Pressure Vessel Inspections

Diunggah oleh

Stephanie Webb100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

2K tayangan29 halamanxdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inixdf

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

2K tayangan29 halamanPressure Vessel Inspections

Diunggah oleh

Stephanie Webbxdf

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 29

Pressure Vessel Inspections

The Pressure Vessel Inspections article provides you information about

the inspection of pressure vessels and pressure vessel tests in a

manufacturing shop.

This article provides you lots of invaluable information about the

following items:

Inspection and Testing During the Manufacturing Phase

Inspection and Testing During the Operation Phase

Pressure Vessel Codes and Regulations

Maintenance and Repairs

The Pressure vessel inspections article, alongside other linked articles

are useful for Manufacturer's Quality Control personnel, Second and

Third Party Inspectors, Purchasers, Sellers, Plant Inspectors, HSE

Engineers, Integrity Engineers, Operation and Maintenance Engineers

and any Other Interested Individuals.

Pressure Vessel Definition - Based on the ASME Code Section VIII,

pressure vessels are containers for the containment of pressure, either

internal or external.

This pressure may be obtained from an external source, or by the

application of heat from a direct or indirect source, or any combination

thereof.

Click on the above link for detailed information about pressure vessel

definition, scope, and boundaries based on ASME and API codes which

specifically focus on pressure vessel inspections.

ASME Code Section 8 - ASME Code Section 8 is the construction code

for Pressure Vessels.

This Code section addresses mandatory requirements, specific

prohibitions, and non-mandatory guidance for pressure vessel

materials, design, fabrication, examination, inspection, testing,

certification, and pressure relief.

You may know that ASME Code Section 8 has three divisions. Division

1 covers pressure up to 3,000 psi, Division 2 has an alternative rule

and covers up to 10,000 psi, and Division 3 can be used for pressure

higher than 10,000 psi.

This section is divided into three parts: subsections, mandatory

appendices, and non-mandatory appendices.

Subsection A consists of Part UG, covering the general requirements

applicable to all pressure vessels.

Subsection B covers specific requirements that are applicable to the

various methods used in the fabrication of pressure vessels. It consists

of Parts UW, UF, and UB, and deals with welded, forged, and brazed

methods, respectively.

Subsection C covers specific requirements applicable to the several

classes of materials used in pressure vessel construction.

It consists of Parts UCS, UNF, UHA, UCI, UCL, UCD, UHT, ULW, and

ULT dealing with carbon and low alloy steels, nonferrous metals, high

alloy steels, cast iron, clad and lined material, cast ductile iron, ferritic

steels with properties enhanced by heat treatment, layered

construction, and low temperature materials, respectively.

Click on the above link for detailed information about ASME code

section 8, which specifically focuses on pressure vessel inspections.

Pressure Vessel Plate Material - You have to be careful

when choosing Pressure Vessel Plate Materials; there are lots of

requirements and specific prohibitions in the ASME code.

Some of these requirements are ASME and Non ASME plate material,

plate specification, inspection requirement and material test report.

ASME Code Sec VIII DIV 1 requires that materials that used for

pressure containing parts are one of the materials specified in ASME

section II, but with some restrictions which are stated in ASME Code

Sec VIII Div 1 in subsection C e.g. UCS, UHF, UNF.

For example, SA 283 plate material is listed in ASME Sec II, but when

you refer to subsection C in Sec VIII Div 1, you see it is not allowed to

be used for lethal substance services as well as for unfired steam

boilers. Also, you cannot use this material when you need your

thickness to be greater than 5/8 of an inch.

Click on the above link for detailed information about pressure vessel

plate materials which are specifically focused on pressure vessel

inspections.

ASME Pressure Vessel Joint Efficiencies - You may know ASME

Pressure Vessel Joint Efficiencies are linked to the radiography testing

grades, and there is concession for full radiography testing per the

UW-11(a) (5) (b) clause, which it is a little bit confusing.

Based on ASME Code requirements, manufacturers have to mark the

type of RT, e.g. RT1, RT2, RT3 and RT4, in the pressure vessel name

plate and state the same in the Pressure Vessel Data Report.

We have seen many professionals including inspectors and quality

control engineers who are confused between RT1 and RT2, specifically

when they see that the ASME Pressure Vessel Joint Efficiencies for

both RT1 and RT2 is the same and is equal to 1(E=1);

They say both RT1 and RT2 are categorized in the Full Radiography

part in UW-11 clause. So why are some joints in RT2 radiographed in

spot? We are doing spot radiography, but it is categorized in full

radiography!!!

Click on the above link to answer to this question, which specifically

focuses on pressure vessel inspections.

ASME Impact Test Requirement - You need to take care about ASME

Impact Test Requirement. Suggest you have pressure vessel in the

design process and construction has not started yet.

Based on ASME impact test requirements, you need to make an

assessment to see that either your pressure vessel is exempted from

impact testing or you need to carry out the test.

There are 4 steps for impact test exemption assessment. You need to

go through these steps, and you might be exempted in the first,

second or third steps, and might not be exempted in step 4;

So if you are in step 4 and you have not exempted, then you need to

carry out the test. This article explains you this assessment process.

First, you have to keep your pressure vessel design data available and

then refer to UG-20 (f), if you are exempted from this clause, you do

not need proceed anymore.

But if you are not exempted by UG-20 (f), you have to proceed to

UCS-66(a). Again if you are exempted, there is no need for more

assessment.

But if not, you have to proceed to UCS-66(b). If you are exempted

now, no need for more assessment, otherwise you have to proceed to

UCS-68(c). Again, if you are still not exempted; you have to carry out

impact testing.

It means for some cases we might be exempted from ASME impact

test requirement in first stage in UG-20 (f), in others in UCS-66(a) or

UCS-66(b) or UCS-68(c) or might not be exempted and must prepare

for doing this costly test.

This test would be more costly out of the US because of the Laboratory

Accreditation requirement. The Accredited Laboratory based US

accreditation system is not used too much in Europe, the Middle East

and other locations.

Click on the above link for detailed information about the ASME Impact

Test Requirement, which specifically focuses on pressure vessel

inspections.

Pressure Vessel Dimension Inspection - Do you know what the

Pressure Vessel Dimension Inspection requirement is? You may know

some fabrication tolerances have not been addressed in ASME Code

Section VIII.

