Dop-A Q Mul 20120423

Diunggah oleh

Royal Ritesh SharmaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dop-A Q Mul 20120423

Diunggah oleh

Royal Ritesh SharmaHak Cipta:

Format Tersedia

Preface

Thank you for purchasing DELTAs DOP-A, AE and AS series. This quick start will be helpful in the

installation, wiring and inspection of Delta HMI. Before using the product, please read this quick start

to ensure correct use. You should thoroughly understand all safety precautions before proceeding

with the installation, wiring and operation. Place this quick start in a safe location for future

reference. Please observe the following precautions:

Install the product in a clean and dry location free from corrosive and inflammable gases or

liquids.

Ensure that all wiring instructions and recommendations are followed.

Ensure that HMI is correctly connected to a ground. The grounding method must comply

with the electrical standard of the country.

Do not modify or remove wiring when power is applied to HMI.

Do not touch the power supply during operation. Otherwise, it may cause electric shock.

For the information of HMI software operation, software installation and hardware wiring,

please refer to the HMI software manual.

If you have any questions during operation, please contact our local distributors or Delta sales

representative.

The content of this quick start may be revised without prior notice. Please consult our distributors or

download the most updated version at 0Hhttp://www.delta.com.tw/industrialautomation.

Safety Precautions

Carefully note and observe the following safety precautions when receiving, inspecting, installing,

operating, maintaining and troubleshooting. The following words, DANGER, WARNING and STOP are

used to mark safety precautions when using the Deltas HMI product. Failure to observe these

precautions may void the warranty!

Installation

Comply with quick start for installation. Otherwise it may cause equipment

damage.

Do not install the product in a location that is outside the stated specification for

the HMI. Failure to observe this caution may result in electric shock, fire, or

personal injury.

Wiring

Connect the ground terminals to a class-3 ground (Ground resistance should not

exceed 100). Improper grounding may result in communication error, electric

shock or fire.

Operation

The users should use Delta Screen Editor software to perform editing in Delta's HMI

product. To perform editing and confirming HMI programs without using Delta

Screen Editor software in Delta's HMI product may result in abnormal operation.

English-1

Do not modify wiring during operation. Otherwise it may result in electric shock or

personal injury.

Never use a hard or pointed object to hit or strike the screen as doing this may

damage the screen and let the screen has not respond at all, and then cause HMI to

work abnormally..

Maintenance and Inspection

Do not touch any internal or exposed parts of the HMI as electrical shock may

result.

Do not remove operation panel while power is on. Otherwise electrical shock may

result.

Wait at least 10 minutes after power has been removed before touching any HMI

terminals or performing any wiring and/or inspection as an electrical charge may

still remain in the HMI with hazardous voltages even after power has been

removed.

Turn the power off before changing backup battery and check system settings after

finishing change. (all data will be cleared after changing battery).

Be sure the ventilation holes are not obstructed during operation. Otherwise

malfunction may result due to bad ventilation or overheating troubles.

Wiring Method

Remove the terminal block from the HMI before wiring.

Insert only one wire into one terminal on the terminal block.

If the wiring is in error, perform the wiring again with proper tools. Never use force

to remove the terminals or wires. Otherwise, it may result in malfunction or

damage.

For the power line that forced to take out, ensure to check wiring again and restart.

Communication Wiring

Comply with communication wiring specification for wiring.

Wiring length should comply with the stated specification for the HMI.

Proper grounding to avoid bad communication quality.

Installation and Storage Conditions

The product should be kept in the shipping carton before installation. In order to retain the warranty

coverage, the HMI should be stored properly when it is not to be used for an extended period of time.

Some storage suggestions are:

Store in a clean and dry location free from direct sunlight.

Store within an ambient temperature range of -20C to +60C (-4F to 140F).

Store within a relative humidity range of 10% to 90% and non-condensing.

Do not store the HMI in a place subjected to corrosive gases and liquids.

Correctly packaged and placed on a solid and durable surface.

Do not mount the HMI adjacent to heat-radiating elements or in direct sunlight.

Do not mount the HMI in a location subjected to corrosive gases, liquids, or airborne dust

or metallic particles.

Do not mount the HMI in a location where temperatures and humidity will exceed

specification.

Do not mount the HMI in a location where vibration and shock will exceed specification.

Do not mount the HMI in a location where it will be subjected to high levels of

electromagnetic radiation.

English-2

Installation

Installation Note:

Improper installation will result in malfunction and greatly reduce the life of the HMI. Be

sure to follow the guidelines in this quick start when installing the HMI.

In order to ensure the HMI being well ventilated, make sure that the ventilation holes are

not obstructed and must provide sufficient free space around HMI.

For use on a flat surface of a Type 4X "Indoor Use Only" enclosure or equivalent.

Installation Method [A and AE Series]:

Step 1:

Ensure to put waterproof gasket into HMI and

then insert the HMI into the panel cutout.

Step 2:

Ensure to insert fasteners into the HMIs insertion

slots and turn the screw till screws touch panel

cutout.

Step 3:

Turn the screw with less than torque 0.7N-M to avoid damage to plastic box. Torque:

6.17lb-inch(0.7N-M)

Installation Method [AS Series]:

Step 1:

Ensure to put waterproof gasket into HMI and

then insert the HMI into the panel cutout.

Step 2:

Ensure to insert fasteners into the HMIs insertion

slots and turn the screw till screws touch panel

cutout.

English-3

Step 3:

Turn the screw with less than torque 0.7N-M to avoid damage to plastic box. Torque:

6.17lb-inch(0.7N-M)

Power Line Installation

The specifications for power terminal wiring are shown in the table below:

Type Wire Gauge (AWG) Stripped length Torque

Solid 28~12 7~8 mm 5 kg-cm (4.3 lb-in)

Stranded 28~12 7~8 mm 5 kg-cm (4.3 lb-in)

The specifications for communication terminal wiring are shown in the table below (AS Series only):

Type Wire Gauge (AWG) Stripped length Torque

Solid 30 ~ 16 5 ~ 6 mm 2 kg-cm (1.7 lb-in)

Stranded 30 ~ 16 5 ~ 6 mm 2 kg-cm (1.7 lb-in)

Be sure to plug power line into HMI according to following arrow direction.

DOP-AS35THTD

DOP-AS38BSTD

DOP-AS57BSTD

DOP-A80THTD1

DOP-AE80THTD

DOP-A(E)10THTD1

English-4

Basic Inspection

Item Content

General Inspection

Periodically inspect the screws of the connection between the HMI and

device. Tighten screws as necessary as they may loosen due to vibration

and varying temperatures.

Ensure that oil, water, metallic particles or any foreign objects do not fall

inside the HMI, control panel or ventilation slots and holes. As these will

cause damage.

Ensure the correct installation and the control panel. It should be free from

airborne dust, harmful gases or liquids.

Inspection before

operation (power is

not applied)

Ensure that all wiring terminals are correctly insulated.

Ensure that all wiring is correct or damage and or malfunction may result.

Visually check to ensure that there are not any unused screws, metal

strips, any conductive or inflammable materials inside HMI.

Ensure to lower electromagnetic interference when devices are influenced

by it.

Ensure that the external applied voltage to HMI is correct and matched to

the controller.

Inspection before

operation (power is

applied)

Check if power LED lights.

Check if the communication among devices is normal.

Please contact our local distributors or Delta sales representative if there

are any abnormal conditions.

Pin Definition of Serial Communication

COM1 Port [A, AE and AS57BSTD Series]

Contact

COM Port PIN

RS-232

1

2 RXD

3 TXD

4

5 GND

6

7 RTS

8 CTS

9

Pin

Note: Blank = No Connection.

English-5

COM2 Port [A Series]

MODE1 MODE2 MODE3

COM Port PIN

RS-232 RS-422 RS-485

1 RXD- D-

2 RXD RXD+ D+

3 TXD TXD+ D+

4 TXD- D-

5 GND

6 RTS-

7 RTS RTS+

8 CTS CTS+

9 CTS-

Pin

Note 1: Blank = No Connection.

Note 2: When selecting Mode3 (for RS-485), D+ indicates that PIN 2 and PIN 3 is connected,

and D- indicates that PIN 1 and PIN 4 is connected.

COM2 and COM3 Port [AE, A80THTD1 and A10THTD1 Series]

MODE1 MODE2 MODE3 MODE4 MODE5 MODE6

COM Port PIN

RS-232 RS-422 RS-485

RS-232*

2

RS-422*

2

RS-485*

2

1 RXD- D- RXD1- D1-

2 RXD RXD+ D+ RXD1 RXD1+ D1+

3 TXD TXD+ D+ TXD1 TXD1+ D1+

COM2

4 TXD- D- TXD1- D1-

5 GND

6 RTS- TXD2- D2-

7 RTS RTS+ TXD2 TXD2+ D2+

8 CTS CTS+ RXD2 RXD2+ D2+

COM3

9 CTS- RXD2- D2-

Pin

Note 1: Blank = No Connection.

