Hot Rolled Steel: The Difference

Diunggah oleh

Nagavardhan Reddy Kudugunta0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan2 halamanCold rolled steel has a smoother, more precise surface texture and tighter thickness tolerances compared to hot rolled steel. Hot rolled steel is rolled above the recrystallization temperature, while cold rolled steel is rolled below this temperature. As a result, cold rolled steel maintains a more consistent shape and size during cooling. Common applications of hot rolled steel include construction materials, while cold rolled steel is preferred for machined parts where dimensional accuracy is important.

Deskripsi Asli:

dfdfd

Judul Asli

Materials

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniCold rolled steel has a smoother, more precise surface texture and tighter thickness tolerances compared to hot rolled steel. Hot rolled steel is rolled above the recrystallization temperature, while cold rolled steel is rolled below this temperature. As a result, cold rolled steel maintains a more consistent shape and size during cooling. Common applications of hot rolled steel include construction materials, while cold rolled steel is preferred for machined parts where dimensional accuracy is important.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

7 tayangan2 halamanHot Rolled Steel: The Difference

Diunggah oleh

Nagavardhan Reddy KuduguntaCold rolled steel has a smoother, more precise surface texture and tighter thickness tolerances compared to hot rolled steel. Hot rolled steel is rolled above the recrystallization temperature, while cold rolled steel is rolled below this temperature. As a result, cold rolled steel maintains a more consistent shape and size during cooling. Common applications of hot rolled steel include construction materials, while cold rolled steel is preferred for machined parts where dimensional accuracy is important.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

What is the main difference between Hot Rolled Steel and Cold Rolled steel?

Cold Rolled steel will have closed thickness profile and good surface texture & flatness compared with Hot Rolled Steel.Hot Rolled Steel is rolled above Recrystallisation Temperature and Cold Rolled steel is of below Recrystallisation Temperature. Hot Rolled coils are available above 1.60 mm to 10.00 mm thickness & Cold rolled sheets are available up to 0.10 mm to 4.00 mm Worldwide.

Hot Rolled Steel

The Difference

The process of hot rolling involves rolling steel at a temperature above the steels recrystallization temperature, which takes place over 1700 degrees Fahrenheit. Steel that is above the recrystallization temperature can be shaped and formed much more easily than colder steel, and the steel can start in much larger sizes. It is also typically cheaper to manufacture than cold rolled steel, and is often manufactured without pauses or delays in the process so the steel doesnt need to be reheated. During the cooling process, hot rolled steel will shrink and the size and shape of the steel will be less predictable than cold rolled steel.

Appearance

Hot rolled products often will have a scaly finish and more rounded and less precise corners than cold rolled steel will.

What Its Used For

Youll find hot rolled products like hot rolled steel bars in the welding and construction trades such as making railroad tracks, I-beams, and other steel construction materials that dont require super precise shapes.

Cold Rolled Steel

The Difference

Cold rolled steel is manufactured at temperatures below its recrystallization temperature, typically at around room temperature. Because the steel is manufactured at a much lower temperature, theres no need to worry about the steel shrinking or changing form or appearance.

Appearance

The cold rolled steel end products like cold finished steel bar has a much smoother appearance and may have square corners more accurate in dimension and finish

What Its Used For

Cold rolled steel is much more preferred in the machining world where the quality of the steel is an important factor of the quality of the final product, and the appearance of the steel is also an important factor.

Anda mungkin juga menyukai

- Yasuki Steel Properties and Heat Treatment GuideDokumen1 halamanYasuki Steel Properties and Heat Treatment GuideCristian BujorBelum ada peringkat

- Light Gauge Steel FramingDokumen14 halamanLight Gauge Steel Framingremon100% (4)

- Project On Summer Internship at Jindal Stainless Limited-HisarDokumen57 halamanProject On Summer Internship at Jindal Stainless Limited-Hisaramit kumarBelum ada peringkat

- AutoForm IncrementalDokumen190 halamanAutoForm Incrementaldubium8100% (5)

- Hot Rolled Vs Cold RolledDokumen3 halamanHot Rolled Vs Cold RolledstephanieBelum ada peringkat

- Hot vs Cold Rolled Steel: Key DifferencesDokumen3 halamanHot vs Cold Rolled Steel: Key DifferencestaknevBelum ada peringkat

- RSW-BT-YONGDokumen10 halamanRSW-BT-YONGfraniancis0922Belum ada peringkat

- Hot Vs ColdDokumen3 halamanHot Vs ColdHarisma Nugraha100% (1)