So you need to refer to other sources for inspection. Most dimensional

controls of Pressure Vessels are either addressed or not addressed in

the ASME Code. They consists of the following items:

Pressure Vessel Inspections - Dimension

Mill Undertolerance of Plates and Pipes

Tolerances for Formed Heads

Out of Roundness of Shell

Nozzles and Attachments Orientation

Nozzles and Attachments Projection

Nozzles and Attachments elevation

Nozzles and Attachments levelness

Weld Mismatch

Weld Reinforcement

Click on the above link for detailed information about Pressure Vessel

Dimension Inspection, which specifically focuses on pressure vessel

inspections.

Pressure Vessel RT Test - Do you know what your Pressure Vessel RT

Tests Requirements are? Is full radiography mandatory for your

vessel? When the full radiography is mandatory? What the acceptance

criteria are? What the RT symbols are?

When one of following condition is existing, you need to do full

radiography:

1. All butt welds in vessels used to contain lethal substances

2. All butt welds in vessels in which the nominal thickness exceeds

specified values

3. All butt welds in unfired steam boilers with design pressure > 50

psi

4. All category A and D butt welds in a vessel when Full

Radiography is optionally selected

As you see, the item numbers 1, 2 and 3 are really mandatory for the

full RT test;

But the pressure vessel manufacturer may make an optional decision

for full radiography in item number 4.

Global TPI Services

We Provide Pre-Shipment Inspection, Vendor Inspection and Commodity Inspection Services. Click

Here for More Information

Why would pressure vessel manufacturers want to spent more money

for full radiography in item Number 4?

Because joint efficiency in full radiography condition is 1, and the

higher joint efficiency in the pressure vessel wall thickness formula

causes less wall thickness, so the manufacturer might save lots of

money with a lower thickness plate material.

But code has given some bonuses to the manufacturer in item 4,

because it is not mandated to do really full radiography in all butt

welds. The manufacturer can do spot radiography in B and C joints

with the same joint efficiency of 1.

Click on the above link for detailed information about Pressure Vessel

RT Tests which are specifically focuses on pressure vessel inspections.

Vessel Pressure Testing - You need to do a hydro-static test after the

completion of construction process, but before the internal parts

assembly, and also before the painting process.

Please note that performing the pneumatic test instead of the hydro-

static testing is not allowed and it can be replaced only when it is not

possible due to design and process.

Vessel Pressure Testing requirements have been addressed in UG-99

and UG-100 in ASME Code Section VIII Div. 1.

The activities are done in 3 stages; the activities before start of the

test, the activities during test and the activities after the test.

Click on the above link for detailed information about pressure vessel

hydro-static testing which is specifically focuses on pressure vessel

inspections.

Pressure Vessel Certification - Do you know what the pressure vessel

certification process is? How Pressure Vessel Manufacturers can be

ASME Stamp Holders? How Third Party inspection companies can be

certified by ASME and be Authorized Inspection Agencies? What is a

U Stamped Pressure Vessel?

You may know pressure vessel manufacture certification is the same

as the Authorization for the ASME Stamp.

The pressure vessel manufacturers can implement the ASME Quality

Control System and then apply for ASME Stamp.

It means that if a manufacture accredited by the ASME organization

for pressure vessel per ASME Code Section VIII Div. 1 can stamp the

letter U in the pressure vessel nameplate. These are the processes

for ASME Stamp Accreditation:

Obtain Application Forms from ASME

Sign a Service Agreement with an Authorized Inspection Agency

(AIA) - Authorized inspection Agencies are Third Party Inspection

Companies that have been accredited by the ASME organization

and their inspectors certified by the National Board Inspection

Code (NBIC).These Inspectors are named Authorized Inspectors

and hold Commission Cards issued by the NBIC

organization. Summary: AIAs are accredited by ASME, but the

inspectors are certified by NBIC.

Submit Application Forms to ASME and Transfer Fees

Purchase ASME Code Books

Describe a QC-System according to the ASME Code Quality

Control manual and have the procedures prepared by the

manufacturer.

Prepare a Demonstration Item - A representative demo pressure

vessel needs to be constructed and all drawings, calculations,

parts lists, purchase orders, material test reports, fabrications,

inspections, tests and reports should be based on the ASME code

section VIII requirement.

Qualify Procedures and Personnel - Quality Control Procedures

and Personnel also need to be approved by manufacture.

Pre-Joint Review by the Supervisor of AIA - It takes almost 4

months to fulfill the above requirements. Then an audit needs to

be conducted by a supervisor authorized inspector, which is

designated by the authorized inspection agency, which is under

contract with the manufacturer. This auditor would report non-

conformities found in the audit process, and then manufacturer

would have some time to correct them.

Joint Review (Audit) with ASME Designee, Inspector and

Supervisor - Finally the Audit would be conducted by an ASME

designated Person, Supervisor Authorized Inspector and

Authorized Inspector. That is the reason this audit is called a

joint review.

Issuance of Certificate and Stamp by ASME

If the result of the audit was satisfactory, the certificate would be

issued by ASME, and then the manufacturer would be authorized to

stamps nameplates with the U Stamp.

Click on the above link for detailed information about Pressure Vessel

Certification, which is specifically focuses on pressure vessel

inspections.

Pressure Vessel Heads - How many standard Pressure Vessel Heads

are in the ASME Code? What are their characteristics?

Ellipsoidal Head, Hemispherical Head and Torispherical Head are three

types of ASME Pressure Vessel Dished Heads.

Under the same design conditions, such as design pressure, design

temperature and material, your calculated wall thickness under

internal pressure for ellipsoidal head will be approximately equal to the

shell thickness. For a torispherical head, the thickness is equal to 1.77

times that of the ellipsoidal, and the shell thickness and for a

hemispherical head is equal to half the shell thickness.

For example, if you have calculated your shell thickness under internal

pressure and obtained 12 mm, your thickness for an ellipsoidal head

will be approximately 12 mm; for a torispherical head, 20.4 mm; and

for hemispherical head, 6 mm.

Click on the above link for detailed information about Pressure Vessel

Heads, which specifically focuses on pressure vessel inspections.

Third Party Inspection for Pressure Vessel - What is the third party

inspection requirement for pressure vessel inspection in a

manufacturing shop?

This article provides information about pressure vessel inspection from

material inspection to final inspection and dispatch to site.

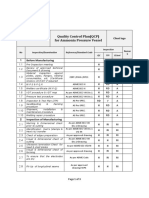

Inspection and Test Plan for Pressure Vessel - The Inspection and

testing requirement is distributed in a different part of the construction

code.

The inspection and test plan have a tabulated format and collect all

these requirements in a simple table and determine the responsibly of

each party, i.e. the manufacturer, third party inspector and purchaser.

