Teaching Note 2 - PLGA

Diunggah oleh

ArdiellaputriHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Teaching Note 2 - PLGA

Diunggah oleh

ArdiellaputriHak Cipta:

Format Tersedia

Controlled Drug Release

REVIEW ARTICLES

POLY LACTIC-CO-GLYCOLIC ACID (PLGA) AS BIODEGRADABLE CONTROLLED DRUG DELIVERY CARRIER

ANISSA Permatadietha Ardiellaputri, 1006661203 Chemical Engineering Department, Universitas Indonesia

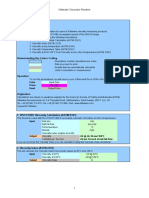

Biodegradable materials are natural or synthetic in origin and are degraded in vivo, either enzymatically or nonenzymatically or both, to produce biocompatible, toxicologically safe by-products which are further eliminated by the normal metabolic pathways. The number of such materials that are used in or as adjuncts in controlled drug delivery has increased dramatically over the past decade. The basic category of biomaterials used in drug delivery can be broadly classified as (1) synthetic biodegradable polymers, which includes relatively The number of such materials that are used in or as adjuncts in controlled drug delivery has increased dramatically over the past decade. The basic category of biomaterials used in drug delivery can be broadly classified as (1) synthetic biodegradable polymers, which includes relatively. PLGA is hydrolytically unstable, they degrade by hydrolytic attack of their ester bonds (Griffith, 2000) resulting in the formation of lactic and glycolic acids. An important attribute of these polymers is the possibility to modulate the degradation rate of a delivery system by changing, e. g. chemical composition (homo-or copolymers of lactic and glycolic acid) or the physical properties (molecular weight, glass-transition temperature) and consequently to control the drug release (Wu and Ding, 2004). PHYSIOCHEMICAL PROPERTIES OF PLGA Poly(lactic acid) (PLA) is a linear aliphatic thermoplastic polyester, produced by polymerization of lactide a cyclic dimer derived from lactic acid. It is a chiral molecule and can be produced as poly (L-lactide). PLA is soluble in common organic solvent. Poly(glycolic acid) (PGA) is the simple linear, aliphatic polyester. Since PGA is highly crystalline, it has a high melting point and low solubility in organic solvents. PGAs high crystallinity is because of its chemical structure lacking the methyl side groups of the PLA (Nieddu et al., 2009). PLGA is a copolymer of lactide and glycolide, which is synthesized by means of random ring-opening copolymerization of two different monomers, the cyclic dimers (1, 4-dioxane-2, 5-diones) of glycolic acid and lactic acid (Figure 1). When PGA randomly copolymerized (30-50 %) with PLA, successive monomeric units (of glycolic or lactic acid) are linked together in PLGA by ester linkages, thus yielding a linear, amorphous aliphatic polyester product . It also make PLGA retains physical properties more readily amenable to processing (those of low-melting thermoplastic with good solubility in common solvents). The degradation rate of PLGA is much faster than that of PLA due to the component glycolic acid in the backbone (Baldwin et al., 1998).

Figure 1 Structure of poly lactic-co-glycolic acid (x is the number of lactic acid units and y is number of glycolic acid units) (Source. Gadad A.P et al., 2012)

Physical properties such as the molecular weight affect the mechanical strength of the polymer and its ability to be formulated as a drug delivery device. Also, these properties may control the polymer biodegradation rate and hydrolysis. The mechanical strength, swelling behavior, capacity to undergo hydrolysis and subsequently, the biodegradation rate are directly influenced by the crystallinity of the PLGA polymer. The resultant crystallinity of the PLGA copolymer is dependent on the type and the molar ratio of the individual monomer components (lactide and glycolide) in the copolymer chain. PLGA polymers containing a 50:50 ratio of lactic and glycolic acids are hydrolyzed much faster than those containing a higher proportion of either of the two monomers. It has a glass transition temperature (Tg) of 45C and an inherent viscosity of 0.5-0.8 mPa. The Tgs of the PLGA co-polymers are above the physiological temperature of 37C and hence they are normally glassy in nature.

