Previews ASHRAE D 98044 Pre

Diunggah oleh

Lee ChorneyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Previews ASHRAE D 98044 Pre

Diunggah oleh

Lee ChorneyHak Cipta:

Format Tersedia

Fundamentals of

Refrigeration

Second Edition

Donald L. Fenton

Your Source for HVAC&R Professional Development

A Course Book for

Self-Directed or Group Learning

I-P

Inch-Pound

Fundamentals of

Refrigeration

Second Edition

Donald L. Fenton

A Course Book for Self-Directed or Group Learning

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

Fundamentals of Refrigeration I-P

Second Edition

A Course Book for Self-Directed or Group Learning

ISBN 978-1-933742-71-7

2010 American Society of Heating, Refrigerating and

Air-Conditioning Engineers, Inc. (ASHRAE)

All rights reserved.

No part of this publication may be reproduced without permission in writing from

ASHRAE, except by a reviewer who may quote brief passages or reproduce illustrations in

a review with appropriate credit; nor may any part of this book be reproduced, stored in a

retrieval system, or transmitted in any way or by any means (electronic, photocopying,

recording or other) without permission in writing from ASHRAE. Requests for permission

should be submitted at www.ashrae.org/permissions.

ASHRAE has compiled this publication with care, but ASHRAE has not investigated, and

ASHRAE expressly disclaims any duty to investigate, any product, service, process, proce-

dure, design or the like that may be described herein. The appearance of any technical data or

editorial material in this publication does not constitute endorsement, warranty, or guaranty by

ASHRAE of any product, service, process, procedure, design or the like. ASHRAE does not

warrant that the information in this publication is free of errors. The entire risk of the use of

any information in this publication is assumed by the user.

ASHRAE STAFF

ASHRAE Learning Institute

Joyce Abrams

Group Manager of Education

Karen Murray

Manager of Professional

Development

Martin Kraft

Managing Editor

Vickie Warren

Secretary/

Administrative Assistant

Special Publications

Mark Owen

Editor/Group Manager of

Handbook and Special Publications

Cindy Sheffield Michaels

Managing Editor

Matt Walker

Associate Editor

Amelia Sanders

Assistant Editor

Elisabeth Parrish

Assistant Editor

Michshell Phillips

Editorial Coordinator

For course information or to order additional materials, please contact:

ASHRAE Learning Institute

1791 Tullie Circle, NE

Atlanta, GA 30329

Telephone: 404/636-8400

Fax: 404/321-5478

Web: www.ashrae.org/ali

E-mail: edu@ashrae.org

Any errors or omissions in the data should be brought to the attention of Special Publications

via e-mail at SDLcorrections@ashrae.org.

ASHRAE

Fundamentals

of

HVAC&R

Series

Print

Fundamentals of...

Psychrometrics

Air System Design

Steam System

Design

Heating and

Cooling Loads

Heating Systems

Thermodynamics

Water System

Design

Refrigeration

eLearning

Fundamentals of...

HVAC Control

Systems

HVAC Systems

Refrigeration

Standard 62.1-2010,

Ventilation for

Acceptable Indoor

Air Quality

Standard 90.1-2004,

Energy Efficiency in

New Buildings

Any updates/errata to this publication will be posted on the

ASHRAE Web site at www.ashrae.org/publicationupdates.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Your Source for HVAC&R Professional Development

1791 Tullie Circle, NE Atlanta, GA 30329-2305 USA Tel 404.636.8400 Fax 404.321.5478 www.ashrae.org

Karen M. Murray Email: kmurray@ashrae.org

Manager of Professional Development

Dear Student,

Welcome to the ASHRAE Learning Institute (ALI) Fundamentals of HVAC&R Series of self-directed or group

learning courses. We look forward to working with you to help you achieve maximum results from this course.

You may take this course on a self-testing basis (no continuing education credits awarded) or on an ALI-moni-

tored basis with credits (PDHs, CEUs or LUs) awarded. ALI staff will provide support and you will have access

to technical experts who can answer inquiries about the course material. For questions or technical assistance,

contact us at 404-636-8400 or edu@ashrae.org.

Skill Development Exercises at the end of each chapter will test your comprehension of the course material.

These exercises allow you to apply the principles you have learned and develop a deeper mastery of the subject

matter. If you take this course for credit, please complete the exercises in the workbook and send copies from

each chapter to: ASHRAE Learning Institute, 1791 Tullie Circle, Atlanta, GA 30329-2305 or edu@ashrae.org.

Please include your student ID number with each set of exercises submitted. Your student ID is the last five dig-

its of your order number, which can be located in the top left corner of your packing slip. You can also email us

for your ID at edu@ashrae.org. We will return answer sheets to the Skill Development Exercises and maintain

records of your progress. Please keep copies of your completed exercises for your own records.

When you finish all exercises, please submit the course evaluation, which is located at the back of your course

book. Once we receive all chapter exercises and the evaluation, we will send you a Certificate of Completion

indicating 35 PDHs/LUs or 3.5 CEUs of continuing education credit. Please note: The ALI does not award par-

tial credit for SDLs. All exercises must be completed to receive full continuing education credit.

We hope your educational experience is satisfying and successful.

Sincerely,

Karen M. Murray

Manager of Professional Development

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

A N I NT E R NA T I ONA L OR GA NI Z A T I ON

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Donald L. Fenton was born in Doylestown, PA, and raised in the Tren-

ton, NJ, area. He attended Kansas State University (KSU), and during

his undergraduate summers he worked as an engineer trainee at the

Naval Air Propulsion Test Center near Trenton. In 1969, he obtained a

bachelor's degree in Mechanical Engineering from KSU and went on to

receive master and doctorate degrees in Mechanical Engineering from

the University of Illinois at Urbana-Champaign in 1971 and 1974,

respectively.

Upon completing his graduate studies, Don worked at the Fine Parti-

cles Section of the IIT Research Institute in Chicago, where he con-

ducted contract research in the areas of air-quality assessment and air-

pollution control. In 1977, he relocated to New Mexico State University

in Las Cruces, where he taught classes and researched solar energy and

combustion systems for nine years. In 1986, he moved to KSU, where

he currently teaches a variety of undergraduate and graduate courses,

including Thermal Systems Design, in the thermal science area. He also

conducts research, some ASHRAE sponsored, relating to the energy

field. Don is the department head of the Mechanical and Nuclear Engi-

neering Department at KSU. He is a registered professional engineer

and has consulted on many industrial projects.

