TPM Visitjun

Diunggah oleh

Balachandar SathananthanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TPM Visitjun

Diunggah oleh

Balachandar SathananthanHak Cipta:

Format Tersedia

VEHICLE ASSEMBLY PRESENTITION BOARD DISPLAY

SR NO 1 2 3 3.1 3.2 3.3 TOPIC SHOP RESULT BOARD - PQCDSME LEVEL WISE TARGES - PQCDSME WIDELY + DEEPLY = KK THOROUGHLY NO ADJUSTMENT THEME NAGARE TESTING BEFORE ASSEMBLY A DRIVE CHAIN B CLUTCH CABLE 3.4 ELIMINATION OF GEAR SHIFTING HARD ISSUE 3.5 ELIMINATION OF ELECRICAL ISSUES IN HI-END BIKES 4 JN UPGRADE DESIGN DOCUMENT 5 JN UPGRADE VEHICLE DISPLAY WITH TAGS 6 JN UPGRADE BOARD DISPLAY 7 KAIZEN THEMES 7.1 AUXILIARY PETROL TANK FOR K3 7.2 OIL COOLER LEAK TEST ELIMINATION 8 Q ISSUES RESOLVED BY NEW WAY APPROACH - HI-END 9 KAIZENS AUTO BARCODE SCANNING ON NUMBER PUNCHING MACHINE 9.1 BY STATIONARY SCANNER - HI END 9.2 VACUUM LEAK TEST OF PETROL TANK PULSAR ONE BARCODE DELETION FOR PULSAR BY NUMBER PRINTING 9.3 ON CARD 10 KARAKURI ENGINE COOLING BY DYNO OPERATED FAN INSTEAD OF 10.1 COOLING BLOWER 10.2 PV CONVEYOR HALL SENSOR AUTO CANCELLATION 10.3 10.4 10.5 10.6 ENGINE SAFETY KARAKURI FAIRING TRANSFER DISCOVER BY SLOPE CONVEYOR CHASSIS DROP LIFT SAFETY KARAKURI AVENGER HANDLE BAR TRANSFER BY SLOPE ON TROLLEY TARGET DATE STATUS 31.05.08 TO BE UPDATED COMPLETED 28.05.08 INPROCESS COMPLETED INPROCESS PENDING PENDING PENDING PENDING INPROCESS INPROCESS INPROCESS INPROCESS INPROCESS TO BE DISCUSS PENDING PENDING INPROCESS

29.05.08 29.05.08

28.05.08 28.05.08 28.05.08 28.05.08 28.05.08

INPROCESS COMPLETED COMPLETED CORRECTION REQUIRED COMPLETED COMPLETED INPROCESS

30.05.08

YAMAGUCHI SAN VISIT POINTS - 12-13 JUNE'08.

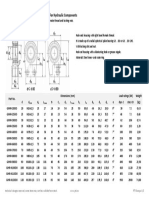

SR NO. KAIZEN IDEA MACHINE CELL PQCDSM

WIDELY + DEEPLY 1 NO ADJUSTMENT THEME CO SETTING K3 HIGH/LOW BEAM SETTING DISCOVER ENGINE FOUNDATION BOLT TAPPER PULSAR HANDLE BAR SETTING MAIN KEY PLASTIC BAG SIZE 2 REDUCTION 3 SEAT PLASTIC BAG DELETION BALL CAGE PLASTIC TRAY 4 REPLACED BY REUSABLE BIN PETROLIEUM JELLY PLASTIC BOTTLE REPLACE BY 5 REUSABLE BARREL 6 TESTING BEFORE ASSLY DRIVE CHAIN ELONGATION CLUTCH CABLE ELONGATION DYNO TESTING ENGINE COOLING BY FAN INSTEAD OF COOLING BLOWER PV CONVEYOR - BLINKER AUTO CANCELLATION KARAKURI CHASSIS / ENGINE SAFETY KARAKURI FAIRING TRANSFER CONVEYOR INSTEAD OF TROLLEY AUXILIARY PETROL TANK FOR K3 VEHICLE DYNO TESTING