1 Universitas Indonesia

Controlled Drug Release

Thus, they have a fairly rigid chain structure, which gives them significant mechanical strength to be formulated as a degradable device. It has been reported that the Tgs of PLGA decrease with the decrease of lactide content in the co-polymer composition with decreasing M.W (Gilding and Reed, 1979). BIOLOGICAL PROPERTIES AND BIODEGRADATION OF PLGA The PLGA co-polymer undergoes degradation in an aqueous environment (hydrolytic degradation or biodegradation) through cleavage of its backbone ester linkages. It has been recorded that the PLGA biodegradation occurs through random hydrolytic chain scissions of the swollen polymer. A three-phase mechanism for PLGA biodegradation has been proposed: 1. Random chain scission process. The M.W. of the polymer decreases significantly, but no appreciable weight loss and no soluble monomer products are formed. 2. In the middle phase, a decrease in M.W. accompanied by a rapid loss of mass and soluble oligomeric and monomer products are formed. 3. Soluble monomer products formed from soluble oligomeric fragments. This phase is that of complete polymer solubilization. PLGA NPs are biodegradable in the body because they undergo hydrolysis of their ester linkages in the presence of water to produce the original monomers, lactic acid and glycolic acid, which are also byproducts of various metabolic pathways in the body under normal physiological conditions (Figure 2).

Figure 2 PLGA undergoes hydrolysis in the body to produce lactic acid and glycolic acid (Source. Kerimoglu and Alarcin., 2012)

Lactic acid, a normal byproduct of anaerobic metabolism in the human body, which is incorporated into the tricarboxylic acid (TCA) cycle and is metabolized and subsequently eliminated from the body as carbon dioxide and water. Glycolic acid is either excreted unchanged in the kidney or it enters the tri-carboxylic acid cycle and eventually eliminated as carbon dioxide and water. The degradation time of PLGA can be controlled from weeks to over a year by varying both the ratio of monomers and the processing condition. The polymer containing a 50:50 ratio of lactic and glycolic acids is hydrolyzed much faster than those containing higher proportions of either of the two monomer (Atala and Robert, 2002). Hydrolytic degradation of members of the polylactide/ glycolide family proceeds through four stages(Figure 3). First stage of water diffusion followed by second stage, in which oligomers with acidic end-groups autocatalyze the hydrolysis reaction. A critical molecular weight is reached at the beginning of third stage, and oligomers start to diffuse out from the polymer. Water molecules diffuse into the void created by the removal of the oligomers, which in turn encourages oligomers diffusion. Marked decrease in polymer mass and a sharp increase in the drug release rate occur during third stage as the drug diffuses from the porous regions. In fourth stage, polymeric matrix become highly porous and degradation proceeds homogeneously and more slowly.

Figure 3 Schematic representation of hydrolytic degradation of polymer (Source. Engineer C. et al., 2011)