Pressure Vessel Handbook - When there is ASME Code Section VIII,

why do we need the Pressure Vessel Handbook? What are the

applications? All design formulas and calculations methods have not

been addressed in ASME Code, and also, there are no fabrication

tolerances in ASME Code.

So the Pressure Vessel Handbook assists us in covering all these

requirements.

The Pressure Vessel Handbook supports pressure vessel inspections

engineers, designers, pressure vessel manufacturer quality control

technicians and engineers, and any other people who deal with

pressure vessels.

Click on the above link for detailed information about the Pressure

Vessel Handbook, which specifically focuses on pressure vessel

inspection.

Spherical Pressure Vessel - What is the construction Code for a

Spherical Pressure Vessel? What is the In-Service Code for Spherical

Pressure Vessel? What are the Spherical Vessel applications? What are

the advantages?

Click on the above link to see the answer to the above questions,

which is specifically focuses on pressure vessel inspections.

- See more at: http://www.inspection-for-industry.com/pressure-vessel-

inspections.html#sthash.7WN5t20v.dpuf

Third Party Inspection for Pressure Vessel

The Third Party Inspection for Pressure Vessel article provides you with

information about pressure vessel inspection and pressure vessel

testing in the manufacturing shop.

Global TPI Services

We Provide Pre-Shipment Inspection, Vendor Inspection and Commodity Inspection Services. Click

Here for More Information

You may need to review this article in conjunction with the following

articles:

Pressure vessel Inspections

Inspection and Test Plan for Pressure Vessel

This content guides you through all the necessary stages in the production of the

pressure vessels, including the raw material, final inspection, preservation and

packing, and dispatch to site.

You need to take this point into account: this article is written for a typical

pressure vessel and might not be detailed for special cases.

This content may be useful for second party inspectors, pressure vessel

manufacturer quality control personnel, engineering companies, and purchasers,

as well.

You may also note that if a pressure vessel is ordered with a U Stamp,

then any Third Party Inspection Agency cannot do the inspection, and

an authorized third party ASME inspection needs to be hired. This also

called third party inspection for U stamp.

The authorized third party inspection agencies must be insurance

company and accreditation by ASME.

All pressure vessel inspection and testing is done against the approved

drawings, purchase order specifications, purchasers or company standards, and

within the practices and rules of the country, state or province and any

government decrees, laws, ordinance or regulation as may apply.

The applicable codes and specifications for a pressure vessel that is under the

construction process is:

Design code

Purchase order specification

Purchaser's standards

Approved drawings

And the applicable codes and standard are:

ASME VIII Division 1 or 2

ASME V

ASME IX

The applicable codes and standard may be based other international

standards such as BS 5500, etc. This content is general and can be

useful if even the design code is different from ASME Code.

Third Party Inspection for Pressure Vessel - Required

Documents for Third Party Inspector Review:

The list of documents normally is agreed upon in the Pre-Inspection meeting,

which is held several weeks before the actual commencement of the inspection

work.

The parties that participate in this meeting are the manufacturer, purchaser and

third party inspection agency representatives.

This already explained in the Inspection and Test Plan for Pressure

Vessel article.

These are the list of documents which are normally agreed to be

presented to the inspector:

Pressure Vessel Manufacture Quality Control Plan

Pressure Vessel Inspection and Test Plan

Pressure Vessel Data Sheet

Pressure Vessel Approved Drawings

Pressure Vessel Strength Calculation Sheets

Pressure Vessel Material Test Reports

Pressure Vessel Welding Specification Procedures (WPS) and Procedure Qualification

Records(PQR)

Pressure Vessel Welding Map

Pressure Vessel Welders Qualifications Reports

Pressure Vessel NDE Procedures (Radiography, Ultrasonic, Magnetic Particle, Dye

Penetration, etc.)

Pressure Vessel NDE Personnel Qualifications Reports

Pressure Vessel Heat Treatment Procedure

Pressure Vessel Calibration Certificates for Test Equipment

Pressure Vessel Hydrostatic Testing Procedure and Water Quality Document

Pressure Vessel Preparation and Painting Procedure

Pressure Vessel Preservation, Packing and Shipping Procedure

Pressure Vessel Packing List

Third Party Inspection for Pressure Vessel - Material Inspection

The first actual inspection work on the pressure vessel is the raw

materials inspection. Based on the ASME Code, providing material test

reports for pressure vessel plates is mandatory. For other components,

the marking inspection will be enough.

But if the purchase order has mandated the MTR to be provided for all

components, such as nozzle pipes, fittings, etc., then the manufacturer

needs to provide them as well.

For more details, you may review the Pressure Vessel Plate article.

As mentioned above, the original or authenticated copies of mill

certificates for plates normally are available at the manufacturer's

premises.

The third party inspector examines these certificates for compliance

with specifications, and where appropriate, drawings.

The review includes checks on:

Certificate No.

Heat or Cast No.

Chemical Composition.

Mechanical Properties.

Heat Treated Condition.

NDE Applied and Results.

Then the inspector witnesses the plate material identification on the

certificates against the plate marking. It is also necessary to check the

identification with the pressure vessel drawing datasheet, material list

and other specifications as appropriate.

The transfer identification to cut off plates also is checked.

Visual inspections for surface finish and probable defects are done and

dimensional compliance with specification also needs to be controlled.

For more detail about pressure vessel raw material inspection, you

may review the Pressure Vessel Dimension Inspection article.

When the third party inspector carries out the material inspection, then provides

the inspection visit report (IVR), the report contains the following items:

Confirmation of satisfactory document review

Record of the endorsement of certification reviewed/witnessed

Record of all non-conformities

Record of any tests witnessed and the result

Third Party Inspection for Pressure Vessel - Fabrication

When the pressure vessel raw material inspection is carried out, and the results

were satisfactory or non-conformities were closed by remedial action, then the

pressure vessel manufacturer will start fabrication.

The third party inspector checks the following points on the pressure vessel,

based on the inspection and test plan (ITP), which has already been agreed

upon between the purchaser and the pressure vessel manufacturer.

The inspection scope is determined in the ITP. Some purchasers prefer to have

stringent controls and assign the TPI for more hold or witness points for

inspection and test activities, and some others prefer less hold or witness points

and assign the TPI much more work in the review document.

This depends in the inspection budget, which purchasers assign for inspection.

Much more inspection will have a much larger cost and less risk, and conversely,

less inspection will have less cost but more risks.

We Provide TPI Inspection Services in Most Industrial Areas Around

the Globe. Click Here for More Information

For more detail, review the Inspection and Test Plan for Pressure

Vessel article. There is a draft of the ITP in this article, which we believe is the

best practice for pressure vessel inspection.

