Dropwise and Fimwise Condensation Lab Report

Diunggah oleh

cocodave100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

9K tayangan1 halamanFilmwise and Dropwise are 2 forms of condensation. In filmwise condensation a laminar film of vapour is created upon a surface. This film can then flow downwards, increasing in thickness as additional vapour is picked up along the way (1). In dropwise condensation vapour droplets form at an acute angle to a surface (1). These droplets then flow downwards, accumulating static droplets below them along the way. The first objective of this experiment is to investigate the difference in heat flux between the 2 forms of condensation for the same set of conditions. The second objective is to investigate what effect the presence of air in the condenser has on the heat flux and surface heat transfer coefficient. This experiment would be used in by any industry which is trying to increase the efficiency of heat transfer.

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniFilmwise and Dropwise are 2 forms of condensation. In filmwise condensation a laminar film of vapour is created upon a surface. This film can then flow downwards, increasing in thickness as additional vapour is picked up along the way (1). In dropwise condensation vapour droplets form at an acute angle to a surface (1). These droplets then flow downwards, accumulating static droplets below them along the way. The first objective of this experiment is to investigate the difference in heat flux between the 2 forms of condensation for the same set of conditions. The second objective is to investigate what effect the presence of air in the condenser has on the heat flux and surface heat transfer coefficient. This experiment would be used in by any industry which is trying to increase the efficiency of heat transfer.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

9K tayangan1 halamanDropwise and Fimwise Condensation Lab Report

Diunggah oleh

cocodaveFilmwise and Dropwise are 2 forms of condensation. In filmwise condensation a laminar film of vapour is created upon a surface. This film can then flow downwards, increasing in thickness as additional vapour is picked up along the way (1). In dropwise condensation vapour droplets form at an acute angle to a surface (1). These droplets then flow downwards, accumulating static droplets below them along the way. The first objective of this experiment is to investigate the difference in heat flux between the 2 forms of condensation for the same set of conditions. The second objective is to investigate what effect the presence of air in the condenser has on the heat flux and surface heat transfer coefficient. This experiment would be used in by any industry which is trying to increase the efficiency of heat transfer.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

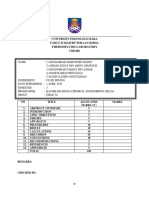

Flows with Friction, Drag and Lift Laboratory Report

Student ID Number: 0851594 Experiment No.: MP2.4

Degree Programme/Level: Mechanical Engineering Level 2 Title: Film and Dropwise Condensation

INTRODUCTION and DESCRIPTION OF EXPERIMENT

Filmwise and Dropwise are 2 forms of condensation. In filmwise condensation a laminar film of vapour is created upon a

surface. This film can then flow downwards, increasing in thickness as additional vapour is picked up along the way (1). In

dropwise condensation vapour droplets form at an acute angle to a surface (1). These droplets then flow downwards,

accumulating static droplets below them along the way. The first objective of this experiment is to investigate the difference in

heat flux between the 2 forms of condensation for the same set of conditions. The second objective is to investigate what effect

the presence of air in the condenser has on the heat flux and surface heat transfer coefficient. This experiment would be used in

by any industry which is trying to increase the efficiency of heat transfer. An example of this is any vapour power cycle such as

the Rankine cycle. By increasing the efficiency of the condenser, its operational pressure can be reduced and the overall

efficiency of the cycle can be increased.

RESULTS, DISCUSSION and CONCLUSIONS

Figure 1 displays a graph which represents the Heat Flux for both

dropwise and filmwise condensation at two different pressures.

This graph shows that; Heat flux increases with steam pressure

and the temperature difference between the steam and the

condenser surface and that the values for Heat flux for each set

value of pressure is higher using dropwise condensation that by

using filmwise condensation in the same conditions. The final

observation is confirmed in the Handbook of Phase Change (2)

which quotes that at atmospheric pressure, the Heat Flux in

dropwise condensation can be more than twenty times larger than

in filmwise. This can be explained in terms of how the

condensation forms on the condenser. The vapour drops in

dropwise condensation are discrete and are continually formed

and released which means that the surface of the condenser is also

continually exposed. In comparison, the film created in filmwise

condensation always covers the surface of the condenser (3). As a

relatively poor conductor of heat, this film creates a thermal

resistance which is the reason why the value for Heat Flux is lower

for filmwise in comparison to dropwise condensation (3).

