Drilling Fluid Technology

Diunggah oleh

Suta VijayaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Drilling Fluid Technology

Diunggah oleh

Suta VijayaHak Cipta:

Format Tersedia

Introduction and Objectives

Technical/Scientific Aspects

Function and Properties

Wellbore Hydraulics, Cuttings

Transport

Fundamentals of Rheology

Drilling Fluids and Borehole

Stability

Filtration Properties

Balancing Formation Pressure

Lost Circulation Problems

Lubrication/Friction Reducing

Corrosion Prevention

Testing Methods/Equipment

Mud Additives Controlling

Properties

Solids Control

Unweighted/Weighted Muds

Types of Drilling Fluid

Systems

Waterbased Mud

Oilbase Mud/Emulsion Systems

KTB-Experiences

Strategy

Pilot Hole

Ultradeep Hole

Conclusions

Lesson I

Lesson II

Drilling Fluid Technology

Drilling Mud Why do we deal with?

Drilling Tasks Information Carrier

Engineers

Scientists

Mud/Fluids

Gas

Tracers

Cuttings

Mud

Gas

Fluids

!Bottomhole Cleaning

!Cuttings Transport

!Borehole Wall Support

!Balancing Formation Pressure

!Cooling the Bit

!Hydraulic Power Transmission

!Data Transmission (MWD)

!Reducing Friction

!Corrosion Protection

Mud

Cores

Cuttings

A

i

d

i

n

g

S

c

i

e

n

t

i

f

i

c

E

v

a

l

u

a

t

i

o

n

Borehole

Logging

Swivel

Kelly

Rotary

Table

Annulus

Casing

Drillstring

Shale

Shaker

Rotary Hose

Standpipe

Mud Pits

Charging Pumps

Transport of Cuttings

to Surface

Support of

Borehole Wall

Transmission of

Data/Hydraulic Power

Cooling Bit

Balancing Formation

Pressure

Cleaning the Bottom of the Hole

Reducing Friction

Torque/Drag

Protection against

Corrosion

Aiding Solids Removal

Mud Pumps

Pump Pressure=f(Pumprate,MudViscosity)

Hydraulic Optimization

Mud CirculationSystem

Technical Key Functions of Drilling Fluids

Mud Properties Controlling Technical Key Functions

Functions

Properties

Complex Interaction

!Aiding Cuttings Removal and

Solids Control

5

Solids Content

weighted/unweighted

Rheological Parameters

Viscosity

Thixotropy

!Cleaning the Bottom of the Hole

!Transport of Cuttings to Surface

!Hydraulic Power

!Data Transmission

!Cooling the Bit

1

!Borehole Wall Support/Stabilization

!Balancing Formation Pressure

Density

Filtration Parameters

Free Water Capacity

2

Lubricity Coefficient !Reducing Friction/Torque and Drag

3

!Protection against Corrosion

Chemical Composition

pH

physico-chemical Parameters

4

V

sett

: Cutting Settling Velocity

depends on:

Mud Parameters

- Rheology (Viscosity)

- Density

Cutting Parameters

-Density

-Diameter

-Shape

Fundamentals of Cutting Transport

D

r

i

l

l

P

i

p

e

Drill

Collar

BHA

Drill Bit

Roundtrip/Circulation Break

Transporting of Cuttings to Surface

V

ann

>>V

sett

V

ann

: Mud Velocity in Annulus

depends on:

Pumprate,

Basic Law of Cuttings Transport

(V

ann

-V

sett

)/V

ann

> 50%

A

n

n

u

l

u

s

1

Drilling/Mud Circulation

Annular Geometry

Fundamentals of Cutting Transport

D

r

i

l

l

P

i

p

e

Drill

Collar

BHA

Drill Bit

Holding Cuttings in Suspension

cutt

<

0

cutt

=(d

c

*g(

c

-

m

))/6

0

: Yield Strength of Mud

depends on:

Rheological Behaviour

Gel Strength, Thixotropy

cutt

: Tangential/Normal Stress

due to Cutting Weight

depends on:

-Cutting Diameter (d

c

)

-Cutting Density (

c

)

-Cutting Shape

-Mud Density (

m

)