Third Party Inspection for Pressure Vessel - Preparation for

Welding

The third party inspector carries out the visual and dimensional check

to ensure compliance with WPS and other specifications. Where

specified, weld bevels are examined by the required code method after

grinding/machining.

It is necessary that the edges and weld bevels are clean, dry and free

from surface defects, laminations, cracks, voids, notches, etc.

They are causes for rejection unless suitable/satisfactory remedial

action can be taken.

Weld repairs are carried out in accordance with the code requirements

and approved by the client before welding proceeds and serious or

excessive defects normally are reported.

If the third party inspector is not in the hold or witness point in the ITP for this

inspection stage, then he/she will review the pressure vessel manufacturer

quality control report in his/her coming visit or on the final inspection day.

Third Party Inspection for Pressure Vessel - Fit-Up Inspection

Shapes and dimensions are checked in accordance with the approved

WPS and drawing.

Tack welds are produced using the applicable WPS conditions, and it is

necessary to be visually free from defects.

Magnetic Testing (MT) or Penetration Testing (PT) may be performed

in accordance with the code requirement.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Monitoring of Weld

Conditions

The third party inspector controls preheat heat temperature and

method, interpass temperatures, weld material control, welder and

process qualifications for conformity to the code requirements.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Back Gouging

Inspection

The third party inspector controls the shape and dimensions of the

back gouged groove for conformity to the WPS requirement.

It is necessary that the visual appearance is clean and free from

defects. NDE examination is done in accordance with the code

requirement.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Post Weld

Inspection

After completion of all welding and grinding operations, a visual

examination confirms there are no harmful defects such as cracks, lack

of fusion, surface porosity or exposed slag inclusions, incomplete

penetration, incorrect profile of the weld, lack of leg length and

overlap.

Temporary attachments are removed, ground smooth, and the areas

are checked for defects by MP or PT for defects.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Non-Destructive

Examination

NDE is performed by qualified personnel by the approved techniques.

The techniques available are dependent on the vessel classification and

the materials used.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

For more detail, review the following articles:

ASME Pressure Vessel Joint Efficiencies

Pressure Vessel RT test

Third Party Inspection for Pressure Vessel - Weld Repair

The pressure vessel weld repairs are completed using an approved

WPS method and retested accordingly.

It is necessary that all repairs are approved before any post weld heat

treatment is carried out.

Third Party Inspection for Pressure Vessel - Post Weld Heat

Treatment

The third party inspector reviews the post weld heat treatment record

of the temperature and time in accordance with the approved

code/procedure.

The results of hardness tests are reviewed in accordance with the code

requirements.

Third Party Inspection for Pressure Vessel - Dimensional

Measurement and Visual Inspection

The third party inspector checks all major dimensions and that the

position/orientation of attachments are in accordance with the code

requirements.

For more details, review the Pressure vessel Dimension

Inspection article.

In addition, a full visual examination of both inside (where practicable)

and outside surfaces of the vessel is completed by the third party

inspector.

Particular attention is paid to the cleanliness of the interior of the

vessel, the condition/appearance of welds and associated areas, and

the condition of the sealing faces.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Pneumatic Test

The third party inspector witnesses the low pressure pneumatic test

for nozzle reinforcing pads, support saddles or other attachments

when specified by approved low pressure pneumatic test procedure

using soapy water as the indicating medium.

A minimum of 1 gauge with correct working ranges as described by

the code is used.

Similarly, If the third party inspector is not in the hold or witness point in the ITP

for this inspection stage, then he/she will review the pressure vessel

manufacturer quality control report in his/her coming visit or on the final

inspection day.

Third Party Inspection for Pressure Vessel - Hydro-static

Testing

The third party inspector controls the following items for Hydro-static

Testing:

Calibration status and correct working ranges of gauges. A

minimum of 2 pressure gauges are attached to each item under

testing.

Adequate provision for venting of high points and draining is

provided.

Test pressure is applied as directed by procedure or code until

the testing limit pressure is reached. During hold period, a

methodical check for leaks is conducted.

Test pressures, metal and water temperatures are recorded.

Water quality is as specified.

We Provide TPI Inspection Services in Most Industrial Areas Around

the Globe. Click Here for More Information

Special requirements of the purchaser's specification for deflection or

strain gauges or pressure/time/temperature recordings are examined

by the inspector and the records are verified.

For more detail in hydro-static testing, review the Vessel Pressure

Testing article.

Third Party Inspection for Pressure Vessel - Final Inspection

After hydrostatic testing, the vessel is thoroughly drained and dried

out by approved methods. All internal fittings, attachments, coatings

or other requirements need to be completed.

The specified post hydrostatic test NDE needs to be completed and the

vessel closed.

All pressure vessels are checked for cleanliness and dryness by an

approved method.

The third party inspector rechecks the nozzle, saddle and bracket

locations and orientations against the assembly drawings.

Third Party Inspection for Pressure Vessel - Name Plate

The content of the marking is checked in accordance with the

approved drawing and specifications by the third party inspector.

Third Party Inspection for Pressure Vessel - Painting and

Coating Inspection

Surface preparation for painting is checked for the following points,

according to specification by the third party inspector:

Cleaning method (Blast or scraping and wire brushing)

Preparation grades

Freedom from weld spatter, blow-holes and other defects

Dry film thickness is checked according to specification

Surface condition needs to be free from pin-holes, runs damage and

other discontinuity

Third Party Inspection for Pressure Vessel - Spares and

Accessories

The third party inspector controls spares, tools and accessories and

makes visual and dimensional inspection for materials, workmanship

and quantity according to the purchase order specification and packing

list.

The marking and/or tag is checked for identification.

Third Party Inspection for Pressure Vessel - Pressure Vessel

Reporting

The third party inspector provides an Inspection Visit Report (IVR) after each

visit, as well as a final report summarizing the activities carried out during the

pressure vessel production in accordance with the contract requirements and

circulated within the time limits specified in the contract.

The report is in the format required by the client and clearly indicates final

acceptance or rejection of the pressure vessel.

Third Party Inspection for Pressure Vessel - Pressure Vessel

Release Note

When required by the contract or purchase order, a release note is issued by the

third party inspection agency and given to the manufacturer when the pressure

vessels have been accepted.

Third Party Inspection for Pressure Vessel - Packing, Marking

and Shipping

The following points are checked by the third party inspector:

Cleanliness and dryness of pressure vessels

Rust prevention for all machined surfaces

Protection for cover for all opening and protruding parts

Packing style and suitably for overseas transportation

Shipping marks and other markings and notification of welding prohibited,

etc.

