Coach Care Report Railway

Diunggah oleh

sharmalokesh47Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Coach Care Report Railway

Diunggah oleh

sharmalokesh47Hak Cipta:

Format Tersedia

1

A

Seminar Report on

Coaching, Caring and Maintenance of Railway Coaches

PRACTICAL TRAINING TAKEN AT

COACH CARE COMPLEX, JAIPUR

NORTH WESTERN RAILWAY

INDIAN RAILWAYS

submitted in partial fulfillment of the

requirements for the degree

of

B.TECH

MECHANICAL ENGINEERING

by

LOKESH SHARMA

11EVJME024

Under the guidance of

MR. SUMIT SHARMA

TRAINING SEMINAR CORDINATOR

DEPARTMENT OF MECHANICAL ENGG,

Vivekananda Institute of Technology

Jagatpura, Jaipur

2013-14

2

3

4

Vivekananda Institute of Technology

DEPARTMENT OF MECHANICAL ENGINEERING

JAIPUR (RAJASTHAN)-302022

CERTIFICATE

This is to certify that this report on Practical Training taken at Coach Care Complex of Indian

Railways is submitted by Lokesh Sharma, 11EVJME024 to the Department of Mechanical

Engineering, VIT, Jaipur, for the award of the degree in B. Tech Mechanical Engineering is a

bonafide record of work carried out by him. The contents of this Seminar report, in full or in

parts have not been submitted to any other Institute or University for the award of any degree or

diploma.

Sumit Sharma/Md. Mukhtar Alam Mr. Peeyush Vats

Incharge (Practical Training Seminar) HOD, ME

5

ACKNOWLEDGEMENT

I express my deep sense of gratitude to Mr. R.K. Sharma, Coaching Depot Officer for their

valuable guidance, keen interest and encouragement at various stages of my training period. I

acknowledge with the thanks the kind of patronage, loving inspiration and timely guidance,

which I have received from my course coordinator Mr. M.P. Singh, Sr. Section Engineer

(Incharge) and Mr. Pankaj Sharma, Sr. Section Engineer and all the staff members of Coach

Care Complex (NWR), Jaipur.

I wish to extend my sincere gratitude to respective Practical Training Seminar Coordinator, Mr.

Sumit Sharma and Md. Mukhtar Alam for their valuable guidance and regular encouragement

which has been absolutely helpful in successful completion of this training report. I am indebted

to Mr. Peeyush Vats (HOD, Department of Mechanical Engineering) for his valuable support. I

am also thankful to all the ME faculty members for their keen interest and at last my coordinal

thanks to my batch mates and friends for their cooperation.

_____________

` Lokesh Sharma

11EVJME024

6

TABLE OF CONTENT

INTRODUCTION 1

1.) ORGANSATION STRUCTURE 3

1.1) Zones of Indian Railways 4

1.2) Departments 7

2.) NORTH WESTERN RAILWAY 8

2.1) Facts and Other Statistics 9

2.2) Brief Outline of the Divisions 11

2.2.1) Jaipur Division 11

2.2.2) Bikaner Division 11

2.2.3) Jodhpur Division 11

2.2.4) Ajmer Division 12

3.) INTRODUCTION TO COACHES 13

3.1) Important Parameters of LHB Coaches 14

3.2) Various Parts of LHB Rake 16

3.2.1) Wheel and Axle Assembly 16

3.2.1.1) Wheel 16

3.2.1.2) Axle 17

3.2.1.3) Components of Wheel and Axle Assembly 18

3.2.1.4) Axle Bearings 19

4.) BOGIE 20

4.1) Bogie Frame 21

4.2)Primary Suspension 22

4.3) Secondary suspension 23

4.3.1) Cross Bar 24

4.3.2) Bolster Assembly 24

4.4) Drawing and Buffing Gear Assembly 24

4.4.1) Screw Coupling 24

4.4.2)Side Buffers 24

5.)SHELL 26

5.1)Body 27

5.1.1) Center Pivot Assembly 27

5.1.2) Body Bogie Connection 28

5.2) The Transmission of Hauling Force 28

5.2.1) Center Pivot 28

7

5.2.2) Longitudinal Bumpstop 28

5.2.3) Articulated Control Arm 28

5.3) Trolley 29

5.3.1) Trolley Frame 29

5.3.2) Center Pivot 29

5.3.3) Side Bearing 29

5.3.4) Brake Cylinders 29

5.3.5) Brake Blocks 29

5.3.6) Equilateral Sterod 30

5.3.7) Anchor Rod 30

5.3.8) Suspension System 30

5.4) The Load Distribution 32

6.) BRAKING SYSTEM 33

6.1) Air Brake System 33

6.1.1) Brake container 34

6.1.2) Connections to the Container 35

6.1.3) Brake Application 36

6.1.4) Brake Release 36

6.2) Bogie Brake Equipment 36

6.2.1) Brake Caliper Units 36

6.2.2) Brake Cylinders 38

6.2.3) Brake Discs 38

6.2.4) Brake Shoe 39

6.3) Brake Rigging System 39

6.4) Wheel Slide Protection Equipment 40

6.5) Center Buffer Coupler 42

7.) CDTS (Control Discharge Toilet system) 43

7.1) Salient Features 43

7.2) Operating Principle 43

7.3) Components of CDTS 45

7.3.1) Types 45

7.3.2) Control Panel 45

7.3.2.1) PLC 46

7.3.2.2) Solenoid Vale 46

7.3.2.3) Control Relay 46

7.3.3) Retention Tank 46

7.3.4) Lower Slide Valve 46

7.3.5) Upper Slide Valve 46

7.3.6) Flush Button 47

7.3.7) Water Pressurizer 47

8

7.3.8) Fail Safe Mode 47

7.4) Operational Description 47

8.) MAINTENANCE OF TRAINS 50

8.1) The Primary Structure 50

8.2) The Maintenance of the Trains 50

8.2.1) Primary Maintenance 51

8.2.2) Round Trip Maintenance 51

8.2.3) Secondary Maintenance 51

8.3) Maintenance Schedule and Overhauling Periods 52

8.4) Periodic Overhauling 52

8.4.1) POH Date and Return Date 53

8.4.2) Significance of Coach Number 53

Conclusion 54

Reference 55

9

LIST OF TABLES

Table No. Name of Table Page No.

Table 1.1) List of Zones of Indian Railways 5

Table 1.2) List of Departments 7

Table 3.1) Overall Dimensions of Coach 14

Table 3.2) Tare Weight of Coaches 15

Table 3.3) No. of seats in Different Coaches 16

Table 5.1) Strength of different types of Steels 26

10

LIST OF FIGURES

Figure No. Name of Figure Page No.

Fig 1.1) Zones Map 5

Fig 2.1 ) Logo of North Western Railway 8

Fig 2.2) Map of North Western Railway 10

Fig 3.1) Rail Wheels 17

Fig 3.2) Axle 18

Fig 3.3) Components of wheel and axle assembly 18

Fig 3.4) Axle Bearing 19

Fig 4.1) Bogie Frame 21

Fig 4.2) Components of Primary Suspension 22

Fig 4.3) Components of Secondary Suspension 23

Fig 4.4) Side Buffers 25

Fig 4.5) Primary Suspension Unit 25

Fig 5.1) Center Pivot Assembly 27

Fig 5.2) Trolley 31

Fig 6.1) Brake equipment for Passenger coach 34

Fig 6.2) Brake equipment panel 34

Fig 6.3) Brake equipment for Generator coaches 35

Fig 6.4) Brake Calliper Unit 37

Fig 6.5) Brake Cylinders and Callipers 38

Fig 6.6) Axle Mounted and Wheel mounted brake disc 39

Fig 6.7) Brake Rigging Pressure 40

Fig 6.8) Speed sensor and Phonic Wheel 41

Fig 6.9) Dump valve and Connector 41

Fig 6.10) Electronic connectors and Electronic Unit 41

Fig 7.1) Schematic Diagram of CDTS 45

Fig 7.2) Operational description of CDTS 47

11

INTRODUCTION

"Lifeline of the Nation"

Type : Public sector undertaking

Reporting mark : IR

Industry : Railways

Founded : April 16, 1853

Headquarters : New Delhi, India

Area served : India

Chairman : Arunendra Kumar

Services : Passenger railways

: Freight services

: Parcel carrier

: Catering and Tourism Services

: Parking lot operations

: Other related services

Track gauge : 1,676 mm (5 ft 6 in)

: 1,000 mm (3 ft 3 38 in)

: 762 mm (2 ft 6 in)

: 610 mm (2 ft)

Electrification : 23,541 kilometers (14,628 mi)

12

Length : 65,000 kilometers (40,000 mi)

Revenue : 1256.8 billion (US$21 billion)

Net income : 104.1 billion (US$1.7 billion)

Owner(s) : Government of India (100%)

Employees : 2.2 million (2012)

Parent : Ministry of Railways through Railway Board (India)

Zones : 17 Railway Zones

Website : www.indianrailways.gov.in

13

CHAPTER-1

ORGANSATION STRUCTURE

Indian Railways (reporting mark IR) is an Indian state-owned enterprise, owned and operated

by the Government of India through the Ministry of Railways. It is one of the world's largest

railway networks comprising 115,000 km (71,000 mi) of track over a route of 65,000 km (40,000

mi) and 7,500 stations. In 2011, IR carried over 8,900 million passengers annually or more than

24 million passengers daily (roughly half of which were suburban passengers) and 2.8 million

tons of freight daily. In 20112012 Indian Railways had revenues of 1119848.9 million (US$19

billion) which consists of 696759.7 million (US$12 billion) from freight and 286455.2 million

(US$4.8 billion) from passengers tickets.