PULSAR K3 DSCOVER

P P P

PULSAR P PULSAR / DISCOVER C PULSAR/DIS COVER C PULSAR/DIS COVER C PULSAR/DIS COVER C PULSAR/DIS COVER Q PULSAR/DIS COVER Q

DYNO METER INSPECTION CONVEYOR DROP LIFT

PULSAR

8 9

PULSAR DISCOVER

Q S

10 11

DISCOVER HI END OIL COOLER LEAKAGE TESTING M/C BEARING RACE PRESSING M/C

P C

OIL COOLER LEAKAGE 12 TESTING BEARING RACE PLACING ON 13 MANDREL BY AUTOMATION BALL FILLING ON TOOL BY 14 AUTOMATION NO PRINTING ON PV CARD BY 15 BARCODE SCANNING PETROL TANK LEAK TEST BY 16 VACUUM

HI END HI END HI END PULSAR PULSAR

P P P Q P

CHASSIS NO PUNCHING BY 17 BARCODE SCANNING DESIGN DOCUMENTS - JN 18 UPGREAD HANDLE BAR TROLLEY 19 MODIFICATION - HOME WORK

NO PUNCNING MACHINE

HI END

OINTS - 12-13 JUNE'08.

PILLAR CONCEPT CURRENT STATUS

KK KK KK KK SHE SHE

NO ADJUSTMENT INPROCESS NO ADJUSTMENT COMPLETE NO ADJUSTMENT COMPLETE NO ADJUSTMENT COMPLETE COST REDUCTION INPROCESS COST REDUCTION INPROCESS COST REDUCTION COST REDUCTION

SHE

COMPLETE

SHE

COMPLETE

KK KK

PDI COMPLAINTS ZERO INPROCESS PDI COMPLAINTS ZERO INPROCESS

KK

KARAKURI

PENDING

KK SHE

KARAKURI KARAKURI

INPROCESS COMPLETE

KK KK

KARAKURI HIGH LEVEL KAIZEN

COMPLETE INPROCESS

KK KK KK KK KK

NAGARE NAGARE NAGARE POKAYOKE TIME SAVING

COMPLETE COMPLETE COMPLETE INPROCESS PENDING

KK

POKAYOKE

COMPLETE

SHE

YOTORI

INPROCESS

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Scania Retarder 2Dokumen27 halamanScania Retarder 2neilevcvr85% (20)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 7 Types of AbnormalitiesDokumen23 halaman7 Types of AbnormalitiesBalachandar SathananthanBelum ada peringkat

- Granulation Area: Tablet ManufacturingDokumen5 halamanGranulation Area: Tablet ManufacturingBalachandar SathananthanBelum ada peringkat

- Job Instruction How To InstructDokumen2 halamanJob Instruction How To InstructBalachandar SathananthanBelum ada peringkat

- Standards Requirement Sheet: FunctionDokumen16 halamanStandards Requirement Sheet: FunctionBalachandar SathananthanBelum ada peringkat

- Standards Requirement Sheet: FunctionDokumen16 halamanStandards Requirement Sheet: FunctionBalachandar SathananthanBelum ada peringkat

- FJMJDokumen1 halamanFJMJBalachandar SathananthanBelum ada peringkat

- Bla BlaDokumen24 halamanBla BlamclorenzBelum ada peringkat

- Standards Requirement Sheet: FunctionDokumen16 halamanStandards Requirement Sheet: FunctionBalachandar SathananthanBelum ada peringkat

- Tolerance Analysis: Norbert Jagodzinski Rochester Institute of TechnologyDokumen30 halamanTolerance Analysis: Norbert Jagodzinski Rochester Institute of TechnologyBalachandar SathananthanBelum ada peringkat

- One Day Experience Sharing Session by Deming Prize and Deming Grand Prize Winners in 2012Dokumen4 halamanOne Day Experience Sharing Session by Deming Prize and Deming Grand Prize Winners in 2012Balachandar SathananthanBelum ada peringkat

- And Reliability (Dokumen1 halamanAnd Reliability (Balachandar SathananthanBelum ada peringkat

