Plate Girder Design Based on AISC Manual 14th Edition (AISC 360-10

Diunggah oleh

angkutanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plate Girder Design Based on AISC Manual 14th Edition (AISC 360-10

Diunggah oleh

angkutanHak Cipta:

Format Tersedia

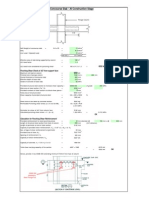

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

STEEL YIELD STRESS F

y

= 50 ksi

SIMPLY SUPPORTED SPAN S = 72 ft

SUPERIMPOSED UNIFORM DEAD LOAD DL = 1 kips / ft

UNIFORM LIVE LOAD LL = 1 kips / ft

POINT DEAD LOAD P

DL

= 60 kips

POINT LIVE LOAD P

LL

= 60 kips

DISTANCE POINT LOAD TO END c = 24 ft

TOP FLANGE WIDTH b

f,top

= 16 in

TOP FLANGE THICKNESS t

f,top

= 1.5 in

BOTTOM FLANGE WIDTH b

f,bot

= 16 in

BOTTOM FLANGE THICKNESS t

f,bot

= 1.5 in

WEB THICKNESS t

w

= 0.5 in

BEAM DEPTH d = 53 in 1/4 x 7 STIFFENER, E. SIDES, AT SUPPORTS ONLY.

UNBRACED LENGTH L

b

= 8 ft FLANGE TO WEB WELDING USE 5/16 in - 24 in @ 41 in o.c.

THE GIRDER DESIGN IS ADEQUATE.

ANALYSIS

CHECK LIMITING WIDTH-THICKNESS RATIOS FOR WEB (AISC 360-10 Table B4.1)

h

c

/ t

w

= 100.00 <

r

= 137.27

>

p

= 90.55

Noncompact Web

where E = 29000 ksi

r

= 5.7 (E / F

y

)

0.5

= 137.27

p

= (h

c

/ h

p

) (E / F

y

)

0.5

/ (0.54 M

p

/ M

y

-0.09)

2

= 93.26 ,for A

f,top

A

f,bot

p

= 3.76 (E / F

y

)

0.5

= 90.55 ,for A

f,top

= A

f,bot

h

c

= 50.00 in h

p

= 50.00 in

M

p

= 6452.1 ft-kips M

y

= 5824.6 ft-kips

CHECK LIMITING WIDTH-THICKNESS RATIOS FOR FLANGES (AISC 360-10 Table B4.1)

0.5 b

f,top

/ t

f,top

= 5.33 <

r

= 17.04

<

p

= 9.15

Compact Flanges

where

r

= 0.95 (k

c

E / F

L

)

0.5

= 17.04

p

= 0.38 (E / F

y

)

0.5

= 9.15

k

c

= Min [0.76 , Max (0.35 , 4 / (h / t

w

)

0.5

)] = 0.39

S

xt

= 1398

in

3

S

xc

= 1398

in

3

F

L

= 35 ksi, (AISC 360-10 Table note B4.1 & Eq F4-6)

DETERMINE CRITERIA FOR ALLOWABLE FLEXURAL STRENGTH (AISC 360-10 Table F1.1)

F2 F3 F4 F5

Double Symmetric x x

Compact Web x x

Noncompact Web

Slender Web M

allowable

=M

n

/ O

b

= 3806.0 ft-kips

Compact Flanges x ( from following analysis)

Noncompact Flanges

Slender Flanges

Applicable Section ok

DETERMINE ALLOWABLE FLEXURAL STRENGTH , M

n

/ O

b

, BASED ON AISC 360-10 Chapter F2

<== Not Applicable.

13.23 ft

32.74 ft

where r

y

= 3.75 in S

x

= 1398

in

3

h

0

= 51.50 in I

y

= 1025

in

4

Chapter F Sections

Required Conditions

x

Plate Girder Design Based on AISC Manual 14th Edition (AISC 360-10)

1.76

p y

y

E

L r

F

= =

2

0

0.7

0

1.95 1 1 6.76

0.7 0.7

r ts ts

y x y

F E Jc E y S h

x

L r r

E Jc

S h F F

t

| |

= + + ~ = |

|

\ .

(cont'd)

C

w

= I

y

h

0

2

/ 4 = 679321 , (AISC 360-10 F2.2)

J = [ 2 b

f

t

f

3

+ (d - t

f

) t

f

3

] / 3 = 38.146

in

4

, (Galambos 1968)

(Use J = 4.0314 in

4

)

r

ts

=[( I

y

C

w

)

0.5

/ S

x

)]

0.5

= 4.34 in

c =

1.0 C

b

= 1.0 , (AISC Manual 14th Table 3-1, page 3-10)

586.73 ksi

6452.1 ft-kips

M

allowable, F2

=M

n

/ O

b

= 3863.5 ft-kips where O

b

= 1.67 , (AISC 360-10 F1)

DETERMINE ALLOWABLE FLEXURAL STRENGTH , M

n

/ O

b

, BASED ON AISC 360-10 Chapter F3

<== Not Applicable.

