16 Ball Filling Degree & Mill Calculation

Diunggah oleh

Elwathig BakhietHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

16 Ball Filling Degree & Mill Calculation

Diunggah oleh

Elwathig BakhietHak Cipta:

Format Tersedia

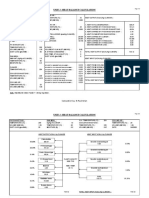

Annex 16.

Mill calculation

Plant : Mill :

D L P l L1 L2

Date : Visa :

5.00 16.00 5,700 3.2 36 64 [m] [m] [kW] [-] [%] [%]

Mill Dimensions

Diameter Length Motor power (inst.) L/D - Ratio Compartment lengths

Data

Internal diameter Internal length Filling degree Spec. media weight Mill speed Drive efficiency mech. Drive efficiency electr. Mill throughput Fineness product Relative mill speed Factor Media weight Motor power abs. Spec. energy consumption Media weight total Motor power mech. abs. Motor power electr. abs. Spec. energy consumption Energy utilization Di Li f r n h h G Blaine Residue %n crit c Q P mec E sp Q tot Pmec P el E sp w

1.Comp.

4.80 6.40 22.0 4.40 15.0 0.960 0.950 155 3,800 77.8 0.250 112.1 2,014 13.0 414 6,931 7,296 47.1 22.4 [t]

2.Comp.

4.83 11.20 32.0 4.60 [min-1] [-] [-] [t/h] [cm/g] [%] 32 [m] [%] 0.212 302.1 4,640 29.9 [kW] motor shaft [kW] electr. counter [kWh/t] [cm/J] [-] [t] [kW] [kWh/t] [m] [m] [%] [t/m3]

Filling Degree Calculations

Mill In / Outlet Filling Degree Internal diameter Free Height Diameter Present Maximum H/D - Ratio Free Height max. Di h d f pres. f max.

1.Comp.

4.80 3.20 1.50 29.2 30.4 0.67 3.15

2.Comp.

4.83 3.05 1.25 33.5 33.7 0.63 3.04 [m] [m] [m] [%] [%] [-] [m]

CMCALC2.XLS

Ver.2.0/PWi/05.07.2001

Holcim Group Support Ltd / CTS

Annex 16.2

Fig.4 : Filling degree f in function of free height h above grinding media charge

h D

D

0,75 Di = Mill diameter 0,70

0,65

0,60 20 25 30 35

filling degree [%]

Fig.5 : Alternative way to determine the free height

h= Di + d 2 + h'

Kma 5.1.99

Tube Mill Dimensioning

CC-99003.dsf

Anda mungkin juga menyukai

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDokumen2 halamanPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplBelum ada peringkat

- Sample Cross-Complaint For Indemnity For CaliforniaDokumen4 halamanSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Blaine Vs ResiduesDokumen3 halamanBlaine Vs ResiduesVisnu Sankar100% (2)

- 16 - Blending and AgitationDokumen20 halaman16 - Blending and AgitationRafael ReyesBelum ada peringkat

- Hydrogeological Survey and Eia Tor - Karuri BoreholeDokumen3 halamanHydrogeological Survey and Eia Tor - Karuri BoreholeMutonga Kitheko100% (1)

- A - PAGE 1 - MergedDokumen73 halamanA - PAGE 1 - MergedGenalyn DomantayBelum ada peringkat

- Refractory Castable SelectionDokumen37 halamanRefractory Castable SelectionElwathig Bakhiet100% (4)

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDokumen44 halamanGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Kfui (K F U I) : Chapter II - A Iln Eed Niformity NdexDokumen25 halamanKfui (K F U I) : Chapter II - A Iln Eed Niformity NdexFranciscoCorreaJara100% (2)

- Report On Cement MillDokumen9 halamanReport On Cement MillYounas Khan100% (1)

- Building A Pentesting Lab For Wireless Networks - Sample ChapterDokumen29 halamanBuilding A Pentesting Lab For Wireless Networks - Sample ChapterPackt PublishingBelum ada peringkat

- Loesche Round Table VICATDokumen20 halamanLoesche Round Table VICATFirdaus Azizan86% (7)

