Rev 8

Diunggah oleh

api-273257329Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rev 8

Diunggah oleh

api-273257329Hak Cipta:

Format Tersedia

Page 1 of 1

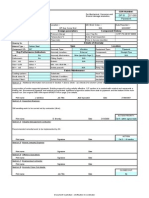

FORM DESCRIPTION

Form No.: F-141

Revision: 0

Material Card

Release: 19-May-09

Part Description:

Customer:

Vehicle type

Sideframe R

BMW

F-15

Coil information

Mill Source:

AK Steel

Part Numbers

Coil Part Number:

Thickness-L (mm) Width (mm)

QB74780065R

0.75 Min

Use

Material Specification

r-Value

n-Value

1.9 min

36000

45000

0.20 min

lbs

lbs

Surface

Exposed

Unexposed

Surface Critical

Gonvauto, Union, SC

Oiling

Type

EGL1/61AUS

Amount

Light

+ 6.35/-0

Requirements

X

GS93032-2

CR4 EG50G/50G E

BMW Part Number:

7287478

Aim To: 0.8

Tolerances:

+0.12/-0

Mechanical properties

Yield

Tensile strength

Elongation

Mpa

Mpa

%

140-180

270-330

39 min

Inside diameter

24"

Min Coil Weight

Outside diameter

40" - 72"

Max Coil Weight

Outer part

Inner visual

Inner non-visual

Ship to:

Material Grade-L

1825

gloss

matt

rough

Burr Tolerance

Surface roughness

Max 10% of

Thickness up to

0.003"

USA STD

Coils Must Be Paperwrapped with VCI Paper

No Welds

Temper Pass

X

Yes

No

Coil Edges

Mill Edge

Slit Last

X

Prime Side

Outside / Top

Inside / Bottom

Coating

X

1 Sided Top

1 Sided Bottom

2 Sided

Slitting Information (if required)

Part Numbers

Slit Coil Part#

Tolerances:

Shipping Information:

Special Slitting Instructions:

Ship to:

Thickness (mm)

Width (mm)

ID

OD

Weight

Packaging

Max Skid Weight

Blanking Information (if required)

Part Numbers

Thickness (mm)

Width (mm)

Length

Squareness Tol

Flatness Tol.

Blanks/Hit

Gross Weight

Net Weight

Blank Part # BB74780065R

0.75

1825

3540

1/2 astm

1/2 astm

83.855

Tolerances:

+0.12/-0

+6.35/-0

+1.5/-0

1

38.036

Aim to Weight - used for theoretical calculations and pc

Aim To:

0.80

89.445

Tolerance:

+0.07/-0.05

price

40.572

Blank Type

Blank Packaging Requirements

Base oiling

Surface

Rectangle

Skid Type

PP1558037

Paper Shroud:

Yes

Type:

7723C Rock Valley Exposed

X

Form Cut

Trapezoid

Chevron

Max Skid Wt

18000

Load

Forklift Side

Amount:

0.8-1.5 g/m^2

Unexposed

Max Skid Ht

711.2mm

** including skid

Wash- Reoil

YES

# Pcs per Skid

200

Oil Side

both

Blanks must be Centered on the pallet - Double Wall Cardboard must be between the blanks and the pallet

Unit

LB

KG

LB

KG

Burr

Max 10% of

Thickness up

to 0.076mm

Ship to:

Stamping Information (if required)

Stamping Part #

Stamping Part #

Part Numbers

SB74780065F

BMW Part#

BMW Part#

7287478

Parts/ Blank

Pcs / Container

Rack / Container

1.00

N09

Part Weight

Nael #

AI/DI

Nael #

AI/DI

16.51 KG

Assembly Information (if required)

Part Numbers

Assembly Part #

Assembly Part #

Ship to:

Part Descr.

Pcs / Container

Rack / Container

Part Weight

BMW Part#

BMW Part#

BMW

Special Comment:

Changed Elongation to the A80 instead of the A50

changed aim to - change oil amount to 0.8-1.5 g/m^2

top blank must be stone on the LH an RH blanks

Date:5-22-2014

created: G. Jones

checked:

Rev. 8

Gestamp South Carolina

1 LSP Road

Union, SC 29379

approved:

GSC Visual Inspections Required upon Receipt

Damage

Excess Oil

Stamping Pics

Wet

Flatness/Bowing

Assemby Pics

Loose Pins

Sheet 1

Rust

Blank Sketch

BB74780065R ON PP1558037

1.