7600.9 ft-kips

where = b

f

/ (2 t

f

) = 5.33

pf

=

p

= 9.15

rf

=

r

= 17.04

M

allowable, F3

=Min(M

n,F2

, M

n,F3

) / O

b

= 3863.5 ft-kips

DETERMINE ALLOWABLE FLEXURAL STRENGTH , M

n

/ O

b

, BASED ON AISC 360-10 Chapter F4

9.59 ft

33.05 ft

where a

w

=h

c

t

w

/ (b

fc

t

fc

) = 1.04

4.34 in

M

p

= Min [Z

x

F

y

, 1.6S

xc

F

y

] = 6452.1 ft-kips

M

yc

= S

xc

F

y

= 5824.6 ft-kips M

yt

= S

xt

F

y

= 5824.6 ft-kips

= h

c

/ t

w

= 100.00

pw

=

p

= 93.26

rw

=

r

= 137.27

1.0912

586.58 ksi, (for I

yc

/ I

y

= 0.50 > 0.23, AISC 360-10 F4-5 )

6355.97 ft-kips

2

2

2

0

1 0.078

b b

cr

ts x

b

ts

E Jc C L

F

r S h

L

r

t

| |

= + =

|

\ . | |

|

\ .

( )

( )

, 2

,

0.7 , ,

, ,

p b p

b p

p p y p p b r b x

n F

r p

cr p r b x

for M L L

L L

Min for C S M M F M L L L

M

L L

Min for S F M L L

s

| | ( | |

| < s ( | = =

|

|

(

\ . \ .

( )

, 3

2

0.7 ,

0.9

,

pf

p p y x

rf pf

n F

c x

for Noncompact Flanges S M M F

M

Ek S

for Slender Flanges

( | |

( |

|

(

\ .

= =

1.1

p t

y

E

L r

F

= =

2

0

0

1.95 1 1 6.76

L

r t

L xc

E J S h F xc

L r

E J

S h F

| |

= + + =

|

\ .

( )

( )

, 4.2

,

, ,

, ,

pc yc b p

b p

pc yc pc yc L pc yc p b r b xc

n F

r p

cr pc yc r b xc

for R M L L

L L

Min for C S R M R M F R M L L L

M

L L

Min for S F R M L L

s

| | ( | |

| < s ( | = =

|

|

(

\ . \ .

2

0

0

1

12

6

fc

t

w

b

r

h h

a

d d h

= =

| |

+

|

\ .

, /

1 , , /

p

c w pw

yc

pc

p p pw p

c w pw

yc yc yc rw pw

M

for h t

M

R

M M M

Min for h t

M M M

= =

( | | | |

> ( | |

| |

(

\ .\ .

2

2

2

0

1 0.078

b b

cr

t xc

b

t

E J C L

F

r S h

L

r

t

| |

= + =

|

\ . | |

|

\ .

(cont'd)

6356 ft-kips

1.0912

M

allowable, F4

=Min( M

n,F4.2

, M

n,F4.3

, R

pt

M

yt

) / O

b

= 3806.0 ft-kips

DETERMINE ALLOWABLE FLEXURAL STRENGTH , M

n

/ O

b

, BASED ON AISC 360-10 Chapter F5

<== Not Applicable.

32.73 ft

50 ksi

50 ksi

1

M

allowable, F5

=Min( R

pg

F

y

S

xc

, R

pg

F

cr,F5.2

S

xc

, R

pg

F

cr,F5.3

S

xc

, F

y

S

xt

) / O

b

= 3487.8 ft-kips

DETERMINE ALLOWABLE SHEAR STRENGTH , V

n

/ O

v

, BASED ON AISC 360-10 Chapter G2

h = d - t

f,top

- t

f,bot

= 50 in , h / t

w

= 100 , A

w

= 26.50 in

2

,

a = 71.4 ft

5.00 0.438

V

n

= 0.6 F

y

A

w

C

v

= 348.13 kips

V

allowable

=V

n

/ O

v

= 208.46 kips O

v

= 1.67 , (AISC 360-10 G1)

TOTAL SUPERIMPOSED GRAVITY LOAD

w = DL + LL = 2.000 kips / ft , P = P

DL

+ P

LL

= 120.00 kips

CHECK EACH SECTION CAPACITIES

Section Left 0.06 S 0.11 S 0.17 S 0.22 S 0.28 S Point 0.44 S 0.56 S 0.67 S 0.78 S 0.89 S Right

Distance 0 4.00 8.00 12.00 16.00 20.00 24.00 32.00 40.00 48.00 56.00 64.00 72.00

d (in) 53 53 53 53 53 53 53 53 53 53 53 53 53

y (in) 27 27 27 27 27 27 27 27 27 27 27 27 27

I (in

4

) 37044 37044 37044 37044 37044 37044 37044 37044 37044 37044 37044 37044 37044

Wt (plf) 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4 248.4

V (kips) 160.94 151.95 142.96 133.96 124.97 115.97 0.00 31.01 48.99 66.98 84.97 102.96 120.94