Railways were first introduced to India in 1853 from Bombay to Thane. In 1951 the systems

were nationalized as one unit, the Indian Railways, becoming one of the largest networks in the

world. IR operates both long distance and suburban rail systems on a multi-gauge network of

broad, meter and narrow gauges. It also owns locomotive and coach production facilities at

several places in India and are assigned codes identifying their gauge, kind of power and type of

operation. Its operations cover twenty nine states and seven union territories and also provide

limited international services to Nepal, Bangladesh and Pakistan.

Indian Railways is the world's ninth largest commercial or utility employer, by number of

employees, with over 1.4 million employees. As for rolling stock, IR holds over 239,281 Freight

Wagons, 59,713 Passenger Coaches and 9,549 Locomotives (43 steam, 5,197 diesel and 4,309

electric locomotives).

The trains have a 5 digit numbering system as the Indian Railways runs about 10,000 trains

daily. As of 31 March 2013, 23,541 km (14,628 mi) (36%) of the total 65,000 km (40,000 mi)

route length was electrified. Since 1960, almost all electrified sections on IR use 25,000 Volt AC

traction through overhead catenary delivery.

14

On 23 April 2014, Indian Railways introduced a mobile app system to track train schedules.

The first railway on Indian sub-continent ran over a stretch of 21 miles from Bombay to Thane.

The idea of a railway to connect Bombay with Thane, Kalyan and with the Thal and Bhore Ghats

inclines first occurred to Mr. George Clark, the Chief Engineer of the Bombay Government,

during a visit to Bhandup in 1843.

Indian Railways runs around 11,000 trains everyday, of which 7,000 are passenger trains.

1.1 Zones of Indian Railways

Indian Railways is divided into several zones, which are further sub-divided into divisions. The

number of zones in Indian Railways increased from six to eight in 1951, nine in 1952 and sixteen

in 2003 and now seventeen. Each zonal railway is made up of a certain number of divisions, each

having a divisional headquarters. There are a total of sixty-nine divisions.

Each of the seventeen zones is headed by a general manager who reports directly to the Railway

Board. The zones are further divided into divisions under the control of divisional railway

managers (DRM).

15

(Fig 1.1 Zones Map)

( Table 1.1 List of Zones of Indian Railways )

Sr.

No

Zone

Name

Abbr. Date

Established

Route

length

( Km)

Headquarter Divisions

1. Central CR 5 November

1951

3905 Mumbai Mumbai, Bhusawal, Pune,

Solapur, Nagpur

16

2. East

Central

ECR 1 October 2002 3628 Hajipur Danapur, Dhanbad,

Mughalsarai, Samastipur,

Sonpur

3. East Coast ECoR 1 April 2003 2572 Bhubaneswar Khurda Road, Sambalpur,

Waltair

4. Eastern ER 14 April 1952 2414 Kolkata Howrah, Sealdah, Asansol,

Malda

5. North

Central

NCR 1 April 2003 3151 Allahabad Allahabad, Agra, Jhansi

6. North

Eastern

NER 14 April 1952 3667 Gorakhpur Izzatnagar, Lucknow, Varanasi

7. North

Western

NWR 1 October 2002 5459 Jaipur Jaipur, Ajmer, Bikaner,

Jodhpur

8. Northeast

Frontier

NFR 15 January

1958

3907 Guwahati Alipurduar, Katihar, Rangia,

Lumding, Tinsukia

9. Northern NR 14 April 1952 6968 Delhi Delhi, Ambala, Firozpur,

Lucknow, Moradabad

10. South

Central

SCR 2 October 1966 5803 Secunderabad Secunderabad, Hyderabad,

Guntakal, Guntur, Nanded,

Vijayawada

11 South East

Central

SECR 1 April 2003 2447 Bilaspur Bilaspur, Raipur, Nagpur

12. South

Eastern

SER 1955 2631 Kolkata Adra, Chakradharpur,

Kharagpur, Ranchi

13. South

Western

SWR 1 April 2003 3177 Hubli Hubli, Bangalore, Mysore

14. Southern SR 14 April 1951 5098 Chennai Chennai, Tiruchirappalli,

Madurai, Palakkad, Salem,

Thiruvananthapuram

15. West

Central

WCR 1 April 2003 2965 Jabalpur Jabalpur, Bhopal, Kota

16. Western WR 5 November

1951

6182 Mumbai Mumbai Central, Ratlam,

Ahmedabad, Rajkot, Bhavnagar,

17

1.2 Departments

A typical division has an average track length of about 1000 km and staff strength of about

15000. All the departments and services of the Indian Railways are represented in a Division.

( Table 1.2 List of Departments )

SR.NO Name of Department Role and function

1. Engineering

Department

Maintenance of all fixed assets of the Division, i.e. Track,

Bridges, Buildings, Roads, Water supply etc.

2. Mechanical

Engineering &

Power Department

Maintenance of all rolling stock of the Division , i.e.

locomotives, passenger and freight cars; and technical super

etc.

3. Electrical Engineering

Department

Maintenance of all electric locomotives, EMUs/MEMUs and

fixed electrical assets of the Division, i.e. Overhead

equipment, lighting and power for railway establishments etc.

4. Signal &

Telecommunication

Engineering Dept

Management of the Signaling and Telecommunication (S&T)

infrastructure of the division for Safe Train operations

5. Operating and Traffic

Department

Train operations

6. Commercial

Department

Passenger ticketing, ticket checking, booking of freight rakes

and collecting fares

7. Medical Department Providing medical facilities to railway employees and their

Families

8. Safety Department Ensuring safety of train operations

9. Stores Department Ensuring material for maintenance of trains (material for all

departments except the Engineering Department)

10. Accounts Department Financial management of the division

11. Personnel Department HR functions

12. Security Department Security of railway material, passenger and passenger

Belongings

18

CHAPTER -2

NORTH WESTERN RAILWAY

Serving Customer with Smile

(Fig 2.1 Logo of North Western Railway)

Reporting mark : N.W.R

Founded : October 1, 2002

Headquarters : Jaipur, Rajasthan

General Manager : R.C.Agrawal

Track gauge : 1,676 mm (5 ft. 6 in)

: 1,000 mm (3 ft. 3 38 in)

Length : 54449.29 kilometers

Stations : 578

Division : 4

Website : www.nwr.indianrailways.gov.in

The North Western Railway is one of the sixteen railway zones in India. It is headquartered at

Jaipur. It comprises four divisions: Jodhpur and reorganized Bikaner division of the erstwhile

Northern Railway and reorganized Jaipur and Ajmer divisions of the erstwhile Western Railway.

This zone came into existence on October 1, 2002. This railway comprises a total of 578 stations

covering a total of 5449.29 route km out of which 2575.03 are broad gauge and 2874.23

are meter gauge.

North Western Railway came being on 1

st

October, 2002. It was carved out of 2 divisions each

from Northern and Western Railways. The formation of this zone along with five other new

19

zones was first approved by Railway Board on 16

th

September, 1996 and foundation stone for

this zone was laid on 17

th

October 1996 by the then Prime Minister Shri H.D. Deve Gowda at

K.P. Singh Stadium, Jaipur. The impetus for formation of New Zone came with the Government

of India notification no. 97/E&R/700/1/Notification dated 14.06.2002 wherein it was decided

that North Western Railway with its jurisdiction over existing Jaipur and Ajmer divisions of

Western Railway and Jodhpur and Bikaner divisions of Northern Railway was to come into

effect from 1.10.2002.

2.1 Facts and Other Statistics

Consisting of four divisions, this railway has a total of 578 stations covering a total of 5449.29

route kms out of which 2575.03 are broad guage and 2874.23 are meter guage. The total track

kilometers of this railway, however, are 6559.546 kms. The four divisions are Ajmer, Bikaner,

Jaipur & Jodhpur. Jaipur & Ajmer divisions were originally part of Western Railway and

Bikaner & Jodhpur were part of Northern Railway. The total number of trains dealt by North

Western Railway amounts to 452 out of which BG trains total 264 and MG trains total 188.

20

(Fig 2.2 Map of North Western Railway)

21

2.2 Brief Outline of the Divisions

2.2.1 Jaipur Division

This division was formed after merging parts of BB&CI, Jaipur State Railways and Rajputana

Malwa Railway, Jaipur Division serves the states of Rajasthan, Uttar Pradesh and Haryana.

