JVDokumen48 halaman3 G 3 JVGeorgiana DumitracheBelum ada peringkat

- E500 Variable Frequency Drives-2Dokumen6 halamanE500 Variable Frequency Drives-2Alessandro DamascenoBelum ada peringkat

- Pin On Disk Tribometer ManualDokumen53 halamanPin On Disk Tribometer Manualanhntran4850100% (1)

- C604 VVVFDokumen39 halamanC604 VVVFWander Gomes100% (2)

- Self Centering Four Jaw ChuckDokumen6 halamanSelf Centering Four Jaw ChuckbalakaleesBelum ada peringkat

- Stepper Motor PDFDokumen2 halamanStepper Motor PDFMohit Kumar SinglaBelum ada peringkat

- IEICOS DTTM Torsion Testing Machine Operation ManualDokumen6 halamanIEICOS DTTM Torsion Testing Machine Operation ManualsunilBelum ada peringkat

- KATALOG ToshibaDokumen17 halamanKATALOG ToshibaAkbar Trilaksono100% (1)

- Vickers Electrics Db3 ManualDokumen138 halamanVickers Electrics Db3 ManualRana M. ZubairBelum ada peringkat

- Stepper Motor ReportDokumen19 halamanStepper Motor ReportIan Bagunas100% (2)

- PM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Dokumen28 halamanPM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Nirmal KumarBelum ada peringkat

- Figure 1.1 4 DOF RobotDokumen15 halamanFigure 1.1 4 DOF RobotPhong NguyenBelum ada peringkat

- HGM1770Dokumen16 halamanHGM1770Thao Nguyen XuanBelum ada peringkat

- Stepper Motor Control Through RF LinkDokumen12 halamanStepper Motor Control Through RF Linkmrx1061100% (1)

- Simple Tuning ASDA-A2&B2 Servo SystemsDokumen41 halamanSimple Tuning ASDA-A2&B2 Servo SystemsNu OlanlaBelum ada peringkat

- Hitachi SJ100SeriesSalesBrochureDokumen20 halamanHitachi SJ100SeriesSalesBrochuresamanthacheeBelum ada peringkat

- C EpopsDokumen695 halamanC EpopsTom DavisonBelum ada peringkat

- Datasheet - M542H Stepper Motor DriverDokumen10 halamanDatasheet - M542H Stepper Motor DriversthollanderBelum ada peringkat

- KNR Drive Shaft Joint Simulation SystemDokumen5 halamanKNR Drive Shaft Joint Simulation SystemIsmail XasmamedzadeBelum ada peringkat

- Eastern Mediterranean UniversityDokumen24 halamanEastern Mediterranean UniversityMpu KatanaBelum ada peringkat

- Section 7 Maintenance StandardDokumen21 halamanSection 7 Maintenance StandardDado OgameBelum ada peringkat

- DX C8700 Series Centrifuge: Operation ManualDokumen11 halamanDX C8700 Series Centrifuge: Operation ManualmarcelaBelum ada peringkat

- 94 79 IVS102 HighPower OperatingInstructions MG12P202Dokumen182 halaman94 79 IVS102 HighPower OperatingInstructions MG12P202evilrich172772Belum ada peringkat

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDari EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisPenilaian: 4 dari 5 bintang4/5 (2)

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960Dari EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960Belum ada peringkat

- Techniques of Helmet Removal From Injured Patients: April 1997Dokumen2 halamanTechniques of Helmet Removal From Injured Patients: April 1997Carlos RamirezBelum ada peringkat

- MDX650 Rotary TutorialDokumen17 halamanMDX650 Rotary TutorialCarlos RamirezBelum ada peringkat

- Gasturbine Engines For Model AircraftDokumen104 halamanGasturbine Engines For Model AircraftSaransiri Wongsiri94% (16)

- Acme Ball ScrewsDokumen27 halamanAcme Ball ScrewsCarlos Ramirez100% (1)

- Actuator BrochureDokumen6 halamanActuator BrochureCarlos Ramirez100% (1)

- MDX650 Rotary TutorialDokumen17 halamanMDX650 Rotary TutorialCarlos RamirezBelum ada peringkat

- 17 ActuatorDokumen1 halaman17 ActuatorCarlos RamirezBelum ada peringkat

- 2008 CatalogDokumen99 halaman2008 CatalogCarlos RamirezBelum ada peringkat

- 2006 Taper BitDokumen1 halaman2006 Taper BitCarlos RamirezBelum ada peringkat

- Zeroing Xyz On MillDokumen1 halamanZeroing Xyz On MillCarlos RamirezBelum ada peringkat

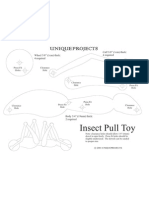

- Insect Pull Toy: Wheel 3/8" (1cm) Thick: 4 Required Calf 3/8" (1cm) Thick: 4 RequiredDokumen1 halamanInsect Pull Toy: Wheel 3/8" (1cm) Thick: 4 Required Calf 3/8" (1cm) Thick: 4 RequiredCarlos RamirezBelum ada peringkat

- Process Control Servo SystemDokumen16 halamanProcess Control Servo SystemCarlos RamirezBelum ada peringkat

- Waterjet CutterDokumen4 halamanWaterjet CutterCarlos RamirezBelum ada peringkat

- Torno t400 BrochureDokumen4 halamanTorno t400 BrochureCarlos RamirezBelum ada peringkat

- mf70 PKGDokumen19 halamanmf70 PKGCarlos RamirezBelum ada peringkat

- The Art of Motion Control - SubcategoryDokumen2 halamanThe Art of Motion Control - SubcategoryCarlos RamirezBelum ada peringkat

- Torchmate Catalog 11-8-04Dokumen29 halamanTorchmate Catalog 11-8-04Carlos RamirezBelum ada peringkat

- KH56KDokumen2 halamanKH56KCarlos RamirezBelum ada peringkat

- Grizzly g0463 MDokumen40 halamanGrizzly g0463 MCarlos RamirezBelum ada peringkat

- Machine Data Sheet: Model G0519 Mill/Drill/Tapping MachineDokumen2 halamanMachine Data Sheet: Model G0519 Mill/Drill/Tapping MachineCarlos RamirezBelum ada peringkat

- Gencata 4 LDokumen74 halamanGencata 4 LCarlos RamirezBelum ada peringkat

- Flying ShearDokumen5 halamanFlying ShearCarlos RamirezBelum ada peringkat

- Cutter GuideDokumen1 halamanCutter GuideCarlos RamirezBelum ada peringkat