A

n

n

u

l

u

s

1

Roundtrip/Circulation Break

Drilling/Mud Circulation

Circulation/Drilling

Dynamic Carrying Capacity

Rheological Behaviour while Flowing

Viscosity dependent on Shear Rate

Cuttings Transport The Role of Drilling Fluid Rheology

Circulation Break/Roundtrip

Static Carrying Capacity

Rheological Behaviour while Stationary

Thixotropy: Fluid Gel reversible

1

Shear Stress - Shear Rate Diagram

Shear Rate

S

h

e

a

r

S

t

r

e

s

s

Theory of Fluid Rheology

Viscosity

P

s

e

u

d

o

p

l

a

s

t

i

c

F

l

u

i

d

(

D

r

i

l

l

i

n

g

M

u

d

)

V

i

s

c

o

s

i

t

y

d

e

p

e

n

d

e

n

t

o

n

S

h

e

a

r

R

a

t

e

1

Newtonian Fluid (Water, Mineral Oil):

Straight Line with Constant Slope

L

o

w

N

e

w

t

o

n

i

a

n

V

i

s

c

o

s

i

t

y

Slope = Viscosity

Slope =

H

i

g

h

N

e

w

t

o

n

i

a

n

V

i

s

c

o

s

i

t

y

A

p

p

a

r

e

n

t

V

i

s

c

o

s

i

t

y

Typical Drilling Muds are

Shear Thinning

Viscosity decreases with

increasing Shear Rate

Drilling Mud Viscosity Measuring Equipment

Marsh Funnel

Rotational Viscosimeter

Determination of Shear Dependent

Viscosity by Measuring Flow Curve at

different Rotational Speeds

Measuring Outflow time (s)

Water: 26 s

946 cm

3

1

Measuring Rheological Behaviour of Drilling Fluids

Determination of Flow Model

1

RPM Reading

600 xx

300 xx

200 xx

100 xx

6 xx

3 xx

Measuring Points

Flow Curve

Reading

Rotational

Speed (RPM)

RPM Reading

3 after 10 s xx

3 after 10 min xx

Measuring Points

Gel Strength

Rotational Viscosimeter

0 100 200 300 400 500 600

0

20

40

60

80

100

120

S

h

e

a

r

S

t

r

e

s

s

(

V

i

s

c

o

s

i

m

e

t

e

r

R

e

a

d

i

n

g

)

Shear Rate (Viscosimeter RPM)

Flow Models Describing Pseudoplastic Drilling Fluid Rheology

True Viscosimeter Readings

R@300 RPM

R@600 RPM

B

i

n

g

h

a

m

S

t

r

a

i

g

h

t

L

i

n

e

Bingham Fluid

YP

YP: Yield Point= 2*R

300

-R

600

Slope = PV

PV: Plastic Viscosity=R

600

-R

300

=YP+PV*

Power Law Fluid

=K*

n

K: Konsistency Index=R

300

/511

n

n: Power Law Coefficient=log(R

600

/R

300

)/0.301)

1

Shear Stress Shear Rate Diagram

High Shear-Range

Low Viscosity

Drillpipe -> Pressure Loss

Bit Nozzles -> Hydraulic Power at Bit

Solids Control -> Cutting Removal

Low Shear-Range

High Viscosity

Annulus -> Cuttings

Transport

A

p

p

a

r

e

n

t

V

i

s

c

o

s

i

t

y

a

p

p

(

m

P

a

s

)

Shear Rate

Shear Thinning of Drilling Fluids Impacts on Drilling Process

app

= / / / /

Bingham Asymptotic Line

for high Shear Rates

app

-> PV

app

= = const

Bingham Fluid

Newtonian Fluid

Power Law Fluid

1

Influence of Yield Point on Cuttings Transport Efficiency

T

r

a

n

s

p

o

r

t

R

a

t

i

o

(

%

)

Yield Point YP (lbs/100sqft)

Annular Geometry: 5 Drillpipe/12 Hole

1

Impact of Mud Rheology on Cutting Lag Depth Correction

L

a

g

D

e

p

t

h

C

o

r

r

e

c

t

i

o

n

(

m

)

L

a

g

D

e

p

t

h

C

o

r

r

e

c

t

i

o

n

(

m

)

Cutting Density (kg/dm

3

)