2 Universitas Indonesia

Controlled Drug Release

The role of enzymes in biodegradation of PLGA is still unclear, early literature concluding that spontaneous hydrolysis was the only mechanism. Further work indicates the conclusion that the PLGA biodegradation does not involve any enzymatic activity and is purely through hydrolysis. However, enzymes could potentially play a role in degradation for polymers in the rubbery state and enzymatic role in PLGA breakdown based upon the difference in the in vitro and in vivo degradation rates. FACTORS AFFECTING BIODEGRADATION OF PLGA Effect of composition (Shieve and Anderson, 1997; Lu L., et al., 2000); Alexis F, 2005) Polymer composition is the most important factor to determine the rate of degradation of a delivery matrix, which influence the rate of degradation. A systematic study of polymer composition with its degradation has been shown by many groups. These results show that increase in glycolic acid percentage in the oligomers accelerates the weight loss of polymer. PLGA 50:50 (PLA/PGA) exhibited a faster degradation than PLGA 65:35 due to preferential degradation of glycolic acid proportion assigned by higher hydrophilicity. Subsequently PLGA 65:35 shows faster degradation than PLGA 75:25 and PLGA 75:25 than PLGA 85:15. Thus, absolute value of the degradation rate increases with the glycolic acid proportion. Effect of Crystallinity (Tsuji H et al., 2000) The crystallinity of the homopolymer or copolymer comprising the microcapsule may play a significant role in modulating the degradation rate. For semicrystalline polyesters, degradation first occurs in the amorphous domains and later in the crystalline regions. During the degradation process, the crystallinity gradually increases resulting in a high crystalline material which is much more resistant to hydrolysis than the starting polymer. Effect of average molecular weight (Tsuji H et al., 2000) Molecular weight and molecular weight distribution may play a role in the degradation behaviour. A large molecular weight distribution would indicate relatively large numbers of carboxylic end groups which can facilitate the autocatalytic degradation of the polymer chains. Large or wide molecular weight distributions thus would be expected to accelerate the rate of degradation whereas a narrow molecular weight distribution would have fewer carboxylic end groups available for catalysis. Tsuji H and coworkers carried out a study in which two molecular weights of the copolymer were used: 10000 and 20000. It was demonstrated that the 10 000 molecular weight polymer degraded approximately twice as fast as the 20 000 molecular weight polymer. Effect of drug type and effect of drug load (Eniola and Hammer, 2005) Amount of drug loading in the drug delivery matrix plays a significant role on the rate and duration of drug release. Matrices having higher drug content possess a larger initial burst release than those having lower content because of their smaller polymer to drug ratio. However, this drug content effect is attenuated when the drug content reaches a certain level depending upon drug type. Effect of size and shape of the matrix (Eniola and Hammer, 2005) The ratio of surface area to volume has shown to be a significant factor for degradation of large devices. Higher surface area ratio leads to higher degradation of the matrix. It has also been reported that bulk degradation is faster than pure surface degradation for PLGA, which makes the release of the drug faster from the devices with higher surface area to volume. Effect of pH (Eniola and Hammer, 2005) The in vitro biodegradation/hydrolysis of PLGA showed that both alkaline and strongly acidic media accelerate polymer degradation. However, the difference between the slightly acidic and neutral media is less pronounced due to autocatalysis by the carboxylic end groups. CONCLUSION PLGA polymers have been shown to be excellent delivery carriers for controlled administration of drugs, peptides and proteins due to their biocompatibility and biodegradability. In general, the PLGA degradation and the drug release rate can be accelerated by greater hydrophilicity, increase in chemical interactions among the

3 Universitas Indonesia

Controlled Drug Release

hydrolytic groups, less crystallinity and larger volume to surface ratio of the device. All of these factors should be taken into consideration in order to tune the degradation and drug release mechanism for desired application.