To check the accuracy of the experiment, the values for the Heat

Transfer Coefficient in the filmwise condenser were compared to

the values which are obtained theoretically using the Nusselt

equation (3). Figure 2 shows that the results derived

experimentally were of a lower value than of those derived

theoretically. One explanation for this is the presence of non-

condensable gases in the steam vapour (1).

The effect of a non condensable gas in the steam vapour is

presented in figure 3. The graph shows that for a certain

temperature difference, the Heat Flux for a condenser using steam

mixed with 5% of air is significantly smaller than pure steam, and

the magnitude of this difference increases with temperature

difference. In the case of Heat Transfer Coefficients, the value for

both steam and steam with air approaches zero, but when the steam

is mixed with air it is consistently low.

In conclusion, dropwise condensation is a more effective method of

heat transfer than filmwise condensation, and the presence of air in

steam vapour significantly reduces the heat transfer.

REFERENCES

(1) Mayhew, Y, Rogers, G. (1992). Engineering thermodynamics:

th

Work & Heat Transfer. 4 ed. Prentice Hall.

(2) Rose, J, Utaka, Y, Tanasawa, I. (1999). Handbook of Phase Change: Dropwise Condensation. Taylor & Francis.

th

(3) Incropera, F, DeWitt, D. (1996). Fundamentals of heat and mass transfer. 4 ed. Wiley.

Date of Experiment: 17/02/2009 Date Report Submitted: 01/05/2009

Anda mungkin juga menyukai

- Lab 7 Filmwise and Dropwise CondensationDokumen10 halamanLab 7 Filmwise and Dropwise Condensationathirah100% (1)

- Tensile Test Lab ReportDokumen2 halamanTensile Test Lab Reportcocodave89% (65)

- Pelleting Handbook Gb04Dokumen152 halamanPelleting Handbook Gb04eliesergs91% (11)

- Alok Mitra NotesDokumen5 halamanAlok Mitra NotesSukanya GuhaBelum ada peringkat

- Filmwise and Dropwise ExperimentDokumen16 halamanFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- Heat Transfer Lab Report: Film vs Dropwise CondensationDokumen14 halamanHeat Transfer Lab Report: Film vs Dropwise CondensationMuhammad FarhanBelum ada peringkat

- Feed Mill InfoDokumen33 halamanFeed Mill InfoSapelBelum ada peringkat

- Sedimentation Studies Apparatus DesignDokumen7 halamanSedimentation Studies Apparatus Designgrkhari1100% (2)

- Tray DryerDokumen16 halamanTray Dryermirdza94Belum ada peringkat

- Free/Force Convection H.T From Pinned&finnedDokumen14 halamanFree/Force Convection H.T From Pinned&finnedIbrahimBelum ada peringkat

- Filmdropwise LabDokumen47 halamanFilmdropwise Labaizaqsyazwan50% (2)

- Film Boiling Condensation ExperimentDokumen17 halamanFilm Boiling Condensation ExperimentTengku AshrafBelum ada peringkat

- Filmwise and Dropwise ExperimentDokumen33 halamanFilmwise and Dropwise ExperimentValentinoDullSatin100% (2)

- Distillation Column Pressure Drop & Refractive IndexDokumen18 halamanDistillation Column Pressure Drop & Refractive IndexAmir Al-AimanBelum ada peringkat

- Film Boiling CondensationDokumen5 halamanFilm Boiling CondensationMohamad Fahmi Abd Rased100% (3)

- Unit Operation Laboratory 2 (CCB 3062)Dokumen7 halamanUnit Operation Laboratory 2 (CCB 3062)Carl Erickson100% (1)