Corundum

Zircon

Magnetite

Amphiboles

Garnets

Mica

Cutting Diameter: 1 mm

Cutting Shape: Sphere

Mud Rheology:

Rotational Viscosimeter:R(300)=16; R(600)=21

Power Law (K=0,68;n=0,39)

Bingham (YP= 5,3 Pa; PV=5 mPas)

Hole Diameter: 8

Drillpipe Diameter: 5

Hole Depth: 10 km

Mud Density: 1,01 kg/dm3

1

Typical Density Ranges of Rock Minerals

Quarz/Feldspars

Gel Building Properties of Drilling Fluids

Time (min)

G

e

l

S

t

r

e

n

g

t

h

G

S

(

P

a

)

fragile Gel

Drilling Fluids show

thixotropic properties

desirable

While static: Gel

While dynamic: Fluid

Measured with Rotational

Viscosimeter @ 3 RPM

Thixotropy: GS@10min-GS@10s

10 30

progressive Gel

dangerous

Initial GS

after 10s

!Excessive Pump Pressures

!Formation Fracturing/Lost Circulation

!Borehole Instability

!Uncontrolled Influx of Formation Fluids

high Surge/Swab Pressures GS too high

GS too low

Insufficient Static

Carrying Capacity for Cuttings

Time dependent Gel Strength

1

0 2 4 6 8 10 12 14 16 18 20

0

20

40

60

80

100

Pump Pressure necessary for

Breaking Gel

G

e

l

B

r

e

a

k

i

n

g

P

r

e

s

s

u

r

e

Gel Strength GS (Pa)

Mining Drilling

5 DP/6Hole

KTB Pilot Hole

R

o

t

a

r

y

D

r

i

l

l

i

n

g

5

D

P

/

1

2

H

o

l

e

5

D

P

/1

7

H

o

le

R

o

t

a

r

y

D

r

i

ll

in

g

Narrow

Annulus

Bit

Pump Rate

H

y

d

r

a

u

l

i

c

P

o

w

e

r

H

P

S

u

r

f

a

c

e

P

a

r

a

s

i

t

i

c

P

r

e

s

s

u

r

e

L

o

s

s

HP

Bit

= HP

Surface

-HP

Parasitic

Optimum

Optimizing Drilling Hydraulics

Jet Nozzles in a Roller Cone Bit

Rule of Thumb for Rotary Drilling:

2/3 of total Pressure Loss at Bit

Minimizing Parasitic Pressure Losses

Drillpipe

Annulus

Surface

Objective: Maximizing Hydraulic Power at Bit

Impact Parameters on Parasitic PL

!Annular Geometry

!Surface Equipment

!Drillpipe Size

!Mud Rheology (YP and PV)

PV as low as possible,

YP as high as necessary for Cuttings Transport

1

Mud Additives Controlling Rheology

!Clays

Bentonite

Attapulgite

Sepiolite

Hectorite

!Polymers

Biopolymers

-Xanthan

- Guar Gum

Polyacrylate/Polyacrylamides

HEC (Hydroxyethylcellulose)

CMC (Carboxymethylcellulose)

Viscosifiers

Dispersants/Deflocculants

!Lignosulfonates

!Lignites

!Phosphates

!SSMA (Styrene Sulfonate Maleic Anhydride)

1

(important for High Temperature Applications)

H

2

0

Mineralogical Structure of Montmorillonite used in Drilling Muds

1

-

Dispersion of Clay in Water

Na

+

, H

2

0

-

Faces negatively charged

Edges positively charged

+

+

+ +

+

Cardhouse Structure

Edge/Face Aggregation

+

+

+

+

+

+

-

+

+

+

-

+

Gel

State Diagram of Colloidal Montmorillonite Suspension in Water

dispersed

Clay

Platelets

D

i

s

p

e

r

s

i

o

n

I

n

c

r

e

a

s

i

n

g

P

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

(

P

V

)

D

e

c

r

e

a

s

i

n

g

F

i

l

t

r

a

t

i

o

n

R

a

t

e

,

I

n

c

r

e

a

s

i

n

g

W

a

t

e

r

B

o

n

d

i

n

g

aggregated

aggregated and flocculated A

g

g

r

e

g

a

t

i

o

n

d

e

c

r

e

a

s

i

n

g

p

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

(

P

V

)