- EtfwreDokumen2 halamanEtfwreBalachandar SathananthanBelum ada peringkat

- Wdvvwcwqcwe 2 EcwcwcDokumen2 halamanWdvvwcwqcwe 2 EcwcwcBalachandar SathananthanBelum ada peringkat

- JDVHCF ASDRKDokumen1 halamanJDVHCF ASDRKBalachandar SathananthanBelum ada peringkat

- To Reduce Cycle Time Variation in GANG PRESSES 5,6,7,8,16&17Dokumen1 halamanTo Reduce Cycle Time Variation in GANG PRESSES 5,6,7,8,16&17Balachandar SathananthanBelum ada peringkat

- Centre of Excellence in TQM: SRM School of ManagementDokumen2 halamanCentre of Excellence in TQM: SRM School of ManagementBalachandar SathananthanBelum ada peringkat

- Financial Bid For Engine Parts Cluster - GCCE 1 - AurangabadDokumen7 halamanFinancial Bid For Engine Parts Cluster - GCCE 1 - AurangabadBalachandar SathananthanBelum ada peringkat

- 1 BHK Good Condition Flat For Sale at Very Good Locality at Nasik Details. Address Narsinha Nagar, Gangapur Road, Nasik. Interested PL May ContactDokumen1 halaman1 BHK Good Condition Flat For Sale at Very Good Locality at Nasik Details. Address Narsinha Nagar, Gangapur Road, Nasik. Interested PL May ContactBalachandar SathananthanBelum ada peringkat

- Daily Work Management SheetDokumen3 halamanDaily Work Management SheetBalachandar SathananthanBelum ada peringkat

- OneWay Cab - Invoice No. - 13175Dokumen1 halamanOneWay Cab - Invoice No. - 13175Balachandar SathananthanBelum ada peringkat

- EfqwfqxDokumen5 halamanEfqwfqxBalachandar SathananthanBelum ada peringkat

- Description Before After: Key Words To Be Used in Setting Time Projects Smed MethodolgyDokumen1 halamanDescription Before After: Key Words To Be Used in Setting Time Projects Smed MethodolgyBalachandar SathananthanBelum ada peringkat

- SBL Flow EfeqfqqDokumen2 halamanSBL Flow EfeqfqqBalachandar SathananthanBelum ada peringkat

- Kaizen Idea - Sheet: Measurement & Adjustment LossDokumen1 halamanKaizen Idea - Sheet: Measurement & Adjustment LossBalachandar SathananthanBelum ada peringkat

- Dexterity TrainingDokumen6 halamanDexterity TrainingBalachandar SathananthanBelum ada peringkat

- Dex. School Items: Pratice BenchDokumen4 halamanDex. School Items: Pratice BenchBalachandar SathananthanBelum ada peringkat

- ELGI Dexterity Plan: SR - No 1 2 3 4 5 6 7 8 9 10 11 12Dokumen8 halamanELGI Dexterity Plan: SR - No 1 2 3 4 5 6 7 8 9 10 11 12Balachandar SathananthanBelum ada peringkat

- Eticket: Chennai Salem Sunday, July 3, 2016Dokumen1 halamanEticket: Chennai Salem Sunday, July 3, 2016Thalapathy VenkatBelum ada peringkat

- SR - No Phase: Content of Dexterity ImplimentationDokumen2 halamanSR - No Phase: Content of Dexterity ImplimentationBalachandar SathananthanBelum ada peringkat

- Dexterity Instructor Selection Should Be Done On Following Points SR - No 1 2 3 4 5 6 7 8 9 10 11 12 13 14Dokumen5 halamanDexterity Instructor Selection Should Be Done On Following Points SR - No 1 2 3 4 5 6 7 8 9 10 11 12 13 14Balachandar SathananthanBelum ada peringkat

- Moteur 400 500cc Geopolis - SatelisDokumen72 halamanMoteur 400 500cc Geopolis - SatelisGeorge BaltzBelum ada peringkat

- Brayton Cycle With RegenerationDokumen6 halamanBrayton Cycle With RegenerationMeshal Al-mutairi100% (1)

