10 - Hydration of Portland Cement

Diunggah oleh

mkpasha55mp0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

13 tayangan3 halaman10_Hydration of Portland Cement

Judul Asli

10_Hydration of Portland Cement

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Ini10_Hydration of Portland Cement

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

13 tayangan3 halaman10 - Hydration of Portland Cement

Diunggah oleh

mkpasha55mp10_Hydration of Portland Cement

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 3

10 HYDRATION OF

PORTLAND CEMENT

Portland cement sets and hardens due to exothermic hydration reac-

tions. Hydration products include colloidal gels and sub-micron crys-

tals. The crystals may be fibres, needles and plates which form an

interlocking microstructure that can be observed with the aid of a scan-

ning electron microscope (SEM). Both chemical and physical processes

are, therefore, involved with the two standard explanations of cement

setting and strength development being Le Chatelier’s interlocking

crystal theory and Michaelis's colloidal gel theory (Benstead; WC;

8/1991, pg 21: Chen & Odler; Cem and Conc Res; Vol 22; 1992, pg 1130)

The reactivity of cement phases with water are in the order aluminate

> alite > ferrite > belite. CsA is the most soluble of the major compounds

and appears to dominate early hydration. Aluminate and, particularly,

silicate hydration reactions are extremely complex and many undoubt-

edly contribute to setting and strength gain of cement (see Lea’s

Chemistry of Cement and Concrete; Arnold, 4th Ed; 1998, pg 241).

Cement hydration can be approximately divided into four stages:

Initial Stage - Within seconds of contact with water, alkali sulphates

dissolve and within minutes, calcium sulphate reaches saturation.

Dissolved aluminate and sulphate react to form ettringite

(CGsA.3CaSO,.32H20) which is precipitated, normally on the surface of

cement particles. Alite dissolves slightly and forms a calcium silicate

hydrate gel (C-S-H) on the surface of alite particles. These hydration

product coatings block further reaction and initiate a dormant period.

This initial period is characterised by heat release. The rate of dissolu-

tion of sulphate relative to aluminate is critical to prevent early stiffen-

ing, of cement paste. A deficiency of sulphate in solution leads to

uncontrolled hydration of C3A to CyA.14H20 and CA.8H;0 which

crystallise to cause flash set. An excess of soluble sulphate leads to pre-

cipitation of gypsum, syngenite, or ettringite in pore solution causing

flash or false set.

Cement Plant Operations Handbook * 157

i

4

=]

>

—

[e)

=

(2)

1

sc

o

=)

er

=

P=

=

=]

(@)

iu

=

mm

=

vam]

Induction or Dormant Stage - This stage lasts 1 to 3 hours while the

hydration of all clinker phases progresses slowly. In the early stages,

Ca®* in pore solution reaches super-saturation with respect to Ca(OH)2,

and nucleation and growth of both C-S-H and Ca(OH). begin. At this

stage of structure development, thin shells of C-S-H and a few ettringite

rods develop around clinker particles. The subsequent decrease in the

concentration of Ca* in solution and the rupture of coatings trigger

renewed acceleration of alite dissolution and heat release. The continu-

ous deposition of C-S-H, Ca(OH): and other hydration products causes

bridging between particles and reduces paste porosity. This signals the

onset of setting.

Acceleration Stage - This stage begins with initial set and continues

with rapid hydration of alite into C-S-H and Ca(OH)2. These reactions

are accompanied by intense heat release which reaches a peak approx-

imately 12 hours into hydration. More ettringite is formed as gypsum is

depleted and the ettringite subsequently dissolves and reacts with

Al(OH):- to form monosulfoaluminate (C3A.CaSOx.12H20). Depending

upon the relative amounts of gypsum and aluminate, monosulfoalumi-

nate formation may be completed before or after the peak of alite hydra-

tion. Final set is reached before peak heat release from alite hydration.