REFERENCE Alexis F. (2005). Factors affecting the degradation and drug release mechanism of poly (lactic acid) and poly [(lactic acid)-co-(glycolic acid)], Polymer International., 54(1), 3646. Astete C. E., Sabliov C. M. (2006). Synthesis and characterization of PLGA Nanoparticles, Biomaterials Sci., 17(3), 247289. Atala A, Robert PL (eds). Methods of Tissue Engineering, Academic Press, USA (2002). Baldwin SP, Saltzman WM. (1993). Materials for protein delivery in tissue engineering, Adv Drug Deliv Rev;33(1-2):71-86. Engineer, C., J. Parikh, & A. Raval. (2011). Review on hydrolitic degradation behavior of biodegradable polymers from controlled drug delivery system. Trends Biomater. Artif. Organs, 25 (2), 79-85. Eniola, A. O., Hammer D. A. (2005). Characterization of biodegradable drug delivery vehicles with the adhesive properties of leukocytes II: Effect of degradation on targeting activity, Biomaterials, 26, 661 670. Gilding D. K., Reed A. M. (1979). Biodegradable polymers for use in surgery- polyglycolic/ poly (lactic acid) homo- and copolymers, Polymer, 20(12), 1459-64. Griffith L G. (2000). Polymeric biomaterials[J]. Acta Mater, 48: 263277. Kerimoglu, Oya and Emine Alarcin. (2012). Poly(Lactic-Co-Glycolic Acid) Based Drug Delivery Devices For Tissue Engineering and Regenerative Medicine. ANKEM Derg; 26(2): 86-98. Lu L., Peter S. J., Lyman M. D., Lai H., Leite S. M., Tamada J. A., Uyama, S., Vacanti J. P., Langer R., Mikos A. G. (2000). In vitro and in vivo degradation of porous poly(-lactic-co-glycolic acid) foams, Biomaterials,21(18), 18371845. Nieddu E, Mazzucco L, Gentile P et al. (2009). Preparation and biodegradation of clay composites of PLA, Reactive Functional Polymers. Biomaterals;69(6):371-9. Shive M. S., Anderson J. M. (1997). Biodegradation and biocompatibility of PLA and PLGA microspheres, Adv Drug Deliv Rev., 28(1), 524. Tsuji H., Mizuno A., Ikada Y. (2000). Properties and morphology of poly(L-lactide). III. Effects of initial crystallinity on longterm in vitro hydrolysis of high molecular weight poly(L-lactide) film in phosphate-buffered solution, J Applied Polym Sci., 77(7), 14521464. Wu L B, Ding J D. (2004). In vitro degradation of three-dimensional porous poly (D,L-lactide -co-glycolide) scaffolds for tissue engineering [J]. Biomaterials, 25: 58215830.

4 Universitas Indonesia

Anda mungkin juga menyukai

- Biodegradable Polymers: 2.1.1. Physico-Chemical PropertiesDokumen19 halamanBiodegradable Polymers: 2.1.1. Physico-Chemical PropertiesJuliaNofadiniBelum ada peringkat

- Poly Lactic-co-Glycolic Acid (PLGA) As Biodegradable Controlled Drug Delivery CarrierDokumen20 halamanPoly Lactic-co-Glycolic Acid (PLGA) As Biodegradable Controlled Drug Delivery CarrierJuliaNofadiniBelum ada peringkat

- Figure 1. Structure of PLGADokumen5 halamanFigure 1. Structure of PLGAJessie ChuBelum ada peringkat

- Biodegradable Polymers, Medical ApplicationsDokumen23 halamanBiodegradable Polymers, Medical ApplicationsCaroline LidyaBelum ada peringkat

- Degradation of PolyDL-lactide-co-glycolide 5050 Im PDFDokumen12 halamanDegradation of PolyDL-lactide-co-glycolide 5050 Im PDFVishwarup GoswamiBelum ada peringkat

- Synthesis of Poly (L-Lactide) and Polyglycolide by PDFDokumen5 halamanSynthesis of Poly (L-Lactide) and Polyglycolide by PDFChau MaiBelum ada peringkat

- Ten Teb 2012 0443Dokumen11 halamanTen Teb 2012 0443Raha AmireskandariBelum ada peringkat

- Development of Drug-Loaded PLGA Microparticles WitDokumen7 halamanDevelopment of Drug-Loaded PLGA Microparticles Witบุญเบญ วงษ์ภัทรโรจน์Belum ada peringkat

- Ijbt 4 (2) 186-193 PDFDokumen0 halamanIjbt 4 (2) 186-193 PDFdian_2108Belum ada peringkat

- Biodegradation of PolymersDokumen8 halamanBiodegradation of PolymersVIJAYAKUMAR K ABelum ada peringkat

- Ijbt 4 (2) 186-193Dokumen8 halamanIjbt 4 (2) 186-193sunilchhindraBelum ada peringkat

- Research ArticleDokumen9 halamanResearch ArticleRegiane Godoy de LimaBelum ada peringkat

- Materials: Multi-Functional Laccase Immobilized Hydrogel Microparticles For Efficient Removal of Bisphenol ADokumen14 halamanMaterials: Multi-Functional Laccase Immobilized Hydrogel Microparticles For Efficient Removal of Bisphenol AcarolasbdBelum ada peringkat