Don resides in Manhattan, KS, with his wife, Mary. Their three

sons, Adam, James, and Michael have completed college and are devel-

oping their own careers. A great joy for Mary and Don is to visit their

grandchildren, Charlie, Lydia, Audrey, and George in Newnan, GA.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Table of Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Chapter 1: Fundamentals of Refrigeration. . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Types of Refrigeration Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Major Processes of Vapor-Compression Refrigeration . . . . . . . . . . . . . . 7

Heat-Pump Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The Field of Refrigeration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2: Fundamentals of Thermodynamics . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Thermodynamic Properties of Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Thermodynamic Laws and Applications . . . . . . . . . . . . . . . . . . . . . . . . 27

Efficiency of Refrigeration and Heat-Pump Cycles . . . . . . . . . . . . . . . . . 30

Energy Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 3: Multistage and Cascade Refrigeration Cycles . . . . . . . . . 45

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Single-Stage Ideal Refrigeration Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . 47

Two-Stage Ideal Refrigeration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cascade Refrigeration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Refrigeration-System Performance Parameters. . . . . . . . . . . . . . . . . . . 59

Deviations of Actual Refrigeration Systems from

Ideal Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Refrigeration System Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Chapter 4: Evaporators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Psychrometrics of Moist-Air Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Air-Cooling Evaporators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Liquid-Cooling Evaporators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

vi Table of Contents

Chapter 5: Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Reciprocating Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Rotary Screw Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Rotary Vane Compressors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Scroll Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Centrifugal Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Chapter 6: Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Condensation Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Air-Cooled Condensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Water-Cooled Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Evaporative Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Chapter 7: Refrigerant Flow in Pipes, Valves, and Pumps . . . . . . . . 173

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Fluid Flow in Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Valve and Pipe-Fitting Equivalent Length. . . . . . . . . . . . . . . . . . . . . . . 186

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Chapter 8: Expansion Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Capillary Tubes and Short Tube Restrictors . . . . . . . . . . . . . . . . . . . . 202

Pressure Control Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Thermostatic Expansion Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Electronic Expansion Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Hand Expansion Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Level Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Turbo Expanders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Chapter 9: Pressure Vessels and Refrigerant Management . . . . . . . 229

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Suction Line Accumulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P vii

Surge Drums. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Flash Tanks and Intercoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Refrigerant Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Chapter 10: Refrigerant Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Types of Refrigerants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Saturation Pressure and Temperature of a Refrigerant . . . . . . . . . . . . 263

Refrigeration Capacity and Efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . 264

Safety of Refrigerants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Environmental Impact of Refrigerants . . . . . . . . . . . . . . . . . . . . . . . . . 271

Codes and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Chapter 11: Product Cooling, Freezing Loads, and

Cooling Secondary Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Cooling Food Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Freezing Food Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Food Freezing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Cooling Liquid-Food Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Cooling Secondary Fluids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Chapter 12: Practical Guide to Refrigeration Systems. . . . . . . . . . . 317

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Refrigeration Racks and Display Cases . . . . . . . . . . . . . . . . . . . . . . . . 319

Refrigerated Warehouses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Meat Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Pharmaceutical Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Skill Development Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Appendix A: Sample Refrigerants. . . . . . . . . . . . . . . . . . . . . . . . . . . 353

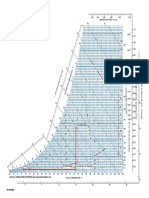

Appendix B: Pressure-Enthalpy Diagrams . . . . . . . . . . . . . . . . . . . . 363

Appendix C: Supplemental Tables. . . . . . . . . . . . . . . . . . . . . . . . . . 371

Skill Development Exercises

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Preface

Refrigeration has been in existence for over 150 years, and over the

years many books have been written explaining its theory and applica-

tion. Despite this, a modern introduction to refrigeration was not pub-

lished until 1999, when ASHRAE recognized this need and

commissioned Donald L. Fenton to author the first edition of Funda-

mentals of Refrigeration. This text is a revised edition of the 1999 text

with the notable addition of a final chapter presenting example applica-

tions of refrigeration.

This second edition continues as an introduction to the field of

refrigeration. The three major areas of refrigeration are covered: com-

fort cooling or air conditioning, commercial refrigeration, and indus-

trial refrigeration. The text is divided into chapters that are sequenced

in a logical progression from the first principles that underpin refrigera-

tion theory, through thermodynamic cycles and practical details, and

finally to four prevalent applications compressor racks in supermar-

kets, refrigeration warehouses, meat processing, and a pharmaceutical

application. Exercises are available at the end of each chapter for stu-

dents and readers to assess their understanding of the material and to

apply their knowledge to new situations. Current ASHRAE Handbook

volumes are used as references throughout, as these are readily avail-

able and contain the latest results of ASHRAE and other research.

The intended audience for this book is anyone seeking an introduc-

tion to refrigeration based on thermodynamic principles. The text con-

tains the thermodynamic property data and other information necessary

to understand the material and to complete the exercises. Two quite dif-

ferent kinds of users are targeted in this book. One is the recent

mechanical engineering school graduate who didnt study refrigeration

while in college. The other is the veteran technician who has worked in

the refrigeration field for a number of years. Both of these, and anyone

who falls between, will benefit from this book. The presentations in the

text use familiar lines of reasoning and appropriate explanations suit-

able for all students and readers seeking an introduction to refrigera-

tion. Consequently, this text strives to be both effective and useful as an

introduction to refrigeration.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Acknowledgments

Refrigeration is a major component of ASHRAEs collective research

effort and knowledge base. Certainly, the ASHRAE HandbookRefrig-

eration, published by ASHRAE every four years, maintains the best

up-to-date information on refrigeration systems and their application.

Acknowledgement is due to ASHRAE for maintaining these activities

for the past 50 years. Much of the technical data used in this book was

drawn from these Handbooks.

Additionally, ASHRAE is acknowledged for providing support of

the author in developing the text, example illustrations, and homework

exercises.

Several leaders in the refrigeration field have made suggestions that

improved the text, corrected errors, and changed several exercises to

make them more effective. These people include: George Briley, Ron-

ald Cole, Brian Friecke, Daniel Kramer, Douglas Rindl, Donald Siller,

and Ronald Vallort. Additionally, Justin Smith, while a senior mechani-

cal engineering student at Kansas State University and using a draft

copy of the text while studying refrigeration in a special topics course,

corrected numerous errors. Special acknowledgment is made to Profes-

sor Will Stoecker for first introducing me to the industrial refrigeration

field and mentoring me often on the topic.

Very special acknowledgement is reserved for my wife, Mary, who

proofread the entire text and corrected many grammatical and context

errors. Also, sincere thanks to my three sons, Adam, James, and

Michael, for allowing me to develop this work when it meant time not

spent with them.

Donald L. Fenton

Manhattan, KS

April 15, 2010

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of

Refrigeration

Second Edition

Donald L. Fenton

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of

Refrigeration

Study Objectives

Chapter 1 introduces the concept of refrigeration and explains how several dif-

ferent refrigeration systems operate. The classification of refrigeration systems

and sample applications of refrigeration are discussed. After studying

Chapter 1, you should be able to

define refrigeration;

name and briefly describe at least two methods of refrigeration;

name and describe the four basic components of a vapor-compression

refrigeration system;

describe the purpose of a heat-pump system; and

identify three applications of refrigeration.