- All Cement Formulae PDFDokumen163 halamanAll Cement Formulae PDFGanapathy SubramaniamBelum ada peringkat

- By-Pass Calculation Method - DocbDokumen2 halamanBy-Pass Calculation Method - DocbElwathig BakhietBelum ada peringkat

- Ball Charge Design and ManagementDokumen36 halamanBall Charge Design and ManagementFran jimenez100% (1)

- Ball Charge DesignDokumen12 halamanBall Charge DesignJackson Vu0% (1)

- Operation of Tube MillsDokumen26 halamanOperation of Tube Millsssk3712100% (2)

- Cement Ball-Mill-Heat-BalanceDokumen3 halamanCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Tromp Curve ExampleDokumen3 halamanTromp Curve Examplesempatik721100% (5)

- Alkali CyclesDokumen14 halamanAlkali CyclesElwathig BakhietBelum ada peringkat

- Alkali CyclesDokumen14 halamanAlkali CyclesElwathig BakhietBelum ada peringkat

- Alkali CyclesDokumen14 halamanAlkali CyclesElwathig BakhietBelum ada peringkat

- Ball Filling Degree Mill CalculationDokumen2 halamanBall Filling Degree Mill CalculationBùi Hắc HảiBelum ada peringkat

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDokumen1 halamanBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- Mill Testing Optimisation and TargetingDokumen134 halamanMill Testing Optimisation and TargetingArtemMirra90% (10)

- 081 - TSP HUA400 20080305 Kiln Audit Dec07Dokumen30 halaman081 - TSP HUA400 20080305 Kiln Audit Dec07mkpq100% (2)

- Grinding Course: Ball Charge Design MethodsDokumen12 halamanGrinding Course: Ball Charge Design MethodsVishnu Vardhan . C100% (12)

- Ball Charge Design - VDokumen11 halamanBall Charge Design - VKaran_Agarwal_4807100% (2)

- GRINDINGDokumen45 halamanGRINDINGTOULASSI-ANANI Yves Lolo100% (3)

- Cement Kiln Shell Specific Surface Radiation Loss CalculationDokumen2 halamanCement Kiln Shell Specific Surface Radiation Loss CalculationvvijaybhanBelum ada peringkat

- 2006 Slag Grinding With MPS Vertical Roller MillsDokumen4 halaman2006 Slag Grinding With MPS Vertical Roller Millslijosh_rexy1983Belum ada peringkat

- CO Sources PDFDokumen11 halamanCO Sources PDFElwathig BakhietBelum ada peringkat

- Audit of Ball Mill Circuits PDFDokumen128 halamanAudit of Ball Mill Circuits PDFTOULASSI-ANANI Yves Lolo100% (3)

- R A R F U: % Passing Size, M Feed Coarse FinesDokumen3 halamanR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütBelum ada peringkat

- The Effects of Oxygen Enrichment On ClinkerDokumen9 halamanThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Clinker Vs Kiln Feed FactorDokumen3 halamanClinker Vs Kiln Feed Factorvvijaybhan100% (6)

- Vertical Raw Mill Heat Balance - SolutionDokumen3 halamanVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDokumen5 halamanUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditBelum ada peringkat

- Vertical Raw Mill Heat Balance SolutionDokumen3 halamanVertical Raw Mill Heat Balance SolutionVaibhav KhodakeBelum ada peringkat

- 8 - 9 - Mill Optimisation Part 1 and 2Dokumen82 halaman8 - 9 - Mill Optimisation Part 1 and 2bulentbulutBelum ada peringkat

- Ball Mill Degree of Filling CalculationDokumen4 halamanBall Mill Degree of Filling Calculationvvijaybhan100% (2)

- Mineralisation PDFDokumen11 halamanMineralisation PDFElwathig BakhietBelum ada peringkat

- Max Ball Size With Respect To Mill Feed SizeDokumen3 halamanMax Ball Size With Respect To Mill Feed Sizevvijaybhan100% (1)