Note 2: When selecting Mode3 (for RS-485), D+ indicates that PIN 2 and PIN 3 is connected,

and D- indicates that PIN 1 and PIN 4 is connected. When selecting Mode6 (for RS-485),

D1+ indicates that PIN 2 and PIN 3 is connected, D1- indicates that PIN 1 and PIN 4 is

connected, D2+ indicates that PIN 7 and PIN 8 is connected, and D2- indicates that PIN

6 and PIN 9 is connected.

COM1 and COM3 [AS38BSTD, AS35THTD Series]

MODE1 MODE2

COM Port PIN

RS-232 RS-232*2

1

2 RXD RXD1

3 TXD TXD1

COM1

4

5 GND

6

7 RTS TXD2

8 CTS RXD2

COM3

9

Pin

Note: Blank = No Connection.

English-6

COM2 Port [AS38BSTD, AS35THTD Series]

MODE1 MODE2

COM Port PIN

RS-422 RS-485

R- RXD- D-

R+ RXD+ D+

T- TXD- D-

T+ TXD+ D+

G GND

R-

Note 1: When selecting Mode2 (for RS-485), D+ indicates that R+ and T+ is connected, and D-

indicates that R- and T- is connected.

COM2 and COM3 Port [AS57BSTD Series]

MODE1 MODE2 MODE3

COM Port PIN

RS-485*2 RS-422*2 RS-422

R- D- RXD- RXD-

R+ D+ RXD+ RXD+

T- TXD- TXD-

COM2

T+ TXD+ TXD+

G GND

R- D- RXD- CTS-

R+ D+ RXD+ CTS+

T- TXD- RTS-

COM3

T+ TXD+ RTS+

COM2

COM3

Note 1: Blank = No Connection.

Note 2: When using RS-422 flow control, please refer to the COM3 Port signals table above for

pin assignments. At this time, COM2 and COM3 ports cannot be used individually.

Comparison of Flow Control Protocols

COM

Port

DOP-AE Series DOP-A Series DOP-AS57 Series

DOP-AS35 / AS38

Series

COM1

RS-232 flow control

supported

RS-232 flow

control

supported

RS-232 flow control

supported

RS-232 flow control

supported. But, when

RS-232 flow control

function is enabled,

COM3 can not be used.

COM2

RS-422 flow

control

supported

RS-422 flow control is

not supported.

COM3

RS-422 flow control

supported. But,

when RS-422 flow

control function is

enabled, COM3 can

not be used. N/A

RS-422 flow control

supported. But, when

RS-422 flow control

function is enabled,

COM3 can not be

used.

RS-232 flow control

supported. But, when

RS-232 flow control

function is enabled,

COM3 can not be used.

Note: For more detailed information regarding the pin definition for flow control, please refer

to the pin definition of serial communication of each series.

English-7

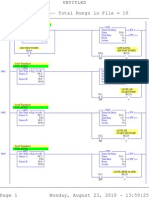

Dimensions

DOP-AS35THTD / DOP-AS38BSTD

118.8

+0.04 +1

(4.68 )

140.8

1

0

4

.

8

0 0

(

3

.

6

5

)

T=1.6mm(0.06in) ~

9

2

.

8

0

+

1

3.0mm(0.12in)

NOTE:

0

+

0

.

0

4

T

4-R3

36.7

Units: mm

DOP-AS57BSTD

0.12in(3.0mm)

T=0.06in(1.6mm) ~

(

5

.

2

1

)

+

1

0

+

0

.

0

4

0

(6.79 )

0

+1 +0.04

0

1

4

4

.

1

(

5

.

6

7

)

184.1(7.25)

6.1(0.24) 39.0(1.54)

172.4

1

3

2

.

4

4-R3(0.12)

T

NOTE:

Units: mm

English-8

DOP-A80THTD1 / DOP-AE80THTD

T=1.6mm(0.06in) ~

3.0mm(0.12in)

(1.75)

1

7

8

.

1

(

7

.

0

1

)

243.1(9.57)

0

+1

231.4 0 (9.11 )

+0.04

+

0

.

0

4

(

6

.

5

5

)

0

+

1

1

6

6

.

4

0

NOTE:

4

-

R

3

.

0

(

0

.

1

2

)

44.4

T

6.1(0.24)

Units: mm

DOP-A(E)10THTD1

3.0mm(0.12in)

+0.04

(11.22 )

+1

0 0

T=1.6mm(0.06in) ~

(

8

.

2

7

)

+

1

0

+

0

.

0

4

0

2

1

0

.

2

285.2

4

-

R

3

.

0

(

0

.

1

2

)

NOTE:

T

297.1(11.70)

2

2

2

.

1

(

8

.

7

4

)

43.1(1.70) 6.1(0.24)

Units: mm

English-9

Specifications

MODEL AS35THTD AS38BSTD AS57BSTD

Display Type

3.5 TFT LCD (65536

colors)

3.8 STN LCD

(8 shades of blue)

5.7 STN LCD

(8 shades of blue)

Resolution 320 x 240 pixels

Back Light

LED Back Light

(less than 30,000

hours half-life at 25

o

C)

(Note 1)

LED Back Light

(less than 10,000

hours half-life at 25

o

C)

(Note 1)

CCFL Back Light

(less than 50,000 hours

half-life at 25

o

C)

(Note 1)

L

C

D

M

O

D

U

L

E

Display Size 70.08 x 52.56mm 76.8 x 57.6mm 115.17 x 86.37mm

Operation System Delta Real Time OS

MCU 32-bit RISC Micro-controller

Flash ROM NOR Flash ROM 2 MB (OS System: 1MB / User Application: 1MB)

SDRAM 8Mbytes 4Mbytes 16Mbytes

Backup Memory

(Bytes)

128K

SM Card N/A

Extension Interface N/A

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-422 / RS-485

Serial

COM

Port

COM3 RS-232 RS-422 / RS-485

Function Key User defined key x 4 + System key x 1

Operation Voltage DC +24V (-10% ~ +15%) (Please use isolated power supply)

(Note 2)

Power

Consumption

(Note 3)

3.36W 2.64W 5.28W

Backup Battery 3V lithium battery CR2032 x 1 / battery life: 5 years

Buzzer 85dB

Perpetual Calendar

(RTC)

Built-in

Cooling Method Natural air circulation

Safety Approval

(Waterproof for

front panel)

IP65 / NEMA4 / CE, UL

Operation Temp. 0C ~ 50C

Storage Temp. -20C ~ +60C

Ambient Humidity

10% ~ 90% RH [0 ~ 40C], 10% ~ 55% RH [41 ~ 50C]

Pollution Degree 2

English-10

MODEL AS35THTD AS38BSTD AS57BSTD

Vibration

Resistance

IEC 61131-2 Compliant

5Hzf9Hz = Continuous: 1.75mm / Occasional: 3.5mm

9Hzf150Hz = Continuous: 0.5g / Occasional: 1.0g

X, Y, Z directions for 10 times

Dimensions

(W) x (H) x (D) mm

140.8 x 104.8 x 44.8 184.1 x 144.1 x 47

Panel Cutout

(W) x (H) mm

118.8 x 92.8 172.4 x 132.4

Weight Approx. 310g Approx. 760g

NOTE

1) The half-life of backlight is defined as original luminance being reduced by 50% when the maximum

driving current is supplied to HMI. The life of LED backlight shown here is an estimated value under 25

o

C

normal temperature and humidity conditions.

2) Users please use isolated power supply except DOP-A80THTD1, DOP-AE80THTD and DOP-A(E)10THTD1

these models.

3) The value of the power consumption indicates the electrical power consumed by HMI only without

connecting to any peripheral devices. In order to ensure the normal operation, it is recommended to use

a power supply which the capacity is 1.5 ~2 times the value of the power consumption.

4) Users can download the Screen Editor V1.05, the program editor of Delta HMI product and the user

manual via the following link: 1Hhttp://www.delta.com.tw/industrialautomation/.

5) The content of this quick start may be revised without prior notice. Please consult our distributors or

download the most updated version at 2Hhttp://www.delta.com.tw/industrialautomation/.