Instructions

Read the material in Chapter 1. At the end of the chapter, complete the skill

development exercises without referring to the text. Review those sections of

the chapter as needed to complete the exercises.

Introduction

Refrigeration is the action of removing heat from an enclosed space or material

for the purpose of lowering its temperature (it is important to note that cold is

not added to the material). Consequently, a refrigeration system must provide a

means by which heat can moved away. Refrigeration systems do this by pro-

viding a cold surface near the material to be cooled. This surface, colder than

the material, causes heat to transfer from that material through the cold surface.

Because heat only flows from a warmer body to a colder body, the temperature

of the cold surface must be less than that of the refrigerated material.

Figure 1-1 shows a diagram of a generic refrigeration system represented

by the rectangle in the center. A refrigeration system is the collection of equip-

ment that generates cold and hot surfaces to perform refrigeration. Observe

that the temperature of the cold surface is less than the temperature of the

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

2 Chapter 1 Fundamentals of Refrigeration

refrigerated space or material. Once heat or thermal energy passes through the

cold surface, the objective of the refrigeration system is to transport the energy

to another locationa hot surface whose temperature is higher than the sur-

rounding outside environment. Figure 1-1 shows the movement of heat from

the refrigerated material through the refrigeration system and out to the sur-

rounding atmosphere.

Again, observe that because heat only flows from a warm body to a cold

body, the hot surface temperature must be greater than that of the surroundings.

In summary, a refrigeration system removes heat from one body and transfers it

to another body.

Types of Refrigeration Systems

Several types of refrigeration systems are available, and each accomplishes the

same task of removing heat from a space or material. The material may be a

gas, liquid, or solid. For example, the refrigeration system in a domestic refrig-

erator cools the inside air to a temperature less than the surroundings, thus

maintaining an appropriate temperature for the storage of food. The means by

which the cold surface is generated in the refrigerated space distinguishes one

refrigeration system from another.

Vapor-Compression System

The vapor-compression system is the most common refrigeration system cur-

rently in use. A vapor-compression system passes a fluid called a refrigerant

through four components in sequence: evaporator, compressor, condenser, and

Figure 1-1 Generic refrigeration system.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 3

expansion device. Figure 1-2 displays a typical small vapor-compression sys-

tem. Since the fluid circulates through the system and returns to its original

position, the system is also referred to as a cycle. The evaporator is the compo-

nent where the actual cooling occurs. A mixture of liquid and vapor refrigerant

at low pressure and low temperature enters the evaporator. The temperature of

the refrigerant mixture in the evaporator is somewhat less than the temperature

of the refrigerated space or material. Therefore, the evaporator absorbs heat

from the space or material, causing the liquid refrigerant to boil or vaporize.

The heat transported from the refrigerated space or material causes the space to

maintain the needed temperature. The low-pressure, low-temperature refriger-

ant vapor leaves the evaporator and enters the compressor; upon exiting the

compressor, the pressure and temperature are increased to that within the con-

denser. The condenser transfers heat from the high-pressure, high-temperature

refrigerant vapor to the surroundings, causing condensation of the vapor into a

liquid. The liquid refrigerant flows to the expansion device, which decreases

the pressure and causes the formation of a low-temperature mixture of vapor

and liquid that enters the evaporator.

In the vapor-compression system, the refrigerant circulates in sequence

among the four components, which constitutes the vapor-compression cycle.

An important feature of the cycle is the conversion of the refrigerant from liq-

uid to vapor and back again as it moves through the system. In this way, the

Figure 1-2 A small vapor-compression system showing the components comprising the

cycle.

Photograph courtesy of the University of Idaho

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

4 Chapter 1 Fundamentals of Refrigeration

refrigerant is not consumed during operation of the system. All components of

the system operate continuously, because the refrigerant is flowing steadily

through the system.

Air-Cycle System

The air-cycle system is different from the vapor-compression system in that the

refrigerant (air) does not undergo the conversion from vapor to liquid and back

again. In the air-cycle system, air from the refrigerated space enters a compres-

sor, which increases the airs pressure and temperature. The air then passes

through a heat exchanger, which results in the high pressure air being cooled to

a temperature near the outside ambient temperature. Next, the air moves

through an expansion device that reduces the air pressure to that of the refriger-

ated space. The temperature of the air is also reduced by the expansion device

to a value somewhat less than that of the refrigerated space. Finally, the chilled

air is re-introduced to the refrigerated space, where it mixes with and lowers

the temperature of the somewhat warmer air. Air continues to be drawn from

the refrigerated space, passing through the refrigeration cycle, until the desired

space temperature is achieved.

A variation of the air-cycle system is used in commercial aircraft to pro-

vide cabin air conditioning. The compressed air is supplied by bleeding a

small airstream from the compressor of the gas turbine engine providing pro-

pulsion. Cooling the high-pressure airstream is accomplished using a heat

exchanger (coil) over which passes high-altitude ambient air. When the cooled

high-pressure air is expanded to cabin pressure, the temperature decreases to

somewhat below the cabin air temperature. The mixing of the expanded cool

air with the cabin air cools the air in the cabin. To keep the cabin pressure

from increasing, an equal amount of warm air is allowed to flow out as the

chilled air is introduced. What differentiates the air-cycle system in aircraft

cabin cooling is that the air does not complete a cycle, but rather begins as air

entering the engines compressor and ends by leaking from the aircraft cabin.

This type of cycle is usually referred to as an open cycle because the same air

does not continue to circulate through the cycle.

Absorption System

An absorption system method of refrigeration is similar to a vapor-compres-

sion system in several respects. Figure 1-3 shows a simplified schematic dia-

gram of an absorption refrigeration system. First, a refrigerant fluid

sequentially moves through the components of the system. Second, the refrig-

erant moves through a condenser, expansion device, and evaporator in a man-

ner similar to that of the vapor-compression cycle. The difference lies in how

the low-pressure, low-temperature refrigerant vapor is changed to a high-pres-

sure, high-temperature vapor. In the absorption cycle, the vapor leaving the

evaporator is absorbed by a liquid solution in a vessel called an absorber. Heat

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 5

must be removed from the absorber to maintain the affinity that the vapor has

for the solution. A pump increases the pressure of the liquid solution to the

level of the condensing pressure; the liquid solution then enters another vessel

called a generator. Heat is added to the generator, driving the refrigerant vapor

out of the solution. At this point, the refrigerant enters the condenser, where the

energy absorbed by the refrigerant is transferred to the atmosphere. The refrig-

erant then passes through an expansion device, which lowers its temperature

and pressure. Finally, the low-temperature, low-pressure refrigerant enters the

evaporator, completing the cycle. A significant quantity of heat at a moderate

temperature is needed to operate the absorption system, and a relatively small

input of electrical power is necessary to operate the pump. Thus, for example,

when waste heat is available from a steam boiler, an absorption system may be

employed to provide low-cost refrigeration. Figure 1-4 shows an absorption

system used to provide chilled water for air conditioning a commercial build-

ing.