- PolyLacticAcid PDFDokumen38 halamanPolyLacticAcid PDFCamilo G100% (2)

- Biodegradable Polymers Explained: Properties and DegradationDokumen39 halamanBiodegradable Polymers Explained: Properties and DegradationPurnahuti PandaBelum ada peringkat

- Kinetics of Formic Acid-Catalyzed Cellulose HydrolDokumen15 halamanKinetics of Formic Acid-Catalyzed Cellulose Hydrolclaudia estupiñanBelum ada peringkat

- Bae 2000Dokumen11 halamanBae 2000Ahmed Abd El-FattahBelum ada peringkat

- 三个问题Dokumen3 halaman三个问题刘哲宁Belum ada peringkat

- In Vitro and in Vivo Anti-Tumor Activities of Nanoparticles Based On doxorubicin-PLGA ConjugatesDokumen13 halamanIn Vitro and in Vivo Anti-Tumor Activities of Nanoparticles Based On doxorubicin-PLGA ConjugatesanoopanandmalikBelum ada peringkat

- Tan 2009Dokumen10 halamanTan 2009Daniel David Pino CherifBelum ada peringkat

- Functionalized PEG for Biologically Relevant ConjugatesDokumen16 halamanFunctionalized PEG for Biologically Relevant ConjugatesFranciscoBelum ada peringkat

- A Litterature Review of PLADokumen22 halamanA Litterature Review of PLAJames WangBelum ada peringkat

- Polylactic Acid (PLA) Research, Development and IndustrializationDokumen12 halamanPolylactic Acid (PLA) Research, Development and IndustrializationΘεανώ ΚαρώνηBelum ada peringkat

- What Are HydrogelsDokumen4 halamanWhat Are HydrogelsHossein NajafzadehBelum ada peringkat

- Blend Starch PLADokumen11 halamanBlend Starch PLAalcy reneBelum ada peringkat

- Use of Supercritical Fluids For Enhancement of Polymerization Process Office 2007 FileDokumen7 halamanUse of Supercritical Fluids For Enhancement of Polymerization Process Office 2007 FilechinmayBelum ada peringkat

- Copyright © 2008 American Scienti C Publishers All Rights Reserved PrintedDokumen10 halamanCopyright © 2008 American Scienti C Publishers All Rights Reserved PrintedDeepakBelum ada peringkat

- Polysaccharide Protein Interactions: C.G. de Kruif, R. TuinierDokumen9 halamanPolysaccharide Protein Interactions: C.G. de Kruif, R. TuinierFelipe Gomes da SilvaBelum ada peringkat

- Improvement of Properties of Poly (-Lactic Acid) Through Solution Blending of Biodegradable PolymersDokumen12 halamanImprovement of Properties of Poly (-Lactic Acid) Through Solution Blending of Biodegradable PolymersMathilda PasaribuBelum ada peringkat

- Sifat Polimer Dan Kemampuan Terbiodegradasi (L-Asam Laktat) (Plla)Dokumen8 halamanSifat Polimer Dan Kemampuan Terbiodegradasi (L-Asam Laktat) (Plla)zuhrotun urfiyahBelum ada peringkat

- J Ijpharm 2007 04 034Dokumen6 halamanJ Ijpharm 2007 04 034thanaBelum ada peringkat

- Impact of Phase Separation of Soy Protein Isolate Sodium Alginate PDFDokumen11 halamanImpact of Phase Separation of Soy Protein Isolate Sodium Alginate PDFJoel PeñaBelum ada peringkat

- Macro Chemistry Physics - 2011 - Quero - Isothermal Cold Crystallization of PLA PBAT Blends With and Without The AdditionDokumen13 halamanMacro Chemistry Physics - 2011 - Quero - Isothermal Cold Crystallization of PLA PBAT Blends With and Without The AdditionGayathri ViswanathanBelum ada peringkat

- Free Radical Biology & MedicineDokumen8 halamanFree Radical Biology & MedicineAlex Conceição BritoBelum ada peringkat