Being a predominately passenger earning division (84.92% of its earning is by way of passenger

traffic), it deals primarily with cross traffic consisting of fertilizer, cement, oil, salt, food grains,

oil seeds, lime stone and gypsum traffic. Container loading is done from here in bulk. The total

no. of stations on this division is 128 and the total no. of trains run are 146. Jaipur station alone

deals with 88 BG & 22 MG trains and 35,000 passengers in a day. In order to ensure that the

passenger does not face any hardship for reservations the division has at the moment 14

functioning Computerized Passenger Reservation System Centres. The staff strength of this

division in all categories is 12007.

2.2.2 Bikaner Division

This division was established in 1924 and it serves the states of Rajasthan, Punjab and Haryana.

This division has an equal amount of passenger and goods traffic. The main outward goods

traffic of this division is food grains, china clay and gypsum. The total no. of situations in these

divisions is 198 and the total no. of trains dealt with are 142 including the rail bus and BG and

MG mail/exp and passenger trains. Bikaner division has 12 Computerized Passenger Reservation

System functioning and one Computerized Passenger Reservation System at Ratangarh is about

to be commissioned. A proposal for opening of PRS at Mahendergarh has already been sent to

Railway Board for sanction. The staff strength of this division in all categories is 13728.

2.2.3 Jodhpur Division

This division was up in the year 1882 and it consists primarily of semiurban districts of

Rajasthan. It covers areas of Jodhpur, Pali Marwar, Nagaur Jalore, Barmer, and Jaisalmer. It also

covers certain districts of Gujarat state. This division also serves certain sensitive areas of

Rajasthan such as Jaisalmer, Barmer and Pokaran. The main commodities loaded on this division

are lime stone, salt and gypsum. This division has a total of 144 stations and deals with 92 trains

22

in the inward and outward directions. Fifteen Computerised Passenger Reservation System

Centers exist over this division and another one is on the anvil. A proposal for four more

locations has already been sent. The staff strength of this division in all categories is 10231.

2.2.4 Ajmer Division

This division is spread over the states of Rajasthan and Gujarat. It is predominantly a cement

loading division as many cement plants of Rajasthan are located within the jurisdiction of Ajmer.

Rock phosphate, soap stone powder are loaded from Udaipur area. This division is prominent on

the religious and tourist map of India as it witnesses large amount of passenger traffic to Ajmer

Sharief, Pushkar, Jain Temples Dilwara at Mount Abu and Ranakpur Temples. This division has

130 stations and the total no. of trains run over the division amounts to 36 in both the passenger

and mail/exp category. At present there are 12 Computerized Passenger Reservation System

Centres functioning over this division and one location is awaiting commissioning. Proposals for

3 more locations have already been sent. The staff strength of this division in all categories is

9046.

23

CHAPTER-3

INTRODUCTION TO COACHES

Till recently, Indian Railways have been transporting passenger traffic mainly through coaches

of ICF design. These coaches are being manufactured at ICF and RCF. A limited number of

these coaches are being manufactured at BEML/Bangalore also. These type of coaches are

having limitations in terms of

i) Speed potential;

ii) Heavy corrosion;

iii) Poor riding comfort;

iv) Wearing of parts in the under gear;

To overcome these limitations, Indian Railways entered into supply and technology transfer

contracts with M/s. ALSTOM LHB/Germany to initially supply 24 coaches consisting of 19.

AC chair cars, 2 AC Executive Class Chair cars and 3 Generator cum Brake vans. The bogies

for these coaches are manufactured by M/s. FIAT/SIG Switzerland. These coaches arrived in

India and got commissioned in the year 2001 and put in service on route. These type of coaches

are far superior w.r.t. passenger comfort, safety, speed, corrosion, maintenance and aesthetics in

appearance. These coaches are also longer as compared to ICF design resulting into more

carrying capacity. The expected benefits from these types of coaches are as under:-

1. Higher carrying capacity - These coaches are about 2 meters longer than ICF coaches.

With this extra length two additional rows of chairs in chair cars or one additional bay in

sleeper coaches can be accommodated.

2. The weight of LHB coach is lesser as compared to ICF design coaches. LHB coach

can accommodate 72 passengers as compared to 64 in conventional AC III Tier Coach.

Thus giving better pay to tier ratio.

3. Low corrosion There will be low corrosion of LHB coaches due to extensive usage of

Stainless Steel and better design and manufacturing techniques.

24

4. Low Maintenance Replacement and removal of sub-systems will be required only

after one million kilometers. There are no doors handles projecting outside the coach thus

mechanized car washing is facilitated.

5. LHB Coaches have aesthetically superior interiors with FRP panels for side wall and

roof. They can be removed easily for maintenance, resist water seepage and are wear

resistant;

6. Safety -There are no visible screws inside the passenger compartment.

7. Better passenger comfort: Ride Index of 2.5 (Not exceeding 2.75) has been specified as

compared to in conventional ICF coaches.

3.1 Important Parameters of LHB Coaches

( Table 3.1 Overall dimensions of coach )

Sr. No. Parameters Dimension(in mm)

1. Gauge 1676

2. Length over Body 23540

3. Length over Buffer 24000

4. Height over Roof 4039

5. Maximum width over body 3240

6. Maximum distance between inner wheels 12345

7. Window opening 1180 X 760

8. Distance between centre pivots 14900

9. Height of compartment floor from rail level under

tare condition

1303

25

10. Maximum buffer drop under gross load and worn

conditions

75

11.

Maximum height of centre line of side buffers

above rail level for empty vehicle

1105

12.

Maximum height of centre line of side buffers

above rail level for loaded vehicle

1030

13.

Wheels mono block 915

( Table 3.2 Tare weight of coaches )

Sr. no. Type of Coach Tare Weight (in tonnes)

1. Chair Car 39.4

2. First AC 40.5

3. Second AC 48.4

4. Third AC 50.6

5. LSLR 37.9

26

( Table 3.3 No. of Seats in Different coach )

3.2 VARIOUS PARTS OF THE LHB RAKE:

3.2.1 WHEEL AND AXLE ASSEMBLY:

It is the part of a rake which is just adjacent to the tracks. It basically consists of four main parts:

1. Wheel

2. Axle

3. Components of wheel and axle assembly

4. Axle Bearings

3.2.1.1 WHEEL:

Wheel of a rake is a specifically made cylindrical portion having an outer edge shape to fit in the

railway track. The material used is stainless steel.

Sr. no. Type of Coach No. of Seats

1. 2

nd

AC Chair Car 78

2. Exe. AC Chair car 56

3. First class sleeper (FAC) 24

4. Two tier AC sleeper (AC2T) 52

5. Three tier AC sleeper (AC3T) 72

27

(Fig 3.1 Rail Wheels)

3.2.1.2 AXLE:

Axle is the main long cylindrical bar on which wheels are fixed with the help of bearings. This is

also made of stainless steel as above. Each axle contains 2 wheels, the brake cylinders are also

attached to it and in case of LHB coaches, the braking discs are fixed on to the axle.

28

(Fig 3.2 Axle)

3.2.1.3 COMPONENTS OF WHEEL AND AXLE

ASSEMBLY

Two brake disks (4), diameter 640 mm

and width 110 mm.

In built slack adjusting brake cylinder

fitted

Two Wheel disc of tread diameter 915

(New), 845 (Worn)

Nomenclature:

1. Axle

2. Plug

3. Wheel

4. Brake disc

AXLE

(Fig 3.3 components of wheel and axle assembly)

29

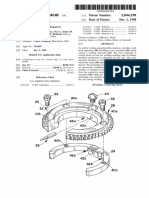

3.2.1.4 Axle Bearings:

A taper roller cartridge type bearing is used and it makes up a preassembled unit. The axle

bearings on the bogie are fitted with sensors for detecting speed (whose signal is elaborated by

the ant slipping system) and a current return device.

The ends of the control arms are fitted with centering devices for the primary suspension spring

assembly. The bearing lubricating plug is fitted in the lower part.

1. Double cup

2. Sealing system

3. Backing ring

FIG. 4-10 AXLE

BEARING

(Fig 3.4 Axle Bearings)

30

CHAPTER-4

BOGIE

The FIAT Bogie is two-axle type, with a primary and a secondary suspension. The bogie

assembly is shown in fig. 4.1. The Salient features of FIAT Bogie are:

1. Solid welded Bogie Frame made up of two longitudinal components connected by two

cross beams. The bogie frame rests on the primary suspension spring units and supports

the vehicle body by means of Bolster beam. The Bolster beam is connected to the bogie

frame by secondary suspension.

2. Primary suspension consist of two steel coil springs (internal/external) laid out on the

Control Arm upper part.

3. Secondary suspension consists of two spring packs which sustain the bolster beam over

the bogie frame. Each spring pack is made up by an internal and external spring. An Anti

roll bar fitted on the bogie frame realizes a constant, reduced inclination coefficient

during running. The bogie frame is linked to the bolster beam through two vertical

dampers, a lateral damper, four safety cables and the traction rods. The bogie frame is

linked to the coach body through two yaw dampers.