English-11

MODEL

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

Display Type

8 TFT LCD

(65536 colors)

10.4 TFT LCD

(65536 colors)

Resolution 640 x 480 pixels

Back Light

CCFL Back Light

(less than 50,000 hours half-life at

25

o

C)

(Note 1)

CCFL Back Light

(less than 30,000 hours half-life at

25

o

C)

(Note 1)

L

C

D

M

O

D

U

L

E

Display Size 162.2 x 121.7mm 211.2 x 158.4mm

Operation System Delta Real Time OS

MCU 32-bit RISC Micro-controller

Flash ROM NOR Flash ROM 8 MB (OS System: 2MB / User Application: 6MB)

SDRAM 32Mbytes

Backup Memory

(Bytes)

512K

SM Card AE

Extension Interface AE

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-232 / RS-422 / RS-485

Serial

COM

Port

COM3 RS-232 / RS-422 / RS-485

Function Key

User defined key x 6 +

System key x 1

User defined key x 7 +

System key x 1

Operation Voltage DC +24V (-10% ~ +15%) (Please use isolated power supply)

(Note 2)

Power

Consumption

(Note 3)

14W 15W

Backup Battery 3V lithium battery CR2032 x 1 / battery life: 5 years

Buzzer 85dB

Perpetual Calendar

(RTC)

Built-in

Cooling Method Natural air circulation

Safety Approval

(Waterproof for

front panel)

IP65 / NEMA4 / CE, UL

Operation Temp. 0C ~ 50C

Storage Temp. -20C ~ +60C

Ambient Humidity

10% ~ 90% RH [0 ~ 40C], 10% ~ 55% RH [41 ~ 50C]

Pollution Degree 2

English-12

MODEL

A80THTD1

AE80THTD

A(E)10THTD1

Vibration

Resistance

IEC 61131-2 Compliant

5Hzf9Hz = Continuous: 1.75mm / Occasional: 3.5mm

9Hzf150Hz = Continuous: 0.5g / Occasional: 1.0g

X, Y, Z directions for 10 times

Dimensions

(W) x (H) x (D) mm

243.1 x 178.1 x 52.4 297.1 x 222.1 x 51.1

Panel Cutout

(W) x (H) mm

231.4 x 166.4 285.2 x 210.2

Weight Approx. 1140g Approx. 1735g

NOTE

1) The half-life of backlight is defined as original luminance being reduced by 50% when the maximum

driving current is supplied to HMI. The life of LED backlight shown here is an estimated value under 25

o

C

normal temperature and humidity conditions.

2) Users please use isolated power supply except DOP-A80THTD1, DOP-AE80THTD and DOP-A(E)10THTD1

these models.

3) The value of the power consumption indicates the electrical power consumed by HMI only without

connecting to any peripheral devices. In order to ensure the normal operation, it is recommended to use

a power supply which the capacity is 1.5 ~2 times the value of the power consumption.

4) Users can download the Screen Editor V1.05, the program editor of Delta HMI product and the user

manual via the following link: 3Hhttp://www.delta.com.tw/industrialautomation/.

5) The content of this quick start may be revised without prior notice. Please consult our distributors or

download the most updated version at 4Hhttp://www.delta.com.tw/industrialautomation/.

English-13

English-14

This page intentionally left blank.

nsz

DELTAnn DOP-A, AE ve AS serisi operatr panellerini setiiniz iin teekkrler. Bu bilgi dkman

Delta HMI kurulum, balant, bakm ve kontrolnde kullancya yardmc olacaktr. Doru kullanm

iin rn kullanmadan nce bu dkman mutlaka okuyunuz. Kurulum, balant ve alma

yapmadan nce gvenlik uyarlarn tamamen anladnzdan emin olunuz. Bu dkman daha sonra

da kullanmak iin iyi muhafaza ediniz. Ltfen aadaki gvenlik uyarlarna dikkat ediniz:

rnn kurulumunu yanc gaz ve svlardan uzak kuru ve temiz ortamlara yapnz.

Balantlar yaparken tm balant kurallarnn salandndan emin olunuz.

HMInn toprak balantsnn doru yapldndan emin olunuz. Topraklama metodunun

rnn kurulduu lke standartlarna uygun olduuna emin olunuz.

HMI enerjili iken kablo balants yapmaynz ya da skmeyiniz.

alma srasnda power supply terminallerine dokunmaynz. Aksi halde elektrik oku

olabilir.

HMI yazlmnn kurulumu, almas ve donanm balants ile ilgili daha fazla bilgi iin

ltfen HMI manualini inceleyiniz.

HMI ile ilgili sorularnz iin ltfen teknik servisimizle balantya geiniz.

Herhangi bir ihbara gerek kalmakszn bu bilgi dkmannn ierii deitirilebilir. Gncellenmi

versiyonunu elde etmek iin teknik servisimize danabilir yada

http://www.delta.com.tw/industrialautomation adresinden indirebilirsiniz.

Gvenlik Uyarlar

rn alrken, kontrol ederken, kurulumunu yaparken, altrrken, bakm ve arza tehisi yaparken

aadaki gvenlik uyarlarna dikkat ediniz. DANGER, WARNING, ve STOP balklar DELTA HMI

rnn kullanrken yaplmas gerekenleri dikkat ekmek iin kullanlmtr. rnn garantisini

muhafaza etmek iin bu uyarlara mutlaka dikkat ediniz!

Kurulum

Kurulumu dokman da belirtildii gibi yapnz. Aksi halde rn zarar grebilir.

Operatr panelini dokman da belirtilen ortam deerlerinin dnda kurulumunu

yapmaynz. Aksi halde elektrik oku, yangn ya da kiisel zararlara sebep olabilir.

Balant

Toprak terminallerini class-3 topraklama yapnz. (Topraklama direnci 100 u

amamaldr). Yanl yaplan topraklama balants haberleme hatasna, elektrik

okuna ve yangna sebep olabilir.

alma

DELTAnn HMI rnlerini programlamak iin Delta Screen Editor yazlm

kullanlmaldr. DELTA HMI rnlerini programlamak iin Delta Screen Editor

yazlm dnda bir yazlm kullanlmas durumunda HMI almasnda problem

meydana gelebilir.

Trke-1

alma srasnda kablo balantlarn deitirmeyiniz. Aksi halde elektrik okuna

veya kiisel zararlara sebep olabilir.

Dokunmatik ekrana sert ve sivri nesneler kullanarak basmaynz. Aksi halde HMI

ekran zarar grebilir ve HMInn anormal almasna sebep olabilir.

Bakm ve Kontroller

HMI iindeki devre elemanlarna dokunmaynz aksi halde elektrik oku meydana

gelebilir.

Enerjili iken operatr panelinin balantlarna mdahale etmeyiniz. Aksi halde

elektrik oku meydana gelebilir.

HMI enerjisi kesildikten sonra HMI zerinde tehlikeli seviyede elektrik arj voltaj

kalabileceinden rne dokunmadan ve balantlara mdahale etmeden nce en az

10 dakika beklenilmesi tavsiye edilir.

Pili deitirmeden nce rnn enerjisini kesiniz ve pili deitirdikten sonra sistem

ayarlarn kontrol ediniz. (Pil deitirildikten sonra tm datalar silinecektir).

alma srasnda havalandrma deliklerinin tkal olmadndan emin olunuz. Aksi

halde kt havalandrmadan veya ar scaklktan dolay rn zarar grebilir.

Balant Metodu

Kablo balants yapmadan nce terminal blounu HMIdan ayrnz.

Terminal bloundaki her bir terminale sadece tek bir kablo balaynz.

Eer balantda hata varsa, balanty uygun aletleri kullanarak tekrar yapnz.

Terminal ya da kablolar skmek iin darbe uygulamaynz. Aksi halde rn zarar

grebilir.

Enerji hattnda bir kopukluk meydana gelmise, balantlarn salamln kontrol

ettikten sonra tekrar enerji verin.

Haberleme Balants

Haberleme balantsn dkman da belirtildii gibi yapnz.

HMI Kablo uzunluklar dkman da belirtildii gibi olmaldr.

Haberlemenin kalitesini arttrmak iin dzgn topraklama yapnz.

Kurulum ve Saklama Koullar

Kurulum yaplana kadar rn orjinal kutusu iinde muhafaza edilmelidir. rnn garanti kapsamnn

devam iin, rn belli bir sre kullanlmayacaksa, HMI uygun bir ekilde saklanmaldr. Baz saklama

nerileri:

Dorudan gne nn temas etmedii kuru ve temiz ortamda saklanmaldr.

20C - +60C (-4F - 140F) scaklk aralnda saklanmaldr.

10% - 90% rutubet aralnda ve younlamasz ortamda saklanmaldr.

HMI andrc sv ve gaz bulunan ortamlarda saklanmamaldr.

rn uygun paketlenmeli, sert ve dz bir yzeyde saklanmaldr.

HMI dorudan gne nn temas ettii yerlere ya da s yayan nesnelerin yaknna monte

edilmemelidir.

HMI andrc gaz ve svnn olduu toz veya metal paracklarn bulunduu yerlere monte

edilmemelidir.

HMI dokman da belirtilen scaklk ve rutubet oranlarnn dndaki ortamlara monte

edilmemelidir.

HMI dokman da belirtilen titreim ve ok oranlarnn zerindeki ortamlara monte

edilmemelidir.

HMI yksek seviyede elektromanyetik radyasyonun bulunduu ortamlara monte

edilmemelidir

Trke-2

Kurulum

Kurulum Notlar:

Yanl kurulum yaplmas rnn zarar grmesini veya alma mrnn ksalmasna

sebep olur. HMI kurulumunun dokman da belirtildii gibi yaplmas gerekir.