- eNERGY cONSUMPTIONDokumen8 halamaneNERGY cONSUMPTIONRefky FBelum ada peringkat

- Hot & Cold Rolled Steel: Farhan Asim B.Arch 3 Year Ansal School of ArchitectureDokumen7 halamanHot & Cold Rolled Steel: Farhan Asim B.Arch 3 Year Ansal School of ArchitecturerachuBelum ada peringkat

- Difference between hot and cold rolled steelDokumen4 halamanDifference between hot and cold rolled steelAnonymous RmzEd3jABelum ada peringkat

- Woodworker's Guide To SteelDokumen4 halamanWoodworker's Guide To SteelAnthony OoiBelum ada peringkat

- Q2. What Is Rolling and Recrystallization Temperature. Explain The Methods of Rolling Steel and Highlight The Major DifferencesDokumen6 halamanQ2. What Is Rolling and Recrystallization Temperature. Explain The Methods of Rolling Steel and Highlight The Major DifferencesArslan RaoBelum ada peringkat

- Fabrication and ApplicationDokumen8 halamanFabrication and Application000Belum ada peringkat

- Bulk Deformation Processes: RollingDokumen17 halamanBulk Deformation Processes: RollingEthan DanielsBelum ada peringkat

- Steel MaterialsDokumen10 halamanSteel Materialsmanideep219Belum ada peringkat

- Amie Material Science NotesDokumen276 halamanAmie Material Science NotesRajendra Kumar Yadav100% (2)

- Steel CoilDokumen20 halamanSteel CoilParimala SubramaniamBelum ada peringkat

- Detail-Material Science NotesDokumen276 halamanDetail-Material Science Notessureshbabu7374Belum ada peringkat

- BMCT 5 Market Surey SteelDokumen25 halamanBMCT 5 Market Surey SteelAastha ShrivastavaBelum ada peringkat

- Introduction HotandColdProcessDokumen16 halamanIntroduction HotandColdProcessRahul BajpaiBelum ada peringkat

- Stainless Steel 2008Dokumen25 halamanStainless Steel 2008hawktripBelum ada peringkat

- Unit 2 MFTDokumen43 halamanUnit 2 MFTDeepak MisraBelum ada peringkat

- MPT CH 2Dokumen24 halamanMPT CH 2molla biyadgieBelum ada peringkat

- Product OverviewDokumen3 halamanProduct OverviewHarrynew123Belum ada peringkat

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDokumen12 halamanRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Forging Presentation (Autosaved)Dokumen12 halamanForging Presentation (Autosaved)Dead IceingBelum ada peringkat

- Advantages and Disadvantages of Cold WorkingDokumen7 halamanAdvantages and Disadvantages of Cold WorkingFadi Innocent100% (4)

- Glossary of Terms - Definitions Commonly Used in Iron & Steel Industry - Ministry of Steel - GoIDokumen16 halamanGlossary of Terms - Definitions Commonly Used in Iron & Steel Industry - Ministry of Steel - GoIkanchanboBelum ada peringkat

- Carbon Steel and Mild Steel DifferenceDokumen8 halamanCarbon Steel and Mild Steel DifferenceSteinol SolutionsBelum ada peringkat

- Material Properties Required For Design: Strength Toughness Ductility Weldability DurabilityDokumen3 halamanMaterial Properties Required For Design: Strength Toughness Ductility Weldability DurabilityCvaShangkaranBelum ada peringkat

- Sheet Material Untuk Proses PressingDokumen4 halamanSheet Material Untuk Proses PressingeltonBelum ada peringkat

- 9b... 2b To 5bDokumen7 halaman9b... 2b To 5bCubillan, Kenneth M.Belum ada peringkat

- Hot Rolling: Plate MillsDokumen4 halamanHot Rolling: Plate MillsMohammed Abu SufianBelum ada peringkat

- Age HardeningDokumen5 halamanAge Hardeninganum_nBelum ada peringkat

- Hot Rolled SteelDokumen2 halamanHot Rolled SteelabhishekBelum ada peringkat

- L3-Structural SteelDokumen58 halamanL3-Structural SteelTjia Tjie100% (1)

- JFE StandardsDokumen38 halamanJFE Standardsispat_jagadeeshBelum ada peringkat

- Information of Steel Pipe and Method of Application1613scribdDokumen2 halamanInformation of Steel Pipe and Method of Application1613scribdJessica TaylorBelum ada peringkat

- Chapter 8 - Stainless Steels - 2016 - Applied Welding EngineeringDokumen8 halamanChapter 8 - Stainless Steels - 2016 - Applied Welding EngineeringJhair Jhamidh Aquino PortocarreroBelum ada peringkat

- Heat Treatment of SteelDokumen3 halamanHeat Treatment of SteelKristine ReyesBelum ada peringkat