- CK Osborne Reynolds PDFDokumen4 halamanCK Osborne Reynolds PDFChaminduKrishanRupasingheBelum ada peringkat

- Fluid Mechanics Lab 3.1Dokumen13 halamanFluid Mechanics Lab 3.1mahmoudBelum ada peringkat

- HEAT TRANSFER EXPERIMENTDokumen19 halamanHEAT TRANSFER EXPERIMENTBen Widdowson100% (2)

- Optimized Solids Suspension: Achieving Uniform Dispersion is Critical to Product QualityDokumen7 halamanOptimized Solids Suspension: Achieving Uniform Dispersion is Critical to Product QualitymichsantosBelum ada peringkat

- Climbing Film EvaporatorDokumen8 halamanClimbing Film Evaporatorsaz140% (1)

- Full Report Exp Batch CPPDokumen18 halamanFull Report Exp Batch CPPAdiba HamidiBelum ada peringkat

- University Thermodynamics Laboratory Report (Ratio of Volume)Dokumen5 halamanUniversity Thermodynamics Laboratory Report (Ratio of Volume)Jackson KcBelum ada peringkat

- Properties Measurement PVT Lab Report UitmDokumen35 halamanProperties Measurement PVT Lab Report UitmAmrun Rusrl100% (1)

- CKB 20104 Reaction Engineering UniKL MICET Mini Project (Stage 1) : Production of Acetylene 80 Metric Ton/year PFRDokumen22 halamanCKB 20104 Reaction Engineering UniKL MICET Mini Project (Stage 1) : Production of Acetylene 80 Metric Ton/year PFRSiti Hajar Mohamed100% (6)

- Softing PointDokumen12 halamanSofting PointMUHAMMAD AKRAMBelum ada peringkat

- Investigation of Liquid-Solid and Gas-Solid Fluidized BedDokumen18 halamanInvestigation of Liquid-Solid and Gas-Solid Fluidized Bedmahbub1332100% (1)

- Aaaaaayidddddd287190871 Thermofluids Lab Fluid MixingDokumen21 halamanAaaaaayidddddd287190871 Thermofluids Lab Fluid Mixingezzat0% (1)

- Heat ExchangerDokumen21 halamanHeat ExchangersedamyrulBelum ada peringkat

- Refrigeration Unit Lab Report FKKDokumen28 halamanRefrigeration Unit Lab Report FKKKicauan KataBelum ada peringkat

- Effux Time EquationsDokumen7 halamanEffux Time EquationsDhananjay KadamBelum ada peringkat

- Center of PressureDokumen10 halamanCenter of PressureMuhammad Adli Amin Mohd AmzukiBelum ada peringkat

- Lab 7Dokumen18 halamanLab 7coopere23100% (1)

- S-Lab Manual Exp 3 - Air Flow Process ControlDokumen12 halamanS-Lab Manual Exp 3 - Air Flow Process Controlarif arifinBelum ada peringkat

- Lab Report Waste Water 1Dokumen10 halamanLab Report Waste Water 1eidalinBelum ada peringkat

- Turbulent Jet Experiment AnalysisDokumen8 halamanTurbulent Jet Experiment AnalysisBakr SaeedBelum ada peringkat

- Shell and Tube Heat Exchanger PerformanceDokumen28 halamanShell and Tube Heat Exchanger PerformanceAmoluck BhatiaBelum ada peringkat

- CKB 20104 Reaction Engineering UniKL MICET Experiment 3a: Effect of Residence Time On The Reaction in A PFR Full Lab ReportDokumen20 halamanCKB 20104 Reaction Engineering UniKL MICET Experiment 3a: Effect of Residence Time On The Reaction in A PFR Full Lab ReportSiti Hajar MohamedBelum ada peringkat

- Process Control Report No.1Dokumen21 halamanProcess Control Report No.1IbrahimDewaliBelum ada peringkat