HMInn havalandrmasnn doru olduuna emin olmak iin, havalandrma deliklerinin

tkal olmadna ve HMI etrafna gerekli boluun brakldna emin olunuz.

Dz yzey, Tip 4X Sadece kapal alanda kullanm ve edeer ortamlarda kurulum

yaplmaldr.

Kurulum Metodu [A ve AE Serisi]:

Adm 1:

HMI iine su geirmez contann takldna

emin olunuz ve sonra pano boluuna

yerletiriniz.

Adm 2:

Montaj aparatlarn HMInn yuvalarna yerletiriniz

ve sonra panoya deene kadar vidalar sknz.

Adm 3:

Plastik kasaya zarar vermemek iin viday 0.7N.Mden az bir tork ile sknz. Tork:

6.17lb-inch(0.7N-M)

Kurulum Metodu [AS Serisi]:

Adm 1:

HMI iine su geirmez contann takldna

emin olunuz ve sonra pano boluuna

yerletiriniz.

Adm 2:

Montaj aparatlarn HMInn yuvalarna yerletiriniz

ve sonra panoya deene kadar vidalar sknz.

Trke-3

Adm 3:

Plastik kasaya zarar vermemek iin viday 0.7N.Mden az bir tork ile sknz. Tork:

6.17lb-inch(0.7N-M)

Power Hatt Kurulumu

Tavsiye edilen balant ekli aadadr:

Tip Kablo Kesiti (AWG) Soyulacak uzunluk Tork

Solid 28~12 7~8 mm 5 kg-cm (4.3 lb-in)

Stranded 28~12 7~8 mm 5 kg-cm (4.3 lb-in)

Tavsiye edilen balant ekli aadadr (Sadece AS Serisi):

Tip Kablo Kesiti (AWG) Soyulacak uzunluk Tork

Solid 30 ~ 16 5 ~ 6 mm 2 kg-cm (1.7 lb-in)

Stranded 30 ~ 16 5 ~ 6 mm 2 kg-cm (1.7 lb-in)

HMIya power konnektrn aada gsterildii gibi balaynz.

DOP-AS35THTD

DOP-AS38BSTD

DOP-A80THTD1

DOP-AE80THTD

DOP-A(E)10THTD1

DOP-AS57BSTD

Trke-4

Temel Kontrol

Madde erik

Genel Kontrol

HMI balantlarn periyodik olarak kontrol ediniz. Titreim ve scaklk

deiiminden dolay geveyen vidalar sknz.

HMI iine, kontrol paneline veya havalandrma slot ve deliklerine ya, su,

metal paralar veya yabanc nesnelerin dmediine emin olunuz. Bu

durum rne zarar verir.

Kurulumu doru yaptnza emin olunuz. Ortamda toz, zararl gaz ve

svlar olmamaldr.

almadan nce

kontrol (enerji

verilmeden nce)

Tm balant terminallerinin doru izole olduundan emin olunuz.

Zarar ve hasar meydana gelmemesi iin tm balantlarn doru yapldna

emin olunuz.

HMI iinde kullanlmayan vidalarn, metal paralarn, iletken veya yanc

maddelerin olmadn gzle kontrol ediniz.

rn etkileyebilecek elektromanyetik grltnn dk olduuna emin

olunuz.

HMI nitesine uygulanan harici voltajn doru ve rne uygun olduunu

kontrol ediniz.

altrmadan nce

kontrol (enerji

verildikten sonra)

Power LED nn yandn kontrol ediniz.

Cihazlar arasnda haberlemenin normal olduunu kontrol ediniz.

Anormal bir durum ile karlatnzda teknik servisimizle balantya

geiniz.

Seri Haberleme Pin Aklamas

COM1 Port [A, AE ve AS57BSTD Serisi]

Balant

COM Port PIN

RS-232

1

2 RXD

3 TXD

4

5 GND

6

7 RTS

8 CTS

9

Pin

Not: Bo pin = Balant yaplmaz.

Trke-5

COM2 Port [A Serisi]

MOD 1 MOD 2 MOD 3

COM Port PIN

RS-232 RS-422 RS-485

1 RXD- D-

2 RXD RXD+ D+

3 TXD TXD+ D+

4 TXD- D-

5 GND

6 RTS-

7 RTS RTS+

8 CTS CTS+

9 CTS-

Pin

Not 1: Bo pin = Balant yaplmaz.

Not 2: Mod 3 seilecei zaman (RS-485 iin), D+ PIN 2 ve PIN 3n balanacan gsterir ve D-

ise PIN 1 ve PIN 4n balanacan gsterir.

COM2 ve COM3 Port [AE, A80THTD1 ve A10THTD1 Serisi]

MOD 1 MOD 2 MOD 3 MOD 4 MOD 5 MOD 6

COM Port PIN

RS-232 RS-422 RS-485

RS-232*

2

RS-422*

2

RS-485*

2

1 RXD- D- RXD1- D1-

2 RXD RXD+ D+ RXD1 RXD1+ D1+

3 TXD TXD+ D+ TXD1 TXD1+ D1+

COM2

4 TXD- D- TXD1- D1-

5 GND

6 RTS- TXD2- D2-

7 RTS RTS+ TXD2 TXD2+ D2+

8 CTS CTS+ RXD2 RXD2+ D2+

COM3

9 CTS- RXD2- D2-

Pin

Not 1: Bo pin = Balant yaplmaz.

Not 2: Mod 3 seildii zaman (RS-485 iin), D+ PIN 2 ve PIN 3n balanacan gsterir ve D-

ise PIN 1 ve PIN 4n balanacan gsterir. Mod 6 seildii zaman (RS-485 iin), D1+

PIN 2 ve PIN 3n balanacan gsterir ve D1- ise PIN 1 ve PIN 4n balanacan

gsterir. D2+ PIN 7 ve PIN 8n balanacan gsterir ve D2- ise PIN 6 ve PIN 9n

balanacan gsterir.

COM1 ve COM3 [AS38BSTD, AS35THTD Serisi]

MOD 1 MOD 2

COM Port PIN

RS-232 RS-232*2

1

2 RXD RXD1

3 TXD TXD1

COM1

4

5 GND

6

7 RTS TXD2

8 CTS RXD2

COM3

9

Pin

Not: Bo pin = Balant yaplmaz.

Trke-6

COM2 Port [AS38BSTD, AS35THTD Serisi]

MOD 1 MOD 2

COM Port PIN

RS-422 RS-485

R- RXD- D-

R+ RXD+ D+

T- TXD- D-

T+ TXD+ D+

G GND

R-

Not 1: Mod 2 seildii zaman (RS-485 iin), D+ gsterilen yere R+ ve T+ terminallerinin

balanacan gsterir ve, D- ise R- ve T- terminallerinin balanacan gsterir.

COM2 ve COM3 Port [AS57BSTD Serisi]

MOD 1 MOD 2 MOD 3

COM Port PIN

RS-485*2 RS-422*2 RS-422

R- D- RXD- RXD-

R+ D+ RXD+ RXD+

T- TXD- TXD-

COM2

T+ TXD+ TXD+

G GND

R- D- RXD- CTS-

R+ D+ RXD+ CTS+

T- TXD- RTS-

COM3

T+ TXD+ RTS+

COM2

COM3

Not 1: Bo pin = Balant yaplmaz.

Not 2: RS-422 flow control kullanld zaman, ltfen yukardaki COM 3 port sinyal tablosu pin

klarn inceleyiniz. Bu durumda COM 2 ve COM 3 bamsz kullanlamaz.

Flow Control Protokol Karlatrmas

COM

Port

DOP-AE Serisi DOP-A Serisi DOP-AS57 Serisi DOP-AS35 / AS38 Serisi

COM1

RS232 flow control

destekler

RS232 flow

control

destekler

RS232 flow control

destekler

RS-232 flow control

destekler. Fakat,

RS-232 flow control

fonksiyonu aktif

edildii zaman, COM3

kullanlamaz.

COM2

RS-422 flow

control

destekler

RS422 flow control

desteklemez.

COM3

RS-422 flow control

destekler. Fakat,

RS-422 flow control

fonksiyonu aktif

edildii zaman,

COM3 kullanlamaz. N/A

RS-422 flow control

destekler. Fakat,

RS-422 flow control

fonksiyonu aktif

edildii zaman, COM3

kullanlamaz.

RS-232 flow control

destekler. Fakat,

RS-232 flow control

fonksiyonu aktif

edildii zaman, COM3

kullanlamaz.

Not: Flow control pin aklamalar ile ilgili daha detayl bilgi iin, ltfen her modelin seri

haberleme pin aklamasna baknz.

Trke-7

ller

DOP-AS35THTD / DOP-AS38BSTD

118.8

+0.04 +1

(4.68 )

140.8

1

0

4

.

8

0 0

(

3

.

6

5

)

T=1.6mm(0.06in) ~

9

2

.