Water and ammonia are commonly paired in absorption refrigeration sys-

tems, with ammonia serving as the refrigerant. Because ammonia is the refrig-

erant, temperatures below the freezing point of water are possible. The success

of the ammonia-water pair is due to ammonias large affinity for water.

Another common fluid pair is water and lithium bromide. In this pair, water is

the refrigerant, and the lowest achievable temperature is limited by its freezing

temperature of 32F. Absorption systems for air conditioning generally use the

Figure 1-3 Simplified schematic diagram of an absorption refrigeration system.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

6 Chapter 1 Fundamentals of Refrigeration

water-lithium-bromide pair, because sufficiently low temperatures are pro-

duced.

Thermoelectric System

In the 1960s, semiconductor materials were developed that allowed for com-

mercial production of thermoelectric systems for refrigeration. These systems

depend on the Peltier effect, first observed by Jean Peltier in 1834, which states

that when an electric current passes through junctions of two dissimilar metals,

one junction is cooled and the other is heated. Consequently, a cold surface is

generated, whereupon heat may be absorbed. The hot surface receives the heat

or thermal energy from the cold junction for transfer into the environment.

Many junctions placed in series and attached to a plate forming a cold side and

another plate for the hot side provide one approach to constructing a practical

system. Figure 1-5 shows a thermoelectric cooler in two configurations: with a

flat cold plate and using an air fan.

Evaporative Cooler

In climates where the air contains little moisture (such as the desert Southwest

of the United States), the evaporative cooler is commonly used to cool residen-

tial and commercial buildings. The evaporative cooler typically consists of

Figure 1-4 An absorption refrigeration system used to supply chilled water for a commercial

building.

Photograph courtesy of McQuay.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 7

pads over which water is dripped. This promotes contact between the water and

a warm dry airstream entering the evaporative cooler by means of a fan. The air

is cooled by the evaporation of water. Reductions in air temperature may

exceed 20F, depending on how dry the outside air is. For evaporative cooling

to be successful, the building must allow some conditioned air to exit, thereby

allowing the cooled air to enter.

Major Processes of

Vapor-Compression Refrigeration

The processes necessary for several different types of refrigeration were

described briefly in the previous section, Types of Refrigeration Systems. We

now direct our attention to the widely used vapor-compression refrigeration

system, which is the focus of this course. Figure 1-6 shows the vapor-compres-

sion cycle and the relationship between the four components: evaporator, com-

pressor, condenser, and expansion device. In this system, an expansion device

is selected to carry out the refrigerants sudden decrease in pressure. Each of

the components is connected at its inlet and outlet by a pipe transporting the

refrigerant to the other components. As shown in Figure 1-6, the refrigerant in

the evaporator absorbs heat from the cold space, while the condenser rejects

heat to the surroundings.

The expansion valve and compressor divide the system into a low-pressure

side and a high-pressure side. The evaporator is on the low-pressure side and the

Figure 1-5 Thermoelectric coolers in two configurations: (a) with a flat cold plate and (b)

using an air fan.

(a) (b)

Photograph courtesy of Thermoelectric Cooler of America, Inc.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

8 Chapter 1 Fundamentals of Refrigeration

condenser is on the high-pressure side. In Figure 1-6, the compressor is shown

with a reciprocating piston and two valves, one for the suction line from the

evaporator and one for the discharge line to the condenser. While Figure 1-6

does not accurately show the geometry of the valves in the compressor, note that

when the piston moves away from the compressors top (or head), the suction

valve is pulled open by the low pressure in the cylinder, and the discharge valve

is forced closed by the high-pressure refrigerant in the discharge line. When the

piston moves toward the compressors head, the suction valve is closed by the

higher pressure inside the cylinder, and the discharge valve opens when the

pressure in the cylinder exceeds the pressure in the discharge line. In this way,

the compressor takes in low-pressure refrigerant vapor and discharges high-

pressure vapor to the condenser. To perform its function, the compressor

requires power, which ultimately goes into the refrigerant and is revealed by an

increase in pressure and temperature.

The refrigerant vapor leaving the compressor is at a temperature exceed-

ing that of the surroundings, thus allowing heat transfer from the refrigerant to

the surroundings. The vapor entering the condenser loses heat to the surround-

ings and begins converting to a liquid (i.e., condenses). It is this condensation

Figure 1-6 Vapor-compression system.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 9

process that rejects most of the heat. The temperature in the condenser, under

ideal conditions, is constant, depending on the pressure of the refrigerant. The

heat transfer rate in the condenser regulates the condensing temperature.

In Figure 1-6, vertical lines are shown on the condenser and evaporator to

represent fins (thin metal plates) augmenting the heat transfer rate. This is one

particular design for these components and the term coil is normally applied to

this configuration. Individual fans may force air through the coils, thereby fur-

ther increasing the heat transfer rate.

The expansion device has two functions in the ideal vapor-compression cycle

shown in Figure 1-6. First, it reduces the pressure of the liquid refrigerant by

passing it through a restriction, thereby forming a mixture of liquid and vapor at

a low temperature for the evaporator. Second, the expansion valve regulates the

flow of refrigerant to the evaporator. In the cycle shown in Figure 1-6, just

enough refrigerant is given to the evaporator so that all the liquid evaporates upon

leaving. Inside the evaporator, the conversion of liquid to vapor occurs at con-

stant temperature and pressure for the ideal cycle. The vaporization or boiling of

the refrigerant inside the evaporator is the process responsible for the absorption

of heat from the cold space. The necessary low temperature is produced by the

low pressure of the refrigerant maintained by the compressor.

Later in this course, this ideal vapor-compression cycle is addressed fur-

ther. Greater detail is provided as to why the system operates as it does, and

demonstrations are given for how to make calculations concerning the heat

transfer rates and other performance characteristics. Variations on this basic

cycle are also presented, including multistage systems for when the needed

pressure increase is too large for a single compressor. Deviations of actual

cycles from the ideal cycle are also discussed.

Heat-Pump Cycle

A refrigeration cycle and a heat-pump cycle differ only in purpose. A refriger-

ation cycle is applied to remove heat from a body. In contrast, a heat-pump

cycle is applied to add heat to a hot body. Heat-pump cycles are used to heat

the interior of a building above the outdoor temperature or to provide a supply

of heat to an industrial process operating at an elevated temperature.

In a vapor-compression system, the same equipment is used to construct

both refrigeration and heat-pump cycles: compressor, condenser, expansion

device, and evaporator. In a vapor-compression heat pump, the working fluid

or refrigerant passes through the components in the above order, but the con-

denser is placed near the need for heat. For example, in an air-source heat-

pump cycle applied to heat a residential building, where both the condenser

and evaporator exchange heat with air, the condenser is located inside and the

evaporator outside. With the use of a reversing valve, the flow direction of the

refrigerant may be reversed and the unit converted to a refrigeration cycle.