M (ft-k) 0 626 1216 1769 2287 2769 3215 3039 2719 2255 1647 896 0

( )

2

5

5 , / 3

/

5 , / 3

v

for a h

a h

for a h

k

+ s

= =

>

( )

2

1.0 , / 1.10

1.10

, 1.10 / 1.37

/

1.51

, 1.37 /

/

v

w

y

v v v

w v

y y y w

v v

w

y y

w

E k

for h t

F

E E E k k k

for h t

h t F F F

E E k k

for h t

F F h t

C

= < s =

<

0.7

r t

y

E

L r

F

t = =

( )

, 5.2

2

2

,

0.3 , ,

, ,

y b p

b p

y y y p b r b

r p

cr F

b

y r b

for F L L

L L

Min for C F F F L L L

L L

F

E C

Min for F L L

L

b

r

t

t

s

| | ( | |

| < s ( |

|

|

(

\ . \ .

= = | |

|

s

|

| | |

| |

|

\ . \ .

( )

, 5.3

2

,

0.3 ,

0.9

,

2

y

pf

y y

rf pf

cr F

c

f

f

for Compact Flanges

F

for Noncompact Flanges

F F

F

Ek

for Slender Flanges

b

t

( | |

( |

( \ .

= =

| |

|

|

\ .

( )

( )

, 10

1 5.7 , 1.0

1200 300 , 10

w c

pg

y w w

Min E a h

Min

R

Min

a t F

| | | |

| = = |

| | +

\ . \ .

( )

, 5.3

2

,

,

0.9

,

pc yc

pf

pc yc pc yc L xc

n F

rf pf

c xc

for Compact Flanges

R M

for Noncompact Flanges S R M R M F

M

Ek S

for Slender Flanges

( | |

( |

| = =

(

\ .

, /

1 , , /

p

c w pw

yt

pt

p p pw p

c w pw

yt yt yt rw pw

M

for h t

M

R

M M M

Min for h t

M M M

= =

( | | | |

> ( | |

| |

(

\ .\ .

(cont'd)

M

max

= 3215.08 ft-kips @ 24.00 ft, from heel.

< M

allowable

= 3806 ft-kips

[Satisfactory]

V

max

= 160.94 kips @ 0.00 ft, from heel.

< V

allowable

= 208.46 kips [Satisfactory]

DETERMINE DEFLECTION AT MID SPAN

0.72 in ( L / 1195 )

(for camber, self Wt included.)

where E = 29000 ksi w = 1.248 kips / ft

I = 37044 in

4

P = 60 kips

b = 0.6 ft L = 72.0 ft

0.58 in ( L / 1482 )

where P = 60 kips w = 1.000 kips / ft

DETERMINE FLANGE TO WEB WELDING (AISC 360-10 J2.4 )

w = 5/16 in

w

min

= 3/16

in, < w

w

max

= 7/16

in, > w

O = 2.0

V

max

= 160.94 kips

Q = A

f

(d - y - 0.5 t

f,top

) = 618

in

3

v

max

= V

max

Q / I = 2.68 kips / in

A = 24 in 41 in. o.c.

USE 5/16 in - 24 in @ 41 in o.c.

DESIGN STIFFENERS

1. BEARING STIFFENERS ARE REQUIRED AT EACH END SUPPORT. (AISC 360-10, J10.8)

2. CHECK LOCAL WEB YIELDING FOR THE CONCENTRATED LOAD. (AISC 360-10, J10.2)

R = P = 120.00 kips

N = 0 in, bearing length, point.

k = t

f,top

+ w = 1.81 in

O = 1.5

26.48 < F

y

/ O [Satisfactory]

-4000

-3500

-3000

-2500

-2000

-1500

-1000

-500

0

M

o

m

e

n

t

s

Length

BENDING LOADS & CAPACITY

-250.00

-200.00

-150.00

-100.00

-50.00

0.00

S

h

e

a

r

F

o

r

c

e

s

Length

SHEAR LOADS & CAPACITY

( )

4

3/ 2

2 2

5 0.06415

384

DL

w Pb L

b L

EI EIL

= + = A

( )

4

3/ 2

2 2

5 0.06415

384

LL

w Pb L

b L

EI EIL

= + = A

( ) ( ) 0.6 0.707

max

EXX

w A F

B

v

= =

O

( )

( )

,

5

,

2.5

R

for c d

N k t

w

R

for c d

N k t

w

>

=

(cont'd)

3. CHECK WEB CRIPPLING FOR THE CONCENTRATED LOAD. (AISC 360-10, J10.3)

O = 2.0

208.57 > P [Satisfactory]

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

4. CHECK SIDESWAY WEB BUCKING FOR THE CONCENTRATED LOAD. (AISC 360-10, J10.4)

d

c

= d - 2k = 49.38 in

C

r

= 960000 ksi

(d

c

/ t

w

) / (l / b

f

) = 16.46

O = 1.76

120.00 > P [Satisfactory]

