Hemispherical Head Design Tool: Pressure Vessel Engineering LTD

Diunggah oleh

majeedrumaniJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hemispherical Head Design Tool: Pressure Vessel Engineering LTD

Diunggah oleh

majeedrumaniHak Cipta:

Format Tersedia

1

2

3

4

5

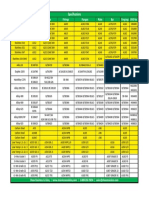

6 Hemispherical Head Design Tool ver E4.01 Page 1 of 1

7 Description

8 Dimensions:

9 24.000 Do [in] - outside diameter of head

10 0.188 tb [in] - thickness before forming

11 0.159 tf [in] - thickness after forming

12 0.010 Corr [in] - corrosion allowance

13 Material and Conditions:

14 SA-240 304 Material

15 20,000 S [psi] - allowable stress

16 1.00 E - head longitudinal efficiency

17 50.0 P [psi] - interior pressure

18 Calculated Properties:

19 Approx. head weight based on steel, lbs = 47.4

20 Approx. head volume, cuft = 2.01

21 Variables:

22 nt [in] = tf-Corr ~~ thickness with corrosion allowance removed 0.159-0.01 = 0.149

23 L [in] = (Do-2*nt)/2 ~~ inside radius with corrosion allowance removed (24-2*0.149)/2 = 11.851

24 Ro [in]= Do/2 24/2 = 12.000

25 Required Thickness: UG-32(f)

26 Treq [in] =

27 0.025

28 CheckTreq = Treq<=tf 0.025<=0.159 = Acceptable

29 Maximum Pressure: UG-32(f)

30 Pmax [psi] =

31 502.9

32 CheckPMax = Pmax >= P 502.9 >= 50 = Acceptable

33 App. 1-4(f) calculation is not included on this sheet

34 Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UHA-44(d)

35 Use the Weld Efficiency program to calculate E

36 The UG-16(b) minimum thickness requirement has not been taken into consideration here.

37 This sheet cannot be used to check for allowable exterior pressure loads.

38 This sheet is for educational use only - use at your own risk.

39

40

41

42

Pressure Vessel Engineering Ltd.

Pressure Vessel Engineering Ltd.

120 Randall Drive, Suite B

Hemispherical Head

Waterloo, Ontario, Canada, N2V 1C6

www.pveng.com (519) 880-9808

(P*L)/(2*S*E-0.2*P)+Corr ~~required minimum thickness

(50*11.851)/(2*20000*1-0.2*50)+0.01 =

(2*S*E*nt)/(L+0.2*nt) ~~ maximum allowed design pressure

(2*20000*1*0.149)/(11.851+0.2*0.149) =

Anda mungkin juga menyukai

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design Toolnaveen_86Belum ada peringkat

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDokumen1 halamanElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design Toolnaveen_86Belum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolSudjono BroBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolssierroBelum ada peringkat

- Nozzle DesignDokumen391 halamanNozzle Designantonio gutierrezBelum ada peringkat

- Copiar de Nozzle - Design - ToolDokumen2 halamanCopiar de Nozzle - Design - ToollavascudoBelum ada peringkat

- Vessel Weld EfficiencyDokumen1 halamanVessel Weld EfficiencyAlvin SmithBelum ada peringkat

- Studding FlangeDokumen6 halamanStudding FlangeDarshan PanchalBelum ada peringkat

- F&D Head Design Tool: Pressure Vessel Engineering LTDDokumen1 halamanF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcBelum ada peringkat

- Tinita Engineering Pvt. LTD.: R-266 Rabale MIDC, T.T.C. Industrial Area, Navi Mumbai-400701. INDIADokumen4 halamanTinita Engineering Pvt. LTD.: R-266 Rabale MIDC, T.T.C. Industrial Area, Navi Mumbai-400701. INDIAalokbdasBelum ada peringkat

- Standard SpecificationDokumen1 halamanStandard SpecificationĐạt TrầnBelum ada peringkat

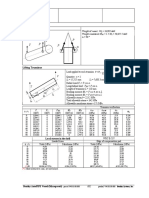

- Cone CalculationDokumen3 halamanCone CalculationVicky NtrjnBelum ada peringkat

- Material P NumberDokumen11 halamanMaterial P NumberChaitanya Sai TBelum ada peringkat

- ASME B 31.3 2016 Process PipingDokumen30 halamanASME B 31.3 2016 Process Pipingr.devendran25% (4)

- Art - 'S TEMA DesignationsDokumen4 halamanArt - 'S TEMA Designationsmuhammad_asim_10Belum ada peringkat

- Tinita: Engineering Private LimitedDokumen2 halamanTinita: Engineering Private LimitedalokbdasBelum ada peringkat