8

0

+

1

3.0mm(0.12in)

NOTE:

0

+

0

.

0

4

T

4-R3

36.7

Birim: mm

DOP-AS57BSTD

0.12in(3.0mm)

T=0.06in(1.6mm) ~

(

5

.

2

1

)

+

1

0

+

0

.

0

4

0

(6.79 )

0

+1 +0.04

0

1

4

4

.

1

(

5

.

6

7

)

184.1(7.25)

6.1(0.24) 39.0(1.54)

172.4

1

3

2

.

4

4-R3(0.12)

T

NOTE:

Birim: mm

Trke-8

DOP-A80THTD1 / DOP-AE80THTD

T=1.6mm(0.06in) ~

3.0mm(0.12in)

(1.75)

1

7

8

.

1

(

7

.

0

1

)

243.1(9.57)

0

+1

231.4 0 (9.11 )

+0.04

+

0

.

0

4

(

6

.

5

5

)

0

+

1

1

6

6

.

4

0

NOTE:

4

-

R

3

.

0

(

0

.

1

2

)

44.4

T

6.1(0.24)

Birim: mm

DOP-A(E)10THTD1

3.0mm(0.12in)

+0.04

(11.22 )

+1

0 0

T=1.6mm(0.06in) ~

(

8

.

2

7

)

+

1

0

+

0

.

0

4

0

2

1

0

.

2

285.2

4

-

R

3

.

0

(

0

.

1

2

)

NOTE:

T

297.1(11.70)

2

2

2

.

1

(

8

.

7

4

)

43.1(1.70) 6.1(0.24)

Birim: mm

Trke-9

zellikler

MODEL AS35THTD AS38BSTD AS57B(C)STD

Display Tipi

3.5 TFT LCD (65536

renk)

3.8 STN LCD

(8 ton mavi)

5.7 STN LCD

(BS: 8 ton mavi

CS: 256 renk)

znrlk 320 x 240 piksel

Arka Ik

LED Arka Ik (25

o

C

yarm mrde 30,000

saatden az)

(Not 1)

LED Arka Ik (25

o

C

yarm mrde 30,000

saatden az)

(Not 1)

CCFL Arka Ik (25

o

C

yarm mrde 50,000

saatden az)

(Not 1)

L

C

D

M

O

D

L

Display

l

70.08 x 52.56mm 76.8 x 57.6mm 115.17 x 86.37mm

letim Sistemi Delta Real Time OS

MCU 32-bit RISC Micro-controller

Flash ROM NOR Flash ROM 2 MB (OS Sistem: 1MB / Kullanc Uygulamas: 1MB)

SDRAM 8Mbyte 4Mbyte 16Mbyte

Backup Memory

(Byte)

128K 128K 128K

SM Card N/A

lave arabirim N/A

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-422 / RS-485

Seri

COM

Port

COM3 RS-232 RS-422 / RS-485

Fonksiyon Tuu 4 adet kullanc tanml tu + 1 adet sistem tuu

alma Voltaj DC +24V (-10% ~ +15%) (Ltfen izoleli g kayna kullannz)

(Not 2)

G Tketimi

(Not 3)

3.36W 2.64W 5.28W

Backup Battery 1 adet 3V lityum pil / pil mr: 5 yl

Buzzer 85dB

Gerek Zaman

Saati (RTC)

Dahili

Soutma Metodu Doal hava soutma

Gvenlik Onay

(Su geirmez n

panel)

IP65 / NEMA4 / CE, UL

alma Scakl 0C ~ 50C

Saklama Scakl -20C ~ +60C

Trke-10

MODEL AS35THTD AS38BSTD AS57B(C)STD

Rutubet Oran

10% ~ 90% RH [0 ~ 40C], 10% ~ 55% RH [41 ~ 50C]

Kirlenme Derecesi 2

Titreim Direnci

IEC 61131-2 Uyumlu

5Hzf9Hz = Srekli: 1.75mm / Geici: 3.5mm

9Hzf150Hz = Srekli: 0.5g / Geici: 1.0g

X, Y, Z ynlerinde 10 defa

ller

(W) x (H) x (D)

mm

140.8 x 104.8 x 44.8 184.1 x 144.1 x 47

Panel Kesim

(W) x (H) mm

118.8 x 92.8 172.4 x 132.4

Arlk Yaklak 310g Yaklak 760g

NOTE

1) Arka k yarm-mr, HMI maksimum akmla beslendiinde orijinal aydnlatmann %50 drld

anlamna gelir. Yukarda gsterilen arka k LED aydnlatma mr 25 derecede normal scaklk ve rutubet

ortamnda tahmin edilen deerlerdir.

2) DOP-A80THTD1, DOP-AE80THTD ve DOP-A(E)10THTD1 modelleri dnda ltfen izoleli g kayna

kullannz.

3) G tketimi HMI nitesinin hi bir cihaza bal olmadan bo olarak tkettii gc gsterir. Normal

almada HMInn boken tkettii gcn 1.5 veya 2 kat g verebilen besleme kayna kullanlmas

tavsiye edilir.

4) Delta HMI Screen editor yazlmn ve user manuali aadaki linkten indirebilirsiniz:

http://www.delta.com.tw/industrialautomation/.

5) Herhangi bir ihbar olmadan bu dkmann ierii deitirilebilir. En son gncellenmi halini firmamzdan

talep edebilir yada aadaki link adresinden indirebilirsiniz

http://www.delta.com.tw/industrialautomation/.

Trke-11

MODEL

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

Display Tipi

8 TFT LCD

(65536 renk)

10.4 TFT LCD

(65536 renk)

znrlk 640 x 480 piksel

Arka Ik

CCFL Arka Ik

(25

o

C yarm mrde 50,000 saatden

az)

(Not 1)

CCFL Arka Ik

(25

o

C yarm mrde 30,000 saatden

az)

(Not 1)

L

C

D

M

O

D

L

Display

l

162.2 x 121.7mm 211.2 x 158.4mm

letim Sistemi Delta Real Time OS

MCU 32-bit RISC Micro-controller

Flash ROM NOR Flash ROM 8 MB (OS Sistem: 2MB / Kullanc Uygulamas: 6MB)

SDRAM 32Mbyte 32Mbyte

Backup Memory

(Byte)

512K

SM Card AE

lave Arabirim AE

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-232 / RS-422 / RS-485

Seri

COM

Port

COM3 RS-232 / RS-422 / RS-485

Fonksiyon Tuu

6 adet Kullanc tanml tu +

1 adet Sistem tuu

7 adet Kullanc tanml tu +

1 adet Sistem tuu

alma Voltaj DC +24V (-10% ~ +15%) (Ltfen izoleli g kayna kullannz)

(Not 2)

G Tketimi

(Not 3)

14W 15W

Backup Battery 1 adet 3V lityum pil CR2032 / pil mr: 5 yl

Buzzer 85dB

Gerek Zaman

Saati (RTC)

Dahili

Soutma Metodu Doal hava soutma

Gvenlik Onay

(Su geirmez n

panel)

IP65 / NEMA4 / CE, UL

alma Scakl 0C ~ 50C

Saklama Scakl -20C ~ +60C

Rutubet Oran

10% ~ 90% RH [0 ~ 40C], 10% ~ 55% RH [41 ~ 50C]

Kirlenme Derecesi 2

Trke-12

MODEL

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

Titreim Direnci

IEC 61131-2 Uyumlu

5Hzf9Hz = Srekli: 1.75mm / Geici: 3.5mm

9Hzf150Hz = Srekli: 0.5g / Geici: 1.0g

X, Y, Z ynlerinde 10 defa

ller

(W) x (H) x (D)

mm

243.1 x 178.1 x 52.4 297.1 x 222.1 x 51.1

Panel Kesim

(W) x (H) mm

231.4 x 166.4 285.2 x 210.2

Arlk Yaklak 1140g Yaklak 1735g

NOTE

1) Arka k yarm-mr, HMI maksimum akmla beslendiinde orijinal aydnlatmann %50 drld

anlamna gelir. Yukarda gsterilen arka k LED aydnlatma mr 25 derecede normal scaklk ve

rutubet ortamnda tahmin edilen deerlerdir.

2) DOP-A80THTD1, DOP-AE80THTD ve DOP-A(E)10THTD1 modelleri dnda ltfen izoleli g kayna

kullannz.

3) G tketimi HMI nitesinin hi bir cihaza ba l olmadan bo olarak tketti i gc gsterir. Normal

al mada HMInn bo ken tketti i gcn 1.5 veya 2 kat g verebilen besleme kayna kullanlmas

tavsiye edilir.

4) Delta HMI Screen editor yazlmn ve user manuali aadaki linkten indirebilirsiniz:

http://www.delta.com.tw/industrialautomation/.

5) Herhangi bir ihbar olmadan bu dkmann ierii deitirilebilir. En son gncellenmi halini firmamzdan

talep edebilir yada aadaki link adresinden indirebilirsiniz

http://www.delta.com.tw/industrialautomation/.