Figure 1-7 shows a schematic diagram of the refrigeration and heat-pump

cycles in conjunction with a reversing valve. The reversing of the refrigerant

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

10 Chapter 1 Fundamentals of Refrigeration

flow direction causes the condenser and evaporator to swap positions. Note

that the figure, while showing how the refrigerant flow direction is reversed,

does not show the use of two separate expansion devices. Two expansion

devices (one used for refrigeration and one used for the heat pump) are needed

to properly control the refrigerant flow rate for each cycle. Generally, check

valves are used to prevent backflow of the refrigerant in actual reversing

cycles.

Figure 1-7 Schematic diagrams of (a) a vapor-compression refrigeration system using a

reversing valve and (b) a vapor-compression heat-pump cycle with the refriger-

ant flow reversed.

(a)

(b)

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 11

The Field of Refrigeration

The field of refrigeration can be loosely divided into three categories: domes-

tic, commercial, and industrial refrigeration. Typical cooling capacities for

these categories are as follows:

Domesticless than 70,000 Btu/h

Commercialmore than 70,000 Btu/h

Industrialsmall to very large

The refrigeration and air-conditioning fields are intertwined, but each has

its own separate considerations as well. Domestic or residential refrigeration

systems include the household refrigerator, food freezer, and the central air-

conditioning system. Commercial refrigeration includes larger refrigeration

systems than domestic refrigeration requires. Examples of commercial units

include supermarket cold-food display cases as well as restaurant walk-in cool-

ers and freezers. Industrial refrigeration is characterized by the application of

refrigeration systems to achieve specific goals, such as the cooling and freezing

of foods or the removal of heat from material streams in chemical, petroleum,

and petrochemical plants. Within the field of air conditioning, refrigeration

finds its greatest application in the cooling of air for human comfort. In terms

of measures such as units manufactured, total sales volume, and employment

level, comfort air conditioning overshadows both commercial and industrial

refrigeration.

However, human-comfort air conditioning involves considerations beyond

only the cooling of air. The term air conditioning, when applied to human

comfort, refers to those processes of air treatment that control temperature,

humidity, cleanliness, and ventilation to meet the comfort requirements of the

occupants in the space. So, air conditioning involves air-heating processes, air-

quality control, appropriate regulation of air velocity, and thermal radiation in

addition to the refrigeration or cooling processes. Generally, cooling for human

comfort requires that refrigeration equipment operate over a relatively narrow

range of temperatures, approximately 35F to 55F. As this temperature range

is small and the market for refrigeration equipment is large, suppliers have

standardized their offerings and packaged them for large-volume production,

thereby achieving lower unit costs.

In contrast to the air-conditioning field, industrial refrigeration involves

custom-designed systems, because the equipment operating temperatures

vary significantly for each system. The temperature range of concern for the

industrial-refrigeration designer extends to approximately 100F. Tempera-

tures from below 100F to near absolute zero (459.67F) are covered in the

field of cryogenics. These fields are bordered by flexible boundaries, which,

from time to time, refrigeration engineers and technicians successfully cross

to participate in design and development.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

12 Chapter 1 Fundamentals of Refrigeration

Refrigeration systems may also be categorized by the type of application

in which they are used. The categories that follow are not absolute. Rather,

they serve to organize the field of refrigeration in several different ways so as

to provide a better understanding. The lines between categories are not abso-

lute, and systems and their applications occasionally cross from one category

to another.

Residential Air Conditioning

Residential air conditioning includes the room air conditioner and unitary or

central system where the condenser and compressor are located outdoors and

the evaporator coil is placed in the air-supply duct near the air-handling unit.

Another system type called a heat pump uses the same basic four components

(see the previous Vapor-Compression System section) and provides both

summer cooling and winter heating.

Vehicle Air Conditioning

The most common air-conditioned vehicle is the private automobile, but trac-

tors, buses, trucks, trains, aircraft, and ships are air conditioned as well. This

application is characterized by the refrigerated space receiving a large quantity

of solar radiation. Also, public transportation vehicles present the added chal-

lenge of quickly cooling a large number of people occupying a relatively small

space.

Medium- and Large-Sized-Building Air Conditioning

Commercial buildings may require cooling even during cold outside condi-

tions, depending on the heat loads generated internally by people, lights, and

office equipment. The responsibility of the refrigeration system is to provide

needed cooling so that the people inside the building can function comfortably

and effectively. The refrigeration system may consist of a central water-chilling

plant as part of a mechanical room. The air-conditioned spaces may be served

by one or more air-supply and return-duct systems linked to the central chiller.

Another approach is to pipe the chilled water to heat exchanger coils within the

air-conditioned spaces where a fan forces the conditioned air through the coil.

Single-story building applications sometimes employ rooftop units that supply

conditioned air directly to the occupied space.

Transport Refrigeration

Perishable products transported by trucks, rail cars, and cargo containers use

vapor-compression refrigeration systems to maintain the required temperature,

preventing loss. These transport refrigeration units are similar to those used in

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 13

other commercial applications where the compressor is powered by an electric

motor or internal combustion engine (gasoline or diesel) that allows for mobile

operation. Air returning from circulating over the products is cooled by the

refrigeration system and blown again across the product to maintain the desired

interior temperature.

Residential Refrigeration

Vapor-compression is the most-used refrigeration system for domestic full-

sized refrigerators and freezers. The refrigerators function is to generate one

or more low temperature spaces suitable for the storage of food. Typically,

32F to 39F is suitable for fresh food storage. Freezer sections of combination

refrigerators-freezers and individual freezers must maintain approximately 0F

storage temperature. However, smaller units, which may be portable, may use

ammonia-water absorption or thermoelectric refrigeration for application in

hotel rooms, recreational vehicles, and portable coolers, as their operating

noise is considerably less.

Refrigerated Vending Machines

Refrigerated vending machines use vapor-compression refrigeration systems to

maintain bottle and can beverages as well as other perishable food products

such as ice cream at appropriate temperatures.

Industrial Air Conditioning

This course defines the broad area of industrial air conditioning to include

adjusting hostile environments for worker comfort and generating conditioned

air appropriate for manufacturing processes. The list of activities involving

refrigeration under this category is huge, represented by the following:

Spot Cooling. Cooled air for worker relief in a hot environment where it is

impractical to cool the entire plant (such as an ore smelting plant).

Environmental Laboratories. Conditions ranging from the simulation of

hot desert climates to those of severe winters (such as chambers for auto-

mobile tests concerned with hot and cold engine starts).

Printing. Humidity regulation needed for proper handling of the paper and

drying of ink.

Textiles. Regulation of humidity so that static electricity is reduced and

fibers have suitable strength and flexibility to travel at high speed through

the machines without failure.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

14 Chapter 1 Fundamentals of Refrigeration

Precision Parts and Cleanrooms. Maintaining the required temperature

and humidity to control dimensional variation for metal parts, prevent rust,

and reduce dust particles with filtration.