- B Jack Nos For Cs Ss MaterialDokumen12 halamanB Jack Nos For Cs Ss MaterialfahadfiazBelum ada peringkat

- Tinita Engineering Pvt. LTD.: Material Identification ReportDokumen2 halamanTinita Engineering Pvt. LTD.: Material Identification ReportalokbdasBelum ada peringkat

- Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Dokumen1 halamanProject JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Darshan PanchalBelum ada peringkat

- Shell Thickness Calculation: C WP F D WP TDokumen16 halamanShell Thickness Calculation: C WP F D WP Tpatiltushar79Belum ada peringkat

- Cone DevelopmentDokumen2 halamanCone DevelopmentpandiangvBelum ada peringkat

- Heat Ex Changers EstimationDokumen46 halamanHeat Ex Changers Estimationshankarbt83Belum ada peringkat

- Compress CalculationDokumen106 halamanCompress CalculationKrupal Patel100% (1)

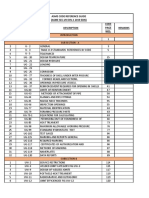

- Asme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)Dokumen2 halamanAsme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)anu radhaBelum ada peringkat

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDokumen4 halamanLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleBelum ada peringkat

- Ansi b36.10 Seamless Pipe SizesDokumen2 halamanAnsi b36.10 Seamless Pipe SizesmohitBelum ada peringkat

- Weight Estimation of Vessels AppsDokumen39 halamanWeight Estimation of Vessels Appsmacwan23Belum ada peringkat

- Auto PipeDokumen18 halamanAuto PipeAdi Sutardi100% (1)

- Ansi B 1500 PDFDokumen1 halamanAnsi B 1500 PDFMilena Lemus FonsecaBelum ada peringkat

- FittingsDokumen50 halamanFittingsashokBelum ada peringkat

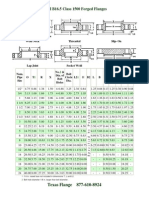

- Flange Asmeviii Div.1 App.2 Rev0Dokumen10 halamanFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- Horizontal Pressure Vessel Calculation (Eng)Dokumen59 halamanHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasBelum ada peringkat

- External PressureDokumen22 halamanExternal PressureAbhijeet SahuBelum ada peringkat

- Tailing LugDokumen2 halamanTailing Lugjagannadha varmaBelum ada peringkat

- Cone Development CalculationsDokumen5 halamanCone Development CalculationssaudimanBelum ada peringkat

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDokumen1 halamanRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutBelum ada peringkat

- Sa516 70Dokumen3 halamanSa516 70Thinh ViproBelum ada peringkat

- REPORTSDokumen18 halamanREPORTSShailesh DeshmukhBelum ada peringkat

- Toriconical Head Ver 1.1Dokumen4 halamanToriconical Head Ver 1.1Iqbal AhmadsBelum ada peringkat

- Oil Gas Construction Factory L.L.CDokumen2 halamanOil Gas Construction Factory L.L.CRenny DevassyBelum ada peringkat

- Pipe Thickness Calculations - : ClassDokumen1 halamanPipe Thickness Calculations - : ClassOluwachidiBelum ada peringkat

- Thickness Calculation AsmeDokumen2 halamanThickness Calculation AsmeSushil WadiyeBelum ada peringkat

- MD PV ASME v0.1Dokumen35 halamanMD PV ASME v0.1rizalramaBelum ada peringkat

- PV Elite Vessel Analysis Program HorizontalDokumen55 halamanPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriBelum ada peringkat

- Asme - HeaderDokumen3 halamanAsme - HeaderReadersmoBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolJosé Juan Jiménez AlejandroBelum ada peringkat

- Diseño Del Cuerpo de Un RecipienteDokumen1 halamanDiseño Del Cuerpo de Un RecipientepedroluischoqueBelum ada peringkat

- 299 - Elliptical Head Design Tool Ver E4.01Dokumen1 halaman299 - Elliptical Head Design Tool Ver E4.01BAHADIRBelum ada peringkat

- 299 - Elliptical Head Design Tool Ver E4.01Dokumen1 halaman299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaBelum ada peringkat

- Diseño de Cabeza ElípticaDokumen1 halamanDiseño de Cabeza ElípticapedroluischoqueBelum ada peringkat

- 299 - Elliptical Head Design Tool Ver E4.01Dokumen1 halaman299 - Elliptical Head Design Tool Ver E4.01mohamed faragBelum ada peringkat

- Cone Design ToolDokumen1 halamanCone Design ToolPramod KumarBelum ada peringkat

- 300 - F&D Head Design Tool Ver E4.01Dokumen1 halaman300 - F&D Head Design Tool Ver E4.01Mo ZeroBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolJaveed KhanBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design ToolSudjono BroBelum ada peringkat

- Elliptical Head Design ToolDokumen1 halamanElliptical Head Design Toolbai tap hoa vo coBelum ada peringkat

