Pipeline Installation - 6-71-0066-Rev2

Diunggah oleh

Naveen Tripuraneni0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

34 tayangan39 halamanEIL Spec for Pipeline Installation

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniEIL Spec for Pipeline Installation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

34 tayangan39 halamanPipeline Installation - 6-71-0066-Rev2

Diunggah oleh

Naveen TripuraneniEIL Spec for Pipeline Installation

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 39

NERS ‘STANDARD SPECIFICATION FOR

GHfotere i ENG! INSTALLATION OF SUBMARINE

seal Gees ONA UMITED,

STANDARD SPECIFICATION No.

PIPELINES AND RELATED 6-71-0066 Rev. 2

FAGILITIES Page 1 of 39

wat Ue a daifiae

Qerst & dear & few

ame fatreet

TANDARD SPECIFICATION

FOR

INSTALLATION OF SUBMARINE

PIPELINES AND RELATED FACILITIES

rere Mang te

3108-08 SPECIFICATION wee ve eve

FEVSEDE REISSUED AS STANDARD

1 osti08 LREISSUED AS o 8 vw AS

(0 241061 ISSUEDASSTANOARD SPECIFICATIONS) —~=RKD.=~*«C*PGR’~SC*RNS

— ‘Standards Standards

Commitee Bureau

Rov. pg pose Prepared checked fe Bureau

Rev pate Purpos pa estan Convenar ch

Approved by

Format No, 6-00-000771 Rew. 0

‘Copyright EIL. — All rights reserved

‘STANDARD SPECIFICATION FOR

‘STANDARD SPECIFICATION No.

SGifetzreT as ENGINEERS INSTALLATION OF SUBMARINE

seats GNA UMITED PIPELINES AND RELATED e700 ev 2

— non ama nae FACILITIES Page 2 of 39

Abbreviations:

ASME American Society of Mechanical Engineers

ASTM, American Society for Testing and Materials

Dnv Det Norske Veritas

API American Petroleum Institute

NDT Non Destructive Testing

PLEM Pipe Line End Manifold

Pipeline Engineering Standards Committee

Convenor: Mr. Ashwani Soni

Members: — Mr. Deepak Dharmarha

Mr. Vinay Mittal

Mr. Suresh Kumar

Mr. Manoj K Malhotra

Dr. R. S. Bhatia (Piping)

Dr. V. R. Krishnan (SMMS)

Mr. Sheel Yadav (PDD)

Mr. Rajiv Kumar (Inspection)

Mr. R. Kannan (HO Construction)

Mr. S. Kaul ( Projects )

Format No. 6-00-0001-F' Rev. 0

‘Copyright EIL — Alrights reserved

STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

Sifezre SS ENGINEERS INSTALLATION OF SUBMARINE.

3a ietstés INDIA UMITED

PIPELINES AND RELATED 6-71-0066 Rev. 2

———_—_—_— FACILITIES Page 3 of 39

CONTENTS

1.0 SCOPE

2.0

3.0

40

5.0

6.0

70

8.0

9.0

10.0

11.0

12.0

13.0

140

15.0

16.0

17.0

18.0

REFERENCE CODES, STANDARD AND SPECIFICATIONS

GENERAL

ENGINEERING REQUIREMENTS

CONSTRUCTION REQUIREMENTS

HANDLING, HAULING STORAGE AND TRANSPORTATION

PIPELINE INSTALLATION

RISER INSTALLATION

PIPELINE CROSSINGS

PIPELINE FREE SPANS AND SUPPORTS.

CATHODIC PROTECTION SURVEYS

ONLINE VALVES, LATERALS AND PLEM INSTALLATIONS,

PIPING DESIGN AND FABRICATION REQUIREMENTS,

CLEAN-UP, RESTORATION AND DISPOSAL OF SURPLUS MATERIALS

AS-BUILT DATA REQUIREMENTS

DOCUMENTATION

DAILY REPORTS

SUPPLY OF MATERIALS

Format No. 6:00-0001-F1 Rev. 0 ‘Copyright El — All rights reserved

‘STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

‘SSafetzteT 4 ENGINEERS: INSTALLATION OF SUBMARINE

tee SRSA UMITED PIPELINES AND RELATED emeee eae

eee ede oe cee FACILITIES Page 4of 29

10 SCOPE

Ll This Specification covers the minimum requirements for transportation, fabrication,

installation and other associated works of submarine pipelines and risers transporting

hydrocarbons in liquid/gaseous phase and injection water.