I

n

c

r

e

a

s

i

n

g

f

i

l

t

r

a

t

i

o

n

r

a

t

e

,

r

e

d

u

c

e

d

w

a

t

e

r

b

o

n

d

i

n

g

i

r

r

e

v

e

r

s

i

b

l

e

Face to Face

reversible

dispersed and flocculated

Flocculation

Increasing Yield Point (YP) and Gel Strength

Face to Edge

1

Support of the Borehole Wall Balancing Formation Pressures

Sufficient Mud Density

Good Filtration Properties

While Drilling Open Hole

Mud Column should act as Hydraulic Casing

2

Insufficient Mud Density

Bad Filtration Properties

-Uncontrolled Fluid Entry

-Borehole Instabilities

-Differential Sticking

Pressure (MPa

D

e

p

t

h

(

k

m

)

Sub

hydrostatic

Formation

Pressure Profile

overhydrostatic subhydrostatic

geopressured Aquifer

Balancing Formation Pressures

Pressure of Mud Column

P

mud

= Density

mud

* g * Depth

Normal Drilling (overbalanced)

Mud Pressure > Formation Pressure

2

Instruments for Measuring Mud Density

Hydrometer

Mud Balance

2

Weighting Materials for Drilling Muds

Mud Density (kg/dm

3

)

Mud Density (kg/dm

3

)

S

o

l

i

d

s

F

r

e

e

S

a

l

t

S

o

l

u

t

i

o

n

s

I

n

e

r

t

S

o

l

i

d

s

2

Solids Content and Mud Density for Various Weighting Materials

Mud Density (kg/dm

3

)

S

o

l

i

d

s

C

o

n

c

e

n

t

r

a

t

i

o

n

(

V

o

l

u

m

e

F

r

a

c

t

i

o

n

)

2

Good Filtration Characteristics

!Quick Filtercake Buildup

!Low Filtration Rate

!Filtercake

-thin

-impermeable

-slick

Supporting the Borehole Wall Hydraulic Casing Effect

Mud Properties

!Mud Density -> Pressure Support

!Filtration Characteristics -> Wall Sealing

!Free Water Activity -> Interaction Rock

Pore Pressure

Filter Cake

Pore Pressure

Buildup of Filtercake

M

u

d

M

u

d

Wall sealed

Beginning Filtration

M

u

d

M

u

d

Invasion of:

Mud Filtrate

Mud Particles

Minimizing Formation Damage

Impermeable

Formation

2

Filtercakes and Differential Sticking Mechanism

Overpull required to unstick BHA

Thick

Mudcake

2

Measuring Filtration Properties

API Filter Press

Parameters measured:

!Filtrate Volume (ml) after 30 min

!Cake Thickness (mm)

Normal Conditions

T: Room Temperature

P: 100 psi (7 bar)

HTHP Conditions

T: 300F( 149C)

P: 500 Psi (35 bar)

P: 100 psi (7 bar)

2

Measuring Free Water Activity of Drilling Fluids

2

Sample after 20 min in Water

CST < 70 s

Destabilisation of Red Shale Caused by Contact with Water

Original Sample

Sample after 24h in Dehydril HT (2%)

CST >3600 s

Destabilisation Process is favoured

by High Free Water Activity

High Free Water Activity <-> Low CST

Low Free Water Activity <-> High CST

2

Additives Controlling Filtration Properties and Free Water Activity

Bentonite

Polymers act as Protection Colloids

Preventing Aggregation of

Clay Particles

Polymers

!Starch

!Polyanionic Cellulose (PAC)

!Sodium

Carboxymethylcellulose(CMC)

!Hydroxyethylcellulose(HEC)

!Polyacrylates/Polyacrylamides

!Vinylsulfonate/Vinylamide-

Copolymers (VS/VA)

2

Types of Materials used:

Fibrous (Raw Cotton, Mineral Fibers, Glass Fibers)

Flaky (Cellophane, Mica, Cotton Seed Hulls)

Granular (Perlite, Ground Plastic, Nut Shells, Wood)

Thick Slurry Pills (Bentonite/Polymer, Cement)

