Master Cylinder

Diunggah oleh

Afit KenshyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Master Cylinder

Diunggah oleh

Afit KenshyHak Cipta:

Format Tersedia

Drum Brakes By the mid-1920s drum brakes with internal-expanding shoes were the general rule.

Early drum brakes were operated mechanically by levers and linkage. Expensive luxury cars such as the 1921 Duesenberg Model A were among the first to have hydraulic drum brakes. Hydraulic brakes started to appear on lower-priced cars in the mid 1920s with Chyslers Light Six, which became the Plymouth. Ford motor company, however, used mechanical brakes through the 1938 model year. The rigid brakes shoes used with drum brakes could be made stronger than the flexible bands of earlier brake desaign. This elimated breakage problems that occurred with greater-braking force thet were required as automobiles got more powerful and faster. With hydraulic actuation, four-wheel drum brakes remained the standard braking system for most cars into the middle and late 1960s. With the coming of FMVSS 105 in 1967, brake systems had to pas specific performance test that made front disc brakes the general rule in the 1970s. Even that beginning of the twenty first century,however,drum brakes are still used on the rear wheels of many cars and light trucks. Disc Brakes Modern automotive disk brakes were developed from aircraft brakes of World War II. Known originally as spot brakes, disc brakes work by applying pressure to two brake pads on opposite sides of a spinning rotor attached to the wheel hub. Disk brake pads are mounted in a caliper that sits above the spinning rotor. The caliper is either fixed or movable on its mounting. With a fixed caliper,hydraulic pressure is applied to pistons on both sides to force the pads against the rotor. With a movable caliper,pressure is applied to a piston on the inboard side only. This forces the inboard pad against the rotor, and the reaction force moves the outboard side of the caliper inward so that both pads grip the rotor.

Master Cylinder You read previously about the brake pedal and lever multiplying and transmitting physical force to the master cylinder pushrod. The master cylinder is the start of the brake hydraulic system. It actually is a cylindrical pump. The cylinder is sealed at one end, and the movable pushrod extends from the other. The pushrod moves a pair of in-line pistons that produce the pumping action. When the brake pedal lever moves the pushrod,it moves the pistons to draw fluid from a reservoir on top of the master cylinder. Piston action then forces the fluid under pressure through outlet ports to the brake lines. All master cylinders for vehicles built since 1967 have two pistons and pumping chambers as shown in figure 2-7. Motor vehicle safety standards require this dual-brake system to provide hydraulic system operation in case one hose,line,or wheel brake assembly loses fluid. Because the brake hydraulic systems is sealed, all the lines and cylinders are full of fluid at all times. When the master cylinder develops system pressure, the amount of fluid moved is only a few ounces.

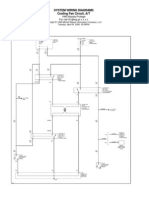

Brake lines and hoses The rigid lines or pipes of a brake hydraulic systems are made of steel tubing for system safety. Flexible rubber hoses connect the wheel brakes to the rigid lines on the vehicle body or frame. The front brakes have a rubber hose at each wheel to allow for steering movement. Rear brakes may have separate hoses at each wheel or a single hose connected to a line on the body or frame if the vehicle has a rigid rear axle. Brake lines and hoses contain the high-pressure fluid,and the fluid acts as a solid rod to transmit force to the wheel cylinders and caliper pistons. Pressure Control Valves Almost all brake hydraulic systems built since 1967 have one or more valves to control system pressure. Metering and proporting valves modulate hydraulic pressure to front disc or rear drum brakes to provide smooth brake application and reduce the tendency to lock the brakes. A pressure differential switch is a type of valve used in most systems to turn on the instrument panel warning lamp if half of the hydraulic systems loses pressure. The hydraulic system may have several individual valves or single combination valve with multiple functions. You learn about pressure control valves in detail in subsequent chapters. Wheel Cylinders and caliper pistons Technically, the wheel cylinders of drum brakes and the caliper pistons of disc brakes are slave cylinders because they operate in response to the master cylinder. These hydraulic cylinders at the wheels change hydraulic pressure back into mechanical force to apply the brakes. Most late-model systems have a single, two pistons cylinder at each wheel with drum brakes. Hydraulic pressure enters the cylinder between the two pistons and forces them outward to act on the brake shoes. As the shoes move outward, the lining contacts the drums to stop the car. Some drum brake installations have two cylinders at each wheel,with one pistons each. A few older systems used wheel cylinders with pistons of different diameters. The caliper pistons for disc brakes also act in response to hydraulic pressure that enters a fluid chamber in the caliper. Hydraulic pressure in a stationary caliper is a applied to one or two pistons on each side of the caliper to force the pads against the rotor as was shown in figure 2-5. Pressure is applied to a single piston in a movable caliper on the inboard pad against the rotor.