1.2 This specification shall be read in conjunction with the requirements of all specifications and

documents included in the Contract.

2.0 REFERENCE CODES, STANDARDS AND SPECIFICATIONS

2.1 Reference has been made in this specification to the latest edition (edition enforce at the time

of issue of enquiry) of the following Codes, Standards and Specifications,

a) DNV 1981 - Rules for Submarine Pipeline Systems.

b) ASMEB31.4 — - Pipelines Transportation Systems for Liquid Hydrocarbons and

Other Liquids.

) ASMEB31.8 — - Gas Transmission and Distribution Piping systems.

4) ASMESec.IX - Boiler and Pressure Vessel Code — Welding and Brazing

Qualifications

©) ASTMB127 — - Specification for Nickel Copper Alloy Plate, Sheet and Strip

) ASTMD2000 - Classification System for Rubber Products in Automotive

Application.

8) API1104 ~ Standard for Welding Pipelines and Related Facilities.

h) APIRP 1111 - Recommended Practice for Design, Construction, Operation and

Maintenance of Offshore Hydrocarbon Pipelines.

i) APIRPSLI - Recommended Practice for Rail-Road Transportation of

Linepipe.

i) APIRPSLW — - Recommended Practice for Transportation of Line Pipe on

Barges and Marine Vessels.

k) Part 195, - Code of Federal Regulations

Title 49 - Minimum Federal Safety Standards for Liquid Pipelines

1) Part 192, - Code of Federal Regulations

Title 49 - Minimum Federal Safety Standards for Gas Lines

m) IP Part 6 - Institute of Petroleum, Model Code of Safe Practice

n) AWSSILE - American Welding Society Standard

©) BS 3072 - Specification for Nickel and Nickel Alloys

p) SIS-055900 ‘Swedish Standard — Pictoral Surface Preparation Standards for

Painting Steel Surfaces.

Format No. €-00-0007-F1 Rev. 0 ‘Copyright EL. — Al rights reserved

SERS A NCRERS STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

INSTALLATION OF SUBMARINE

SRR UMITED PIPELINES AND RELATED 6-71-0066 Rev. 2

ES ame FACILITIES Page 5 0f 30

2.2 In case of conflict between the requirements of this specification and that of the above

referred codes, standards and specifications, the requirement of this specification shall

govern.

3.0 GENERAL

3.1 Contractor shall furnish and maintain all necessary barges, tugs, supply vessels, survey

vessels, equipments, tools and tackles, materials, consumables, labour, inspection and

monitoring services for the successful fabrication, installation and other associated operations

of submarine pipelines. All materials, equipments and vessels shall be subject to Company

approval prior to their use.

32 Contractor shall fully familiarize himself with all aspects of the environmental information

available for the area in which the Work is to be carried out. Prior to the commencement of

‘Work, the Contractor shall be deemed to be fully familiar with the site conditions relating to

seabed, wind, waves, tides, currents, etc.

33 Contractor shall also fully familiarize himself with the location and depth of all existing

facilities and obstructions, including wrecks, boulders, pipelines, cables, structures ete.,

which may affect the pipeline installation and other associated operations.

34 Contractor shall consider the limiting weather, sea and current state in which the marine

spreads can operate, whilst ensuring safety and integrity of the personnel, equipment, the

‘Work and any other facilities in the working area and shall accordingly select equipments for

the pipeline/riser installation and other associated operations to complete the Works within

the schedule mentioned in the Contract.

‘Company reserves the right to audit all marine vessels and other construction equipment

proposed for use by the Contractor. Any equipment failing to comply with either the

Company specifications or environmental or safety requirements, as determined by

‘Company, shall be replaced or modified by the Contractor prior to its use.

3.5 The Contractor shall acquaint himself and comply with all the applicable laws and statutory

regulations of the Government Agencies having jurisdiction over the area of Work, while

carrying out the pipeline/riser installation and other associated operations. All such laws and

regulations enforced from time to time shall be binding upon the Contractor.