4. Traction Centre - The traction Centre transmits traction and braking forces between

bogie frame and body by a traction lever on the bolster beam pin and two rods.

5. Disk Brakes The FIAT bogie is fitted with pneumatic disk brakes. The pneumatically

operated brake cylinders are fitted with automatic device for taking up the clearances.

6. Taper Roller Cartridge Bearing Fiat Bogie is fitted with 130 mm Cartridge type

roller bearings.

31

4.1 Bogie frame

The bogie frame is a solid welded frame made by steel sheets and forged or cast parts.

The frame is made up of two longitudinal components (1) connected by two cross-beams (2)

which also support the brake units. The various supports which connect the different bogie

components are welded to the frame. The bogie frame rests on the primary suspension spring

units and supports the vehicle body by means of a bolster beam. The bolster beam is connected

to the bogie frame by the secondary suspension.

(Fig 4.1 Bogie Frame)

Nomenclature:

1. Bogie frame longitudinal component

2. Cross-beam

BOGIE FRAME

32

4.2 Primary suspension

Primary suspension is implemented by two units of two steel coil springs (internal (4) and

external (5)) laid out on the control arm upper part (13) by a centering disk (8) and adjustment

shims, as shown in figure 4.2.

The suspension is also completed by the following components:

A control arm (13), fitted with twin-layer elastic joints (12), connecting the axle bearing to the

bogie frame and transmitting, not stiffly, lateral, longitudinal and part of the vertical forces;

A vertical damper (14).

Rubber elements (2) separate the primary suspension from the bogie to realize noise

reduction.

Stops and protections are mounted on the bogie frame for the lifting.

Nomenclature:

1. Bogie frame

2. Rubber disks

3. Centering disk

4. Internal spring

5. External spring

6. Bump stop

7. Shim

8. Centering disk

9. Control Arm Lower Part

10. Plate (Fig 4.2 Components of Primary Suspension)

33

11. Block

12. Rubber joint

13. Control Arm Upper Part

14. Damper

4.3 Secondary suspension

The secondary suspension enables lateral and vertical displacements and bogie rotation with

respect to body when running through curves.

It is implemented by two spring packs which sustain the bolster beam (1) over the bogie frame

(6). Each spring pack is made up by an internal (3) and an external spring (4), mounted and

positioned through the centering discs (5).

An anti-roll bar (2), fitted on the bogie frame (6), realizes a constant, reduced inclination

coefficient during running.

The bogie frame is linked to the bolster beam through two vertical dampers (7), a lateral damper

(8), four safety cables (9) and the traction rods (10).

The bogie frame is also linked to the coach body through two yaw dampers (11).

Nomenclature:

1. Bolster beam

2. Anti- roll bar

3. Internal spring

4. External spring

5. Centering disk

6. Bogie frame

7. Vertical damper (Fig 4.3 Components of Secondary Suspension)

34

8. Lateral damper

9. Safety cables

10. Traction rod

11. Yaw damper

4.3.1 Cross Bar: Cross bar is the connection between the two ends of the trolley which also

maintains the uniform distribution of the hauling force to all wheels to ensure equal velocity.

4.3.2 Bolster Assembly: Bolster assembly is the host of the secondary suspension system. In

other words it is like two interconnected housing for springs. It also connects trolley and the

body of the rake. The main function of bolster assembly is to transform the hauling force and the

raking force form body to wheel and from wheel to body respectively.

4.4 Draw and Buffing Gear Assembly: Draw and buffing gears are attached to the end of one

coach and this two gear mechanisms are made to suit two adjacent coaches into an uniform

continuous movement. They also transform the hauling force from main engine to the following

rake, draw gear is specialized for these purpose, where as the buffing gears are essential for

maintaining a vibration less motion of a coach with respect to its former one.

We have two different arrangements of draw and buffing gear assembly in ICF and LHB

coaches. They are-

4.4.1 Screw coupling and the side buffers serves the aforesaid purpose in case of the draw and

buffing gears respectively in case of ICF coaches. Screw coupling not only gives the boost but

also let two coaches to connect in the formation of a continuous rake. The two jaws of the screw

on both sides are guarded with spring and rubber to minimize the vibration the hauling force

produces. They are called the DRAFT GEARS.

4.4.2Side buffers are uniquely shaped buffers. They have a flat plate made of stainless steel and

duly lubricated in contact to each other facing each other in motion. They are also guarded with

the iron plated and spring and rubber to minimize the vibration as much as possible.

35

For LHB coaches we have a multipurpose serving coupling between the two coaches. It is called

in technical terms the Center Buffer Coupling. It has got a special locking system operated by a

handle.

(Fig 4.4 Side Buffers) (Fig 4.5 Primary Suspension Unit)

36

CHAPTER 5

SHELL

The body shell is of integral light weight construction consisting of separate assembly group for

under frame, side wall, roof and end wall. The individual assemblies are joint to each other by

welding. Three types of steel are used for manufacture of body shell.

(Table 5.1 Strengths of Different type of steels)

Shell Assemblies Steels used and their

%age compositions

UTS

N/mm

2

Yield Stress

N/mm

2

Side wall, End wall

and Roof structure

X2 Cr8 Ferritic Steel

(SS 409M)

(C< .03%, Cr 10-12%,

Si 1%, Mn 1.5%)

450-600

320

Roof sheet and

Trough floor

X5 CrNi 18 10

Austenitic Steel (SS

304)

(C< .07%, Cr 18%, Ni

10 % Si 1%, Mn 2%)

700-850

235

Under frame IRS M-41 /Carbon Steel

( C < .01%, Cr .35 -

.6%, Ni .2 - .4%

Cu .3 - .6% Si .3 - .7%,

Mn .25%)

440-480

320

37

5.1 BODY:

Body is basically the coach itself without the braking mechanisms and suspensions. It has the

following constituents. They are discussed below:

1. The Carriage is the main structure of the coach. This contains a floor which is called

Turf. There are Arch Levers which maintain the weight distribution throughout the whole

coach. And then there is the roof which is of a typical aero dynamical shape.

2. At the bottom of the carriage there are two kind of bars made of stainless steel which

transfers the weight from the carriage to the wheels.

a. The Sole Bar is throughout the whole body of the coach vertically. These are at

the bottommost position of the body.

b. The Cross Bar is the horizontally arranged bars across the body. They get their

support from the sole bar.

5.1.1 Center Pivot Assembly:

Center Pivot is welded to the upper bolster plank and passes through the supporting frame which

is rectangular in shape. This is a pivoting system used in transportation of force through a

mechanically advantageous system of pivot. At the bottom of the center pivot there is a traction

lever. A traction rod is also connected at the end of traction lever having its other end connected

with the cross bar.

(Fig 5.1 Center Pivot Assembly)

38

5.1.2 Body- Bogie connection: Especially in case of the LHB Coaches, there are a special kind

of bolts called swing bolts, which are four numbered in each trolley. These connect the body to

the bogie to the body. Each bolt is fastened with a pin which can swing in the direction of the

motion

5.2THE TRANSMISSION OF HAULING FORCE:

The transmission of hauling force is an important observation phenomenon of the running of

rakes with engines. It is done through a number of ways and each way consists of a number of

steps:

5.2.1 Center Pivot: Hauling force is first transmitted to the Screw Couplings which are

connected at the front of a coach. From there the force is transmitted to the draft gear

then to the crossbar, to the sole bar, all the way to the bolster assembly through

swing bolts. Then due to this the swing bolt moves forward and so does the traction

lever and the traction rod. So the crossbar moves forward and the wheels start rolling.

5.2.2 Longitudinal Bumpstop: There is another way of transmission of hauling force from

the center pivot which is through the longitudinal bumpstop. This is partly cubical in

shape attached at the front of pivot assembly. When pivot moves forward it also

moves covering up the little gap between the frame and the bumpstop. Through the

supporting frame it goes to the crossbar.

5.2.3 Articulated Control Arm: The articulated control arm is a direct connection

between the body and the bogie. Through this the force is directly given to the

bearings.

39

5.3 TROLLEY:

Trolley is basically the separated part containing the wheel and other similar components which

are essential to run a coach. When they are attached with the body they are called the bogie.

Here we are going to discuss about the trolley parts of the ICF coaches.

5.3.1 Trolley Frame: Trolley frame is the main construction of the trolley on which the

other components rest. This is a metallic construction just like a cage having

different gaps in between to fit the components.

5.3.2 Center Pivot: This is the centrally situated hole which will indicate the correct

position of the trolley when fitted with the body. There is a counter part of the

hole attached at the body itself to indicate the perfect position of the trolley. When

assembled they should match perfectly.

5.3.3 Side Bearing: Side bearing is the bearing space engulfed by lubes and a bearing

made of bronze which plays a good role in distributing the weight throughout the

trolley.