- A comparative study on Poly (ε-caprolactone) film degradation atDokumen8 halamanA comparative study on Poly (ε-caprolactone) film degradation atHugo David Enriquez EspinosaBelum ada peringkat

- PLGA-Based Drug Delivery Systems Produced: PLA With Supercritical CO - A Green Future For Particle Formulation?Dokumen33 halamanPLGA-Based Drug Delivery Systems Produced: PLA With Supercritical CO - A Green Future For Particle Formulation?sriBelum ada peringkat

- Process Biochemistry: Attaf Djoullah, Yanis Djemaoune, Florence Husson, Rémi SaurelDokumen9 halamanProcess Biochemistry: Attaf Djoullah, Yanis Djemaoune, Florence Husson, Rémi SaurelDjoullah AttafBelum ada peringkat

- Synthesis of Polylactic AcidDokumen26 halamanSynthesis of Polylactic AcidErika DanielaBelum ada peringkat

- Synthesis of Alkyl Polyglycoside Surfactants From Tert-Butyl Glycosides and Fatty AcidsDokumen6 halamanSynthesis of Alkyl Polyglycoside Surfactants From Tert-Butyl Glycosides and Fatty AcidsSimón RamírezBelum ada peringkat

- Effect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCDokumen9 halamanEffect of Microstructure On Hydrolytic Degradation Studies of PLLA 2009 HPLCTOUFIKBelum ada peringkat

- Properties of Chemically Modified Gelatin Films: Brazilian Journal of Chemical EngineeringDokumen9 halamanProperties of Chemically Modified Gelatin Films: Brazilian Journal of Chemical EngineeringMuhammad Rizky AKBelum ada peringkat

- Chaochanchaikul Et Al-2021-Journal of Polymers and The EnvironmentDokumen11 halamanChaochanchaikul Et Al-2021-Journal of Polymers and The EnvironmentPornlada PongmuksuwanBelum ada peringkat

- Silica-Polyethylene Glycol Matrix Synthesis by Sol-Gel Method and Evaluation For Diclofenac Diethyloammonium ReleaseDokumen11 halamanSilica-Polyethylene Glycol Matrix Synthesis by Sol-Gel Method and Evaluation For Diclofenac Diethyloammonium ReleaseNelson SouzaBelum ada peringkat

- Tributyl Citrate Oligomers As Plasticizers For PLA 2003Dokumen10 halamanTributyl Citrate Oligomers As Plasticizers For PLA 2003TOUFIKBelum ada peringkat

- Biodegradable Polymers FinalDokumen38 halamanBiodegradable Polymers Finalanupnakat100% (1)

- Effects of PH Alterations On Stress - and Aging-IndDokumen24 halamanEffects of PH Alterations On Stress - and Aging-IndLESLIE EVELIN LOMA JIMENEZBelum ada peringkat

- Cellulose Degradation ThesisDokumen8 halamanCellulose Degradation Thesissheritorizsaltlakecity100% (2)

- 10 37662-jpt 2022 1012432-2037197Dokumen23 halaman10 37662-jpt 2022 1012432-2037197fanta tasfayeBelum ada peringkat

- Impact of Surfactant Structure on Foaming and Defoaming of Nonionic Block CopolymersDokumen12 halamanImpact of Surfactant Structure on Foaming and Defoaming of Nonionic Block CopolymersAndika KristianBelum ada peringkat

- Mechanical Color and Barrier Properties of Biodegradable Nanocomposites Polylactic Acidnanoclay 2155 6199 1000455Dokumen5 halamanMechanical Color and Barrier Properties of Biodegradable Nanocomposites Polylactic Acidnanoclay 2155 6199 1000455yurinnelBelum ada peringkat

- Endothelial Cell Functions in Vitro Cultured On Poly (-Lactic Acid) Membranes Modified With Different MethodsDokumen8 halamanEndothelial Cell Functions in Vitro Cultured On Poly (-Lactic Acid) Membranes Modified With Different MethodsFahreza RachmatBelum ada peringkat