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

5. DETERMINE STIFFENER SIZE.

t

w

= 5/8 in , b

st

= 7 in

b

st

/ t

w

= 11.20 < 0.56 (E / F

y

)

0.5

, (AISC 360-10 Table B4.1)

[Satisfactory]

A

g

= 11.75 in

2

, I =

159

in

4

R = 160.9 kips

O

c

= 1.67 , (AISC 360-10 E1)

K l / r =

0.75 h / ( I / A

eff

)

0.5

= 10.2

C

c

= 4.71 ( E/ F

y

)

0.5

= 113

2751.51 ksi

349.1 kips, (AISC 360-10 E2)

> R [Satisfactory]

Technical Reference:

1. AISC: "Steel Construction Manual 14th Edition", American Institute of Steel Construction, 2010.

1.5

2

1.5

2

0.80 1 3 , 0.5

/ 1/

0.40 1 3 , 0.5

yw f w

w

f w

yw f w

w

f w

t EF N t

for c d t

d t t

Rn

t EF N t

for c d t

d t t

(

| |

| |

(

+ > |

|

| (

\ .

\ .

O = O

(

| |

| |

( + < |

|

| ( \ .

\ .

=

3

3

2

3

3

2

/ /

0.4 , 1.7

/ /

/ /

/ 1/ 1 0.4 , 1.7 2.3

/ /

/

, 2.3

/

r w f c w c w

f f

r w f c w c w

f f

c w

f

C t t d t d t

for

l l b b h

C t t d t d t

for Rn

l l b b h

d t

P for

l b

(

| |

(

< |

| (

\ .

(

| |

(

O = O + s < |

| (

\ .

O >

=

/ /

,

0.658

0.877 ,

F y

y c Fe

R A n c g c

e c

kl

for

C F

r

kl

for

C F

r

= O O

(

s

(

>

( )

2

2

/

Fe

E

kl r

t

= =

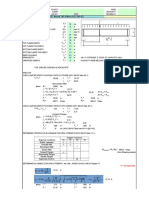

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

Plate Girder Design Based on AISC-ASD 9th, Chapter G

INPUT DATA & DESIGN SUMMARY

STEEL YIELD STRESS F

y

= 50 ksi

SIMPLY SUPPORTED SPAN S = 72 ft

SUPERIMPOSED UNIFORM DEAD LOAD DL = 1 kips / ft

UNIFORM LIVE LOAD LL = 1 kips / ft

POINT DEAD LOAD P

DL

= 60 kips

POINT LIVE LOAD P

LL

= 60 kips

TOP FLANGE WIDTH b

f,top

= 16 in

TOP FLANGE THICKNESS t

f,top

= 1.5 in

BOTTOM FLANGE WIDTH b

f,bot

= 16 in

BOTTOM FLANGE THICKNESS t

f,bot

= 1.5 in

WEB THICKNESS t

w

= 0.5 in

BEAM DEPTH d = 70 in 1/4 x 7 STIFFENER, E. SIDES, AT SUPPORTS ONLY.

DISTANCE POINT LOAD TO END c = 24 ft FLANGE TO WEB WELDING USE 5/16 in - 24 in @ 57 in o.c.

UNBRACED LENGTH l = 8 ft

THE GIRDER DESIGN IS ADEQUATE.

ANALYSIS

DETERMINE F

b

(AISC-ASD, F1.3, page 5-46)

1.02

r

T

= 4.16 in , A

f

= 24.00

in

2

11.43 ft

15.84 ft

35.42 ft

30.0 ksi

16.7 ksi

30.0 ksi

33.0 ksi

CHECK WEB SLENDERNESS (AISC-ASD, G1, page 5-51)

a = 71.4 ft, the max clear distance between stiffeners.

h / t

w

= 134.00 > 132.30 [Satisfactory]

< 282.84

[Satisfactory]

( )

76

20000

,

/

f

c

f y y

b

MIN

L

d

A F F

| |

| = =

|

\ .

( )

102000 12000

,

0.6 /

T

b b

u

y f y

C C

MAX

L r

d

F A F

| |

| = =

|

\ .

3

510000

T

b

y

C

L r

F

= =

( )

2

1

/

2

, 0.6

3 1530000

T

y

b y y

b

l

F r

MIN

F F F

C

| |

(

|

(

= =

|

(

\ .

( )

2

2

170000

,

3

/

T

y

b

b

F

C

MIN

F

l

r

| |

|

= =

|

\ .

( )

3

12000

, 0.6

/

b

b y

f

C

MIN

F F

l d

A

| |

| = =

|

\ .

( )

( )

1 3 3

2 3 3

0.66 ,

0.6 ,

, ,

, ,

y c

y c u

b

b b u

b b

for l

F L

for l

F L L

F

MAX for l

F F L L

MAX for l

F F L

s

< <

= =

s <

>

2

2

2 2

1

2

2

2 2

4 4

1

1.75 1.05 0.3 1.75 1.05 0.3

2

2

b

M l S M l S

C

M M S

S

| |

| | | | | |

= + + ~ + + =

|

| | |

|

\ . \ . \ .