5.3.4 Brake Cylinder: If we see the trolley in the direction of the motion we will see

two brake cylinders one after one which have the air supply through one outlet.

These brake cylinders operate in a critical air pressure and contains a piston which

we call the slug adjuster. At that particular pressure the piston inside those

cylinders moves and the brakes hold firm onto the wheels.

5.3.5 Brake Blocks: In ICF coaches we generally use the K & L types of brake blocks.

These are used as components of shoe brakes attaches at wheels. These special

40

types of blocks are used because of their increased coefficient of friction and also

the heat absorbing capability.

5.3.6 Equilateral Sterod: This is attached to the trolley symmetrically along the trolley

frame horizontally to minimize the lateral force when in motion.

5.3.7 Anchor Rod: These are rods attached vertically to minimize the longitudinal

load. Both of them are made of stainless steel.

5.3.8 Suspension Systems: These are anti vibration attachments which are attached to

the main frame and the wheel bearing.

41

(Fig 5.2 Trolley)

42

5.4 THE LOAD DISTRIBUTION:

SIDE BEARING

UPPER SPRING BEAM

SECONDARY SUSPENSION

SUSPENSION LINK

HANGER LINK

HANGER BLOCK

PRIMARY SPRING

AXLE BOX WING

JOURNAL

BEARING

AXLE

WHEEL

43

CHAPTER 6

BRAKING SYSTEM

6.1 AIR BRAKE SYSTEM:

In Air Brake system compressed air is used for operating the brake system. The

locomotive compressor charges the feed pipe and the brake pipes throughout the length of

the train. The feed pipe is connected to the auxiliary reservoirs and the brake pipe is

connected to the brake cylinders through the distributor valve. Brake application takes

place by dropping the pressure in the brake pipe. The schematic arrangement of the brake

equipment is shown as Fig. 6.1 (For passenger coaches), Fig 6.2 (For Generator coaches)

Components of Air Brake System

1. Brake Container (Brake Equipment Panel)

2. Distributor valve

3. Pressure Tanks (125 litres, 75 litres, 6 litres)

4. Indicators

5. B.P./F.P. Couplings and Hoses

6. Emergency Brake Pull Box

7. Emergency Brake valve

8. Bogie Brake Equipment, consisting of-

Brake Discs

Brake Caliper Units (consisting of Brake Cylinder, Brake Calipers, Brake Pads)

9. Wheel Slide Control System, consisting of-

Microprocessor Control Unit

Speed Sensor/Pulse Generator

44

(Fig 6.1 Brake equipment for passenger coach)

6.1.1 Brake Container (Brake equipment panel):

The Brake Container (Brake equipment panel) consists of a Manifold on which various

devices like the Distributor Valve, Cocks, Test fittings etc. are mounted. It also consists

of the reservoirs required for the Brake system. The container is mounted under the car

body and different lines (Feed pipe, Brake pipe, etc.) are connected to it.

(Fig 6.2 Brake equipment panel)

45

(Fig 6.3 Brake equipment for Generator coach)

6.1.2 Connections to the container:

There are 4 connections to the container for Passenger Coach:

1. Feed pipe(FP)

2. Brake pipe(BP)

3. Brake cylinder pressure -- bogie

4. Auxiliary support pipe ( for toilet)

There is an additional connection for the containers of the generator coaches,

1. Support for Indicating device of handbrake

2. These connections from the container to car body are provided at the back plate

fitted with Ernesto type fittings.

46

6.1.3 Brake application:

1. The driver lowers the BP pressure by engaging the A-9 valve in the engine.

2. This loss in pressure is transmitted from one bogey to the next.

3. Since CR pressure remains same, the main diaphragm(above the CR) moves up in

response to the pressure drop in DV.

4. As a result the three pressure valve opens the AR-BC port .

5. Thus the AR pressure of 6 kg/cm2 flows into the BC through pressure limiters

which reduces BC pressure to 3.8.

6.1.4 Brake Release:

1. BP pressure is again increased to 5 kg/cm2.

2. Consequently, main diaphragm move down and the three pressure valve closes

the AR-BC port and opens the BC-atm. port.

3. BC pressure is released and the brake caliper is disengaged.

6.2 BOGIE BRAKE EQUIPMENT:

The Bogie Brake equipment consists of:

1. Brake Caliper Units

2. Brake Cylinder

3. Brake Discs

4. Brake Shoes

Each axle is equipped with two grey cast iron brake discs. The brake energy is dissipated

only at the axle mounted brake discs, so the wheel set is only stressed by the weight of

the coach. The advantage of this arrangement is that the superposition of the thermal

stresses and mechanical stresses is avoided.

6.2.1 BRAKE CALIPER UNITS

The brake caliper units are readyto-use combinations of a brake caliper and brake

cylinder, providing automatic slack adjustment for wear (abrasion) on brake pads and

47

brake discs. Consequently, the clearance required between the disc and pads for smooth

running remains practically constant while the brakes are released.

Brake Caliper units consist essentially of the brake cylinder, the brake caliper, and the

brake shoes d1 and d2 with snap lock gates. The brake caliper units are held in the

vehicle bogies by a three point-mounting arrangement.

6.2.1.1 Working principle:

Applying the service brake charges the brake cylinder and presses the brake pads against

the brake disc. Brake force is built up when the pads are applied. Venting the brake

cylinder releases the service brake. The return spring in the brake cylinder moves the

caliper levers to the release position.

The handbrake lever is moved mechanically. The piston is pushed forward, and the brake

pads are applied to the disc. When the parking brake is released, the caliper levers are

drawn to the release position by the return spring in the brake cylinder.

(Fig 6.4 Brake Caliper Unit)

48

6.2.2 BRAKE CYLINDERS:

U-series brake cylinders with automatic slack adjustment are used to operate the friction brakes

in rail vehicles. U-series brake cylinders are essentially distinguished by their integral, force

controlled slack adjustment mechanism which is designed as a single acting clearance adjuster.

The working of this mechanism is not influenced in any way by the elastic brake rigging

deflection, which varies according to the brake force. In the course of braking, the slack adjuster

quickly and automatically corrects the increasing brake pad or brake block clearance due to

wear.

(Fig 6.5 Brake Cylinder & Calipers)

6.2.3 BRAKE DISCS:

The axle mounted brake disc consists of a gray cast iron friction ring and a cast steel hub,

connected by means of radially arranged elastic resilient sleeves which are secured in the

hub by means of hexagon screws. The friction ring is manufactured as a solid component

or in a split version. In the latter case, the two halves are held together by two tight fit

screws.

49

Axle Mounted Brake Discs Wheel Mounted Brake Discs

(Fig 6.6 Axle Mounted and Wheel Mounted Brake Discs)

6.2.4 BRAKE SHOE:

The brake shoe is provided with a brake pad holder carrying replaceable pads. The brake shoe

consists of the brake pad holder, the vertical pins and the brake pad. The brake pad holder is

provided with a dovetail guide into which the pad is slipped. The pad is held in place by a

captive gate, which is pivoted at the pad holder. To lock the gate a locking spring of spring steel

has been provided which is pre-tensioned such that in one position it secures the gate in the pad

holder and in the other (released) position it holds the gate open. For each brake disc a right and

a left hand brake shoe are required.

6.3 BRAKE RIGGING SYSTEM:

1. Due to BC pressure, the piston moves forward and strikes against the brake caliper.

2. The lever arm of the brake caliper presses onto the disc brake through the brake shoe.

3. The disc brakes are mounted on the wheel axle and so rotate along with the wheels.

4. Due to application of brake shoes, the discs begin to lose their angular speed.

5. As a result the axle also begins to slow down since the two are connected.

50

6. Ultimately, the wheels stop rotating as they are mounted on the same axle.

(Fig 6.7 Diagram showing Brake Rigging Pressure)

6.4 WHEEL SLIDE PROTECTION EQUIPMENT

1. Operates as a pressure regulation device of the air pressure inside the brake cylinder and

adjusted the braking force to the wheel to rail friction conditions so as to prevent the

wheels from locking and reduce the barking distance

2. In the case of the adhesion coefficient provided by a dry rail, the device does not interact

with the pneumatic system. The device enters into action when a loss of adhesion of the

axles is detected and, moment by moment, it adjusts the braking force to the present

adhesion conditions.

3. The operation is controlled so that the skidding wheel is allowed to find the most

favorable area for the adhesion-skidding characteristics.

4. The action of the device is controlled in order to keep the skidding wheel in the most

favorable area of the adhesion-skid characteristic.

5. Speed signal derived for CDTS.

51

(Fig 6.8 Speed sensor & Phonic wheel)

(Fig 6.9 Dump Valve and Connector)

(Fig 6.10 Electronic Connectors & Electronic unit)

52

6.5 CENTER BUFFER COUPLER:

The coupler provides a means of mechanically connecting individual adjacent vehicles in order

to make a train. The coupler is located at both ends of each vehicle. When connected to a coupler

of an adjacent vehicle, it allows the vehicles to move independently to accommodate track

curvature and elevation change while remaining connected (coupled) together.