- BT-MR 550Dokumen2 halamanBT-MR 550David VallsBelum ada peringkat

- Catalog Lowara PDFDokumen47 halamanCatalog Lowara PDFMariana VacaruBelum ada peringkat

- S5000V Parts List ManualDokumen6 halamanS5000V Parts List ManualluisBelum ada peringkat

- 303-14 Electronic Engine Controls - Removal and Installation - Camshaft Position CMP SensorDokumen6 halaman303-14 Electronic Engine Controls - Removal and Installation - Camshaft Position CMP SensorCARLOS LIMADABelum ada peringkat

- Fujitsu Inverter Ac Service ManualDokumen18 halamanFujitsu Inverter Ac Service ManualPratibanBelum ada peringkat

- Bearing Isolator: Steam Turbine - Low TempDokumen1 halamanBearing Isolator: Steam Turbine - Low Tempbincoleto5536Belum ada peringkat

- New 610X: Heavy Duty Wheel DriveDokumen2 halamanNew 610X: Heavy Duty Wheel DriveLUISFELIPE2009LBelum ada peringkat

- NEHS0901NEHS0901-01 - Maquina de Bruñido CaterpillarDokumen40 halamanNEHS0901NEHS0901-01 - Maquina de Bruñido CaterpillarCarlosBelum ada peringkat

- Alpha Lubricator System - Operation Manual, 2009 3045-0110-0001Dokumen216 halamanAlpha Lubricator System - Operation Manual, 2009 3045-0110-0001Cristel_DCBelum ada peringkat

- Rei Vol ViiiDokumen2 halamanRei Vol ViiiDineshBelum ada peringkat

- 15.5. Variables That Affect Diesel Engine Performance, Efficiency, and EmissionsDokumen10 halaman15.5. Variables That Affect Diesel Engine Performance, Efficiency, and EmissionsDUVAN FELIPE MUNOZ GARCIABelum ada peringkat

- 337 4pages Maintenance ChartDokumen4 halaman337 4pages Maintenance ChartwangBelum ada peringkat

- Krombach Strainers & GGCDokumen35 halamanKrombach Strainers & GGCMeanRatBelum ada peringkat

- Single Phase Induction Motor - Electrical4uDokumen8 halamanSingle Phase Induction Motor - Electrical4uKalai LakshmanBelum ada peringkat

- Ammco 800OTV Operation ManualDokumen27 halamanAmmco 800OTV Operation Manualrich8837Belum ada peringkat

- HL7607ADokumen6 halamanHL7607AluismdmjBelum ada peringkat

- Compressor Anti-Surge ValveDokumen2 halamanCompressor Anti-Surge ValveMoralba SeijasBelum ada peringkat

- F 90Dokumen35 halamanF 90ulises100% (1)

- LEHM20671-00 - C4.4 Electronic Data SheetDokumen3 halamanLEHM20671-00 - C4.4 Electronic Data Sheetkman548Belum ada peringkat

- Pumps and Pumping SystemsDokumen40 halamanPumps and Pumping SystemsMohamed Elshahat Badr100% (1)

- Spark Controlled Compression IgnitionDokumen18 halamanSpark Controlled Compression IgnitionLEONARDO DAVINCIBelum ada peringkat

- Precision Products and Solutions: Smoother. Faster. LongerDokumen60 halamanPrecision Products and Solutions: Smoother. Faster. LongerVladimir Illich Pinzon BallenBelum ada peringkat

- EG6500CL ManualDokumen84 halamanEG6500CL ManualJose Antonio CarmonaBelum ada peringkat

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDokumen1 halamanGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinBelum ada peringkat

- Induction Motor - WikipediaDokumen16 halamanInduction Motor - WikipediaagrajitBelum ada peringkat

- OSHA Training Toolbox Talk - Lockout-Tagout Energy Isolation DevicesDokumen2 halamanOSHA Training Toolbox Talk - Lockout-Tagout Energy Isolation DevicesZeeshan BajwaBelum ada peringkat

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dokumen4 halaman2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliBelum ada peringkat