Photographic Products. Proper temperature and humidity to reduce dete-

rioration of photographic raw materials and precisely controlled tempera-

tures for film coating processes.

Mine Air Conditioning. Air cooling and ventilation for worker safety and

comfort mandated by the mines high humidity and high temperature and

the need for adequate oxygen.

Industrial Refrigeration

Industrial Refrigeration is another broad area for the application of refrigera-

tion. A large category within industrial refrigeration is the processing and stor-

age of food, while the pharmaceutical and chemical industries also use

specialized refrigeration systems. A partial list of applications is provided in

the following subsections.

Unfrozen- and Frozen-Food Storage

The time period during which most foods can be safely stored is significantly

increased as temperature is reduced. Foods stored at temperatures slightly

above their freezing temperature include beef, chicken, fish, eggs, bananas,

oranges, apples, tomatoes, lettuce, cabbage, potatoes, onions, and many others.

Foods stored at temperatures below freezing include ice cream, fish, poultry

products, beef, pork, concentrated fruit juice, prepared foods, and candy.

Process Freezing

Process freezing is the rapid freezing of some foods to minimize growth of ice

crystals and extend safe storage time. Common methods of food process freez-

ing include air-blast freezing, where a low-temperature airstream flows past the

product; immersion freezing by a low-temperature brine; and contact freezing,

where the product (such as ice cream cartons) is placed between cold plates.

Food Processing

Refrigeration may be required in food processing where the foods chemical

nature is altered. Example processes that require refrigeration include the cur-

ing of milk curds for cheese production; beer fermentation, where the removal

of heat is necessary to complete the process; wine storage after fermentation at

below room temperature for a period of six months to two years; and fruit juice

concentrate production, where refrigeration is used to condense water vapor

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Fundamentals of Refrigeration I-P 15

removed from fruit juice. The freeze-drying process also uses refrigeration to

condense water removed from food products.

Chemical and Process Industries

Numerous processes that require special refrigeration systems include the sep-

aration of gases, the condensation of gases, solidification by freezing one

chemical in a mixture, storage of a liquid at a low temperature avoiding high

pressure, and the removal of heat from a chemical reaction.

Additional Applications

Additional applications include drinking fountains, dehumidifiers, ice makers,

ice-skating rinks, manufacturing plants, environmental test chambers and wind

tunnels, construction (freezing soil for excavation and concrete cooling during

hardening), and water desalination.

Next Step

The information in Chapter 2 provides a review of thermodynamics, which is

important for understanding the processes that comprise the vapor-compression

refrigeration system.

Summary

Chapter 1 introduced the refrigeration system as the means by which heat is

removed from a material or space and transported elsewhere. Refrigerationsys-

tem types, including vapor-compression, air cycle, absorption, and thermoelec-

tric systems, were discussed, and their essential features were provided.

Evaporative cooling was also presented, in which an airstream is cooled by the

evaporation of water. The field of refrigeration was categorized by capacity,

refrigerating temperature, and application. The boundaries of the categories

overlap but, nevertheless, provide structure to the field of refrigeration. You

should now be able to

define what is meant by the term refrigeration;

describe the refrigeration systems;

discuss the similarities and differences between air conditioning and indus-

trial refrigeration;

describe the basic operation of three refrigeration system types;

identify and describe the four major components in a vapor-compression

refrigeration system;

Describe the purpose of a heat-pump system and how it is different from a

refrigeration system; and

list five major applications of refrigeration and give an example of each.

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

16 Chapter 1 Fundamentals of Refrigeration

Complete these questions by writing your answers on the worksheets at the back of this book.

1-1 After arriving home from a long day at work, you open your refrigerator door

and remove a bottle containing a cold beverage. What refrigeration-cycle pro-

cesses occurred to produce your cold drink?

1-2 Describe in your own words the meaning of the word refrigeration.

1-3 For the vapor-compression refrigeration system, name the four major compo-

nents and their functions.

1-4 Describe in your own words the purpose of the heat pump-system.

1-5 Explain the similarities and differences between the fields of air conditioning,

commercial refrigeration, and industrial refrigeration.

1-6 Name and describe three applications of refrigeration systems in both the air-

conditioning and industrial-refrigeration fields.

Skill Development Exercises for Chapter 1

American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). For personal use only.

Additional reproduction, distribution, or transmission in either print or digital form is not permitted without ASHRAEs prior written permission.

Anda mungkin juga menyukai

- Handbook of Dehumidification TechnologyDari EverandHandbook of Dehumidification TechnologyPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- A Guide in Practical Psychrometrics for Students and EngineersDari EverandA Guide in Practical Psychrometrics for Students and EngineersBelum ada peringkat

- Fundamentals of Psychrometrics PDFDokumen178 halamanFundamentals of Psychrometrics PDFCarlos López100% (3)

- Fundamentals of Heating and Cooling Loads I-PDokumen314 halamanFundamentals of Heating and Cooling Loads I-PMahmoud Gwaily96% (27)

- Ashrae Pocket Guide I P PDFDokumen36 halamanAshrae Pocket Guide I P PDFMUKESH DAYMABelum ada peringkat

- Fundamentals of Air System Design I-P, 2nd Ed.Dokumen378 halamanFundamentals of Air System Design I-P, 2nd Ed.Mahmoud Gwaily100% (16)

- Technical Development Program: Principles of Mechanical RefrigerationDokumen8 halamanTechnical Development Program: Principles of Mechanical RefrigerationSusan Lam0% (1)

- Fundamental Desgin Control Central Chilled Water Plant IpDokumen336 halamanFundamental Desgin Control Central Chilled Water Plant IpAbou Hasiba Mohamed92% (12)

- ASHRAE Fundamentals of Water System PDFDokumen350 halamanASHRAE Fundamentals of Water System PDFPappu100% (3)

- ASHRAE Fundamentals of Steam System PDFDokumen236 halamanASHRAE Fundamentals of Steam System PDFPappu100% (5)

- Symbols - STD 134Dokumen32 halamanSymbols - STD 134Joaquim MonteiroBelum ada peringkat

- Fundamentals of Water System Design ASHRAE PDFDokumen350 halamanFundamentals of Water System Design ASHRAE PDFNabeel AK100% (2)

- Fundamentals of Psychrometrics SI, 2nd Ed PDFDokumen180 halamanFundamentals of Psychrometrics SI, 2nd Ed PDFZaw Moe Khine100% (2)

- Fundamentals of Building Operation Maitenance and ManagmentDokumen304 halamanFundamentals of Building Operation Maitenance and ManagmentKhaled Reda88% (16)

- Cold-Climate Buildings Design GuideDokumen20 halamanCold-Climate Buildings Design Guideaftab ali AnsariBelum ada peringkat