Anda mungkin juga menyukai

- Hydraulic Brake SystemDokumen5 halamanHydraulic Brake SystemSatyanshu Pratap SinghBelum ada peringkat

- Hydro Pneumatic Braking SytemDokumen11 halamanHydro Pneumatic Braking Sytempramo_dass100% (1)

- ATT Brakes - Example TextbookDokumen15 halamanATT Brakes - Example TextbookSooraj KrishnaBelum ada peringkat

- Hydrolic Breaking SystemDokumen56 halamanHydrolic Breaking SystemAnkush JainBelum ada peringkat

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDari EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiBelum ada peringkat

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDari EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesPenilaian: 5 dari 5 bintang5/5 (1)

- Overhaul: - Oil Pump AssyDokumen3 halamanOverhaul: - Oil Pump AssyHenry SilvaBelum ada peringkat

- Engine System ComponentsDokumen33 halamanEngine System Componentsgatul denaenBelum ada peringkat

- Hydrostatic DriveDokumen13 halamanHydrostatic DriveDhanraj PatilBelum ada peringkat

- Point of No Return - Returnless Fuel Injection SystemsDokumen5 halamanPoint of No Return - Returnless Fuel Injection SystemsrxhughesBelum ada peringkat

- INSPECT AND SERVICE COOLING SYSTEMS - QuizDokumen8 halamanINSPECT AND SERVICE COOLING SYSTEMS - QuizbalalaBelum ada peringkat

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDokumen42 halamanInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirBelum ada peringkat

- Report On I.C.E (Replica)Dokumen46 halamanReport On I.C.E (Replica)Ariel PortugalBelum ada peringkat

- Air Brake Manual PDFDokumen102 halamanAir Brake Manual PDFVignesh VSBelum ada peringkat

- Lab Manual: Department of Mechanical EngineeringDokumen46 halamanLab Manual: Department of Mechanical EngineeringsrknotesBelum ada peringkat

- Air Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307Dokumen24 halamanAir Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307priyanka priya100% (1)

- Valve Timing Diagram - Diesel EngineDokumen2 halamanValve Timing Diagram - Diesel EngineDileepBelum ada peringkat

- Air Brake SystemDokumen4 halamanAir Brake SystemYemaneDibetaBelum ada peringkat

- Petrol EngineDokumen19 halamanPetrol EngineJameBelum ada peringkat

- Sanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportDokumen29 halamanSanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportRITESH ROHILLABelum ada peringkat

- Hydro-Boost: GM Full Size Vans 1987-1997 Repair GuideDokumen7 halamanHydro-Boost: GM Full Size Vans 1987-1997 Repair GuideEndry Enrique Rincón VargasBelum ada peringkat

- Wa380 3Dokumen12 halamanWa380 3wanglg100% (1)

- SM - VOLVO L50D WHEEL LOADER Service Repair ManualDokumen20 halamanSM - VOLVO L50D WHEEL LOADER Service Repair ManualJulio CesarBelum ada peringkat

- Manual Transmission 5 SpeedDokumen12 halamanManual Transmission 5 Speedav1135100% (1)

- Starting Sys PDFDokumen42 halamanStarting Sys PDFAnonymous 8GJQCGaeBelum ada peringkat

- GDIDokumen30 halamanGDIMartinchemBelum ada peringkat

- Me Lab ReportDokumen20 halamanMe Lab ReportJassondemapan100% (1)