The coupler is opened manually using the coupler operating rod and is closed automatically

when the couplers on adjacent vehicles are mated. The coupler automatically locks when fully

mated.

LHB coaches have been provided with tight lock centre buffer couplers instead of screw

coupling.

Couplers are AAR-H type and have anti climbing features because of vertical interlocking.

Couplers have adequate strength for:

1. Satisfactory hauling of a train of 26 coaches at 110 kmph

2. Satisfactory hauling of a train of 18 coaches at 160 kmph

Coupling is possible under angular misalignment both horizontally and vertically. The coupler

permits coupled trains to negotiate vertical and horizontal curves and allows rotational

movements. The draw gear ensures cushioning effective in both buff and draft.

53

CHAPTER 7

CONTROL DISCHARGE TOILET SYSTEM (CDTS)

LHB coaches are fitted with controlled discharge toilet units to avoid soiling of track in station

and inhabited areas.

The toilet system is designed to operate with a pressurized water bowl wash that covers 100% of

the toilet bowl area. The waste is removed from the toilet bowl and transferred to a retention tank

with a minimal amount of water. Water consumption is only 2.5 liters per flush cycle for the

Indian style toilet bowl and 1.5 liters for the European style toilet bowl.

7.1 Salient Features of CDTS:

1. Programmable.

2. Requirement of less Air and Water.

3. P.L.C Controlled.

4. Easy to clean.

5. Hygienic.

7.2 Operating Principle of CDTS:

1. This system works on electrical & pneumatic pressure arrangement. The retention tank

stores effluent has two openings. These two openings activates by double acting

pneumatic cylinders fed by Feed pipe of air brake system with the help of

electromagnetic solenoid valves.

2. The system starts working on a single push of flush switch. As the flush switch is

pressed, water flows into the toilet bowl & the upper slide valve opens which is

connected between the toilet bowl & retention tank. All the toilet waste is transferred into

the retention tank. At the end of each flush cycle the supply of water is stopped & the

54

upper slide valve is closed. Thus, the toilet is sealed from the retention tank, preventing

odour entering from the toilet room.

3. The waste accumulated in the retention tank remains in the retention tank until two

parameters are satisfied.

4. A predetermined no. of flush counts.

5. The train is reached a predetermined speed.

6. As soon as these above two parameters are met, the lower slide valve of retention tank

opens & the toilet waste accumulated in the tank is discharged out of the tank to the rail

side, away from the station & city.

7. The lower slide valve of the retention tank remains open for only small period of time to

empty the retention tank. The lower slide valve then remains closed until the above

discharge parameter conditions is again satisfied.

55

(Fig 7.1 Schematic Diagram of CDTS)

7.3 Toilet system has following components:

7.3.1 Indian & European toilet basin with flush nozzles: These are two types of toilet

basin used in CDTS system.

7.3.2. Control panel:

56

Control panel of CDTS consists of following equipments:

7.3.2.1 Programmable logic controller (PLC):

The Programmable logic controller works on 24 V DC having 8 inputs & 4 outputs. It

records the no. of flush cycles for opening/closing of lower slide to drain out the effluent

from retention tank. PLC also controls the opening/closing of lower slide when signals

received from WSP regarding speed of vehicle through WSP System to control the

flushing & signal received from Empty WC switch.

7.3.2.2 Solenoid valve:

The solenoid valve control the entry & exit of pneumatic air in the pneumatic cylinders

fitted on the upper & lower slide valves after receipt of signal from PLC.

7.3.2.3 Control relay:

Control relay is fitted aside of PLC on the control panel. A supply of 110 V DC is present

in the control relay. This control relay operates at 24 V DC &connect 110 V DC supply.

When 24 V DC supply is received from PLC, control relay operates & the 110 VDC

supply present in control relay is passed on to the water pressurizer.

7.3.3 Retention tank:

The effluent drained from the toilet basin bowl after flushing is stored in the retention

tank. In case of extra flush (beyond the capacity of tank), overflow pipe is provided to

drain out the effluent.

7.3.4 Lower Slide valve:

Lower slide valve is designed to operate on two parameters (predetermined no. of flush

counts, & predetermined speed of vehicle). As soon as these above two parameters are

met, the retention tanks lower slide valve open. The toilet wastes accumulated in the tank

are discharged out of the tank..

7.3.5 Upper Slide valve:

Upper slide valve is opened with the operation of flush switch. It closes after effluent

enters the retention tank. The slide valves open & closes by the movement of piston of

pneumatic cylinders controlled by PLC & solenoid valves.

57

In the latest version, the flapper arrangement has been introduced instead of upper slide

valves, to overcome slide jamming problems. This flapper arrangement consists of a flap,

which is connected by means of connecting links to one pneumatic cylinder. This flapper

operates in vertical direction (open & closes). The difference between slides & flapper

arrangement is the axis of movement of opening arrangement.

7.3.6 Flush button:

This is an electrical switch. On pressing this switch the electric circuit is completed with

the PLC & flush cycle starts.

7.3.7 Water Pressurizer:

Water pressurizer is fitted in the inlet of water pipe line connection to the CDTS system.

As the flush button is operated this water pressurizer is started & pressurized water is

supplied to the toilet basin.

7.3.8 Fail Safe Mode:

A FAIL SAFE MODE of operation is been provided in both Indian and European Style

Toilet System.

In the event of a loss of air, a loss of electricity or both, to enable use of the toilet, the

FAIL SAFE MODE is provided. It is also termed as manual flush.

7.4 Operational Description:

Stand-by condition

The status of various components/devices is listed below:

Water Pressurizer Off

Water check Valve Closed

Upper Slide Valve Closed

Lower Slide Valve Closed

58

Flush Cycle

Depress momentarily Flush Button and the status of various components / devices is listed

below:

Step 1

1. Water Pressurizer & Water check valve On (for a

predetermined time)

2. Upper Slide Valve Open (for a predetermined time)

Step 2

1. Water Pressurizer & Water check valve Off

2. Upper Slide Valve Closed

Retention Tank Discharge Cycle

Condition I

If train speed is - below 30 kmph then the retention tank lower

slide valve closed

Condition II

If train speed is above 30 kmph and Flush Count is below Predetermined value, then the

Retention Tank Lower Slide Valve remain closed.

If the train is above 30 kmph and Flush Count is equal or above Predetermined value, the

Retention Tank Lower Slide Valve Opens (for a predetermined time).

End of Retention Tank Discharge Cycle

Flush Count restarts at ZERO (0)

59

(Fig 7.2 Operational description of CDTS)

60

CHAPTER 8

MAINTAINENCE OF TRAINS

8.1 THE PRIMARY STRUCTURE:

Train is the combination of various types of coach and the train engine. There are many kind of

rakes which play an important role in serving the main purpose of driving a train. Like public

transportation and carrying goods etc.

There are also varieties of train engines depending on the medium they are driven by, like

electrical and fuel based, especially diesel. Here we are going to concentrate on the trains which

are used mainly for travelling and are equipped with such facilities.

So rake can be defined as the combination of coaches attached together after detachment of the

engine from the train.

8.2 THE MAINTENANCE OF THE TRAINS:

The maintenance of the trains is an important criteria for every coaching facility and workshop.

This is very important to make the system run smoothly and to look after the passenger safety.

So knowledge about the proper maintenance is essential.

Seen from the point of view of the train itself there are three kinds of maintenance available in

Eastern railways.

Down train arriving

at platform

Drawn out of the

platform

Engine

detached

The rake stabled

at the yard or sent

for maintenance

61

8.2.1Primary Maintenance:

According to the rules of railways, every division of railways possesses the responsibility

of running some specific trains. For those trains under the consecutive divisions primary

maintenance is done before that train leaves that section of railways. In other words the

primary maintenance is done at the mother or the terminal station.

Here every aspect of pressure related systems, and aspects of public safety are checked.

The continuity, the bonding between coaches etc is also taken care of. This takes at about

5 6 and half an hour duration until it is given the fit to run certificate.

Each primary maintenance comprises a form which is known as the v-5 form. This form

has information spaces about those aspects that are secured during this maintenance. If a

train is given fit instead of any fault not so fatal, that is written in the certificate.

8.2.2 Round trip/Turn Around Maintenance:

This maintenance takes place after the train reaches its final destination from the staring

one. This is a short duration maintenance preparing the train to send it back to the

terminal station. Just the necessary maintenance is carried out.

This takes about one hour forty minutes to about two hours to complete.

8.2.3 Secondary Maintenance:

Secondary maintenance is a specific type of the primary maintenance. When the train

runs for about 3500 kilometers or about 3 days, either way, then at the destination station

the train undergoes the secondary maintenance. Here the measures taken are just similar

to the primary one. The duration is about six to seven hours.