- Previews ASHRAE D 90439 PreDokumen21 halamanPreviews ASHRAE D 90439 PreCotejo GermieBelum ada peringkat

- HVAC Handbook CARRIER 2 Air DistributerDokumen99 halamanHVAC Handbook CARRIER 2 Air DistributerTanveer100% (5)

- HVAC Handbook New Edition Part 4 Refrigerant Brines OilsDokumen71 halamanHVAC Handbook New Edition Part 4 Refrigerant Brines OilsShakir Ahmed Kalkundri100% (3)

- 5 - HVAC Handbook - New Edition - Part.5 - Water ConditioningDokumen52 halaman5 - HVAC Handbook - New Edition - Part.5 - Water ConditioningIsak Tao100% (2)

- Water 09 00098 v2Dokumen40 halamanWater 09 00098 v2enlightened171880% (5)

- HVAC Handbook 9 Systems Applications CarrierDokumen27 halamanHVAC Handbook 9 Systems Applications CarrierTanveer100% (3)

- AHRI Standard 410-2001 With Addenda 1 2 and 3Dokumen67 halamanAHRI Standard 410-2001 With Addenda 1 2 and 3Oziel Reyes100% (1)

- Carrier HVAC Handbook Part 7 Refrigeration EquipmentDokumen71 halamanCarrier HVAC Handbook Part 7 Refrigeration EquipmentTanveer100% (3)

- ASHRAE Workshop Control SamHui Part 4Dokumen53 halamanASHRAE Workshop Control SamHui Part 4feliprolBelum ada peringkat

- Applying VRF?: Don't Overlook Standard 15Dokumen7 halamanApplying VRF?: Don't Overlook Standard 15Eric G. MagnayeBelum ada peringkat

- PrinciplesDokumen608 halamanPrinciplesspeedkillz83% (6)

- HVAC Simplified Solution ManualDokumen78 halamanHVAC Simplified Solution ManualJulian Arlisdianto88% (26)

- Redline Ashrae 41.1 2013-1986R2006Dokumen64 halamanRedline Ashrae 41.1 2013-1986R2006Huzaifah Bin YounusBelum ada peringkat

- ASHRAE Workshop Control SamHui Part 2Dokumen64 halamanASHRAE Workshop Control SamHui Part 2Rami Reddy100% (1)

- 170 2013 Ae 20141008 PDFDokumen8 halaman170 2013 Ae 20141008 PDFDamir ĆavarBelum ada peringkat

- Chilled Water SystemDokumen107 halamanChilled Water SystemPhang S. Sun93% (30)

- (Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration EquipmentDokumen71 halaman(Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration Equipmentlyly20983% (6)

- ASHRAE Fundamentals of Thermodynamics PDFDokumen323 halamanASHRAE Fundamentals of Thermodynamics PDFPappuBelum ada peringkat

- AshraeDokumen85 halamanAshraelayth salah100% (7)

- TDP-502 Water Piping and PumpsDokumen63 halamanTDP-502 Water Piping and PumpsAmr HeshamBelum ada peringkat

- Carrier Handbook Part 1Dokumen162 halamanCarrier Handbook Part 1Tanveer100% (3)

- Ansi Ashrae Acca 183-2007 (Ra 2014)Dokumen10 halamanAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- Ashrae: StandardDokumen52 halamanAshrae: StandardsamadonyBelum ada peringkat

- Duct Systems Design GuideDokumen186 halamanDuct Systems Design GuideIbrahem Salameh100% (6)

- ASHRAE Design Guide For Air Terminal Units Selection, Application, Control, and CommissioningDokumen249 halamanASHRAE Design Guide For Air Terminal Units Selection, Application, Control, and Commissioningtran duy75% (4)

- Ashrae Pumping SystemsDokumen1 halamanAshrae Pumping SystemsAnonymous 73gEYyEtLBelum ada peringkat

- Ashrae Pocket Guide I-P PDFDokumen36 halamanAshrae Pocket Guide I-P PDFlumomomoro100% (5)

- 04 Water Soure Heat PumpsDokumen96 halaman04 Water Soure Heat PumpsLmkjh nko01Belum ada peringkat

- (ASHRAE datacom series bk. 9) American Society of Heating Refrigerating and Air-Conditioning Engineers - Real-time energy consumption measurements in data centers-American Society of Heating, Refriger.pdfDokumen297 halaman(ASHRAE datacom series bk. 9) American Society of Heating Refrigerating and Air-Conditioning Engineers - Real-time energy consumption measurements in data centers-American Society of Heating, Refriger.pdfVaibhav Rao0% (1)

- CARRIER Part-11 - All-Water-SystemDokumen35 halamanCARRIER Part-11 - All-Water-SystemNahiyan AbdullahBelum ada peringkat

- HVAC Equations, Data, and Rules of Thumb, Third EditionDari EverandHVAC Equations, Data, and Rules of Thumb, Third EditionBelum ada peringkat

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationDari EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationPenilaian: 1 dari 5 bintang1/5 (1)

- 2019 Lee David ThesisDokumen93 halaman2019 Lee David ThesisVikas PatidarBelum ada peringkat

- FluidPower NAVEDTRA 14105Dokumen248 halamanFluidPower NAVEDTRA 14105Anonymous ntE0hG2TP100% (1)

- Design Modeling and Control of A Thermal Management SystemDokumen185 halamanDesign Modeling and Control of A Thermal Management Systemflorin chisBelum ada peringkat

- Be Projects Hello-Engineers - BlogspotDokumen123 halamanBe Projects Hello-Engineers - Blogspotjonny727Belum ada peringkat

- Mendoza Rmo Introduction To Chemical ThermodynamicsDokumen223 halamanMendoza Rmo Introduction To Chemical ThermodynamicsStrahinja DonicBelum ada peringkat

- AFT FathomDokumen173 halamanAFT Fathompca97Belum ada peringkat

- Spray Cooling Masters ThesisDokumen151 halamanSpray Cooling Masters ThesisDr. Brian GlassmanBelum ada peringkat

- ASHRAE - SystemPerformanceEvaluationDokumen140 halamanASHRAE - SystemPerformanceEvaluation2742481Belum ada peringkat

- Previews-ASHRAE 90316 PreDokumen14 halamanPreviews-ASHRAE 90316 PreEsteban Araya CastroBelum ada peringkat

- Previews ASHRAE D 90453 PreDokumen25 halamanPreviews ASHRAE D 90453 PreronychavesBelum ada peringkat

- Scaffolding Instruction For Ells-Resource Guide For Mathem PDFDokumen83 halamanScaffolding Instruction For Ells-Resource Guide For Mathem PDFjenBelum ada peringkat

- Dynamics Model For VehicleDokumen217 halamanDynamics Model For VehicleBruno Ramos0% (1)

- 13 MathForManufacturing v143 Dec2013 ICCBDokumen130 halaman13 MathForManufacturing v143 Dec2013 ICCBJosephi_abbasBelum ada peringkat