- Cone Design ToolDokumen1 halamanCone Design ToolssierroBelum ada peringkat

- Strength Calculation ARTDokumen34 halamanStrength Calculation ARTdenstar silalahiBelum ada peringkat

- 297 - Pipe and Shell Design Tool Ver E4.01 MMDokumen1 halaman297 - Pipe and Shell Design Tool Ver E4.01 MMBAHADIRBelum ada peringkat

- Inspection & Testing Requirements: & Specifications As Noted BelowDokumen1 halamanInspection & Testing Requirements: & Specifications As Noted Belownaveen_86Belum ada peringkat

- Material Requisition Review Checklist: Long Term Agreement For Offshore Facilities CONTRACT No. 6600035841 (OOK)Dokumen1 halamanMaterial Requisition Review Checklist: Long Term Agreement For Offshore Facilities CONTRACT No. 6600035841 (OOK)naveen_86Belum ada peringkat

- Inq 612 Sa 234 GR - WPB BW FittingsDokumen1 halamanInq 612 Sa 234 GR - WPB BW Fittingsnaveen_86Belum ada peringkat

- 00 C C 00 Co P Qa 00 002 - 00Dokumen80 halaman00 C C 00 Co P Qa 00 002 - 00naveen_86100% (3)

- Material Requisition OF Corrosion Inhibitor Injection UnitDokumen20 halamanMaterial Requisition OF Corrosion Inhibitor Injection Unitnaveen_86100% (1)

- Requirement For Wn/Blind Flanges Astm A350/A350M: INQ - 612 Rev.: A Page: 1 of 1 Doc NoDokumen1 halamanRequirement For Wn/Blind Flanges Astm A350/A350M: INQ - 612 Rev.: A Page: 1 of 1 Doc Nonaveen_86Belum ada peringkat

- Requirement For Wn/Blind Flanges Astm A105/A105M: INQ - 612 Rev.: A Page: 1 of 1 Doc NoDokumen1 halamanRequirement For Wn/Blind Flanges Astm A105/A105M: INQ - 612 Rev.: A Page: 1 of 1 Doc Nonaveen_86Belum ada peringkat

- Inq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - SsDokumen1 halamanInq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - Ssnaveen_86Belum ada peringkat

- Requirement For Cs Seamless Pipe Api 5L GR.B - 0.5" To 12": INQ - 612 Rev.: A Page: 1 of 1Dokumen1 halamanRequirement For Cs Seamless Pipe Api 5L GR.B - 0.5" To 12": INQ - 612 Rev.: A Page: 1 of 1naveen_86Belum ada peringkat

- Inq - 612 - Mss Sp-75 BW FittingsDokumen1 halamanInq - 612 - Mss Sp-75 BW Fittingsnaveen_86Belum ada peringkat

- Inspection Datasheet For Pumps Skids' Frame & Skid Assembly (EDR - 950-2-0151-000-VOG-InP-DTS-1590 - 001 - A) - 1Dokumen8 halamanInspection Datasheet For Pumps Skids' Frame & Skid Assembly (EDR - 950-2-0151-000-VOG-InP-DTS-1590 - 001 - A) - 1naveen_86Belum ada peringkat

- Requirement For Wn/Blind Flanges Astm A350/A350M: INQ - 612 Rev.: A Page: 1 of 1 Doc NoDokumen1 halamanRequirement For Wn/Blind Flanges Astm A350/A350M: INQ - 612 Rev.: A Page: 1 of 1 Doc Nonaveen_86Belum ada peringkat

- Inq - 612 - Api 5l Gr. x60Dokumen1 halamanInq - 612 - Api 5l Gr. x60naveen_86Belum ada peringkat

- Inq - 610 - RF Dual Plate Check Val - 2 Inch To 10 Inch - SsDokumen1 halamanInq - 610 - RF Dual Plate Check Val - 2 Inch To 10 Inch - Ssnaveen_86Belum ada peringkat

- Inq - 610 - RF Dual Plate Check Val - 2 Inch To 10 Inch - SSDokumen1 halamanInq - 610 - RF Dual Plate Check Val - 2 Inch To 10 Inch - SSnaveen_86Belum ada peringkat

- Requirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc NoDokumen1 halamanRequirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc Nonaveen_86Belum ada peringkat

- Requirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc NoDokumen1 halamanRequirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc Nonaveen_86Belum ada peringkat

- Inq - 610 - RF Butterfly Valves - 14 Inch To 24 Inch - SsDokumen1 halamanInq - 610 - RF Butterfly Valves - 14 Inch To 24 Inch - Ssnaveen_86Belum ada peringkat

- Requirement For Butt Welded Fittings Astm A403 Gr. Wp316L/316L-WxDokumen1 halamanRequirement For Butt Welded Fittings Astm A403 Gr. Wp316L/316L-Wxnaveen_86Belum ada peringkat