Trke-13

Trke-14

Bu sayfa not almanz iin bo braklmtr.

-1

DOP-AAEAS

NFPA 70:

National Electrical Code, 2005 Ed.

http://www.delta.com.tw/industrialautomation/

class-3100

10

-2

-20C to +60C-4F to 140F

10%90%

()

Type 4X

AAE

-3

0.7N-M

6.17lb-inch0.7N-M

AS

0.7N-M

6.17lb-inch0.7N-M

AWG

28 ~ 12 7 ~ 8 mm 5 kg-cm4.3 lb-in

30 ~ 12 7 ~ 8 mm 5 kg-cm4.3 lb-in

AS

AWG

30 ~ 16 5 ~ 6 mm 2 kg-cm1.7 lb-in

30 ~ 16 5 ~ 6 mm 2 kg-cm1.7 lb-in

-4

DOP-A80THTD1

DOP-AE80THTD

DOP-A(E)10THTD1

DOP-AS35THTD

DOP-AS38BSTD

DOP-AS57BSTD

-5

COM1 AAEAS57BSTD

COM Port

RS-232

1

2 RXD

3 TXD

4

5 GND

6

7 RTS

8 CTS

9

COM2 A

MODE1 MODE2 MODE3

COM Port

RS-232 RS-422 RS-485

1 RXD- D-

2 RXD RXD+ D+

3 TXD TXD+ D+

4 TXD- D-

5 GND

6 RTS-

7 RTS RTS+

8 CTS CTS+

9 CTS-

1

2Mode3 D+Pin2Pin3 D-Pin1Pin4

COM2COM3 AEA80THTD1A10THTD1

MODE1 MODE2 MODE3 MODE4 MODE5 MODE6

COM Port

COM

Port

RS-232 RS-422 RS-485

RS-232*

2

RS-422*

2

RS-485*

2

1 RXD- D- RXD1- D1-

2 RXD RXD+ D+ RXD1 RXD1+ D1+

3 TXD TXD+ D+ TXD1 TXD1+ D1+

COM2

4 TXD- D- TXD1- D1-

5 GND

6 RTS- TXD2- D2-

7 RTS RTS+ TXD2 TXD2+ D2+

8 CTS CTS+ RXD2 RXD2+ D2+

COM3

9 CTS- RXD2- D2-

1

2Mode3 D+Pin2Pin3 D-Pin1Pin4

Mode6 D1+Pin2Pin3 D1-Pin1Pin4 D2+Pin7Pin8

D2-Pin6Pin9

Pin

Pin

Pin

-6

COM1COM3 AS38BSTDAS35THTD

MODE1 MODE2

COM Port COM Port

RS-232 RS-232*2

1

2 RXD RXD1

3 TXD TXD1

COM1

4

5 GND

6

7 RTS TXD2

8 CTS RXD2

COM3

9

COM2 AS38BSTDAS35THTD

MODE1 MODE2

COM Port

RS-422 RS-485

R- RXD- D-

R+ RXD+ D+

T- TXD- D-

T+ TXD+ D+

G GND

1Mode2 D+R+T+D-R-T-

COM2COM3 AS57BSTD

MODE1 MODE2 MODE3

COM Port COM Port

RS-485*2 RS-422*2 RS-422

R- D- RXD- RXD-

R+ D+ RXD+ RXD+

T- TXD- TXD-

COM2

T+ TXD+ TXD+

G GND

R- D- RXD- CTS-

R+ D+ RXD+ CTS+

T- TXD- RTS-

COM3

T+ TXD+ RTS+

1

2RS-422 MODE3 COM2COM3

Pin

COM2

COM3

R-

-7

COM

Port

DOP-AE DOP-A DOP-AS57 DOP-AS35AS38

COM1 RS-232

RS-232

RS-232

RS-232

COM3

COM2

RS-422

RS-422

COM3

RS-422

COM3

N/A

RS-422

COM3

RS-232

COM3

DOP-AS35THTDDOP-AS38BSTD

118.8

+0.04 +1

(4.68 )

140.8

1

0

4

.

8

0 0

(

3

.

6

5

)

T=1.6mm(0.06in) ~

9

2

.

8

0

+

1

3.0mm(0.12in)

NOTE:

0

+

0

.

0

4

T

4-R3

36.7

DOP-AS57BSTD

0.12in(3.0mm)

T=0.06in(1.6mm) ~

(

5

.

2

1

)

+

1

0

+

0

.

0

4

0

(6.79 )

0

+1 +0.04

0

1

4

4

.

1

(

5

.

6

7

)

184.1(7.25)

6.1(0.24) 39.0(1.54)

172.4

1

3

2

.

4

4-R3(0.12)

T

NOTE:

mm

mm

-8

DOP-A80THTD1DOP-AE80THTD

T=1.6mm(0.06in) ~

3.0mm(0.12in)

(1.75)

1

7

8

.

1

(

7

.

0

1

)

243.1(9.57)

0

+1

231.4 0 (9.11 )

+0.04

+

0

.

0

4

(

6

.

5

5

)

0

+

1

1

6

6

.

4

0

NOTE:

4

-

R

3

.

0

(

0

.

1

2

)

44.4

T

6.1(0.24)

DOP-A(E)10THTD1

3.0mm(0.12in)

+0.04

(11.22 )

+1

0 0

T=1.6mm(0.06in) ~

(

8

.

2

7

)

+

1

0

+

0

.

0

4

0

2

1

0

.

2

285.2

4

-

R

3

.

0

(

0

.

1

2

)

NOTE:

T

297.1(11.70)

2

2

2

.

1

(

8

.

7

4

)

43.1(1.70) 6.1(0.24)

mm

mm

-9

AS35THTD AS38BSTD AS57BSTD

3.5 TFT LCD

65536

3.8 STN LCD

8

5.7 STN LCD

8

320 x 240 pixels

LED Back Light

25

o

C >3

(Note 1)

LED Back Light

25

o

C >1

(Note 1)

CCFL Back Light

25

o

C >5

(Note 1)

70.08 x 52.56mm 76.8 x 57.6mm 115.17 x 86.37mm

Delta Real Time OS

32-bit RISC Micro-controller

ROM NOR Flash ROM 2 MB(OS System: 1MB / User Application: 1MB)

8Mbytes 4Mbytes 16Mbytes

Bytes

128K 128K 128K

SM Card N/A

N/A

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-422RS-485

COM3 RS-232 RS-422RS-485

x 4 + x 1

DC +24V-10% ~ +15%

(Note 2)

(Note 3)

3.36W 2.64W 5.28W

3V CR203215

85dB

IP65NEMA4CE, UL

0C ~ 50C

-20C ~ +60C

10% ~ 90% RH0 ~ 40C10% ~ 55% RH41 ~ 50C2

-10

AS35THTD AS38BSTD AS57BSTD

IEC61131-2 5Hz-9Hz 3.5mm9Hz-150Hz 1G

5Hz-9Hz 1.75mm9Hz-150Hz 0.5G

X, Y, Z 10

WxHxD

mm

140.8 x 104.8 x 44.8 184.1 x 144.1 x 47

WxHmm

118.8 x 92.8 172.4 x 132.4

310g 760g

NOTE

1)

25

o

C

2) DOP-A80THTD1, DOP-AE80THTD, DOP-A(E)10THTD1

3) 1.5~2

4) DOP-A/AE/ASHMI Screen Editor 1.05

http://www.delta.com.tw/industrialautomation/

5)

http://www.delta.com.tw/industrialautomation/

-11

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

8 TFT LCD

65536

10.4 TFT LCD

65536

640 x 480 pixels

CCFL Back Light

25

o

C >5

(Note 1)

CCFL Back Light

25

o

C >3

(Note 1)

162.2 x 121.7mm 211.2 x 158.4mm

Delta Real Time OS

32-bit RISC Micro-controller

ROM NOR Flash ROM 8 MB (OS System: 2MB / User Application: 6MB)

32Mbytes

Bytes

512K

SM Card AE

AE

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-232RS-422RS-485

COM3 RS-232RS-422RS-485

x6 +

x1

x7 +

x1

DC +24V-10% ~ +15%

(Note 2)

(Note 3)

14W 15W

3V CR203215

85dB

IP65NEMA4CE, UL

0C ~ 50C

-20C ~ +60C

10% ~ 90% RH0 ~ 40C10% ~ 55% RH41 ~ 50C2

IEC61131-2 5Hz-9Hz 3.5mm9Hz-150Hz 1G

5Hz-9Hz 1.75mm9Hz-150Hz 0.5G

X, Y, Z 10

-12

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

WxHxD

mm

243.1 x 178.1 x 52.4 297.1 x 222.1 x 51.1

WxHmm

231.4 x 166.4 285.2 x 210.2

1140g 1735g

NOTE

1)