- Questions (Cod Lab Report)Dokumen1 halamanQuestions (Cod Lab Report)putriyusairah_91Belum ada peringkat

- Lab10 CompleteDokumen22 halamanLab10 CompleteMastura Ahmad Termizi100% (1)

- Lab 2 - Distillation Column CompleteDokumen18 halamanLab 2 - Distillation Column CompleteHadiChan100% (1)

- CKB 20104 Reaction Engineering UniKL MICET Experiment 2a Effect of RTD On The Reaction in CSTR Full Lab ReportDokumen29 halamanCKB 20104 Reaction Engineering UniKL MICET Experiment 2a Effect of RTD On The Reaction in CSTR Full Lab ReportSiti Hajar Mohamed100% (6)

- Linear N Radial Heat Conduction ApparDokumen16 halamanLinear N Radial Heat Conduction ApparisdiantiBelum ada peringkat

- Exp 1-Fluid MixingDokumen12 halamanExp 1-Fluid MixingKhairulAzwanizam100% (1)

- Tray Drying Experiment: Effects of Air Velocity on Drying RateDokumen13 halamanTray Drying Experiment: Effects of Air Velocity on Drying RateSrinyanavel ஸ்ரீஞானவேல்75% (4)

- Heat Pump Performance AnalysisDokumen22 halamanHeat Pump Performance Analysisahmad pidotBelum ada peringkat

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportDokumen9 halamanCPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportSiti Hajar MohamedBelum ada peringkat

- Influence of Air Velocity on Drying Rate of Wet SandDokumen3 halamanInfluence of Air Velocity on Drying Rate of Wet SandJohanBelum ada peringkat

- FLUID MACHINERY - CENTRIFUGAL PUMP LAB REPORTDokumen31 halamanFLUID MACHINERY - CENTRIFUGAL PUMP LAB REPORTHarizx SaufixBelum ada peringkat

- Heat Exchanger Lab Report GuideDokumen19 halamanHeat Exchanger Lab Report GuideGriezmann Haziq50% (2)

- Thermal Laboratory - Lab Experiment-1Dokumen7 halamanThermal Laboratory - Lab Experiment-1Raj PratyushBelum ada peringkat

- Venturi MeterDokumen7 halamanVenturi MeterGregory Nick Toledo VelizBelum ada peringkat

- Drying: Merry Jessah S. TorresDokumen6 halamanDrying: Merry Jessah S. TorresFrancis Val FranciscoBelum ada peringkat

- CONTINUOUS DistillationDokumen5 halamanCONTINUOUS DistillationNaseer SattarBelum ada peringkat

- Series and Parallel Pumps: Flow Rate & PressureDokumen11 halamanSeries and Parallel Pumps: Flow Rate & PressureKevin Devastian100% (1)

- Fluid Mixing ExpDokumen9 halamanFluid Mixing ExpNawal DaBombBelum ada peringkat

- Exp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctDokumen7 halamanExp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctKawar Abid100% (1)

- Lab 7 ThermoDokumen25 halamanLab 7 Thermoadib assoliBelum ada peringkat

- Film Boiling Heat Transfer of Droplet Streams and SpraysDokumen15 halamanFilm Boiling Heat Transfer of Droplet Streams and SprayseidelsayedBelum ada peringkat

- International Journal of Thermal Sciences: F.J. AriasDokumen4 halamanInternational Journal of Thermal Sciences: F.J. AriasPrashant IngaleBelum ada peringkat

- ChE 0101 Final ReportDokumen29 halamanChE 0101 Final ReportPaartiban PaneerselvamBelum ada peringkat

- Description Assembly Order No.: Static DataDokumen1 halamanDescription Assembly Order No.: Static DatacocodaveBelum ada peringkat

- Design of A PID Altitude Controller For A Micro HelicopterDokumen26 halamanDesign of A PID Altitude Controller For A Micro Helicoptercocodave100% (2)

- Human Perception of Mobile Phone VibrationDokumen9 halamanHuman Perception of Mobile Phone VibrationcocodaveBelum ada peringkat