Prevention of Lost Circulation Factors to Consider

Types of Lost Circulation Zones

High Permeable Gravel

Natural/Artificial Fractures

Caverneous Formation

Preventive Methods

Reducing Mud Density

Avoiding Pressure Surges

Lowering Gel Strength

Lowering Equivalent Circulation Density

(ECD)

Fighting Against Lost Circulation

Application of Sealing Material

Sealing at

Fracture

Face

Sealing within

The Fracture

Proper Size Distribution

2

Rotating

Drillstring

Trip In/Out

Drillstring

B

o

r

e

h

o

l

e

C

u

r

v

a

t

u

r

e

Borehole Curvature

Dogleg Severity: deg/m

Reducing Friction Controlling Torque/Drag

3

Normal Force F

N

Drag (Trip In/Out)

Torque (Rotation)

Friction Force F

R

F

R

= * F

N

Mud Lubricity Coefficient

Lubricity Coefficients of Drilling Muds

3

Inhibiting Corrosion

!Uniform Corrosion

!Localized Corrosion (Pitting)

Bimetallic Corrosion

Oxygen Concentration Cells

-Crevice Corrosion

-Air/Water Interface

-Oxygen Tubercles

-Scaling/Sludges

!Corrosion Fatigue

!Stress Corrosion

Sulfide Cracking

Hydrogen Embrittlement

Corrosion is the Major Cause

of Drillpipe Failures

Forms of Corrosion

!Raising pH of Mud

!Reducing dissolved Oxygen in

Mud

Vacuum Degassing

Oxygen Scavengers

-Sodium Sulfite

-Sodium Nitrite

!Addition of Corrosion Inhibitors

Filming Amines

Sulfide Scavengers

Zinc Carbonate

Sodium Molybdate

Measures

4

Pitting Corrosion Inside Drillpipe Stress Corrosion at DP-Tooljoint

Mud Additives for pH and Alkalinity Control

4

Shaker Screen

Mud Circulation System and Solids Control Equipment

Centrifuge

Degasser

Desilter

Desander

Mud Return

Flowline

Swivel

Kelly Hose

Standpipe

Suction Pit

Mud Pump

Mixing Hopper

5

Mud Properties Must Aid

Effective Cuttings Removal

Solids Control Equipment

Is the Base for

Cutting Sampling

Anda mungkin juga menyukai

- 00 Hole CleaningDokumen159 halaman00 Hole CleaningMOH HAIDLER ALI SYAFIIBelum ada peringkat

- Drilling Fluids PresentationDokumen81 halamanDrilling Fluids PresentationNamwangala Rashid Natindu100% (1)

- 7B - HydraulicsDokumen33 halaman7B - Hydraulicsagus alexandriBelum ada peringkat

- IDM Basic Training - EzCleanDokumen22 halamanIDM Basic Training - EzCleanThomas DuBelum ada peringkat

- 04-Drilling& CompletionDokumen123 halaman04-Drilling& CompletionYoussef BarsoumBelum ada peringkat

- 01 - Well Planning - UnlockedDokumen10 halaman01 - Well Planning - UnlockedDeniz AkoumBelum ada peringkat

- Drilling Engineering Overview: Project ManagementDokumen24 halamanDrilling Engineering Overview: Project ManagementIgorCencičBelum ada peringkat

- GBP-2 - Cuttings PDFDokumen32 halamanGBP-2 - Cuttings PDFisfanBelum ada peringkat

- GBP-2 - Cuttings PDFDokumen32 halamanGBP-2 - Cuttings PDFisfanBelum ada peringkat

- Rock Type Course - Rev2Dokumen225 halamanRock Type Course - Rev2Mario Mallaviabarrena100% (4)

- Drilling Fluid Functions: Hole CleaningDokumen6 halamanDrilling Fluid Functions: Hole CleaningJonathan DarioBelum ada peringkat

- 7 BHA - Misc ToolsDokumen25 halaman7 BHA - Misc ToolsKaleem UllahBelum ada peringkat

- Drilling: 1. Rig TypesDokumen9 halamanDrilling: 1. Rig TypesEssam AnanyBelum ada peringkat

- Shear Viscosity - Malvern - Torsten Remmler - EngDokumen24 halamanShear Viscosity - Malvern - Torsten Remmler - EngAnanthanarayananBelum ada peringkat