62

8.3 THE MAINTENANCE SCHEDULES AND THE OVERHAULING PERIODS:

There are normally seven kinds of maintenance schedules depending on the condition of coaches

and wagons. They are respectively -

1. A- Schedule: after 30 days of manufacturing or of periodic overhauling, repetitive

2. B-Schedule: after 90 days of manufacturing or of periodic overhauling, repetitive

3. C-Schedule: after 180 days of manufacturing or of periodic overhauling, repetitive

4. Intermediate Overhauling: after 9 months of manufacturing or of periodic

overhauling

5. Periodic Overhauling: after the returning date given by the workshop after periodic

overhauling.

6. Non-Periodic Overhauling: This is done after 12 months or 18 months after the

manufacturing date or the periodic overhauling date depending

on the condition of the corresponding coach.

7. Inter lifting schedule: This is a special kind of maintenance done within the

maintenance facility with lifted coach and parts.

8.4 PERIODIC OVERHAULING:-

Periodic overhauling is the best available process of maintenance of coaches in India. This

generally operated after 12 or 18 months after the manufacturing or the previous periodic

overhauling done in any workshop. This undergoes a huge process of lifting the coach, isolating

the all parts, and changing or replacing the necessary or damaged parts. In other words this is the

process of renewing the coaches. Here are some varieties-

63

1. 12 month basis

2. 18 months basis

a. Mail and express trains

b. Passenger trains

3. For MLR coaches - 18 months

4. For new built coaches - 24 months

8.4.1 POH DATE AND RETURN DATE:

POH date is that date on which its POH has been done previously in an workshop. This is written

on the coach. And the return date is the date on which it is to be dropped off from the track and

to be taken for another periodic overhauling. Generally they have a 12 month or 18 month gap

between them in accordance with the definition of the POH.

Both of the dates should be given by the corresponding workshop where its POH has been done.

8.4.2SIGNIFICANCE OF COACH NUMBER:

Every coach has its own unique number attached to it which obviously carries some significant

information to us. Generally in India that is of five numbered.

The first two digits represents the year of manufacturing of the coach. And the rest three digits

represent the list of types of coaches. It represents of which type the coach is.

64

CONCLUSION

This training program is an excellent opportunity for us to get to the ground level and experience

the things that we would have never gained through going straight into a job. I am grateful to

Coach Care Complex, INDIAN RAILWAYS, Jaipur for giving me this wonderful

opportunity. The main objective of the industrial training is to provide an opportunity to

undergraduates to identify, observe and practice how engineering is applicable in the real

industry. It is not only to get experience on technical practices but also to observe management

practices and to interact with fellow workers. Also I learnt the way of work in an organization,

the importance of being punctual, the importance of maximum commitment, and the

importance of team spirit. As we all know that INDIAN RAILWAYS is the backbone of Indian

Transportation and a large population is dependent on it and as a result it give a lucrative

turnover to the Indian Government. People look up to Railways for good career opportunities as

it provides large no. of employment, also Railways are now a days taking their keen interest in

increasing the speed limit and working on the bullet train.

By attending the 6 weeks training in Coach Care Complex Jaipur division, NWR. I conclude that

this primary requirement of train transportation is to ensure safe, speedy, reliable and punctual

movement of passengers and goods to various parts of the country. The role of the Coach Care

Complex of the Indian Railways is to provide modern, efficient and reliable Coaches for speedy,

smooth and safe running of trains, as well as an effective and reliable mode of relief in

passengers. For this purpose POH (Periodic Overhauling) of coaches is done to service it time to

time for e.g. each and every bogie and coach are sent for POH in every 12 months and 18 months

respectively. This training also acquainted me to the practical applications of numerous topics

which have been covered in the university curriculum but only in theory, like I came to know

about the selection of springs for different coaches, practical work on different shops, work

sequences, etc. For this and everything else, I am eternally indebted to all the officers and staff of

Jaipur Division (N.W.R).

65

REFERENCES

1. www.indianrail.gov.in/ir_zones.pdf list of all the zones and division

2. http://www.nwr.indianrailways.gov.in/view_section.jsp?lang=0&id=0,1,285 , figure

and data related to the Jaipur division and North western zone.

3. http://en.wikipedia.org/w/index.php?title=File%3ARailway_network_schematic_map

_2009.png Railway Zonal Map .

4. http://www.nwr.indianrailways.gov.in/uploads/files/1401775686459-NWR.pdf coach

maintain manual of NWR zone.

5. http://www.nwr.indianrailways.gov.in/view_section.jsp?lang=0&id=0,1,263,602hard

ware used in japur zone in PRS.

6. http://cris.org.in/CRIS/Projects/PRS , content about the PRS.

7. https://www.google.co.in/search?q=CONCERT+Network+topology&client=firefox-

a&hs=31y&rls=org.mozilla:en-

US:official&source=lnms&tbm=isch&sa=X&ei=QhDuU4P7Ecjh8AXA5oC4Cg&ve

d=0CAgQ_AUoAQ&biw=1280&bih=857 concert network implementation.

8. Manual No.516/RRI61/A to Manual No.516/RRI61/D about bogie, coaches design

used in N.W.R Jaipur zone

9. Manual No.019/OFC09/1/23 technique and equipments used in LHB Coaches.

Anda mungkin juga menyukai

- Design Features of LHB Fiat BogieDokumen38 halamanDesign Features of LHB Fiat BogienagaBelum ada peringkat

- Coaches and Wagons Codification and Numbering System: R.Venkatachari SR - Lecturer/C&W STC/SCDokumen32 halamanCoaches and Wagons Codification and Numbering System: R.Venkatachari SR - Lecturer/C&W STC/SCmaharshi DaddyBelum ada peringkat

- 1567754796924-Question Bank On LHB Design Coaches PDFDokumen100 halaman1567754796924-Question Bank On LHB Design Coaches PDFsoumen_eg100% (1)

- LHB April 20Dokumen83 halamanLHB April 20nwdsumanfacebookcomBelum ada peringkat

- C&W Obj Que Bank With AnsDokumen23 halamanC&W Obj Que Bank With Ans1553Belum ada peringkat

- TROM1.3.5-Loco & Crew LinksDokumen45 halamanTROM1.3.5-Loco & Crew LinksSandeep Joseph100% (2)

- LHB Coaches - WikipediaDokumen21 halamanLHB Coaches - Wikipedia4179309100% (1)

- 1434531469746-Coach & Wagon Bogies PDFDokumen156 halaman1434531469746-Coach & Wagon Bogies PDFabhimanyutiwari12340% (2)

- 1514285018697-Q Bank (Li)Dokumen46 halaman1514285018697-Q Bank (Li)Vara PrasadBelum ada peringkat

- LHB Coach Maintenance - 1Dokumen61 halamanLHB Coach Maintenance - 1Dhanraj chavan100% (1)

- TRO Train ROllinG Stock Operations PDFDokumen35 halamanTRO Train ROllinG Stock Operations PDFNalin Lochan GuptaBelum ada peringkat

- ALCO Locomotive Bogies PDFDokumen73 halamanALCO Locomotive Bogies PDFmajjisat100% (1)

- NCR Departmental Exam Carriage and Wagon Objective Question Bank PDFDokumen23 halamanNCR Departmental Exam Carriage and Wagon Objective Question Bank PDFPravinBelum ada peringkat

- Indian Railways Coach Maintenance Manual For BG CoachesDokumen204 halamanIndian Railways Coach Maintenance Manual For BG CoachesSrinivas Guduru86% (7)

- Mainenace Guidelines For LHB Cocahes.Dokumen7 halamanMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- 1514285051142-Rehresher Course Book PDFDokumen99 halaman1514285051142-Rehresher Course Book PDFSaptarshi Pal100% (1)

- Presentation On LHB BOGIESDokumen38 halamanPresentation On LHB BOGIESVijay AnandBelum ada peringkat

- PM (Dr. S.N.Saxena)Dokumen45 halamanPM (Dr. S.N.Saxena)Rk SkBelum ada peringkat

- A REPORT ON REVIEW OF MAINTENANCE PERIODICITY OF ICF AND LHB COACHE (1) VHVVDokumen39 halamanA REPORT ON REVIEW OF MAINTENANCE PERIODICITY OF ICF AND LHB COACHE (1) VHVVsubashritunalco100% (1)

- Development in Wagon FinalDokumen133 halamanDevelopment in Wagon Finalkr_abhijeet72356587100% (5)

- Troubleshooting Directory For 25 KV AC EMU-MEMUDokumen80 halamanTroubleshooting Directory For 25 KV AC EMU-MEMUGopal Dixit100% (1)

- Jli NotesDokumen107 halamanJli NotesHanuma Reddy100% (1)

- Linkee Hofman Bush (LHB)Dokumen49 halamanLinkee Hofman Bush (LHB)Aghu AkzBelum ada peringkat

- LHB WorkDokumen26 halamanLHB WorkŠäçhín KâmbléBelum ada peringkat

- Container wagons-BLC Train Operation and Maintenance PracticeDokumen12 halamanContainer wagons-BLC Train Operation and Maintenance PracticeRakesh JainwalBelum ada peringkat

- Diesel Module Examination PDFDokumen29 halamanDiesel Module Examination PDFae1329Belum ada peringkat