- TurboDokumen9 halamanTurboPedro Alejandro Campos CatrianBelum ada peringkat

- The Battery: SubjectDokumen36 halamanThe Battery: SubjectporkfaceBelum ada peringkat

- Autotrans Fluid ChangeDokumen5 halamanAutotrans Fluid ChangeHermawan 0103Belum ada peringkat

- CH 11Dokumen34 halamanCH 11Getachew TikueBelum ada peringkat

- VVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Dokumen5 halamanVVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Luqman AzamBelum ada peringkat

- Common Rail Fuel Injection Technology in Diesel EnginesDari EverandCommon Rail Fuel Injection Technology in Diesel EnginesBelum ada peringkat

- Fuel Injectors ModifiedDokumen10 halamanFuel Injectors ModifiedSarath ChandraBelum ada peringkat

- See Figures 1 Thru 7: Suspension SystemDokumen28 halamanSee Figures 1 Thru 7: Suspension SystembalajigandhirajanBelum ada peringkat

- 29 Junet Babu CRDi 3Dokumen20 halaman29 Junet Babu CRDi 3Jaiveer YadavBelum ada peringkat

- Fuel SystemDokumen7 halamanFuel SystemখালিদহাসানBelum ada peringkat

- 05 Fuel Injection SystemDokumen42 halaman05 Fuel Injection SystemVishal JohaheerBelum ada peringkat

- E31 Relays and FusesDokumen1 halamanE31 Relays and FusesAndre Vershun Pernell II100% (1)

- BRAKESDokumen46 halamanBRAKESDianna MadejaBelum ada peringkat

- Fuel Evaporation SystemDokumen9 halamanFuel Evaporation SystemToua YajBelum ada peringkat

- Govt - Poly Technic College Perinthalmanna: Sreenivas.U.P MS5Dokumen17 halamanGovt - Poly Technic College Perinthalmanna: Sreenivas.U.P MS5Kkbhuvan KkBelum ada peringkat

- Turbo Installation 91913Dokumen5 halamanTurbo Installation 91913MoeinBelum ada peringkat

- Diagnosing Misfires: Steady MisfireDokumen3 halamanDiagnosing Misfires: Steady MisfireDawood SubedarBelum ada peringkat

- Training COMMERCIAL REFRIGERATION Cold Controls PDFDokumen4 halamanTraining COMMERCIAL REFRIGERATION Cold Controls PDFFranco TadayBelum ada peringkat

- Hydraulic Basics: Automatic Transmission Hydraulic SystemsDokumen21 halamanHydraulic Basics: Automatic Transmission Hydraulic SystemsSumanth Vasista100% (2)

- Turbocharging of Ic EnginesDokumen5 halamanTurbocharging of Ic EnginesKrishna MurthyBelum ada peringkat

- Alternator TroubleshootingDokumen2 halamanAlternator Troubleshootinghagleyr5638Belum ada peringkat

- Ac Compressor Oil CheckingDokumen3 halamanAc Compressor Oil CheckingToua YajBelum ada peringkat

- MM 36Dokumen23 halamanMM 36renganathan21051990Belum ada peringkat

- ZD30 Engine Fault ListDokumen61 halamanZD30 Engine Fault Listlocario1Belum ada peringkat

- 003 - Engine BlockDokumen29 halaman003 - Engine Blockmax_simonsBelum ada peringkat

- Cooling System PDFDokumen7 halamanCooling System PDFdhirendra singh100% (2)

- Fruitland Vacuum Pump: Operation and Maintenance ManualDokumen48 halamanFruitland Vacuum Pump: Operation and Maintenance ManualALEXBelum ada peringkat

- Starter Motor: HistoryDokumen4 halamanStarter Motor: HistoryKaiser CarloBelum ada peringkat

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDari EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceBelum ada peringkat

- Hydraulic BrakeDokumen6 halamanHydraulic BrakeHemantha DalugamaBelum ada peringkat

- 4th Lecture - Handling Tricky SituationsDokumen3 halaman4th Lecture - Handling Tricky SituationsKevin fxBelum ada peringkat

- World Class Revision ExercisesDokumen3 halamanWorld Class Revision ExercisesNivia MartinezBelum ada peringkat