- Stress Wave Propagation Lab ReportDokumen5 halamanStress Wave Propagation Lab ReportcocodaveBelum ada peringkat

- Plate Bending Theory and Electronic Speckle Pattern Interferometry Lab ReportDokumen15 halamanPlate Bending Theory and Electronic Speckle Pattern Interferometry Lab ReportcocodaveBelum ada peringkat

- An Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementDokumen15 halamanAn Assessment of Singapore Airlines Environmentally Sustainable Energy ManagementMamta AgarwalBelum ada peringkat

- Bottom-Up Cost Evaluation of SOEC Systems (10-100MW)Dokumen14 halamanBottom-Up Cost Evaluation of SOEC Systems (10-100MW)Roy JudeBelum ada peringkat

- FisicaDokumen352 halamanFisicaCg Tonio100% (1)

- WP Bdi GB 1000 2012Dokumen10 halamanWP Bdi GB 1000 2012prijepolje72Belum ada peringkat

- Effectiveness of Sootblowers in Boilers Thermal Power StationDokumen7 halamanEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123Belum ada peringkat

- LM 3900Dokumen16 halamanLM 3900Fredy CasillaBelum ada peringkat

- Exercise-01 Check Your Grasp: O CH HO HODokumen7 halamanExercise-01 Check Your Grasp: O CH HO HOChesta MalhotraBelum ada peringkat

- AERMOTORDokumen12 halamanAERMOTORSharid PickeringBelum ada peringkat

- 1st PU Chemistry May 2015 PDFDokumen2 halaman1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- Preparation Before Storage of Aviation BatteriesDokumen1 halamanPreparation Before Storage of Aviation BatteriesRaymond ZamoraBelum ada peringkat

- Clase 05 - Chapter 9 - AAS-experimentalDokumen44 halamanClase 05 - Chapter 9 - AAS-experimentalLuisa GallegoBelum ada peringkat

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDokumen2 halamanMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongBelum ada peringkat

- 3.electromagnetic Theory NET-JRF VKSDokumen31 halaman3.electromagnetic Theory NET-JRF VKSSijil SalimBelum ada peringkat

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesDokumen6 halamanJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanBelum ada peringkat

- Introduction To Batteries - BatteryDokumen17 halamanIntroduction To Batteries - BatteryJ dixojoBelum ada peringkat

- Cornell Notes 3Dokumen3 halamanCornell Notes 3api-302904199Belum ada peringkat

- BHELDokumen38 halamanBHELSharath Chandra100% (1)

- Chemistry Practice Paper SA1 Class 9 CBSEDokumen2 halamanChemistry Practice Paper SA1 Class 9 CBSEgurdeepsarora8738Belum ada peringkat

- EV Technology QPDokumen3 halamanEV Technology QPvcetnaac c6Belum ada peringkat

- Ductable Fan Coil Unit: Product Selection DataDokumen26 halamanDuctable Fan Coil Unit: Product Selection DataNelson MartinsBelum ada peringkat

- Data Sheet (English) - 8036 Industrial ControlsDokumen44 halamanData Sheet (English) - 8036 Industrial ControlsNabil ShaukatBelum ada peringkat

- Module 2: Diffusion: Lecture No. 5Dokumen2 halamanModule 2: Diffusion: Lecture No. 5Mehwish NoorBelum ada peringkat

- Solar Electric Tiffin Box (1) - 2Dokumen36 halamanSolar Electric Tiffin Box (1) - 2imrashi18kBelum ada peringkat

- Eco NicalDokumen13 halamanEco Nicalluizfellipe95Belum ada peringkat

- Curved Data KEW PUMP KSSE 3 1Dokumen1 halamanCurved Data KEW PUMP KSSE 3 1Haryono SyalimBelum ada peringkat

- 0620 s14 QP 11Dokumen5 halaman0620 s14 QP 11Kevin DanyBelum ada peringkat

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Dokumen18 halamanPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanBelum ada peringkat