- Ex-Texas Cop Charged For Shooting Teen Eating HamburgerDokumen11 halamanEx-Texas Cop Charged For Shooting Teen Eating HamburgerLee ChorneyBelum ada peringkat

- Cuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetDokumen6 halamanCuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetLee ChorneyBelum ada peringkat

- Dramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Dokumen10 halamanDramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Lee ChorneyBelum ada peringkat

- Britney Spears Poses Topless in Daisy Dukes For New Instagram PicDokumen6 halamanBritney Spears Poses Topless in Daisy Dukes For New Instagram PicLee ChorneyBelum ada peringkat

- Hawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCUDokumen5 halamanHawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCULee ChorneyBelum ada peringkat

- 8 CENM-HV-F1: Certified Performance DataDokumen10 halaman8 CENM-HV-F1: Certified Performance DataLee ChorneyBelum ada peringkat

- Flexmaster U.S.A.® 4NI: Submittal DataDokumen1 halamanFlexmaster U.S.A.® 4NI: Submittal DataLee ChorneyBelum ada peringkat

- Riello RTC Data Sheet Rev4Dokumen8 halamanRiello RTC Data Sheet Rev4Lee ChorneyBelum ada peringkat

- 101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideDokumen4 halaman101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideLee ChorneyBelum ada peringkat

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDokumen1 halamanState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyBelum ada peringkat

- 235-Custom Air Handling Unit Submittal (For Record) - Record Purpose Shop Drawings - 2017-02-03-115802 PDFDokumen173 halaman235-Custom Air Handling Unit Submittal (For Record) - Record Purpose Shop Drawings - 2017-02-03-115802 PDFLee ChorneyBelum ada peringkat

- FL TZDokumen1 halamanFL TZLee ChorneyBelum ada peringkat

- 4/6/19, 7@15 PM Page 1 of 4Dokumen4 halaman4/6/19, 7@15 PM Page 1 of 4Lee ChorneyBelum ada peringkat

- Why This Trainer Works His Clients For Just 30 MinutesDokumen10 halamanWhy This Trainer Works His Clients For Just 30 MinutesLee ChorneyBelum ada peringkat

- Salma Hayek, 53, Posts Revealing Photo To Celebrate Reaching 12 Million Instagram FollowersDokumen8 halamanSalma Hayek, 53, Posts Revealing Photo To Celebrate Reaching 12 Million Instagram FollowersLee ChorneyBelum ada peringkat

- Works His Clients For Just 30 MinutesDokumen1 halamanWorks His Clients For Just 30 MinutesLee ChorneyBelum ada peringkat

- Heat Transfer Lecture#5Dokumen10 halamanHeat Transfer Lecture#5Chemical EngineeringBelum ada peringkat

- Surface Tension (Water Properties), USGS Water Science SchoolDokumen2 halamanSurface Tension (Water Properties), USGS Water Science SchoolrajkumarBelum ada peringkat

- PackoDokumen30 halamanPackoikuzma_1Belum ada peringkat

- Removal of Foaming - Sigmapure TechnologyDokumen1 halamanRemoval of Foaming - Sigmapure Technologypeter2mBelum ada peringkat

- General Information: Section 1Dokumen11 halamanGeneral Information: Section 1ShaarawyBelum ada peringkat

- Liquid Loading in Gas Wells Remedial Operations PDFDokumen33 halamanLiquid Loading in Gas Wells Remedial Operations PDFAna Carolina Lazcano DuranBelum ada peringkat

- 18CV33 NewDokumen102 halaman18CV33 NewAkon JoshBelum ada peringkat

- Bomba de Diafragma 0.25Dokumen24 halamanBomba de Diafragma 0.25Antony CarbajalBelum ada peringkat

- Science Chapter 3 F1Dokumen26 halamanScience Chapter 3 F1brownsofaBelum ada peringkat

- 5 Grade - Lesson 2.3 Mixing Liquids To Identify An Unknown Liquid ObjectiveDokumen6 halaman5 Grade - Lesson 2.3 Mixing Liquids To Identify An Unknown Liquid ObjectiveAndrea GamutanBelum ada peringkat

- Mars5 Operation ManualDokumen99 halamanMars5 Operation Manualmj alvarezBelum ada peringkat

- Moisture Transmission PrintDokumen49 halamanMoisture Transmission PrintMusical Black DiaryBelum ada peringkat

- CHEE3004 Project 1Dokumen34 halamanCHEE3004 Project 1faizziBelum ada peringkat

- Chapter 12 - Liquids and SolidsDokumen35 halamanChapter 12 - Liquids and SolidsGörkem DamdereBelum ada peringkat

- Shok Waves AplicationsDokumen68 halamanShok Waves AplicationsLuis Florian SalasBelum ada peringkat

- Gravity-Driven Fluid Oscillations in A Drinking StrawDokumen4 halamanGravity-Driven Fluid Oscillations in A Drinking StrawAmaury DuránBelum ada peringkat

- DemisterDokumen4 halamanDemistermariniabrahanBelum ada peringkat

- Dry Low NOxDokumen28 halamanDry Low NOxRiza Agung NugrahaBelum ada peringkat

- Learning Module BTECH TBC - Part1.chem Module1Dokumen9 halamanLearning Module BTECH TBC - Part1.chem Module1Jen LabaoBelum ada peringkat

- Flexible Liquid Storage Tanks PDFDokumen8 halamanFlexible Liquid Storage Tanks PDFPT Putra Industries EnergyBelum ada peringkat

- GRADE 4 SCIENCE Chap 2 Lesson 1-3Dokumen5 halamanGRADE 4 SCIENCE Chap 2 Lesson 1-3Joaquin Inigo P. EstebarBelum ada peringkat

- Ideal Solubility ParametersDokumen14 halamanIdeal Solubility ParametersYuppie Raj100% (2)

- Lab Report Absorption ColumnDokumen18 halamanLab Report Absorption ColumnArina Hazirah100% (1)

- 615 Innovaswitch DatasheetDokumen4 halaman615 Innovaswitch DatasheetJavier CarrizoBelum ada peringkat

- Technical Paper-WSD 2018Dokumen6 halamanTechnical Paper-WSD 2018krbabu1969Belum ada peringkat

- Surface Vehicle Standard: Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesDokumen9 halamanSurface Vehicle Standard: Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesIgor BastosBelum ada peringkat

- Etextbook 978 0134292380 Fundamentals of Hydraulic Engineering Systems 5th EditionDokumen61 halamanEtextbook 978 0134292380 Fundamentals of Hydraulic Engineering Systems 5th Editionjohnny.holley803100% (48)

- Alberta Pipeline ActDokumen56 halamanAlberta Pipeline ActFredrick Martin100% (1)

- Optimizing Spray Performance With Computational Fluid DynamicsDokumen8 halamanOptimizing Spray Performance With Computational Fluid DynamicsDavidBelum ada peringkat