3.6 Contractor shall take all necessary precautions to prevent damage to the existing facilities,

during the installation and the associated operations. Contractor shall be responsible for any

damage to the existing pipelines, its coatings and/or appurtenances, during the operations.

The cost of repair or replacement of the existing facilities as a result of damage by

Contractor's operations shall be borne by the Contractor.

3.7 Contractor shall provide full access to the Company Representative of all Work areas during

all phases of Work and shall also provide access to documentation related to the Work

covered in the Contract.

3.8 Contractor shall provide office, communication and accommodation facilities for specified

number of Company personnel onboard the pipeline installation vessel, as well as personnel

transports facilities as mentioned elsewhere in the Contract.

3.9 In case any pipeline installation at shore approach is included in the Work to be performed,

Contractor shall provide round-the-clock transport facilities for the Company Representative

between shore and the barge till the completion of the entire installation operation at the

shore.

Format No, 8-00-0007-F1 Rev. 0 Copyright El — All rights reserved

STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

INSTALLATION OF SUBMARINE

STAT BY ENGNEERS.

ates GNA UMITED PIPELINES AND RELATED 6-71-0066 Rev. 2

‘Rocatnardnan! FACILITIES Page 6 of 38

3.10

3.1

40

41

42

5.0

Sa

52

53

Contractor shall provide all diving services required to ascertain and confirm that the pipeline

and appurtenances have been installed in accordance with the requirements of this

Specification

Contractor shall carry out all works related to pipeline installation viz, Trenching, back-

filling, hydrostatic testing, etc. as applicable, as per the relevant Company specifications

included in the Contract and the Company approved procedures.

ENGINEERING REQUIREMENTS.

Procedures, drawings and calculations relevant to the pipeline/riser installation and other

associated operations shall be prepared and submitted for Company approval, detailing all

aspects of the installation operations.

Calculations

‘The Contractor shall calculate the stresses induced in the pipelines due to pipe laying and

riser installation, Pipeline End Manifold (PLEM) and Lateral installation and other associated

operations. The Contractor shall outline the method and basis of the calculations in the

documents submitted for Company Approval. In case any computer programs are proposed,

Contractor shall furnish in his Bid, a brief description of the analytical methods employed in

the program along with the basis and theory used, Failure to submit the required information

will make the document liable for rejection.

CONSTRUCTION REQUIREMENTS

Contractor shall investigate and select the lay barge positioning system taking into

consideration:

water depth

- general lay out of the pipelines

- existing installations and pipeline crossings

= sea bottom soil conditions

- general environmental conditions

- laying tolerances

Contractor shall be responsible for laying the lines within 2 metre on either side of the

pipeline route shown in the Company approved drawings for a distance of upto 1000 metre

from the Platform/PLEM or sub-sea installation, The tolerance for the rest of the area shall be

10 metres. However at shore approaches, the tolerance shall be + 0.5 metres. Company

reserves the right to seek realignment of the installed pipeline in case the above limits are not

complied with. Realignment if any shall be carried out by the Contractor to comply the above

limits, at no extra cost to Company.

At Platform approaches where pipelines, and pipeline appurtenances, etc. are existing,

Contractor shall be responsible for laying the pipelines within the tolerances specified

without endangering the safety of the existing installations, taking into account the minimum,

possible barge clearances from the Platform and constraints imposed by existing pipelines /

installations.

Format No. 6-00-0001-F1 Rev. 0 Copyright Ell — All rights reserved

STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

ENGINEERS, INSTALLATION OF SUBMARINE

ae OGRA UMITED PIPELINES AND RELATED aoe ev. 2)

aS OS nevnenrans FACILITIES Page 7 of 39

5.4 Contractor shall continuously monitor sea-state and general meteorological conditions from

55

56

587

60

61

6.2

63

64

65

the weather forecasting receiving facilities throughout the pipeline/riser installation and

associated operations.