- 07 Lecture SP21 (Bio Polymer) CHM 748Dokumen14 halaman07 Lecture SP21 (Bio Polymer) CHM 748sobia tabassumBelum ada peringkat

- Polylactic Acid Polyols in Urethane Coatings - 2019-11-01 - PCI MagazineDokumen17 halamanPolylactic Acid Polyols in Urethane Coatings - 2019-11-01 - PCI MagazineTomGaliciaBelum ada peringkat

- Characterization and Ageing Study of PLA Films Plasticized with Oligomeric Lactic AcidDokumen8 halamanCharacterization and Ageing Study of PLA Films Plasticized with Oligomeric Lactic AcidTOUFIKBelum ada peringkat

- Glycated AlbuminDokumen9 halamanGlycated AlbuminfarzanaBelum ada peringkat

- Glycoconjugate Research: Proceedings of the Interior Symposium on GlycoconjugatesDari EverandGlycoconjugate Research: Proceedings of the Interior Symposium on GlycoconjugatesBelum ada peringkat

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeDari EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeBelum ada peringkat

- Photosynthesis: A New Approach to the Molecular, Cellular, and Organismal LevelsDari EverandPhotosynthesis: A New Approach to the Molecular, Cellular, and Organismal LevelsSuleyman I. AllakhverdievBelum ada peringkat

- The Role of Catalysis for the Sustainable Production of Bio-fuels and Bio-chemicalsDari EverandThe Role of Catalysis for the Sustainable Production of Bio-fuels and Bio-chemicalsKostas TriantafyllidisBelum ada peringkat

- Teaching Note 3 - Emulsification and Solvent EvaporationDokumen4 halamanTeaching Note 3 - Emulsification and Solvent EvaporationArdiellaputriBelum ada peringkat

- Teaching Note 2 - PLGADokumen4 halamanTeaching Note 2 - PLGAArdiellaputriBelum ada peringkat

- Teaching Note - GITractDokumen7 halamanTeaching Note - GITractArdiellaputriBelum ada peringkat

- Teaching Note - GITractDokumen13 halamanTeaching Note - GITractArdiellaputriBelum ada peringkat

- InTech-The Effects of Hydrogenation On Soybean OilDokumen22 halamanInTech-The Effects of Hydrogenation On Soybean OilArdiellaputriBelum ada peringkat

- Teaching Note 3 - Emulsification and Solvent EvaporationDokumen4 halamanTeaching Note 3 - Emulsification and Solvent EvaporationArdiellaputriBelum ada peringkat

- Teaching Note 2 - PLGADokumen4 halamanTeaching Note 2 - PLGAArdiellaputriBelum ada peringkat

- Directed EvolutionDokumen29 halamanDirected EvolutionArdiellaputriBelum ada peringkat

- A Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyDokumen5 halamanA Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyArdiellaputriBelum ada peringkat

- Directed EvolutionDokumen29 halamanDirected EvolutionArdiellaputriBelum ada peringkat

- JE Survey Chain Tape CorrectionsDokumen3 halamanJE Survey Chain Tape CorrectionsAbhinay Kumar0% (1)

- 1-5 Practice - ADokumen2 halaman1-5 Practice - AStanleyBelum ada peringkat

- Monte Carlo Algorithms for Pi and Sphere VolumeDokumen6 halamanMonte Carlo Algorithms for Pi and Sphere VolumePradeep KumarBelum ada peringkat

- R.P. Feynman - A Relativistic Cut-Off For Classical ElectrodynamicsDokumen8 halamanR.P. Feynman - A Relativistic Cut-Off For Classical ElectrodynamicsnellopostiBelum ada peringkat

- Gregersen 2008 ICTAM ICE7Dokumen2 halamanGregersen 2008 ICTAM ICE7michelle_lilBelum ada peringkat

- A I Che 20151122Dokumen9 halamanA I Che 20151122Adriana Cordero GarcíaBelum ada peringkat