- Olen Sampson, Ariel Needham - Know All About Jewelry Making, Jewelry Designing and Metal Working (2012, World Technologies) - Min - Parça10Dokumen15 halamanOlen Sampson, Ariel Needham - Know All About Jewelry Making, Jewelry Designing and Metal Working (2012, World Technologies) - Min - Parça10mare_sierraBelum ada peringkat

- Stainless Steel Metallurgy-Manufacturing Process, Grades & Role of Alloying ElementsDokumen35 halamanStainless Steel Metallurgy-Manufacturing Process, Grades & Role of Alloying ElementsLalit MohanBelum ada peringkat

- Forms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Dokumen13 halamanForms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Varsha DasBelum ada peringkat

- Sheet Metal Design1Dokumen57 halamanSheet Metal Design1Mohamed ZeinBelum ada peringkat

- From Blast Furnace to Finished SteelDokumen2 halamanFrom Blast Furnace to Finished Steelalma kobicBelum ada peringkat

- Equinox International LTD - Stainless Steel - ST ST Fabrication - 62 PDFDokumen3 halamanEquinox International LTD - Stainless Steel - ST ST Fabrication - 62 PDFeugenio.gutenbertBelum ada peringkat

- HRS VS CRSDokumen6 halamanHRS VS CRSHumberto GalvezBelum ada peringkat

- AMT-Forming (Compatibility Mode)Dokumen15 halamanAMT-Forming (Compatibility Mode)Abdulhmeed MutalatBelum ada peringkat

- Galvanizing ProcessDokumen27 halamanGalvanizing ProcessReymart C. EnteraBelum ada peringkat

- Types of Rolling - Flat Strip RollingDokumen4 halamanTypes of Rolling - Flat Strip RollingvijayakumarBelum ada peringkat

- Ductile vs Grey Cast Iron: Properties and Uses in Bench VicesDokumen12 halamanDuctile vs Grey Cast Iron: Properties and Uses in Bench ViceshecavodBelum ada peringkat

- Steel & InternationalDokumen75 halamanSteel & InternationalSara LopezBelum ada peringkat

- Basic Workshop PDFDokumen15 halamanBasic Workshop PDFniyati DesaiBelum ada peringkat

- Rolling (metalworking) GuideDokumen13 halamanRolling (metalworking) GuideRishabh PataitBelum ada peringkat

- Normalizing Process For SteelsDokumen3 halamanNormalizing Process For Steelsduazo2009Belum ada peringkat

- Forging Process ExplainedDokumen14 halamanForging Process Explainedrehan RNBelum ada peringkat

- Hot and Cold Working of MetalsDokumen20 halamanHot and Cold Working of MetalsVitthal GawhaleBelum ada peringkat

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDari EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelBelum ada peringkat

- CAD-CAE Training Inam PDFDokumen16 halamanCAD-CAE Training Inam PDFInam Ul HaqBelum ada peringkat

- Cimatrone Diedesign: Your Expertise, Our ToolsDokumen6 halamanCimatrone Diedesign: Your Expertise, Our ToolsmotomotomitomitoBelum ada peringkat

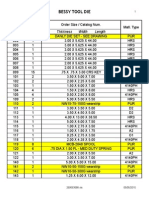

- BESSY Tool Die Job #4100-01 Detail ListDokumen3 halamanBESSY Tool Die Job #4100-01 Detail ListNagavardhan Reddy KuduguntaBelum ada peringkat

- Creating An ExplodeDokumen9 halamanCreating An ExplodeVikas JagadeeshBelum ada peringkat

- CATIA V5 Assembly DraftingDokumen34 halamanCATIA V5 Assembly DraftingPratik PatelBelum ada peringkat

- Master DocumentationDokumen58 halamanMaster DocumentationNagavardhan Reddy KuduguntaBelum ada peringkat

- Book 1Dokumen1 halamanBook 1Nagavardhan Reddy KuduguntaBelum ada peringkat

- C 3 LabDokumen1 halamanC 3 LabNagavardhan Reddy KuduguntaBelum ada peringkat

- C 3 LabDokumen1 halamanC 3 LabNagavardhan Reddy KuduguntaBelum ada peringkat

- ComputerDokumen3 halamanComputerNagavardhan Reddy KuduguntaBelum ada peringkat

- GD TopicsDokumen16 halamanGD TopicsNagavardhan Reddy KuduguntaBelum ada peringkat

- Units ConvFactors - Mit Energy Club Factsheet.v8Dokumen2 halamanUnits ConvFactors - Mit Energy Club Factsheet.v8sanjeet4friendsBelum ada peringkat

- Part and Mold Design Guide (2005)Dokumen174 halamanPart and Mold Design Guide (2005)naitikpanchal100% (4)