- 2 Manish KumarDokumen13 halaman2 Manish KumarcyrilbhaskerBelum ada peringkat

- 21 - Hole Cleaning BMS 2013Dokumen21 halaman21 - Hole Cleaning BMS 2013Slim.B100% (1)

- Drilling Vs Safety MULTISERVDokumen39 halamanDrilling Vs Safety MULTISERVamrhegazyBelum ada peringkat

- Metodos de DiseñoDokumen25 halamanMetodos de DiseñoMrcial BrachBelum ada peringkat

- Offshore Drilling Overview: Challenges and Solutions (Shell)Dokumen27 halamanOffshore Drilling Overview: Challenges and Solutions (Shell)National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling100% (2)

- Plug and Abandonment - PresentationDokumen8 halamanPlug and Abandonment - PresentationKseniaBelum ada peringkat

- Section 07 - Hole CleaningDokumen82 halamanSection 07 - Hole CleaningRobert MorauskasBelum ada peringkat

- 5 - PENILAIAN FORMASI (Coring and Core Analysis)Dokumen56 halaman5 - PENILAIAN FORMASI (Coring and Core Analysis)Muhamad Zamzam Istimaqom100% (4)

- Drilling Operation: by Huner KareemDokumen67 halamanDrilling Operation: by Huner KareemMohamed Kamal100% (1)

- Prakarsa-Iliadi - Slickline - Rigless Application 20180307Dokumen90 halamanPrakarsa-Iliadi - Slickline - Rigless Application 20180307AsfanBelum ada peringkat

- JDS - Drilling Fluid - 2021 - HandoutsDokumen57 halamanJDS - Drilling Fluid - 2021 - Handoutsrainaldy sebastianBelum ada peringkat

- Well Construction CO2Dokumen29 halamanWell Construction CO2b4rfBelum ada peringkat

- 8 Bitselection 180813115555Dokumen19 halaman8 Bitselection 180813115555jalalBelum ada peringkat

- 8.1 Hole CleaningDokumen45 halaman8.1 Hole CleaningJesús LeyvaBelum ada peringkat

- Introduction Formation Evaluation 1646567801Dokumen61 halamanIntroduction Formation Evaluation 1646567801Emadeldin AbdelghaniBelum ada peringkat

- Mud System and HydraulicsDokumen27 halamanMud System and HydraulicsRyan PermanaBelum ada peringkat

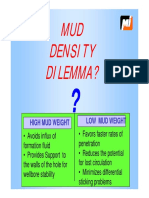

- MUD Density Dilemma?: Low Mud Weight High Mud WeightDokumen16 halamanMUD Density Dilemma?: Low Mud Weight High Mud WeightpaimanBelum ada peringkat

- SLIDE2-Basic Rock PptiesDokumen100 halamanSLIDE2-Basic Rock PptiesolaseyeBelum ada peringkat

- Coal Bed MethaneDokumen16 halamanCoal Bed Methanevignesh0% (1)

- 2 Side Track CoringDokumen26 halaman2 Side Track CoringREGHIS HaouesBelum ada peringkat

- 9 Hydraulic FracturingDokumen45 halaman9 Hydraulic FracturingAyoub EL-hamrouniBelum ada peringkat

- Section 06 - Hole CleaningDokumen81 halamanSection 06 - Hole CleaningRicardo Villar100% (3)

- Pore PressureDokumen202 halamanPore PressureMuhammad ShahrukhBelum ada peringkat

- KG32103 Lecture 2Dokumen83 halamanKG32103 Lecture 2Rie UsunBelum ada peringkat

- 6.1a Introduction To CementingDokumen102 halaman6.1a Introduction To CementingSamuel Okezie100% (1)

- Improving The Earthquake Performance of Bridges Using Seismic IsolationDokumen101 halamanImproving The Earthquake Performance of Bridges Using Seismic IsolationArkarBelum ada peringkat

- Unit 1 Overview of Drilling FluidsDokumen80 halamanUnit 1 Overview of Drilling FluidsHamid SiddiqueBelum ada peringkat

- Pet 331Dokumen46 halamanPet 331Joshua meinfadeBelum ada peringkat

- Borehole Instability ExtendedDokumen67 halamanBorehole Instability ExtendedIon MarinBelum ada peringkat