- Engg Mathematics and Sciences Formulas SeriesDokumen443 halamanEngg Mathematics and Sciences Formulas SeriesFrancis Jem Reyes100% (1)

- Understanding The Colour Coding: Kittiwake Viscotube ReadmeDokumen15 halamanUnderstanding The Colour Coding: Kittiwake Viscotube ReadmemusaveerBelum ada peringkat

- Bioenergetics of Aquatic AnimalsDokumen182 halamanBioenergetics of Aquatic AnimalsDaniel FernándezBelum ada peringkat

- LightDokumen84 halamanLightsenjicsBelum ada peringkat

- Bouwer Rice Slug Test Hydraulic Conductivity WRR1976Dokumen6 halamanBouwer Rice Slug Test Hydraulic Conductivity WRR1976Simson MuliaBelum ada peringkat

- Fadum Chart SampleDokumen3 halamanFadum Chart SampleSa'ad Abd Ar RafieBelum ada peringkat

- Evaluating a Vertical Fire Sprinkler SystemDokumen17 halamanEvaluating a Vertical Fire Sprinkler SystemMarc Danielle G Josue IIBelum ada peringkat

- Note 1442244739 PDFDokumen19 halamanNote 1442244739 PDFSiva GaneshBelum ada peringkat

- Uch610 PDFDokumen2 halamanUch610 PDFKidus BelayBelum ada peringkat

- 13 - Representations of The Angular Momentum Operators and Rotations PDFDokumen17 halaman13 - Representations of The Angular Momentum Operators and Rotations PDFUltrazordBelum ada peringkat

- Untitled0 - 1132Dokumen1 halamanUntitled0 - 1132Mark Evan SalutinBelum ada peringkat

- Measuring Temperature with ThermometersDokumen57 halamanMeasuring Temperature with ThermometersCyril Lyn Natividad Credo91% (11)

- Welcome Back To Physics 211: - Oscillations - Simple Harmonic Motion - ResonanceDokumen25 halamanWelcome Back To Physics 211: - Oscillations - Simple Harmonic Motion - ResonanceAjay Francis SurinBelum ada peringkat

- Moore-Penrose Pseudo Inverse ExplainedDokumen3 halamanMoore-Penrose Pseudo Inverse ExplainedcmtinvBelum ada peringkat

- Lesson Plan Science Level 7Dokumen58 halamanLesson Plan Science Level 7aries triwidajati100% (4)

- UFM interpretation synopsisDokumen1 halamanUFM interpretation synopsistazjuan1100% (1)

- Meredith Et Al. (1996) Measurement of The Microhardness and Young's Modulus of Human Enamel and Dentine Using An Indentation TechniqueDokumen7 halamanMeredith Et Al. (1996) Measurement of The Microhardness and Young's Modulus of Human Enamel and Dentine Using An Indentation TechniqueMaja Maja BułkaBelum ada peringkat

- Are Red Flowers Really Red?Dokumen4 halamanAre Red Flowers Really Red?Mikaella CapiralBelum ada peringkat

- Detection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation TechniqueDokumen7 halamanDetection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation Techniquekamal gandhiBelum ada peringkat

- Torque SteerDokumen7 halamanTorque SteerAyushBelum ada peringkat

- Eastman 50D 5245Dokumen6 halamanEastman 50D 5245Felipe Gaglianone OlabarrietaBelum ada peringkat

- Solving Partial Differential Equations with Boundary ConditionsDokumen3 halamanSolving Partial Differential Equations with Boundary ConditionsabefardyyahoocomBelum ada peringkat

- Fracture Model Generation - 2010 PDFDokumen23 halamanFracture Model Generation - 2010 PDFslhippoBelum ada peringkat

- Lowell W. Beineke & Robin J. Wilson & Peter J. Cameron - Topics in Algebraic Graph TheoryDokumen293 halamanLowell W. Beineke & Robin J. Wilson & Peter J. Cameron - Topics in Algebraic Graph TheoryÖzkan Yılmaz100% (2)