- Yard StickDokumen3 halamanYard Stickarun1380% (5)

- 1.introduction To Carriage Workshop LallagudaDokumen28 halaman1.introduction To Carriage Workshop Lallagudavenkatesh naniBelum ada peringkat

- CBC Couplers: A Report On LHB and Wagon CbcsDokumen10 halamanCBC Couplers: A Report On LHB and Wagon CbcsWheel Bogie Parel WSBelum ada peringkat

- Centre Buffer CouplerDokumen51 halamanCentre Buffer Couplersaurabh kumar100% (1)

- LVPH BPC ValidityDokumen4 halamanLVPH BPC ValidityJeetendra Singh ChauhanBelum ada peringkat

- Final Report On Examination Time For Diffrent Rake LengthDokumen45 halamanFinal Report On Examination Time For Diffrent Rake LengthRakesh JainwalBelum ada peringkat

- Maintenance Handbook of Pantograpgh AM12 & Similar DesignDokumen46 halamanMaintenance Handbook of Pantograpgh AM12 & Similar DesignMaddi vasuBelum ada peringkat

- (IRFCA) Indian Railways FAQ - Acronyms and Abbreviations - II PDFDokumen8 halaman(IRFCA) Indian Railways FAQ - Acronyms and Abbreviations - II PDFGaurang singhBelum ada peringkat

- ESC Minutes of Meeting of 61st ESCDokumen62 halamanESC Minutes of Meeting of 61st ESCpradeeepgargBelum ada peringkat

- Maintenance Book1Dokumen200 halamanMaintenance Book1rakesh ranjanBelum ada peringkat

- ICF Load Distribution in Indian RailwaysDokumen3 halamanICF Load Distribution in Indian RailwaysTapas kumarBelum ada peringkat

- Diesel Locomotive ShedDokumen8 halamanDiesel Locomotive ShedDrSumedha SarmaBelum ada peringkat

- Course Book Mse MJR Iii Workshop PDFDokumen133 halamanCourse Book Mse MJR Iii Workshop PDFPratap Singh GangwarBelum ada peringkat

- Casnub BogiesDokumen58 halamanCasnub Bogieskr_abhijeet72356587100% (5)

- General Rules: Eastern RailwayDokumen343 halamanGeneral Rules: Eastern RailwayMunish KumarBelum ada peringkat

- Mechanical Question BankDokumen22 halamanMechanical Question Bankmustafa67% (3)

- Escort Brake - SystemDokumen16 halamanEscort Brake - SystemNikhil TiwaryBelum ada peringkat

- GDR Check TimeDokumen12 halamanGDR Check TimeMurali KrishnanBelum ada peringkat

- Pamphlet On Air SuspensionDokumen4 halamanPamphlet On Air SuspensionArijitNandiBelum ada peringkat

- Air Brake System of LHBDokumen86 halamanAir Brake System of LHBAbhishek patelBelum ada peringkat

- BCNHL DoorsDokumen12 halamanBCNHL DoorsRakesh JainwalBelum ada peringkat

- Question Bank On Coaching Stock PDFDokumen130 halamanQuestion Bank On Coaching Stock PDFsahoogch0% (1)

- Question Bank On HHP LocomotivesDokumen14 halamanQuestion Bank On HHP LocomotivesIndian RailwayBelum ada peringkat

- Question Bank On HHP Locomotives MinDokumen76 halamanQuestion Bank On HHP Locomotives Mink l pandey100% (1)

- Incentive Scheme 21 JET 1Dokumen39 halamanIncentive Scheme 21 JET 1Saptarshi PalBelum ada peringkat

- Wagon Details PDFDokumen36 halamanWagon Details PDFpraveenthomasBelum ada peringkat

- 1487153979637-JE-II Question Bank PDFDokumen43 halaman1487153979637-JE-II Question Bank PDFSk zalaluddin100% (2)

- Freight LocomotiveDokumen68 halamanFreight Locomotivedeepak_gupta_pritiBelum ada peringkat

- CBCDokumen15 halamanCBCabheypriyaBelum ada peringkat

- DSL ObjectiveDokumen8 halamanDSL ObjectiveK John PeterBelum ada peringkat

- Introduction To LHB CoachDokumen68 halamanIntroduction To LHB Coachkr_abhijeet72356587100% (4)

- Maintenance Schedules of Coaches in Indian RailwaysDokumen12 halamanMaintenance Schedules of Coaches in Indian RailwaysTapas kumarBelum ada peringkat

- Introduction Handbook On FIAT Bogie PDFDokumen95 halamanIntroduction Handbook On FIAT Bogie PDFAshlin AugustyBelum ada peringkat

- Designandanalysisof V6 EngineDokumen88 halamanDesignandanalysisof V6 EngineENGINEERING INTELLIGENCEBelum ada peringkat

- AGCO Power Gensets Land V2Dokumen2 halamanAGCO Power Gensets Land V2Tawfiq ZidanBelum ada peringkat

- D399 AttachmentDokumen50 halamanD399 AttachmentNOUR ZAINBelum ada peringkat

- 1996 Club Car DS Golf Cart Owner's ManualDokumen48 halaman1996 Club Car DS Golf Cart Owner's Manualdriver33b60% (5)

- Torque Values RTJ (B16.5)Dokumen3 halamanTorque Values RTJ (B16.5)Dave Donohue100% (9)

- Rycroft HT BreezeDokumen16 halamanRycroft HT BreezesatejBelum ada peringkat

- Experiment 5 - FLUIDSDokumen7 halamanExperiment 5 - FLUIDSJoeBelum ada peringkat

- Concrete PoolDokumen2 halamanConcrete Pooljorge010% (2)

- EGF305 Topic 5-Intro To Failure Analysis PDFDokumen34 halamanEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdBelum ada peringkat

- Little Helper. Igantic Effect!: 150 VarioDokumen12 halamanLittle Helper. Igantic Effect!: 150 Variokgv_mailsBelum ada peringkat

- XTRACT Calculul Unui Perete de B.ADokumen1 halamanXTRACT Calculul Unui Perete de B.AHDu13Belum ada peringkat

- Deformation ProcessDokumen25 halamanDeformation Processutpal singhaBelum ada peringkat

- L3548 4 07Dokumen2 halamanL3548 4 07Héctor Hugo Sánchez GómezBelum ada peringkat

- Materials System SpecificationDokumen19 halamanMaterials System SpecificationGOSP3 QC MechanicalBelum ada peringkat

- Compiled By: Sir Sumair: KinematicsDokumen6 halamanCompiled By: Sir Sumair: KinematicsHasan NawazBelum ada peringkat

- Cummins D1703 Engine Parts Catalog PDFDokumen72 halamanCummins D1703 Engine Parts Catalog PDFxxxxxxxxxxxxxxxxxxx100% (2)

- United States Patent (19) : Benway Et Al. (45) Date of PatentDokumen9 halamanUnited States Patent (19) : Benway Et Al. (45) Date of PatentAngel GutierrezBelum ada peringkat

- Cooling Tower SolutionDokumen38 halamanCooling Tower SolutionThabangBelum ada peringkat

- U15 QuestionsDokumen2 halamanU15 Questionsapi-248642018Belum ada peringkat

- PC2 - Practice Exam WorkedDokumen12 halamanPC2 - Practice Exam WorkednomsyBelum ada peringkat

- Aggregate Crushing Value Test For AggregateDokumen2 halamanAggregate Crushing Value Test For AggregateQuality JamBelum ada peringkat

- PrimeRoyal HPD LE IOMDokumen82 halamanPrimeRoyal HPD LE IOMTadeo FajardoBelum ada peringkat

- Cuptor Coven - 6emd UslDokumen22 halamanCuptor Coven - 6emd UslPaul MocanuBelum ada peringkat

- AFRC - Improving Performance of Coker HeatersDokumen29 halamanAFRC - Improving Performance of Coker Heatersashutosh_garg_10Belum ada peringkat

- Thakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingDokumen4 halamanThakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingAshwini ChaurasiaBelum ada peringkat

- 03 FloWatch HGVF Input and OutputDokumen21 halaman03 FloWatch HGVF Input and Outputedwin_triana_9Belum ada peringkat

- Type 1: Technical ParametersDokumen7 halamanType 1: Technical ParametersMuhammad AliBelum ada peringkat

- Wiring Layout For Dta EcuDokumen5 halamanWiring Layout For Dta EcuJay Daffurn100% (3)

- Estimation TCI Sanmar - EDC Vent Condenser Tag No E-102Dokumen5 halamanEstimation TCI Sanmar - EDC Vent Condenser Tag No E-102Raviraj Shashikant PatilBelum ada peringkat

- PNSMV025Dokumen36 halamanPNSMV025Philippe Alexandre100% (1)

- Carrier VRF Installation Manual For 20 - 22 - 26 KWDokumen16 halamanCarrier VRF Installation Manual For 20 - 22 - 26 KWMohamedBelum ada peringkat