Diver operations for pipe burial, unsupported spans, crossings, riser inspection and other

underwater operations shall be monitored by close circuit television and underwater camera,

Contractor shall make video tape recordings of completed underwater Works and permit

Company Representative for TV viewing to enable monitoring of underwater works. Video

tapes of such recordings shall be submitted to the Company for record purposes. Recordings

shall be on VHS format tapes and shall be suitable for PAL system.

Contractor shall carry out all Works related to pipeline/riser and other operations, strictly in

accordance with the requirements of this specification and the Company approved drawings

and documents, without damaging the existing pipeline installations.

Contractor shall not commence any work on installation of pipelines and associated facilities

prior to the approval of the methods/procedures by Company.

HANDLING, HAULING, STORAGE AND TRANSPORTATION

Contractor shall receive and take over against requisition all Company supplied materials

from Company's designated place(s) of delivery as defined in the Contract. The Contractor

shall be totally responsible for all materials until the acceptance of the Work by the

Company,

In case of Company supplied materials, Representatives of the Contractor and the Company

shall jointly inspect all coated pipes and other associated materials at the time of handing

over. Contractor shall perform visual inspection and defects, if any noted, shall be recorded

separately in the presence of Company Representative. The Contractor shall be entitled to

extra compensation for repair and rectification of such defects in accordance with the

procedures previously approved by the Company at the rates set forth in the Contract.

Damage to pipes which occur after the Contractor has taken delivery of Company supplied

pipes such as dents, flats or damage to weld ends shall be cut off or removed and pipes

rebevelled and repaired again as necessary. The cost of this Work, as well as that of the pipe

lost in cutting and repair in excess of the wastage allowance shall be to the Contractor's

account. All such Works shall be carried out after written approval of the Company

Representative.

Contractor shall unload, load, stockpile and transport the concrete coated pipes using suitable

means and in a manner to avoid damages to coating, pipe body and bevelled ends, from

designated place(s) of delivery to the Work site. Contractor shall submit to Company for

approval a detailed procedure including necessary drawings of cargo barges for handling,

hauling, storage and transportation prior to commencement of any handling operations. In

general, pipes shall be transported in accordance with API RP SLI and API RP SLW.

Contractor shall carry out a dynamic transportation analysis based on 1-year storm conditions

mentioned elsewhere in the Contract, considering the proposed marine transportation scheme

i.e. cargo barges and the securing arrangement and establish that the proposed transportation

arrangement is safer and stable. ‘The results of the analysis shall be submitted to company for

approval, prior to undertaking the transportation of line pipe to the Works site(3).

Adequate strapping and padding shall be provided during handling. All pipe handling

equipment shall be approved by Company prior to their use. All lifting equipments shall be of

such a design so as to prevent damages to the line pipe or coating. Pipes shall not be allowed

to bump against any other pipe o other objects. Rolling, skidding or dragging of pipes shall

Format No. 6-00-0001-F1 Rev. 0 ‘Copyright EIL — Al rights reserved

STANDARD SPECIFICATION FOR STANDARD SPECIFICATION No.

SHES ET Se ENGNEERS INSTALLATION OF SUBMARINE

waeeee S| INDIA UMITED

PIPELINES AND RELATED 6-71-0066 Rev. 2

TARAS nana FACILITIES Page 8 0f 39

66

67

68

69

6.10

6.11

6.12

70

TA

Td

713

not be permitted. The pipe ends during handling and st

bevel protectors.

ing shall be always protected with

Coated line pipes shall be handled at all times with wide non-abrasive slings and belts or end.

hooks. End hooks shall have sufficient width and depth to fit the inside of the pipe and

padded with soft material like rubber, Teflon or equivalent so as not to cause damages to

bevel or pipe ends.

Stacking of coated pipes shall be carried out in such a manner to prevent concrete coating

from being damaged. Stacks shall consist of a limited number of layers such that the pressure

exercised by the pipes own weight docs not cause damages to concrete coating. Contractor

shall calculate based on the characteristics of the concrete used, the number of layers for

stacking and submit the same to Company for approval.

‘Truck, train and barge bolsters shall be at least 300 mm wide and well padded. When pipe is

laid directly onto barge deck or the flat surfaces, these surfaces shall be clear of projecting

bolt heads, uneven areas or loose hard substances such as rocks that could damage the pipe or

coating. Suitable protection shall be provided in case of bolt head projection.