- 7.1 Formation EvaluationDokumen25 halaman7.1 Formation EvaluationSamuel OkezieBelum ada peringkat

- Well Integrity Management System: 3 Days Workshop, 14 - 16 Jan 2021 Summarized By: Hudan HidayatullohDokumen34 halamanWell Integrity Management System: 3 Days Workshop, 14 - 16 Jan 2021 Summarized By: Hudan HidayatullohIslamBelum ada peringkat

- LF Metis Technology August 2018Dokumen9 halamanLF Metis Technology August 2018ЕвгенийBelum ada peringkat

- Hudson River Tunnels, Mega Projects, and Risk - A Designer's PerspectiveDokumen33 halamanHudson River Tunnels, Mega Projects, and Risk - A Designer's PerspectiveKhải TrươngBelum ada peringkat

- Mud Functions and Lab Test ReviewDokumen112 halamanMud Functions and Lab Test ReviewfeoBelum ada peringkat

- (2.3) Drilling & CementingDokumen36 halaman(2.3) Drilling & CementingDivyansh Singh ChauhanBelum ada peringkat

- Oil & Gas Industry Cycle: Where Are The Hydrocarbons?Dokumen38 halamanOil & Gas Industry Cycle: Where Are The Hydrocarbons?ahza hanifBelum ada peringkat

- Fracturing-School 2003 PakistanDokumen175 halamanFracturing-School 2003 PakistanUmar RasheedBelum ada peringkat

- TAILENG - SC3 - 2021 - Lecture9 - Design Considerations - Winckler - FinalDokumen55 halamanTAILENG - SC3 - 2021 - Lecture9 - Design Considerations - Winckler - FinalMariaBelum ada peringkat

- The Use of Post Tensioning in Marine StructuresDokumen39 halamanThe Use of Post Tensioning in Marine StructuresmonkeyDivanBelum ada peringkat

- Drilling: OperationDokumen7 halamanDrilling: OperationaminBelum ada peringkat

- 04 Road ConstructionDokumen122 halaman04 Road ConstructionHishmat Ezz AlarabBelum ada peringkat

- Brazil Onshore - 2011 - FinalDokumen32 halamanBrazil Onshore - 2011 - FinalDiego D. LasalleBelum ada peringkat

- Overview of CBM & It's Workover OperationsDokumen24 halamanOverview of CBM & It's Workover OperationsvigneshBelum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Rivers and Floodplains: Forms, Processes, and Sedimentary RecordDari EverandRivers and Floodplains: Forms, Processes, and Sedimentary RecordBelum ada peringkat

- Fluid and Particle Mechanics: Chemical Engineering DivisionDari EverandFluid and Particle Mechanics: Chemical Engineering DivisionBelum ada peringkat

- Manta Rig Move 1 - Songkhla - E. PlatformDokumen22 halamanManta Rig Move 1 - Songkhla - E. Platforms v poyilBelum ada peringkat

- PBR Packer Setting StepsDokumen6 halamanPBR Packer Setting Stepss v poyilBelum ada peringkat

- Universal ValuesDokumen36 halamanUniversal Valuess v poyilBelum ada peringkat

- Well (C-23) Activity During 8 " Hole DrillingDokumen2 halamanWell (C-23) Activity During 8 " Hole Drillings v poyilBelum ada peringkat

- Formate Brine TableDokumen12 halamanFormate Brine Tables v poyil100% (1)

- Linx Refresher Sept 2012 IPD PPD Without AnswersDokumen7 halamanLinx Refresher Sept 2012 IPD PPD Without AnswersDeyn EstoqueBelum ada peringkat

- 4.ASME B31 3.3 Process Piping Course ASME B3Dokumen6 halaman4.ASME B31 3.3 Process Piping Course ASME B3abhi kumBelum ada peringkat

- The Viscosity of The Lower Mantle: D - P. MckenzieDokumen16 halamanThe Viscosity of The Lower Mantle: D - P. Mckenziedai_erenBelum ada peringkat

- WK 16 Revision Offshore & Subsea Structures LNB40702 LNB30602Dokumen71 halamanWK 16 Revision Offshore & Subsea Structures LNB40702 LNB30602ardelBelum ada peringkat