\ .

760

b

F

=

( )

14000

, 1.5

16.5

2000

, 1.5

yf yf

yf

for a h

F F

for a h

F

>

(cont'd)

DETERMINE ALLOWABLE FLEXURAL STRESS (AISC-ASD G2, pg 5-51)

A

w

= 33.50 in

2

, o = 0.6 F

yw

/ F

b

= 0.91

0.999

0.998

32.89 ksi

DETERMINE ALLOWABLE SHEAR STRESS (F4-2, pg 5-49)

h = d - t

f,top

- t

f,bot

= 67 in , h / t

w

= 134

= 5.36 = 0.27

4.65 ksi

TOTAL SUPERIMPOSED GRAVITY LOAD

w = DL + LL = 2.000 kips / ft , P = P

DL

+ P

LL

= 120.00 kips

CHECK EACH SECTION CAPACITIES

Section Left 0.06 S 0.11 S 0.17 S 0.22 S 0.28 S Point 0.44 S 0.56 S 0.67 S 0.78 S 0.89 S Right

Distance 0 4.00 8.00 12.00 16.00 20.00 24.00 32.00 40.00 48.00 56.00 64.00 72.00

d (in) 70 70 70 70 70 70 70 70 70 70 70 70 70

y (in) 35 35 35 35 35 35 35 35 35 35 35 35 35

I (in

4

) 68848 68848 68848 68848 68848 68848 68848 68848 68848 68848 68848 68848 68848

Wt (plf) 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3 277.3

V (kips) 161.98 152.87 143.77 134.66 125.55 116.44 0.00 30.89 49.11 67.33 85.55 103.77 121.98

M (ft-k) 0 630 1223 1780 2300 2784 3232 3057 2737 2272 1660 903 0

f

v

(ksi) 4.63 4.37 4.11 3.85 3.59 3.33 0.00 0.88 1.40 1.92 2.44 2.96 3.49

f

b

(ksi) 0.00 3.84 7.46 10.86 14.03 16.98 19.71 18.65 16.70 13.86 10.13 5.51 0.00

f

b,max

= 19.71 ksi @ 24.00 ft, from heel.

< F'

b

= 32.89 ksi

[Satisfactory]

-35.00

-30.00

-25.00

-20.00

-15.00

-10.00

-5.00

0.00

f

b

(

k

s

i

)

&

F

'

b

(

k

s

i

)

Length

BENDING STRESS

-5.00

-4.00

-3.00

-2.00

-1.00

0.00

f

v

(

k

s

i

)

&

F

v

(

k

s

i

)

Length

SHEAR STRESS

'

b PG

b

F F R R

e

= =

, 0.4

2.89

y v

y v

C F

MIN

F F

| |

= =

|

\ .

( )

( )

2

2

5.34

4.0 , / 1.0

/

4.0

5.34 , / 1.0

/

v

for a h

a h

for a h

a h

k

+ s

+ >

( )

2

45000

, 0.8

/

190

, 0.8

/

v

y w

v

v

y w

k

for

C

v

h

t F

k

for

C

v

h

t F

C

>

( )

14000

, 1.5

16.5

2000

, 1.5

yf yf

yf

for a h

F F

for a h

F

>

760

1 0.0005 , 1.0

w

PG

f b

h

A

MIN

R

t

A F

| | | |

= = | |

| |

\ . \ .

( )

3

12 3

, 1.0

12 2

w

f

e

w

f

A

A

MIN

R

A

A

o

o

( | |

+ ( |

|

(

\ .

= =

(

| |

(

+

|

|

(

\ .

(cont'd)

f

v,max

= 4.63 ksi @ 0.00 ft, from heel.

< F

v

= 4.65 ksi [Satisfactory]

DETERMINE DEFLECTION AT MID SPAN

0.40 in ( L / 2173 )

(for camber, self Wt included.)

where E = 29000 ksi w = 1.277 kips / ft

I = 68848 in

4

P = 60 kips

b = 0.6 ft L = 72.0 ft

0.31 in ( L / 2755 )

where P = 60 kips w = 1.000 kips / ft

DETERMINE FLANGE TO WEB WELDING

w = 5/16 in

w

min

= 3/16

in, < w

w

max

= 7/16

in, > w

V

max

= 161.98 kips

Q = A

f

(d - y - 0.5 t

f,top

) = 822

in

3

v

max

= V

max

Q / I = 1.93 kips / in

A = 24 in 57 in. o.c.

USE 5/16 in - 24 in @ 57 in o.c.