25

o

C

2) DOP-A80THTD1, DOP-AE80THTD, DOP-A(E)10THTD1

3) 1.5~2

4) DOP-A/AE/ASHMI Screen Editor 1.05

http://www.delta.com.tw/industrialautomation/

5)

http://www.delta.com.tw/industrialautomation/

@_

DOP-AAEAS

NFPA 70:

National Electrical Code, 2005 Ed.

http://www.delta.com.tw/industrialautomation/

__Q[

class-3100

10

-1

_]Q|

-20C to +60C-4F to 140F

10%90%

_)@[_@

()

Type 4X

AAE

-2

0.7N-M

6.17lb-inch0.7N-M

AS

0.7N-M

6.17lb-inch0.7N-M

Q

AWG

28 ~ 12 7 ~ 8 mm 5 kg-cm4.3 lb-in

30 ~ 12 7 ~ 8 mm 5 kg-cm4.3 lb-in

AS

AWG

30 ~ 16 5 ~ 6 mm 2 kg-cm1.7 lb-in

30 ~ 16 5 ~ 6 mm 2 kg-cm1.7 lb-in

-3

DOP-AS35THTD

DOP-AS38BSTD

DOP-A80THTD1

DOP-AE80THTD DOP-AS57BSTD

DOP-A(E)10THTD1

_

-4

@___

COM1 AAEAS57BSTD

COM Port

RS-232

1

2 RXD

3 TXD

4

5 GND

6

7 RTS

8 CTS

9

Pin

COM2 A

MODE1 MODE2 MODE3

COM Port

RS-232 RS-422 RS-485

1 RXD- D-

2 RXD RXD+ D+

3 TXD TXD+ D+

4 TXD- D-

5 GND

6 RTS-

7 RTS RTS+

8 CTS CTS+

9 CTS-

Pin

1

2Mode3 D+Pin2Pin3 D-Pin1Pin4

COM2COM3 AEA80THTD1A10THTD1

MODE1 MODE2 MODE3 MODE4 MODE5 MODE6

COM Port

COM

Port

RS-232 RS-422 RS-485

RS-232*

2

RS-422*

2

RS-485*

2

1 RXD- D- RXD1- D1-

2 RXD RXD+ D+ RXD1 RXD1+ D1+

3 TXD TXD+ D+ TXD1 TXD1+ D1+

COM2

4 TXD- D- TXD1- D1-

5 GND

6 RTS- TXD2- D2-

7 RTS RTS+ TXD2 TXD2+ D2+

8 CTS CTS+ RXD2 RXD2+ D2+

COM3

9 CTS- RXD2- D2-

Pin

1

2Mode3 D+Pin2Pin3 D-Pin1Pin4

Mode6 D1+Pin2Pin3 D1-Pin1Pin4 D2+Pin7Pin8

D2-Pin6Pin9

-5

COM1COM3 AS38BSTDAS35THTD

MODE1 MODE2

COM Port COM Port

RS-232 RS-232*2

1

2 RXD RXD1

3 TXD TXD1

COM1

4

5 GND

6

7 RTS TXD2

8 CTS RXD2

COM3

9

Pin

COM2 AS38BSTDAS35THTD

MODE1 MODE2

COM Port

RS-422 RS-485

R- RXD- D-

R+ RXD+ D+

T- TXD- D-

T+ TXD+ D+

G GND

R-

1Mode2 D+R+T+D-R-T-

COM2COM3 AS57BSTD

MODE1 MODE2 MODE3

COM Port COM Port

RS-485*2 RS-422*2 RS-422

R- D- RXD- RXD-

R+ D+ RXD+ RXD+

T- TXD- TXD-

COM2

T+ TXD+ TXD+

G GND

R- D- RXD- CTS-

R+ D+ RXD+ CTS+

T- TXD- RTS-

COM3

T+ TXD+ RTS+

COM2

COM3

1

2RS-422 MODE3 COM2COM3

-6

COM

Port

DOP-AE DOP-A DOP-AS57 DOP-AS35AS38

COM1 RS-232

RS-232

RS-232

RS-232

COM3

COM2

RS-422

RS-422

COM3

RS-422

COM3 N/A

RS-422

COM3

RS-232

COM3

]Q

DOP-AS35BSTDDOP-AS38BSTD

118.8

+0.04 +1

(4.68 )

140.8

1

0

4

.

8

0 0

(

3

.

6

5

)

T=1.6mm(0.06in) ~

9

2

.

8

0

+

1

3.0mm(0.12in)

NOTE:

0

+

0

.

0

4

T

4-R3

36.7

)_mm

DOP-AS57BSTD

0.12in(3.0mm)

T=0.06in(1.6mm) ~

(

5

.

2

1

)

+

1

0

+

0

.

0

4

0

(6.79 )

0

+1 +0.04

0

1

4

4

.

1

(

5

.

6

7

)

184.1(7.25)

6.1(0.24) 39.0(1.54)

172.4

1

3

2

.

4

4-R3(0.12)

T

NOTE:

)_mm

-7

DOP-A80THTD1DOP-AE80THTD

T=1.6mm(0.06in) ~

3.0mm(0.12in)

(1.75)

1

7

8

.

1

(

7

.

0

1

)

243.1(9.57)

0

+1

231.4 0 (9.11 )

+0.04

+

0

.

0

4

(

6

.

5

5

)

0

+

1

1

6

6

.

4

0

NOTE:

4

-

R

3

.

0

(

0

.

1

2

)

44.4

T

6.1(0.24)

)_mm

DOP-A(E)10THTD1

3.0mm(0.12in)

+0.04

(11.22 )

+1

0 0

T=1.6mm(0.06in) ~

(

8

.

2

7

)

+

1

0

+

0

.

0

4

0

2

1

0

.

2

285.2

4

-

R

3

.

0

(

0

.

1

2

)

NOTE:

T

297.1(11.70)

2

2

2

.

1

(

8

.

7

4

)

43.1(1.70) 6.1(0.24)

)_mm

-8

Q|Q

AS35THTD AS38BSTD AS57BSTD

3.5 TFT LCD

65536

3.8 STN LCD

8

5.7 STN LCD

8

320 x 240 pixels

LED Back Light

25

o

C >3

(Note 1)

LED Back Light

25

o

C >1

(Note 1)

CCFL Back Light

25

o

C >5

(Note 1)

70.08 x 52.56mm 76.8 x 57.6mm 115.17 x 86.37mm

Delta Real Time OS

32-bit RISC Micro-controller

ROM NOR Flash ROM 2 MB(OS System: 1MB / User Application: 1MB)

8Mbytes 4Mbytes 16Mbytes

Bytes

128K 128K 128K

SM Card N/A

N/A

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-422RS-485

COM3 RS-232 RS-422RS-485

x 4 + x 1

DC +24V-10% ~ +15%

(Note 2)

(Note 3)

3.36W 2.64W 5.28W

3V CR203215

85dB

IP65NEMA4CE, UL

0C ~ 50C

-20C ~ +60C

10% ~ 90% RH0 ~ 40C10% ~ 55% RH41 ~ 50C2

-9

AS35THTD AS38BSTD AS57BSTD

IEC61131-2 5Hz-9Hz 3.5mm9Hz-150Hz 1G

5Hz-9Hz 1.75mm9Hz-150Hz 0.5G

X, Y, Z 10

WxHxD

mm

140.8 x 104.8 x 44.8 184.1 x 144.1 x 47

WxHmm

118.8 x 92.8 172.4 x 132.4

310g 760g

NOTE

1)

25

o

C

2) DOP-A80THTD1, DOP-AE80THTD, DOP-A(E)10THTD1

3) _|_]{[_|_[_j____|1.5~2 ]

j]]_

4) DOP HMI Screen Editor 1.05

http://www.delta.com.tw/industrialautomation/

5)

http://www.delta.com.tw/industrialautomation/

-10

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

8 TFT LCD

65536

10.4 TFT LCD

65536

640 x 480 pixels

CCFL Back Light

25

o

C >5

(Note 1)

CCFL Back Light

25

o

C >3

(Note 1)

162.2 x 121.7mm 211.2 x 158.4mm

Delta Real Time OS

32-bit RISC Micro-controller

ROM NOR Flash ROM 8 MB (OS System: 2MB / User Application: 6MB)

32Mbytes

Bytes

512K

SM Card AE

AE

USB Host 1 USB Host Ver 1.1

USB Client 1 USB Client Ver 1.1

COM1 RS-232

COM2 RS-232RS-422RS-485

COM3 RS-232RS-422RS-485

x6 + x1 x7 + x1

DC +24V-10% ~ +15%

(Note 2)

(Note 3)