Where nitrogen purge is specified the gas pressure is checked and the

presence of warning notices checked.

Third Party Inspection for Pressure Vessel - Pressure Vessel

Final Book (Dossier)

The following final documents are reviewed and signed off by the third

party inspector:

As built, drawings if required, Manufacturer's data reports, Material

certificate or certified mill test reports for all pressure parts, Material

list or map, Welder record for each seam or map, Heat treatment

records (Temperature-time record chart during PWHT), Dimensional

record, NDE records, Production test record/mock test record, Alloy

verification records, (if required), hydrostatic test record, Pneumatic

test record, Hardness test record, Post weld heat treatment NDE, if

specified, Name plate or other marks, Packing list, Spare parts and

tool list

- See more at: http://www.inspection-for-industry.com/third-party-inspection-for-

pressure-vessel.html#sthash.E3fNNIos.dpuf

Pressure Vessel Handbook

The Pressure Vessel Handbook article provides you information about

handbook application in pressure vessel design and pressure vessel

inspection.

When there is ASME Code Section VIII, why we need Handbook? What

are the applications?

All design formulas and calculations methods have not been addressed

in ASME Code and also there are no fabrication tolerances in ASME

Code.

So handbook assists us to cover all these requirements.

The Pressure Vessel handbook supports pressure vessel designers,

pressure vessel manufacturer quality control technicians and

engineers, third party inspectors and any other dealing persons with

pressure vessels.

What is the Application of Pressure Vessel Handbook?

1. Non-Covered ASME Code Section VIII Design Formula and

Methods

You may review ASME Code Section VIII Div. 1 in U2 (g) clauses, you

will see following statement:

This Division of Section VIII does not contain rules to cover all details

of design and construction. Where complete details are not given, it is

intended that the Manufacturer, subject to the acceptance of the

Inspector, shall provide details of design and construction which will be

as safe as those provided by the rules of this Division.

So the manufacture is responsible for non-covered item in design

process, but what reference manufactures need to use for these kinds

of cases.

Here is the place manufactures use handbook for design formulas and

calculations.

The lists of non-covered design details have been addressed in UG-22

clauses; the code says the manufacturer need to consider following

loading in his design:

Weight of the vessel

Superimposed static reactions from weight of attached

equipment

Cyclic and dynamic reactions

Wind, snow, and seismic reactions

etc.

Above items are examples, for design calculation manufactures need

to use Press. Vessel Handbook.

2. Non-Covered Construction Tolerances

You may review ASME Code Forward, you will see following statement:

The Code does not fully address tolerances. When dimensions, sizes,

or other parameters are not specified with tolerances, the values of

these parameters are considered nominal and allowable tolerances or

local variances may be considered acceptable when based on

engineering judgment and standard practices as determined by the

designer.

So what is the reference book for these tolerances, here is another

application of pressure vessel handbook.

Some of these construction tolerances are :

Nozzles and attachment deflection tolerances

Nozzles and attachment orientation tolerances

Nozzles and attachment elevation tolerances

Nozzles and attachment projection tolerances

Overall length, measured between the tangents lines tolerances

etc.

3. Facilitate Design Calculation

You may review following statements in ASME Code Forward:

It is not intended that this Section be used as a design handbook

And in other place says:

The Code is not a handbook and cannot replace education,

experience, and the use of engineering judgment.

So the code book is like law book, we need take care about specific

prohibitions and mandatory requirement but for design we need

handbook to facilitate our design process.

The aim of your handbook is to be easily handled and consulted. Some

tables and charts eliminate the necessity for calculations.

- See more at: http://www.inspection-for-industry.com/pressure-vessel-

handbook.html#sthash.jqf8VDvB.dpuf

Spherical Pressure Vessel

The Spherical Pressure Vessel article provides you with information

about this vessels characteristics and related points for the pressure

vessel inspection.

What is construction code for spherical pressure vessel? What is In-

Service code for spherical vessel? What are the applications? What are

the advantages?

This article either provides you the answers of your questions or refers

you to the specific sources.

What is the Difference Between the Design Formula of a

Cylindrical Shell and a Spherical Shell?

In the same design condition with the same design pressure, design

temperature and material, the thickness you obtain from the internal

pressure formula for spherical pressure vessel will be half that of the

cylindrical pressure vessel.

The design formula for the cylindrical shell is t = PR/ (SE-0.6P) and for

the spherical shell is t = PR/ (2SE-0.2P)

When the t is represent Thickness, R the Inside Radius, S the

Allowable Stress, P the Design Pressure and E the Joint Efficiency;

For example, if your design pressure is 250 psi, inside radius 20 inch. ,

allowable stress 20,000 psi and joint efficiency 1.

Your thickness for cylindrical shell will be 0.24 inch. or 6.10 mm, and

for the spherical shell, it will be 0.125 inch. or 3.175 mm.

What is the Application and Advantage of a Spherical Pressure

Vessel?

When you need to make storage for a great amount of pressurized

liquid or gas, meaning you need a big volume, then you need a big

pressure vessel, so a spherical shell pressure vessel would be more

economical.

As you see above, the thickness is half that for a similar design

condition. Also placing a long cylindrical pressure vessel might not be

suitable in regards to the regarding plant layout.

What is the Disadvantage of a Spherical Pressure Vessel?

Spherical shell pressure vessels are more expensive than cylindrical

pressure vessels to fabricate, and this higher price is only justifiable

for large vessels.

What is Difference in Fabrication Method Between Cylindrical

and Spherical Shell Pressure Vessel?

Cylindrical shell pressure vessels generally are built in the shop and

then transferred to the plant field except for long process towers,

which might be built in two pieces and completed in the field by one

circumferential weld.

This is only because of the facilitating shipping process.

But spherical shell pressure vessels are assembled in the field. The

plates generally are formed in the rolling shop and then carefully

transferred to the field for assembly.

What is the Difference in the Post Weld Heat Treatment

(PWHT) Process?

If PWHT is a code or process requirement, the PWHT for cylindrical

shell pressure vessels generally are done in the furnace, and if the

vessel is too long, it is done in two heating process with a 5 ft.

overlap.

But PWHT for spherical shell pressure vessels are done by one or more

high velocity burners that are fired into the vessel using the top or

bottom manways (or both) as burner entry and exhaust positions.

This is done because using a PWHT furnace is not possible.

What Kinds of Materials are Stored in a Spherical Pressure

Vessel?

Most of the LNG (Liquid Natural Gas) and LPG (Liquid Petroleum Gas)

tanks are Spherical Vessels.

Butane, Propane, Ammonia, oxygen, hydrogen and nitrogen also are

stored in spherical vessels.