- Surface Area Structural SteelDokumen6 halamanSurface Area Structural Steelnaveen_8667% (3)

- Calculation of Pipe SupportDokumen6 halamanCalculation of Pipe Supportnaveen_86Belum ada peringkat

- RFQ 2108 SA 403 GR - WP316-316LDokumen1 halamanRFQ 2108 SA 403 GR - WP316-316Lnaveen_86Belum ada peringkat

- PSA Norway - Guidelines Regarding The Facilities Regulations - 2015Dokumen37 halamanPSA Norway - Guidelines Regarding The Facilities Regulations - 2015naveen_86Belum ada peringkat

- CDS-210-Rev4 C-002 Warning Sign 2 Risk of Injury Sept. 2015Dokumen1 halamanCDS-210-Rev4 C-002 Warning Sign 2 Risk of Injury Sept. 2015naveen_86Belum ada peringkat

- CDS-101 C-001 Architectural Room Programme March 2015Dokumen6 halamanCDS-101 C-001 Architectural Room Programme March 2015naveen_86Belum ada peringkat

- Productsheet C-Dur Deluxe ENDokumen1 halamanProductsheet C-Dur Deluxe ENfelghazi87Belum ada peringkat

- Crystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversityDokumen7 halamanCrystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversitybluecreteBelum ada peringkat

- ConductorDokumen3 halamanConductorRaimon Guitart Garcia 78151008KBelum ada peringkat

- Sample Quotation For Plumbing WorkDokumen1 halamanSample Quotation For Plumbing WorkIzat Malaya100% (1)

- IS Standard For Isolators and DisconnectorsDokumen44 halamanIS Standard For Isolators and DisconnectorsdillehBelum ada peringkat

- Computer-Integrated ManufacturingDokumen12 halamanComputer-Integrated ManufacturingGagandeep Singh SidhuBelum ada peringkat

- 2011 CatalogDokumen25 halaman2011 CatalogClaudiaPagginiBelum ada peringkat

- Blends DyeingDokumen232 halamanBlends DyeingMuhammad Qamar Tusief100% (1)

- D7GDokumen8 halamanD7Gfirman manaluBelum ada peringkat

- ANCQ 9/10 Help BookDokumen9 halamanANCQ 9/10 Help BookSatyankar Chandra100% (1)

- Belt ConveyorDokumen8 halamanBelt ConveyorneoBelum ada peringkat

- Leco TgaDokumen2 halamanLeco TgaMAmarBelum ada peringkat

- Burnit Comfort PM PM/BDokumen56 halamanBurnit Comfort PM PM/BAleksandar GuskovBelum ada peringkat

- Reduction in Steam NeDokumen14 halamanReduction in Steam NeArif ShafiBelum ada peringkat

- Electricity QuestionsDokumen22 halamanElectricity Questionssanat kr pratiharBelum ada peringkat

- 35423-10 Eco Testr Ph2Dokumen2 halaman35423-10 Eco Testr Ph2Sally Salina FarahBelum ada peringkat

- .Au Graphite Laminate MSDSDokumen7 halaman.Au Graphite Laminate MSDSJayzaa_Jay_8120Belum ada peringkat

- SPE-68789-MS One PetroDokumen5 halamanSPE-68789-MS One PetroAlex ZamanBelum ada peringkat

- Stainless Steel 317L PipesDokumen6 halamanStainless Steel 317L PipesNilesh JainBelum ada peringkat

- HSCDokumen13 halamanHSCrexdindigulBelum ada peringkat

- 17ME64 DME II Module 5Dokumen13 halaman17ME64 DME II Module 5Shridhar ChinuuBelum ada peringkat

- Cable MarkingDokumen64 halamanCable MarkingJesús Sánchez100% (1)

- TSPP9Dokumen90 halamanTSPP9Ian NaylorBelum ada peringkat

- Battery ChargingDokumen7 halamanBattery Charging123olympiakosBelum ada peringkat

- AWS D1 Visual InspectionDokumen2 halamanAWS D1 Visual InspectionBHUSHAN KALEBelum ada peringkat

- Design A Hybrid Solar BicycleDokumen32 halamanDesign A Hybrid Solar Bicycleakash100% (1)

- Series 4000 - Bituminous Layers and SealsDokumen52 halamanSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- Upholstery Leather Collection (Superhouse Limited)Dokumen13 halamanUpholstery Leather Collection (Superhouse Limited)PROFESSIONAL STUDIESBelum ada peringkat

- Porcelain Catalog 2024Dokumen66 halamanPorcelain Catalog 2024roofingasrBelum ada peringkat

- Hl500pin ManualDokumen1 halamanHl500pin ManualMarious NavBelum ada peringkat