Stacks shall be suitably secured against falling and shall consist of pipe sections having the

same diameter and wall thickness.

If the Company Representative observes coating or pipe damage due to handling, Contractor

shall review the handling procedure adopted and take corrective actions as required to the

satisfaction of the Company Representative. Damaged pipes shall not be loaded until the

repairs are done.

Contractor shall be responsible for the load out, sea fastening and transportation to site of all

materials necessary for installation and satisfactory completion of all pipeline installations.

Contractor shall be solely responsible for scheduling the delivery, handling and hauling of

appropriate materials to various intermediate and final locations as required by the activities

enumerated in the scope of Work forming part of the Contract. Delays or lost time as a result

of the Contractor's inability to schedule deliveries in time shall be to Contractor's account.

PIPELINE INSTALLATION

Survey Requirements

Any information available with the Company regarding bathymetry, soil and other surveys

carried out by Other Agencies pertaining to the Work covered in the Contract are enclosed

along with the Contract Document. Any additional survey required to carry out and complete

the Works in all respects shall be done by the Contractor at no extra cost to Company. All

surveys shall comply the requirements stated in the relevant Company survey specifications

included in the Contract, as and to the extent applicable.

Pre-engineering survey

Pre engineering survey of the pipeline route/corridor, shore approach as well as the platform

approach and Jacket Faces shall be carried out by the Contractor, in case the same is required

to be performed by the Contractor as per the Contract.

Pre-construction survey

Format No, 6-00-0001-F1 Rev. 0 ‘Copyright El — All rights reserved

Anda mungkin juga menyukai

- IK - Manufacturers - XLSX 7 19 18Dokumen428 halamanIK - Manufacturers - XLSX 7 19 18Naveen TripuraneniBelum ada peringkat

- Pigging TerminologyDokumen90 halamanPigging TerminologyNaveen TripuraneniBelum ada peringkat

- OIMDokumen37 halamanOIMNaveen TripuraneniBelum ada peringkat

- Tros 650 MsdsDokumen8 halamanTros 650 MsdsNaveen TripuraneniBelum ada peringkat

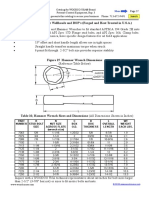

- API Flange Bolt Wrenches, Hammer Wrenches for Wellheads and BOP's, Size Chart, Striking Wrenches, Hammer Wrenches for API Flanges and Clamps, Slugging Wrenches, Made in USA for API 6A, 16A, 17D Flanges, Made in U.SDokumen2 halamanAPI Flange Bolt Wrenches, Hammer Wrenches for Wellheads and BOP's, Size Chart, Striking Wrenches, Hammer Wrenches for API Flanges and Clamps, Slugging Wrenches, Made in USA for API 6A, 16A, 17D Flanges, Made in U.SNaveen Tripuraneni100% (2)

- API Related, Oilfield Pressure Control Equipment, Terms and Definitions, GlossaryDokumen36 halamanAPI Related, Oilfield Pressure Control Equipment, Terms and Definitions, GlossaryNaveen TripuraneniBelum ada peringkat

- Bolt ChartDokumen1 halamanBolt ChartNaveen TripuraneniBelum ada peringkat

- Model-Based Systems Engineering (MBSE) Challenge: Modeling & Simulation Interoperability (MSI) Team Status UpdateDokumen105 halamanModel-Based Systems Engineering (MBSE) Challenge: Modeling & Simulation Interoperability (MSI) Team Status UpdateNaveen TripuraneniBelum ada peringkat

- Pipeline Drying TechniquesDokumen10 halamanPipeline Drying TechniquesNaveen TripuraneniBelum ada peringkat

- Acceptance of Concrete Compressive StrengthDokumen19 halamanAcceptance of Concrete Compressive Strengthwayne1925Belum ada peringkat

- Codes and StandardsDokumen7 halamanCodes and StandardsNaveen TripuraneniBelum ada peringkat

- Power Generation Using Speed Breakers and Efficient Use of Energy Created by It.Dokumen52 halamanPower Generation Using Speed Breakers and Efficient Use of Energy Created by It.Tochi Krishna AbhishekBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)