What are the In-Service Inspection Requirements for Spherical

Shell Pressure Vessels?

In-service inspection requirements are similar to those for the

cylindrical pressure vessel and are based on the requirement of the

API STD 510 Standard.

Some important points about in-service inspection are:

The inspection plan needs to be developed for the vessels, and

generally, internal inspection is a mandatory requirement.

You need to do internal inspection in intervals not exceeding one half

of the remaining life, or 10 years, whichever is less.

You can calculate the remaining life with the following simple formula:

RL = (Tc-Tmin)/CR ;

When Tc is Actual Thickness, and Tmin is Minimum Required

Thickness, it is can be obtained by the deduction of nominal thickness

from corrosion allowance, and CR is corrosion rate.

Example: you have a spherical shell storage vessel with an actual

thickness of 1.121 in., and the minimum required thickness is 1.0 and

the corrosion rate is 0.005 in./year, so the reaming life will be:

(1.121-1.0)/0.005 = 24.2 years;

So the internal inspection interval will be:

Half-life = 24.2/2 = 12.1, so 10<12.1, then the internal inspection

interval will be 10 years.

But in most plants, evacuation of storage vessels is very difficult and

costly, so integrity engineers try to find a new technique to replace

internal inspection.

API STD 510 allows the On-Stream inspection to be replaced with the

internal inspection with some conditions.

This is the definition of On-Stream Inspection per the API 510

Standard:

An inspection performed from the outside of a pressure vessel while it

is on-stream using NDE procedures to establish the suitability of the

pressure boundary for continued operation.

But only you may replace this technique if all of following conditions

are met with your vessel:

The general corrosion rate is less than 0.005 inch. per year, remaining

life is greater than 10 years, there is no corrosive character in the

contents, no questionable condition is observed in the External

inspection and the vessel is not subject to SCC cracking.

What is the Best Technique to Use as On-Stream Inspection?

The best technique, which is widely used, is acoustic emission testing.

In this technique, the spherical vessel is completely filled by content

fluid to maximize stresses.

Meanwhile highly-sensitive proprietary acoustic sensors are attached

to the vessel wall to detect the fracture of corrosion products during

the monitoring period.

The suspect areas are identified and located. If the suspect shows a

high risk issue, then the vessel would be evacuated for internal

inspection and necessary repairs.

What are the Repair Methods for a Spherical Shell Pressure

Vessel?

There are three sources for repair of a spherical pressure vessel; API

STD 510 has provided some repair requirements and instructions.

Based the API 510, only repair organizations are allowed to do repairs,

and the definition and condition for being a repair organization has

been provided in the API 510.

The other source is the ASME-PCC-2, which provides you detailed

instructions and requirements.

The other source is the NBIC Part 3 Code book, which similarly

provides requirements and instructions.

Please note if your spherical pressure vessel is a U or U2 stamped

pressure vessel, only repair organizations that are R stamp holders

from NBIC are allowed to do repair on your vessel.

For more detail on the stamped pressure vessel, review the Pressure

Vessel Certification article.

- See more at: http://www.inspection-for-industry.com/spherical-pressure-

vessel.html#sthash.RspU0AVi.dpuf

Inspection and Test Plan for Pressure Vessel

The inspection and test plan for pressure vessel article provides you

information about pressure vessel inspection and pressure vessel test

in manufacturing shop. The draft Inspection and test plan for pressure vessel

provided as well.

Click here if you like immediately review the Inspection & Test Plan for

Pressure Vessel draft sheet.

You may need to review this article in conjunction of following articles:

Pressure Vessel Inspections

Third Party Inspection for Pressure Vessel

The ASME Code Section VIII Div. 1 or 2 requirements normally are applied

for inspection and test plan in pressure vessel manufacturing shop.

The witness of some inspection and test by third party inspector or

authorized inspector is mandatory and cannot be waived.

Global TPI Services

We Provide Pre-Shipment Inspection, Vendor Inspection and Commodity Inspection Services. Click

Here for More Information

Some others can only monitored and fully witnessing are not necessary, for

these items, the inspection man-days etc. depends to the purchaser

decision, some prefer stringent monitoring and even assign resident

inspector in pressure vessel manufacturing shop and some others relay to

quality control system of the pressure vessel manufacture and assign only

few days for monitoring points.

These are some of inspection points which need to be witnessed, checked

monitored and reviewed by third party or ASME authorized inspector.

Inspection and Test Plan for Pressure Vessel - Important Points

All plates need to be identified against mill test certificates at the

Vendonr`s works before commencement of fabrication.

Ensuring that welding procedure and welders are qualified and

welding electrodes are approved before commencement of

fabrication.

Selection of location for spot radiography

Reviewing of radiographs

Witnessing of hydrostatic test

Dimensionally checking and carrying out final internal and

external inspection for quality of workmanship.

Checking that all material test certificates and, where applicable,

heat treatment charts are in order

If specified witnessing any crack detection, hardness checks,

ultrasonic tests etc.

Checking fit-up and chipping-back of welded seams.

Monitoring welding process based WPS

Monitoring all NDE activities

Ensuring that Vendor is familiar with the requirements regarding

data books and ensure that the documentation is submitted

without any delay.

Checking internal lining of reactors and vessels (if applicable) to

specifications.

Checking trays of each diameter and type, mock assembled in

the shop. (for process towers)

Checking for interchangeability of parts, where applicable for

process towers

Ensuring that any uncommon down comers are fully assembled

and offered along with their respective trays. (for process

towers)

- See more at: http://www.inspection-for-industry.com/inspection-and-test-plan-for-

pressure-vessel.html#sthash.RAR0QhZk.dpuf

Anda mungkin juga menyukai

- Pressure Vessel Inspection and DesignDokumen48 halamanPressure Vessel Inspection and DesignMohammed Raje100% (2)

- ASME Pressure Vessel Joint EfficienciesDokumen4 halamanASME Pressure Vessel Joint EfficienciesliamcsBelum ada peringkat

- Inspection and Test Plan For Pressure VesselDokumen2 halamanInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Pressure Vessel Plate RequirementsDokumen71 halamanPressure Vessel Plate RequirementsVILLANUEVA_DANIEL2064100% (2)

- Pressure Vessel Inspection 01Dokumen9 halamanPressure Vessel Inspection 01Bhavani PrasadBelum ada peringkat

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsDari EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsPenilaian: 4 dari 5 bintang4/5 (12)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersDari EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersPenilaian: 3.5 dari 5 bintang3.5/5 (19)