- Process Train Ball MillDokumen28 halamanProcess Train Ball MillvvijaybhanBelum ada peringkat

- Vertical Mill CalculationsDokumen11 halamanVertical Mill CalculationsSai Sricharan Reddy84% (19)

- Axial Test Finish MillDokumen5 halamanAxial Test Finish MillVijay Bhan100% (1)

- RedoxDokumen7 halamanRedoxElwathig BakhietBelum ada peringkat

- Viscosity PDFDokumen1 halamanViscosity PDFElwathig BakhietBelum ada peringkat

- Burnability ExercisesDokumen1 halamanBurnability ExercisesElwathig BakhietBelum ada peringkat

- Burnability ExercisesDokumen1 halamanBurnability ExercisesElwathig BakhietBelum ada peringkat

- Burnability ExercisesDokumen1 halamanBurnability ExercisesElwathig BakhietBelum ada peringkat

- Co2 Emission Per Ton ClinkerDokumen5 halamanCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- VRM Heat and Mass BalanceDokumen1 halamanVRM Heat and Mass BalanceRajeshRockBelum ada peringkat

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseDokumen1 halamanCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseElwathig BakhietBelum ada peringkat

- Process Strategy: Powerpoint Slides by Jeff HeylDokumen13 halamanProcess Strategy: Powerpoint Slides by Jeff HeylMuizzBelum ada peringkat

- Pradeepkumar - Rawmix Characteristics FinalDokumen96 halamanPradeepkumar - Rawmix Characteristics FinalJackson VuBelum ada peringkat

- Kiln Cooler Heat Mass BalanceDokumen84 halamanKiln Cooler Heat Mass BalancePrabhakar Reddy PeramBelum ada peringkat

- Cement Mill Calculation DesaignDokumen1 halamanCement Mill Calculation DesaignHilmy MuhammadBelum ada peringkat

- ACC Thane - Clinker FactorDokumen17 halamanACC Thane - Clinker FactorSaji KumarBelum ada peringkat

- Effect of Clinker Composition On GrindingDokumen5 halamanEffect of Clinker Composition On GrindingAlbar Budiman100% (1)

- By Pass SystemDokumen56 halamanBy Pass SystemIrshad Hussain100% (2)

- International Cement Review, September 2002: Burning The MixDokumen5 halamanInternational Cement Review, September 2002: Burning The MixarylananylaBelum ada peringkat

- Annual Audit of CM 1Dokumen26 halamanAnnual Audit of CM 1Tamer Fathy100% (1)

- Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseDari EverandAdvances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UsePenilaian: 4.5 dari 5 bintang4.5/5 (12)

- Grindability CalculationDokumen3 halamanGrindability CalculationAnoop Tiwari100% (1)

- Cement Milling I Blue Circle PDFDokumen24 halamanCement Milling I Blue Circle PDFIrshad HussainBelum ada peringkat

- 3500TPD Cement Plant Heat BalanceDokumen2 halaman3500TPD Cement Plant Heat BalanceIrshad HussainBelum ada peringkat

- Clinker CoolersDokumen12 halamanClinker CoolersAkhilesh Pratap SinghBelum ada peringkat

- OSepaseparator 1Dokumen6 halamanOSepaseparator 1Slobodan StrainovićBelum ada peringkat

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDokumen16 halamanTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- Heat Balance DiagramDokumen29 halamanHeat Balance Diagramsanju_cgh100% (2)

- New Zamil Pacu SelectionDokumen13 halamanNew Zamil Pacu SelectionArt JamesBelum ada peringkat

- Combustion Data Combustion and AnalysisDokumen75 halamanCombustion Data Combustion and AnalysisxavierBelum ada peringkat

- Combustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringDokumen75 halamanCombustion Data Acquisition and Analysis: Department of Aeronautical and Automotive EngineeringKidus DawitBelum ada peringkat

- Ar No. # Diesel Engine Replacement: 1 Mmbtu 1,000,000 Btu, 1 KWH 3,413 BtuDokumen3 halamanAr No. # Diesel Engine Replacement: 1 Mmbtu 1,000,000 Btu, 1 KWH 3,413 Btuahmed_eng_1500Belum ada peringkat