DESIGN STIFFENERS

1. BEARING STIFFENERS ARE REQUIRED AT EACH END SUPPORT. (AISC-ASD, K1.8, page 5-82)

2. CHECK LOCAL WEB YIELDING FOR THE CONCENTRATED LOAD. (AISC-ASD, K3, page 5-81)

R = P = 120.00 kips

N = 0 in, bearing length, point.

k = t

f,top

+ w = 1.81 in

26.48 < 0.66F

y

[Satisfactory]

3. CHECK WEB CRIPPLING FOR THE CONCENTRATED LOAD. (AISC-ASD, K4, page 5-81)

206.68 > P [Satisfactory]

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

4. CHECK SIDESWAY WEB BUCKING FOR THE CONCENTRATED LOAD. (AISC-ASD, K5, page 5-81)

d

c

= d - 2k = 66.38 in

(d

c

/ t

w

) / (l / b

f

) = 22.13

120.00 > P [Satisfactory]

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

( )

4

3/ 2

2 2

5 0.06415

384

DL

w Pb

L

b L

EI EIL

= + =

A

( )

4

3/ 2

2 2

5 0.06415

384

LL

w Pb

L

b L

EI EIL

= + =

A

( )( ) 0.3 0.707

max

w A

F

u

B

v

= =

( )

( )

,

5

,

2.5

R

for c d

N k

t

w

R

for c d

N k

t

w

>

=

1.5

2

1.5

2

67.5 1 3 , 0.5

34 1 3 , 0.5

yw f

w

w

f w

yw f

w

w

f w

t F N

t

for c d

t

d

t t

R

t F N

t

for c d

t

d

t t

(

| |

| |

(

+ >

|

|

|

(

\ .

\ .

=

(

| |

| |

(

+ <

|

|

|

(

\ .

\ .

=

3

3

3

3

6800 / /

0.4 , 1.7

/ /

6800 / /

1 0.4 , 1.7 2.3

/ /

/

, 2.3

/

w c w c w

f f

w c w c w

f f

c w

f

t d t d t

for

h l l

b b

t d t d t

R for

h l l

b b

d t

P for

l

b

(

| |

(

< |

| (

\ .

(

| |

(

= + s < |

|

(

\ .

>

=

(cont'd)

5. DETERMINE STIFFENER SIZE.

t

w

= 5/8 in , b

st

= 7 in

b

st

/ t

w

= 11.20 < 95 / F

y

0.5

, AISC-ASD, B5.1

[Satisfactory]

A

eff

= 11.75 in

2

, I =

159

in

4

f

a

= 13.8 ksi

E

s

= 29000 ksi

K l / r =

0.75 h / ( I / A

eff

)

0.5

= 13.7

C

c

= (2 t

2

E

s

/ F

y

)

0.5

= 107

28.9 ksi, (AISC-ASD, E2, page 5-42)

> f

a

[Satisfactory]

Technical Reference:

1. AISC: "Manual of Steel construction 9th", American Institute of Steel Construction, 1990.

3

3

3

3

6800 / /

0.4 , 1.7

/ /

6800 / /

1 0.4 , 1.7 2.3

/ /

/

, 2.3

/

w c w c w

f f

w c w c w

f f

c w

f

t d t d t

for

h l l

b b

t d t d t

R for

h l l

b b

d t

P for

l

b

(

| |

(

< |

| (

\ .

(

| |

(

= + s < |

|

(

\ .

>

=

( )

( ) ( )

( )

2

2

3

3

2

2

/

1

2

,

3 / /

5

3 8 8

12

,

23 /

y

c

c

a

c c

c

kl r

F

C

kl

for

C

r

kl r kl r

F

C C

E kl

for

C

r

kl r

t

(

(

(

==

+

>

Anda mungkin juga menyukai

- Design of corbel reinforcementDokumen9 halamanDesign of corbel reinforcementalurabhilash1Belum ada peringkat

- CribDokumen1 halamanCribskumarsrBelum ada peringkat

- Pile Cap Design (4-Piles)Dokumen4 halamanPile Cap Design (4-Piles)Uttam Kumar GhoshBelum ada peringkat

- Concrete Design SummaryDokumen3 halamanConcrete Design Summaryyanu13Belum ada peringkat

- Plate GirderDokumen22 halamanPlate GirdertitlesaengBelum ada peringkat

- Aluminum DesignDokumen2 halamanAluminum DesignUmesh ChamaraBelum ada peringkat

- STAT100 Fall19 Test 2 ANSWERS Practice Problems PDFDokumen23 halamanSTAT100 Fall19 Test 2 ANSWERS Practice Problems PDFabutiBelum ada peringkat

- всё необходимое для изучения английского языкаDokumen9 halamanвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- Plate Girder DesignDokumen30 halamanPlate Girder DesignVarun Shastry100% (1)

- 005 Deck SlabDokumen15 halaman005 Deck SlabFerkei UngBelum ada peringkat

- 3bow-String Girder - Design Construction Aspects PDFDokumen12 halaman3bow-String Girder - Design Construction Aspects PDFankur mundraBelum ada peringkat