14W 15W

3V CR203215

85dB

IP65NEMA4CE, UL

0C ~ 50C

-20C ~ +60C

10% ~ 90% RH0 ~ 40C10% ~ 55% RH41 ~ 50C2

IEC61131-2 5Hz-9Hz 3.5mm9Hz-150Hz 1G

5Hz-9Hz 1.75mm9Hz-150Hz 0.5G

X, Y, Z 10

-11

A80THTD1

AE80THTD

A10THTD1

AE10THTD1

WxHxD

mm

243.1 x 178.1 x 52.4 297.1 x 222.1 x 51.1

WxHmm

231.4 x 166.4 285.2 x 210.2

1140g 1735g

NOTE

1)

25

o

C

2) DOP-A80THTD1, DOP-AE80THTD, DOP-A(E)10THTD1

3) _|_]{[_|_[_j____|1.5~2 ]

j]]_

4) DOP HMI Screen Editor 1.05

http://www.delta.com.tw/industrialautomation/

5)

http://www.delta.com.tw/industrialautomation/

-12

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Presentation 2Dokumen3 halamanPresentation 2Royal Ritesh SharmaBelum ada peringkat

- Uio-2 2022Dokumen5 halamanUio-2 2022Royal Ritesh SharmaBelum ada peringkat

- SitrainDokumen20 halamanSitrainAhmed KhairyBelum ada peringkat

- Screen Working Manual ExcelDokumen1 halamanScreen Working Manual ExcelRoyal Ritesh SharmaBelum ada peringkat

- DcmachineDokumen54 halamanDcmachineRoyal Ritesh SharmaBelum ada peringkat

- Eplans Comprehensive User Guide: Draft Version 1.3 February, 2013Dokumen137 halamanEplans Comprehensive User Guide: Draft Version 1.3 February, 2013Royal Ritesh SharmaBelum ada peringkat

- Vdocument - in Siemens-RelayDokumen12 halamanVdocument - in Siemens-RelayRoyal Ritesh SharmaBelum ada peringkat

- Supervisory Control and Data Acquisition (SCADA) : July 2017Dokumen24 halamanSupervisory Control and Data Acquisition (SCADA) : July 2017Royal Ritesh SharmaBelum ada peringkat

- Vdocument - in 3 Ac and DC MotorsDokumen32 halamanVdocument - in 3 Ac and DC MotorsRoyal Ritesh SharmaBelum ada peringkat

- Chapter 2 Basic GatesDokumen22 halamanChapter 2 Basic GatesRoyal Ritesh SharmaBelum ada peringkat

- Number System:: Following Are The Imp Points To Be Noted Before Start PLC ProgrammingDokumen2 halamanNumber System:: Following Are The Imp Points To Be Noted Before Start PLC ProgrammingRoyal Ritesh SharmaBelum ada peringkat

- Advance Hydraulics TrainingDokumen2 halamanAdvance Hydraulics TrainingRoyal Ritesh SharmaBelum ada peringkat

- SH 080787 EngjDokumen106 halamanSH 080787 EngjRoyal Ritesh SharmaBelum ada peringkat

- SH 080787 EngjDokumen106 halamanSH 080787 EngjRoyal Ritesh SharmaBelum ada peringkat

- S7 300 ProgrammingDokumen13 halamanS7 300 Programmingrkmoore2010100% (1)

- Sheet Design Solid DesignDokumen710 halamanSheet Design Solid DesignRoyal Ritesh SharmaBelum ada peringkat

- FactoryTalk View SE LabDokumen164 halamanFactoryTalk View SE LabRoyal Ritesh SharmaBelum ada peringkat

- Datasheet 80-3355-0 enDokumen6 halamanDatasheet 80-3355-0 enRoyal Ritesh SharmaBelum ada peringkat

- Logix Ap007b en PDokumen56 halamanLogix Ap007b en PRoyal Ritesh SharmaBelum ada peringkat

- Sensors - Encoders1 PDFDokumen2 halamanSensors - Encoders1 PDFRoyal Ritesh SharmaBelum ada peringkat

- PLC TutorialDokumen19 halamanPLC TutorialJilani Hayder100% (1)

- Voltage DividerDokumen1 halamanVoltage DividerRoyal Ritesh SharmaBelum ada peringkat

- AlternatorDokumen4 halamanAlternatorRoyal Ritesh SharmaBelum ada peringkat

- WPLSoft ManualDokumen137 halamanWPLSoft Manualminlwinthein89% (9)

- Nexgenie PLCDokumen5 halamanNexgenie PLCAmit ChaturvediBelum ada peringkat

- Citect With SVDokumen18 halamanCitect With SVuumpBelum ada peringkat

- Delta PLC-Program O en 20130530Dokumen753 halamanDelta PLC-Program O en 20130530Vaibhav PurnaleBelum ada peringkat

- PLC TutorialDokumen19 halamanPLC TutorialJilani Hayder100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Opengl CodeDokumen7 halamanOpengl CodeGouree DeshpandeBelum ada peringkat

- SRS Document - Dhaval PaswalaDokumen8 halamanSRS Document - Dhaval PaswalaQIT HarikaBelum ada peringkat

- L5190 DatasheetDokumen2 halamanL5190 DatasheetpopaadicljBelum ada peringkat

- Alienware Area-51m Setup and Specifications: Regulatory Model: P38E Regulatory Type: P38E001Dokumen20 halamanAlienware Area-51m Setup and Specifications: Regulatory Model: P38E Regulatory Type: P38E001Anonymous ObCDlHBelum ada peringkat

- Period Start Time PLMN Name: RTCH - Attempts RTCH Assignment Fail Rate2Dokumen72 halamanPeriod Start Time PLMN Name: RTCH - Attempts RTCH Assignment Fail Rate2danielBelum ada peringkat

- Chatbot Technology PDFDokumen18 halamanChatbot Technology PDFShaikh Mohd AdnanBelum ada peringkat

- Training Suggestion System (SS)Dokumen38 halamanTraining Suggestion System (SS)Ibnu AlfiansyahBelum ada peringkat

- GIGABYTE - c7b - 8I848E - Rev.1.01Dokumen38 halamanGIGABYTE - c7b - 8I848E - Rev.1.01Leo MeleanBelum ada peringkat

- Betta Sat CatalogueDokumen2 halamanBetta Sat CatalogueCorey AcevedoBelum ada peringkat

- Boardsim UserefDokumen1.985 halamanBoardsim UserefIoana FumorBelum ada peringkat

- The Lecture Contains:: Lecture 15: Memory Consistency Models and Case Studies of Multi-CoreDokumen9 halamanThe Lecture Contains:: Lecture 15: Memory Consistency Models and Case Studies of Multi-CoreProdip KunduBelum ada peringkat

- CS110T Lab02 PDFDokumen6 halamanCS110T Lab02 PDFmBelum ada peringkat

- Install Safebridge Training Client GuideDokumen5 halamanInstall Safebridge Training Client GuidePrashant SinghBelum ada peringkat

- Java PackageDokumen4 halamanJava PackageVASUDEVAN N (RC2113003011006)Belum ada peringkat

- 2 - Access Layer (Phase 1)Dokumen32 halaman2 - Access Layer (Phase 1)MostafaEl-sayedBelum ada peringkat

- Power management in 802.11 wireless LANsDokumen8 halamanPower management in 802.11 wireless LANssiva kumaarBelum ada peringkat

- Review PythonDokumen12 halamanReview PythonRachna TomarBelum ada peringkat

- Assignment 5Dokumen4 halamanAssignment 5Vince DieselBelum ada peringkat

- Yineth Natalia Mañunga Esteban Orbes Rosero Leonardo ZambranoDokumen47 halamanYineth Natalia Mañunga Esteban Orbes Rosero Leonardo Zambranocondorito10100% (3)

- Congestion Control AlgorithmsDokumen19 halamanCongestion Control AlgorithmsAmit GuptaBelum ada peringkat

- 70-743 Upgrading Your Skills To Mcsa Windows Server 2016 v1 by Fiber PDFDokumen366 halaman70-743 Upgrading Your Skills To Mcsa Windows Server 2016 v1 by Fiber PDFAsad MahmoodBelum ada peringkat

- PyxmlDokumen18 halamanPyxmlOkibe Jeffery IfereBelum ada peringkat

- Dan French: Banner HealthDokumen2 halamanDan French: Banner Healthapi-4055236Belum ada peringkat

- Strapless Futalicious For G8F: B - Manual ProcedureDokumen4 halamanStrapless Futalicious For G8F: B - Manual ProcedureAuroraBelum ada peringkat

- JAP305 Lecture 9Dokumen5 halamanJAP305 Lecture 9markjohnBelum ada peringkat

- Update List Product Sultan DecDokumen126 halamanUpdate List Product Sultan DecTIDAK ADILBelum ada peringkat

- Convertir MER 4.0 A EditableDokumen11 halamanConvertir MER 4.0 A EditableHdez AhfBelum ada peringkat

- DWM Unit2Dokumen65 halamanDWM Unit2Hansica MadurkarBelum ada peringkat

- Javascript: Head First ProgrammingDokumen24 halamanJavascript: Head First ProgrammingUlisse_DiniBelum ada peringkat