Deceleration Stage - This spans many days and is characterised by low

heat evolution and a decreased overall rate of reaction as the reacting,

species become used up and diffusion slows with decreasing porosity.

Belite becomes the primary hydrating phase. C-S-H is believed to

undergo polycondensation of the SiOs tetrahedral chains with progres-

sively increasing strength

It has been observed that setting is largely independent of CsA concen-

tration and it is now believed that both setting and strength develop-

ment are largely caused by hydration of CsS to tobermorite, a C-S-H gel

of variable composition

Hydration of cement typically involves combined water of about 22%

relative to clinker weight. Given that a normal water:cement ratio in

concrete is 0.4-0.5, it is clear that excess water must be used for worka-

bility and that this excess water causes strength loss. The relative con-

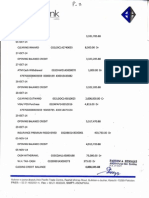

tributions to strength development are shown in the following diagram.

158 * Cement Plant Operations Handbook

Compressive

Strength (ka/em2)

500 gS

250 os

Cah

AE

x 0

Time (days)

Figure 10.1: Strength Gain of Cement Compounds

Pozzolanic activity is the result of the reaction of soluble SiO» from the

pozzolan with CaO in solution. As free CaO will always be present in

solutions in contact with hydrated cement, pozzolanic reactions provide

‘self-curing’ of cracks in pozzolanic concrete.

oe

Cement Plant Operations Handbook ¢ 159

=

a

=]

5

=

©

Pa

o

"TI

a")

oO

|

=|

=

Pd

=

=]

@)

Ua

=

m

=

=|

Anda mungkin juga menyukai

- Loeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700Dokumen5 halamanLoeffler Engineering Group 20511 Highland Lake Drive, Lago Vista, Texas 78645 512-267-8700mkpasha55mpBelum ada peringkat

- Circular Water Tank (Rigid Joint)Dokumen28 halamanCircular Water Tank (Rigid Joint)Lachu M. SharmaBelum ada peringkat

- MS Welding ElectrodesDokumen7 halamanMS Welding Electrodesmkpasha55mpBelum ada peringkat

- Imported Items Shipment Details: PO PO# Date SupplierDokumen4 halamanImported Items Shipment Details: PO PO# Date Suppliermkpasha55mpBelum ada peringkat

- VRM Kiln CoolerDokumen130 halamanVRM Kiln Coolermkpasha55mpBelum ada peringkat

- BOQ Suryadev ChennaiDokumen2 halamanBOQ Suryadev Chennaimkpasha55mpBelum ada peringkat

- Beam Analysis: Analysis of A Single Beam Subject To Transvers and Distributed LoadDokumen17 halamanBeam Analysis: Analysis of A Single Beam Subject To Transvers and Distributed Loadmkpasha55mpBelum ada peringkat

- Beam3 PortalDokumen33 halamanBeam3 Portalmkpasha55mpBelum ada peringkat

- B3 ConveyingDokumen4 halamanB3 Conveyingmkpasha55mpBelum ada peringkat

- LIST of MaterialDokumen8 halamanLIST of Materialmkpasha55mpBelum ada peringkat

- Statement P 4Dokumen1 halamanStatement P 4mkpasha55mpBelum ada peringkat

- Statement P 1Dokumen1 halamanStatement P 1mkpasha55mpBelum ada peringkat

- 11 - Other Kiln TypesDokumen7 halaman11 - Other Kiln Typesmkpasha55mpBelum ada peringkat

- Statement P 2Dokumen1 halamanStatement P 2mkpasha55mpBelum ada peringkat

- 16mm Thick: Description Hook Bolt Size 150mm QuantityDokumen1 halaman16mm Thick: Description Hook Bolt Size 150mm Quantitymkpasha55mpBelum ada peringkat

- Statement P 3Dokumen1 halamanStatement P 3mkpasha55mpBelum ada peringkat

- 30mm Hook BoltDokumen1 halaman30mm Hook Boltmkpasha55mpBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)