- Pressure Vessel InspectionDokumen44 halamanPressure Vessel Inspectionأحمد صبحى100% (4)

- ASME Pressure Vessel Certification Process for ManufacturersDokumen4 halamanASME Pressure Vessel Certification Process for ManufacturersalokbdasBelum ada peringkat

- Owner-User Pressure Equipment Integrity ManagementDokumen43 halamanOwner-User Pressure Equipment Integrity ManagementInspection EngineerBelum ada peringkat

- Onshore Regeneration Gas Subcooler Internal Inspection ProcedureDokumen16 halamanOnshore Regeneration Gas Subcooler Internal Inspection Procedurekptl6185Belum ada peringkat

- Occidental Oil and Gas pressure vessel inspectionDokumen17 halamanOccidental Oil and Gas pressure vessel inspectionedwinsazzzBelum ada peringkat

- Pressure Vessel Fabrication, Testing, and Inspection StandardsDokumen70 halamanPressure Vessel Fabrication, Testing, and Inspection Standardsjishnunelliparambil100% (1)

- Pressure Vessel Dimension InspectionDokumen12 halamanPressure Vessel Dimension Inspectionalokbdas100% (3)

- PNEUMATIC TESTDokumen2 halamanPNEUMATIC TESTdyke_engg50% (2)

- TPI For Pressure VesselDokumen10 halamanTPI For Pressure VesselBhavani Prasad100% (2)

- Pressure Vessel Inspection Procedure Rev.2Dokumen24 halamanPressure Vessel Inspection Procedure Rev.2Ariq Fauzan100% (7)

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDokumen3 halamanQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Pressure VesselDokumen80 halamanPressure Vesselkart_rl75% (4)

- Pressure Vessel Fabrication InspectionDokumen82 halamanPressure Vessel Fabrication InspectionHrishikesan100% (3)

- PSV TestingDokumen26 halamanPSV Testingmanoj thakkar100% (1)

- Inspection of Unfired Pressure VesselsDokumen35 halamanInspection of Unfired Pressure Vesselstbmari100% (7)

- SBU-Quality Services Valves Inspection GuideDokumen85 halamanSBU-Quality Services Valves Inspection GuideAnand Kesarkar86% (7)

- Pressure Vessel Repair ProcedureDokumen7 halamanPressure Vessel Repair ProcedureAndy UgohBelum ada peringkat

- Visual Inspection of Tanks & Pressure VesselsDokumen29 halamanVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- Maintenanc and Repair of Pressure VesselsDokumen93 halamanMaintenanc and Repair of Pressure VesselsVimin Prakash100% (12)

- Introduction To Pressure VesselsDokumen52 halamanIntroduction To Pressure VesselsAkankshya Mishra100% (4)

- Maintenance and Repair of Pressure VesselsDokumen81 halamanMaintenance and Repair of Pressure Vesselsjishnunelliparambil100% (3)

- Welding Inspection Pressure VesselDokumen37 halamanWelding Inspection Pressure Vesselken100% (3)

- Vessel Inspection ProcedureDokumen16 halamanVessel Inspection Proceduremahmoud_elnaggar_5100% (2)

- API 598 Testing Procedure-20130720-032647Dokumen2 halamanAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- Piping Inspect & Testing ProcedureDokumen11 halamanPiping Inspect & Testing ProcedureErlanggaBonaparteBelum ada peringkat

- Fabrication of Pressure Vessels PDFDokumen2 halamanFabrication of Pressure Vessels PDFRachel0% (1)

- PIPING PNEUMATIC TEST PROCEDUREDokumen2 halamanPIPING PNEUMATIC TEST PROCEDUREruzla67% (3)

- API 510 PREPARATION CLASSDokumen162 halamanAPI 510 PREPARATION CLASSAli Ahmed100% (3)

- Itp VesselDokumen4 halamanItp VesselHakim BaihaqiBelum ada peringkat

- API 510 PV Inspection ChecklistDokumen9 halamanAPI 510 PV Inspection ChecklistSreekumar SBelum ada peringkat

- SGS Oil, Gas & Chemical Services Provides Tank Calibration Using ORLM TechniqueDokumen5 halamanSGS Oil, Gas & Chemical Services Provides Tank Calibration Using ORLM TechniqueJahidul Islam100% (1)

- API 510 External Inspection ChecklistDokumen3 halamanAPI 510 External Inspection ChecklistMetallurgist007100% (3)

- Inspection and Testing Plan for Pressure VesselDokumen6 halamanInspection and Testing Plan for Pressure Vesselmuhammad afrizalBelum ada peringkat

- Heat Exchanger InspectionDokumen7 halamanHeat Exchanger InspectionHamid Albashir100% (1)

- Inspection of Unfired Pressure Vessel Std-128Dokumen34 halamanInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- Summary of ASME Section VIIIDokumen3 halamanSummary of ASME Section VIIIAMALENDU PAUL100% (2)

- Third Party Inspection For Storage TankDokumen8 halamanThird Party Inspection For Storage TankGeroldo 'Rollie' L. QuerijeroBelum ada peringkat

- Mawp and MDMT Calculations PDFDokumen5 halamanMawp and MDMT Calculations PDFobuse100% (7)

- API 572 Inspection of Pressure VesselsDokumen14 halamanAPI 572 Inspection of Pressure VesselsTahseen JwadBelum ada peringkat

- ASME Section VIII Pressure Vessel Quality ManualDokumen51 halamanASME Section VIII Pressure Vessel Quality ManualNguyen Duc Dung75% (4)

- Piping External Visual Inspection ProcedureDokumen3 halamanPiping External Visual Inspection Procedurecamasa2011100% (1)

- 静设备英文 Static Equipment Installation ProcedureDokumen6 halaman静设备英文 Static Equipment Installation Procedurejie100% (4)

- Piping QuestionsDokumen13 halamanPiping QuestionsMani KantaBelum ada peringkat

- Hydrotest & Pneumatic TestDokumen3 halamanHydrotest & Pneumatic TestjokishBelum ada peringkat

- Asset Integrity Management A Complete Guide - 2020 EditionDari EverandAsset Integrity Management A Complete Guide - 2020 EditionBelum ada peringkat

- Corrosion - ControlDokumen10 halamanCorrosion - ControlJithin FrancizBelum ada peringkat

- Pressure Vessel InspectionsDokumen8 halamanPressure Vessel InspectionsCepi Sindang KamulanBelum ada peringkat

- Pressure Vessel RT Test RequirementsDokumen3 halamanPressure Vessel RT Test RequirementsYetkin Erdoğan100% (1)