- Base Plate Hss2Dokumen37 halamanBase Plate Hss2Sana UllahBelum ada peringkat

- Portal FrameDokumen42 halamanPortal Framesurendra_pangaBelum ada peringkat

- Plate Girder DesignDokumen23 halamanPlate Girder DesignMatthew Chin100% (1)

- STRENGTH CALCULATION: Decking Profile 51mm/961mm: Safe Safe SafeDokumen5 halamanSTRENGTH CALCULATION: Decking Profile 51mm/961mm: Safe Safe SafePratyayaParija100% (2)

- Bored Pile Design for BridgesDokumen5 halamanBored Pile Design for BridgesKanu PreiyaBelum ada peringkat

- Design of Through Type Plate GirderDokumen9 halamanDesign of Through Type Plate GirderAnju Kl0% (1)

- Is 800 - 1984 & 2007 Comparative StudyDokumen149 halamanIs 800 - 1984 & 2007 Comparative Studyprabhu81100% (1)

- Staad Pro-Circular Plate With A HoleDokumen5 halamanStaad Pro-Circular Plate With A HoleV.m. RajanBelum ada peringkat

- PRYING9.xls AISC Prying Action AnalysisDokumen5 halamanPRYING9.xls AISC Prying Action AnalysisCarlos Valverde PortillaBelum ada peringkat

- Steel Design LatestDokumen52 halamanSteel Design LatestAhsan HabibBelum ada peringkat

- Crane Girder Capacity CalculationDokumen4 halamanCrane Girder Capacity Calculationsatoni12Belum ada peringkat

- Splices & ConnectionsDokumen37 halamanSplices & Connectionsprabhu81Belum ada peringkat

- Design of Pedestal Mkd. On Grid A (Braced Bay)Dokumen10 halamanDesign of Pedestal Mkd. On Grid A (Braced Bay)Kaustubh JadhavBelum ada peringkat

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADokumen23 halamanAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarBelum ada peringkat

- Structural Steelwork ConnectionsDokumen4 halamanStructural Steelwork Connectionstheunknown076Belum ada peringkat

- Lacing 1Dokumen1 halamanLacing 1Purnima ArkalgudBelum ada peringkat

- Concrete slab strengthening designDokumen4 halamanConcrete slab strengthening designSherwin CairoBelum ada peringkat

- RCC BOX BRIDGE DESIGNDokumen53 halamanRCC BOX BRIDGE DESIGNSreeraja SreevilasanBelum ada peringkat

- Design of Base PlateDokumen161 halamanDesign of Base PlatemaheshbandhamBelum ada peringkat

- Punching Shear Check For SlabDokumen2 halamanPunching Shear Check For SlabArnab Sur50% (2)

- Plate Girder DesignDokumen8 halamanPlate Girder Designkalpanaadhi100% (1)

- Launching Scheme Br. 39& DesignDokumen12 halamanLaunching Scheme Br. 39& DesignTamil Arasu SBelum ada peringkat

- 3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)Dokumen2 halaman3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)vivekBelum ada peringkat

- Plinth Beam Design CalculationDokumen4 halamanPlinth Beam Design CalculationVinod NairBelum ada peringkat

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDokumen7 halamanUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LBelum ada peringkat

- Steel Section Design as per IS 800:2007Dokumen12 halamanSteel Section Design as per IS 800:2007vishalnalwar100% (1)

- STAADDokumen15 halamanSTAADBaladad HaroldBelum ada peringkat

- Wind Load Calculation For Roof TrussDokumen4 halamanWind Load Calculation For Roof TrussPartha GangopadhyayBelum ada peringkat

- Is 800 2007Dokumen12 halamanIs 800 2007Ragavan100% (1)

- Retaining Wall DesignDokumen9 halamanRetaining Wall DesignEngr Benalito A Catap IIIBelum ada peringkat

- RaftDokumen48 halamanRaftHariom KhungarBelum ada peringkat

- Insert Plate DesignDokumen8 halamanInsert Plate DesignPiyushBelum ada peringkat

- Design If Deck Slab Sailent Fetures of Super-StructureDokumen15 halamanDesign If Deck Slab Sailent Fetures of Super-StructuredsureshcivilBelum ada peringkat

- Combined Excel SheetDokumen14 halamanCombined Excel SheetZain SaeedBelum ada peringkat

- CIRCBASE STEEL COLUMN ANALYSISDokumen9 halamanCIRCBASE STEEL COLUMN ANALYSISjigarshah21Belum ada peringkat

- Transport Shop Foundation Design ReportDokumen63 halamanTransport Shop Foundation Design ReportchetanchintaBelum ada peringkat

- Pdelta & Repeat LoadDokumen5 halamanPdelta & Repeat LoadGautam PaulBelum ada peringkat

- Openwell StaircaseDokumen8 halamanOpenwell StaircaseAbdul AzeemBelum ada peringkat

- Design of Purlin structural members and load calculationsDokumen3 halamanDesign of Purlin structural members and load calculationsGeorge GeorgianBelum ada peringkat