- Oedometer Test: Soil Mechanics 2 CE PC 504Dokumen26 halamanOedometer Test: Soil Mechanics 2 CE PC 504SumanHaldarBelum ada peringkat

- Stresses in Beams (Basic Topics)Dokumen108 halamanStresses in Beams (Basic Topics)Fábio1 GamaBelum ada peringkat

- A Reduction in The Pilots Effort To Move The Controls Against High Air LoadsDokumen26 halamanA Reduction in The Pilots Effort To Move The Controls Against High Air LoadsGonçalo FernandesBelum ada peringkat

- Tutorial 9 - Brayton CycleDokumen3 halamanTutorial 9 - Brayton CycleasdfsdjhBelum ada peringkat

- Formulas in Foundation PDFDokumen2 halamanFormulas in Foundation PDFkenkenmusicBelum ada peringkat

- 1997-Free Ferrite in Pearlitic Ductile Iron - Morphology and Its Influence On Mechanical PropertiesDokumen7 halaman1997-Free Ferrite in Pearlitic Ductile Iron - Morphology and Its Influence On Mechanical PropertiesSelauco Vurobi JrBelum ada peringkat

- Moodle Cba Based CH 4 Heat WorksheetDokumen4 halamanMoodle Cba Based CH 4 Heat WorksheetnaishaBelum ada peringkat

- Process Control ProblemsDokumen4 halamanProcess Control ProblemsMarco SarmientoBelum ada peringkat

- Fem-Aided Experimental Determination of Fatigue Properties of Thermomechanically Processed 34crnimo6 SteelDokumen4 halamanFem-Aided Experimental Determination of Fatigue Properties of Thermomechanically Processed 34crnimo6 SteelNiku PascaBelum ada peringkat

- Well Test Analysis Will Be Felt at The Well Reservoir Models A Reservoir PDFDokumen47 halamanWell Test Analysis Will Be Felt at The Well Reservoir Models A Reservoir PDFadeeyoBelum ada peringkat

- Materials 14 00506 v2Dokumen24 halamanMaterials 14 00506 v2steve rubioBelum ada peringkat

- 1 - Gas Liquid Contact-HumidityDokumen8 halaman1 - Gas Liquid Contact-HumidityAriana ReligiosoBelum ada peringkat

- Problem Set 4Dokumen5 halamanProblem Set 4Jobelle SDBelum ada peringkat

- API2000Dokumen39 halamanAPI2000Sudhanshu Shekhar50% (2)

- Mechanics of Materials 1Dokumen304 halamanMechanics of Materials 1opulithe100% (2)

- 2176 - Multi Layer Insulation (MLI)Dokumen10 halaman2176 - Multi Layer Insulation (MLI)mohamedBelum ada peringkat

- Abaqus Soil Examples - 2Dokumen34 halamanAbaqus Soil Examples - 2Gustavo NagelBelum ada peringkat

- Nozzles and Combustion - Boiler Parts - Boilerparts - Co.keDokumen72 halamanNozzles and Combustion - Boiler Parts - Boilerparts - Co.keboilerpartsBelum ada peringkat

- Water Eng OCF NotesDokumen57 halamanWater Eng OCF NotesDavid ThomsonBelum ada peringkat

- Physics Equilibrium QueDokumen3 halamanPhysics Equilibrium QueLemi NegesoBelum ada peringkat

- IX General Sc.Dokumen3 halamanIX General Sc.Kulachi Hansraj Model School100% (1)

- Science Grade9 Q4 LP6Dokumen4 halamanScience Grade9 Q4 LP6Marian GalosoBelum ada peringkat

- Ramjets: Unit-2 Ramjet PropulsionDokumen25 halamanRamjets: Unit-2 Ramjet Propulsionprabhat ranjan mishraBelum ada peringkat

- Keph 201Dokumen13 halamanKeph 201Omkar RajBelum ada peringkat

- Prestressed ConcreteDokumen12 halamanPrestressed Concretebabu1434100% (2)

- Buoyancy: Physics For Engineers 2 LabDokumen8 halamanBuoyancy: Physics For Engineers 2 LabYoo JeongyeonBelum ada peringkat