- Ajuste Calibracion de Valvulas TH460Dokumen4 halamanAjuste Calibracion de Valvulas TH460UilmerKrdenasBelum ada peringkat

- LSU Scouting ReportDokumen6 halamanLSU Scouting ReportKaleb Sulak AbbottBelum ada peringkat

- HYSTER H3-0FT L177 Engine Spare PartsDokumen85 halamanHYSTER H3-0FT L177 Engine Spare PartsMelwyn Fernandes100% (1)

- Game Disaster PresentationDokumen9 halamanGame Disaster PresentationChristopher ShawBelum ada peringkat

- Pathfinder Uniform - Club Ministries - North American DivisionDokumen6 halamanPathfinder Uniform - Club Ministries - North American DivisionJoe FajiculayBelum ada peringkat

- Curriculum Vitae - Zulfa October 2011Dokumen4 halamanCurriculum Vitae - Zulfa October 2011Gusti Ryanda FazrinBelum ada peringkat

- Trebinje Vertikaltrka U Kamenu 2022 (2022.)Dokumen10 halamanTrebinje Vertikaltrka U Kamenu 2022 (2022.)Бранко ПоповићBelum ada peringkat

- Saturation Table R 410ADokumen5 halamanSaturation Table R 410Aalex2628Belum ada peringkat

- Homeric Hymn To Delian ApolloDokumen8 halamanHomeric Hymn To Delian ApolloSharnBelum ada peringkat

- App c4 Design of SailplanesDokumen32 halamanApp c4 Design of SailplanesfakeBelum ada peringkat

- BPL Sponsorship Proposal PDFDokumen14 halamanBPL Sponsorship Proposal PDFSaikotBelum ada peringkat

- Parts Catalog: StackerDokumen46 halamanParts Catalog: StackerАлександр ОбозовBelum ada peringkat

- AppsDokumen1 halamanAppsJessica AlexandraBelum ada peringkat

- Emergence and Governance of Sports in IndiaDokumen12 halamanEmergence and Governance of Sports in IndiashubhamBelum ada peringkat

- Principles of The Inline Speed Skating StrokeDokumen17 halamanPrinciples of The Inline Speed Skating Strokejbmd999100% (3)

- POLAR FavorDokumen10 halamanPOLAR FavornetsheldonBelum ada peringkat

- Toyota R150 R151Dokumen4 halamanToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- ATN Performance ListDokumen10 halamanATN Performance ListCory Mull0% (1)

- Fanatic Magazine Blood Bowl 7Dokumen2 halamanFanatic Magazine Blood Bowl 7Psygnosis ReddevilsBelum ada peringkat

- Ace Phantom Ax 124 Catalouge - 4wd - FinalDokumen255 halamanAce Phantom Ax 124 Catalouge - 4wd - FinalGarcia Manolo RicharBelum ada peringkat

- NFL 101 - Introducing The Basics of Cover 4 - Bleacher ReportDokumen11 halamanNFL 101 - Introducing The Basics of Cover 4 - Bleacher Reportwill27ns100% (1)

- Magic The Gathering Premier Event Invitation Policy PDF1Dokumen16 halamanMagic The Gathering Premier Event Invitation Policy PDF1Antonio Guardián FrancoBelum ada peringkat

- Hometown - Kaslo & AreaDokumen8 halamanHometown - Kaslo & AreaPennywise PublishingBelum ada peringkat

- Mazda Protege 1990Dokumen22 halamanMazda Protege 1990aljerez813Belum ada peringkat

- Lee Nelson Ebook Lets Play PokerDokumen128 halamanLee Nelson Ebook Lets Play PokerTeodor Mihai100% (4)

- Pokémon Shiny Gold Sigma 1.3.7Dokumen101 halamanPokémon Shiny Gold Sigma 1.3.7Erick Jair MolinaBelum ada peringkat

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDokumen12 halamanRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Complementarytraining Net Strength Training Planning The Training Block Part 3Dokumen7 halamanComplementarytraining Net Strength Training Planning The Training Block Part 3Nacho MoreiraBelum ada peringkat