- Load Combination Is 800-2007Dokumen5 halamanLoad Combination Is 800-2007Jitendra PBelum ada peringkat

- Pile Cap Design SolutionDokumen42 halamanPile Cap Design Solutionkhantha velBelum ada peringkat

- 1.1 Subject Information: Statical Calculation For Masonry Abutment DesignDokumen10 halaman1.1 Subject Information: Statical Calculation For Masonry Abutment DesignabadittadesseBelum ada peringkat

- AQUDUCTDokumen139 halamanAQUDUCTMadhu SudhanBelum ada peringkat

- Design Example ASD Beam CompositeDokumen9 halamanDesign Example ASD Beam Compositecrealraj100% (1)

- Single girder section properties analysisDokumen8 halamanSingle girder section properties analysisamirBelum ada peringkat

- 498 Plate Girder CombinedDokumen1 halaman498 Plate Girder CombinedapooladiBelum ada peringkat

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-08Dokumen3 halamanBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-08yanu13Belum ada peringkat

- Flange Tapered GirderDokumen12 halamanFlange Tapered GirderZevanyaRolandTualakaBelum ada peringkat

- Plate Girder Design SummaryDokumen15 halamanPlate Girder Design SummaryAnisha MayaBelum ada peringkat

- SteelColumn 8Dokumen8 halamanSteelColumn 8Mahbub AlamBelum ada peringkat

- Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDokumen3 halamanConcrete Column Design Based On ACI 318-11: Input Data & Design Summaryjaimeleoxxx0% (1)

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheDokumen2 halamanArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiBelum ada peringkat

- AgentScope: A Flexible Yet Robust Multi-Agent PlatformDokumen24 halamanAgentScope: A Flexible Yet Robust Multi-Agent PlatformRijalBelum ada peringkat

- Sentinel 2 Products Specification DocumentDokumen510 halamanSentinel 2 Products Specification DocumentSherly BhengeBelum ada peringkat

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDokumen4 halamanMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeBelum ada peringkat

- 15 - 5 - IoT Based Smart HomeDokumen6 halaman15 - 5 - IoT Based Smart HomeBhaskar Rao PBelum ada peringkat

- Exercises2 SolutionsDokumen7 halamanExercises2 Solutionspedroagv08Belum ada peringkat

- Jfif 1.02Dokumen9 halamanJfif 1.02Berry Hoekstra100% (1)

- House Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Dokumen4 halamanHouse Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Raphael Eyitayor TyBelum ada peringkat

- Malware Reverse Engineering Part 1 Static AnalysisDokumen27 halamanMalware Reverse Engineering Part 1 Static AnalysisBik AshBelum ada peringkat

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalDokumen41 halaman2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcBelum ada peringkat

- Whisper Flo XF 3 PhaseDokumen16 halamanWhisper Flo XF 3 Phasehargote_2Belum ada peringkat

- SEG Newsletter 65 2006 AprilDokumen48 halamanSEG Newsletter 65 2006 AprilMilton Agustin GonzagaBelum ada peringkat

- Portfolio by Harshit Dhameliya-1Dokumen85 halamanPortfolio by Harshit Dhameliya-1Aniket DhameliyaBelum ada peringkat

- Tech Data: Vultrex Production & Drilling CompoundsDokumen2 halamanTech Data: Vultrex Production & Drilling CompoundsJeremias UtreraBelum ada peringkat

- Radio Frequency Transmitter Type 1: System OperationDokumen2 halamanRadio Frequency Transmitter Type 1: System OperationAnonymous qjoKrp0oBelum ada peringkat

- NewspaperDokumen11 halamanNewspaperКристина ОрёлBelum ada peringkat

- GlastonburyDokumen4 halamanGlastonburyfatimazahrarahmani02Belum ada peringkat

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDokumen20 halamanSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyBelum ada peringkat

- Exp 8 - GPG - D12B - 74 PDFDokumen4 halamanExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMEBelum ada peringkat

- Traffic LightDokumen19 halamanTraffic LightDianne ParBelum ada peringkat

- Guiding Childrens Social Development and Learning 8th Edition Kostelnik Test BankDokumen16 halamanGuiding Childrens Social Development and Learning 8th Edition Kostelnik Test Bankoglepogy5kobgk100% (27)

- Mercedes BenzDokumen56 halamanMercedes BenzRoland Joldis100% (1)

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDokumen7 halamanNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisBelum ada peringkat

- Manual Analizador Fluoruro HachDokumen92 halamanManual Analizador Fluoruro HachAitor de IsusiBelum ada peringkat

- 17BCE0552 Java DA1 PDFDokumen10 halaman17BCE0552 Java DA1 PDFABHIMAYU JENABelum ada peringkat

- TWP10Dokumen100 halamanTWP10ed9481Belum ada peringkat

- 5054 w11 QP 11Dokumen20 halaman5054 w11 QP 11mstudy123456Belum ada peringkat

- Cold Rolled Steel Sections - Specification: Kenya StandardDokumen21 halamanCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroBelum ada peringkat