- Thermodynamics-Ii Lab: Submitted ToDokumen61 halamanThermodynamics-Ii Lab: Submitted Toharis khalilBelum ada peringkat

- Assignment 1Dokumen2 halamanAssignment 1Yamaneko ShinBelum ada peringkat

- Ijfeat: Application of Electrostatic Precipitator in Cement PlantDokumen7 halamanIjfeat: Application of Electrostatic Precipitator in Cement PlantElwathig BakhietBelum ada peringkat

- Ss PolymorphsDokumen9 halamanSs PolymorphsElwathig BakhietBelum ada peringkat

- First PrinciplesDokumen2 halamanFirst PrinciplesElwathig BakhietBelum ada peringkat

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseDokumen1 halamanCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseElwathig BakhietBelum ada peringkat

- CSAF Exercise PDFDokumen1 halamanCSAF Exercise PDFElwathig BakhietBelum ada peringkat

- Docsity Detailed Lesson Plan 5Dokumen4 halamanDocsity Detailed Lesson Plan 5Sydie MoredoBelum ada peringkat

- T-Tess Six Educator StandardsDokumen1 halamanT-Tess Six Educator Standardsapi-351054075100% (1)

- Manual Samsung Galaxy S Duos GT-S7562Dokumen151 halamanManual Samsung Galaxy S Duos GT-S7562montesjjBelum ada peringkat

- s15 Miller Chap 8b LectureDokumen19 halamans15 Miller Chap 8b LectureKartika FitriBelum ada peringkat

- A SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Dokumen15 halamanA SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Batuhan ElçinBelum ada peringkat

- Hindi ShivpuranDokumen40 halamanHindi ShivpuranAbrar MojeebBelum ada peringkat

- Fmicb 10 02876Dokumen11 halamanFmicb 10 02876Angeles SuarezBelum ada peringkat

- Lego Maps ArtDokumen160 halamanLego Maps ArtВячеслав КозаченкоBelum ada peringkat

- OVDT Vs CRT - GeneralDokumen24 halamanOVDT Vs CRT - Generaljaiqc100% (1)

- DIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Dokumen2 halamanDIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Laurice Carmel AgsoyBelum ada peringkat

- The International Poker RulesDokumen2 halamanThe International Poker RulesOutontheBubbleBelum ada peringkat

- Object-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Dokumen15 halamanObject-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Rishabh MalikBelum ada peringkat

- Course Projects PDFDokumen1 halamanCourse Projects PDFsanjog kshetriBelum ada peringkat

- Vernacular ArchitectureDokumen4 halamanVernacular ArchitectureSakthiPriya NacchinarkiniyanBelum ada peringkat

- Meniere's Disease - Retinal Detatchment - GlaucomaDokumen3 halamanMeniere's Disease - Retinal Detatchment - Glaucomaybet03Belum ada peringkat

- Kidney Stone Diet 508Dokumen8 halamanKidney Stone Diet 508aprilBelum ada peringkat

- Estate TaxDokumen10 halamanEstate TaxCharrie Grace PabloBelum ada peringkat

- Properties of LiquidsDokumen26 halamanProperties of LiquidsRhodora Carias LabaneroBelum ada peringkat

- Onset Hobo Trade T Cdi 5200 5400 User ManualDokumen3 halamanOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- PDS (OTO360) Form PDFDokumen2 halamanPDS (OTO360) Form PDFcikgutiBelum ada peringkat

- Vedic Maths Edited 2Dokumen9 halamanVedic Maths Edited 2sriram ABelum ada peringkat

- A Review of Stories Untold in Modular Distance Learning: A PhenomenologyDokumen8 halamanA Review of Stories Untold in Modular Distance Learning: A PhenomenologyPsychology and Education: A Multidisciplinary JournalBelum ada peringkat

- Mode of Action of Vancomycin: L D D D D DDokumen8 halamanMode of Action of Vancomycin: L D D D D DNolanBelum ada peringkat

- Liquid Chlorine SdsDokumen7 halamanLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRIBelum ada peringkat