- Pressure Vessel InspectionsDokumen41 halamanPressure Vessel InspectionsJJBelum ada peringkat

- Pressure Vessel RT TestDokumen4 halamanPressure Vessel RT TestalokbdasBelum ada peringkat

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDokumen9 halamanASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplBelum ada peringkat

- ASME Sec VIII the most common code for oil & gas pressure vesselsDokumen14 halamanASME Sec VIII the most common code for oil & gas pressure vesselsShieeplBelum ada peringkat

- ASME Sec VIII the most common code for oil & gas pressure vesselsDokumen13 halamanASME Sec VIII the most common code for oil & gas pressure vesselsShieeplBelum ada peringkat

- Welding Requirements: Suggestions For Welding Stainless SteelDokumen7 halamanWelding Requirements: Suggestions For Welding Stainless SteelStephanie WebbBelum ada peringkat

- Types Vgof Reheating FurnacesDokumen5 halamanTypes Vgof Reheating FurnacesNiladri BhattacharyyaBelum ada peringkat

- Profile Format Niladri BhattacharyyaDokumen2 halamanProfile Format Niladri BhattacharyyaStephanie WebbBelum ada peringkat

- FiltrationDokumen18 halamanFiltrationStephanie WebbBelum ada peringkat

- Inergen Sizing CalculationDokumen3 halamanInergen Sizing CalculationStephanie Webb0% (1)

- Inergen Sizing CalculationDokumen3 halamanInergen Sizing CalculationStephanie Webb0% (1)

- NFPADokumen1 halamanNFPAStephanie WebbBelum ada peringkat

- Blueprints 3 - Booleans: Unreal 4Dokumen2 halamanBlueprints 3 - Booleans: Unreal 4Janice RinBelum ada peringkat

- 07-Onboarding FunnelDokumen4 halaman07-Onboarding FunnelmirzynomiBelum ada peringkat

- Experiment No. 5 Demonstration of Continuity Equation: I. ObjectivesDokumen5 halamanExperiment No. 5 Demonstration of Continuity Equation: I. ObjectivesMark B. Barroga100% (1)

- Circular Singly Linked List: Data Structures Using C Satish 8886503423Dokumen32 halamanCircular Singly Linked List: Data Structures Using C Satish 8886503423Singanamalla jyoshnaBelum ada peringkat

- Pruebas y Ajustes r1300GDokumen21 halamanPruebas y Ajustes r1300GYersonBelum ada peringkat

- Transient AnalysisDokumen19 halamanTransient AnalysisjoselosabeloBelum ada peringkat

- TP672P 330-350W poly moduleDokumen2 halamanTP672P 330-350W poly moduleAchrafSaadaouiBelum ada peringkat

- AQUALERT 6051 Hardness Analyze RDokumen2 halamanAQUALERT 6051 Hardness Analyze RSarmiento HerminioBelum ada peringkat

- Aruba ClearPass Essentials, Rev. 20.11Dokumen3 halamanAruba ClearPass Essentials, Rev. 20.11ru4angelBelum ada peringkat

- Ship Design Vents GuideDokumen3 halamanShip Design Vents GuideghadirsarkisBelum ada peringkat

- Systematic Review For AI-based Language Learning Tools: Jin Ha Woo Heeyoul ChoiDokumen10 halamanSystematic Review For AI-based Language Learning Tools: Jin Ha Woo Heeyoul ChoiAgron TeliBelum ada peringkat

- Hotel Management System: Minor Project Sem - V BCADokumen8 halamanHotel Management System: Minor Project Sem - V BCABaba BakchodBelum ada peringkat

- Technical-Vocational-Livelihood Computer Systems Servicing NC Ii Quarter 3 - Module 3Dokumen13 halamanTechnical-Vocational-Livelihood Computer Systems Servicing NC Ii Quarter 3 - Module 3Avigail Valeza-PadillaBelum ada peringkat

- 5c2097a335af3a7484d625ac - Sara Sae BOP Accumulators - ManifoldsDokumen14 halaman5c2097a335af3a7484d625ac - Sara Sae BOP Accumulators - ManifoldsMuthia AstriBelum ada peringkat

- OOC Super Important TieDokumen3 halamanOOC Super Important TiePrajval KpBelum ada peringkat

- General Operating-Instructions-DXC V1.1 200810 ENDokumen36 halamanGeneral Operating-Instructions-DXC V1.1 200810 ENWarBelum ada peringkat

- EagleBurgmann - E06092 - E2 - Mechanical Seals For Sorters - 03.11Dokumen2 halamanEagleBurgmann - E06092 - E2 - Mechanical Seals For Sorters - 03.11munhBelum ada peringkat

- Quantitative Economics with Julia SetupDokumen1.174 halamanQuantitative Economics with Julia SetupNasuoBelum ada peringkat

- Manpower Requisition Form - EngineerDokumen2 halamanManpower Requisition Form - EngineerYatendra TyagiBelum ada peringkat

- Scope of Work in GIS Sub StationDokumen63 halamanScope of Work in GIS Sub StationsparkCEBelum ada peringkat

- Artificial Intelligence For BusinessDokumen103 halamanArtificial Intelligence For Businesssachjithm1Belum ada peringkat

- CanecoBT INST101 ENGDokumen1 halamanCanecoBT INST101 ENGThomas ShelbyBelum ada peringkat

- Unearthing of Medicinal Plants Using Deep LearningDokumen7 halamanUnearthing of Medicinal Plants Using Deep LearningIJRASETPublicationsBelum ada peringkat

- (Ais) ReviewerDokumen12 halaman(Ais) Reviewerphia triesBelum ada peringkat

- Introduction To Biostatistics - Lecture 1 - Introduction and DescrDokumen49 halamanIntroduction To Biostatistics - Lecture 1 - Introduction and DescrFawaz Nasser AL-HeibshyBelum ada peringkat

- CS 1 - HirarcDokumen28 halamanCS 1 - HirarcMd EliasBelum ada peringkat

- Duze Cooling and Fire Extinguishing Systems For Tanks - EnglishDokumen18 halamanDuze Cooling and Fire Extinguishing Systems For Tanks - EnglishstroiebogdanBelum ada peringkat

- Affinity Service Manual Rev7Dokumen235 halamanAffinity Service Manual Rev7Ákos Lengyel100% (1)

- Non Regular Residents Registration For Tax PurposesDokumen9 halamanNon Regular Residents Registration For Tax Purposesno name isBelum ada peringkat

- Therblig Chart (17 MotionsDokumen10 halamanTherblig Chart (17 MotionsMarianne Tajanlangit BebitBelum ada peringkat