After the blanking process check the location of Blanks on Pallet as Shown in figure 2.

2.

Place pins on pallet as shown in figure 2.

a.

All pins must be tight to blank wall

b. Verify all pin nuts are torqued to a maximum of a 75 ft-lbs

3.

Wire brush side walls, inspect for burrs / slivers-remove if detected

4.

Place VCI paper over pins covering both the top and side walls of the blanks.

5. Place Batch and Part number on top of VCI paper

6. Lift tag must be applied to right hand side of fork lift entry.

7. Dock audit Certification labels must be applied to top of packaging.

130mm

100mm

3937mm

Gennie Jones 8/6/2013

Anda mungkin juga menyukai

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- Datasheet Phe OnwjDokumen1 halamanDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Kia Sorento 2015 Service ManualDokumen20 halamanKia Sorento 2015 Service ManualMaria100% (56)

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDokumen2 halamanMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Belum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDokumen11 halamanPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900Belum ada peringkat

- Catering Service Sop 06 611Dokumen23 halamanCatering Service Sop 06 611Dr Gajanan Shirke100% (1)

- Iconic Cars 5-Book Bundle: Mustang, Camaro, Corvette, Porsche, BMW M SeriesDari EverandIconic Cars 5-Book Bundle: Mustang, Camaro, Corvette, Porsche, BMW M SeriesBelum ada peringkat

- Olefins Production PDFDokumen64 halamanOlefins Production PDFAnonymous 0zrCNQBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Bar Screening Environmental EngineeringDokumen11 halamanBar Screening Environmental EngineeringRajat Kushwaha100% (1)

- Data Sheet Fuel Gas Filter Rev 0Dokumen22 halamanData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoBelum ada peringkat

- L028 Me Dat 01 00122 001 00Dokumen8 halamanL028 Me Dat 01 00122 001 00sivasan10006098Belum ada peringkat

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Dokumen24 halamanBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- High Rise Structural Systems: Presented byDokumen35 halamanHigh Rise Structural Systems: Presented byvidi herdianaBelum ada peringkat

- Application of DryingDokumen31 halamanApplication of Dryinguzzal ahmedBelum ada peringkat

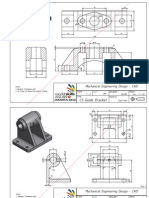

- CS Guide Bracket: Mechanical Engineering Design - CADDokumen10 halamanCS Guide Bracket: Mechanical Engineering Design - CADgundhiufsBelum ada peringkat

- Borneman Pump ManualDokumen56 halamanBorneman Pump Manualiskalkos100% (2)

- Rev 8Dokumen2 halamanRev 8api-273257329Belum ada peringkat

- Rev 12Dokumen2 halamanRev 12api-273257329Belum ada peringkat

- 2092 Rev 2Dokumen2 halaman2092 Rev 2api-273257329Belum ada peringkat

- 2122 Rev 8Dokumen1 halaman2122 Rev 8api-273257329Belum ada peringkat

- Rev 10Dokumen3 halamanRev 10api-273257329Belum ada peringkat

- 2 Rev 9Dokumen21 halaman2 Rev 9Sidiq PramokoBelum ada peringkat

- AHU CLCP Dimension DrawingsDokumen92 halamanAHU CLCP Dimension DrawingsPhạm ĐạtBelum ada peringkat

- EP Petroecuador Refineria Esmeraldas: Drive Unit SettingsDokumen2 halamanEP Petroecuador Refineria Esmeraldas: Drive Unit SettingsLuis PullasBelum ada peringkat

- Data Sheet Tag 180-Pu-011eDokumen8 halamanData Sheet Tag 180-Pu-011eSarah PerezBelum ada peringkat

- HP 1Dokumen12 halamanHP 1api-273257329Belum ada peringkat

- Inventorwizard: Miniature Model Engine 6 Cylinder - Radial Engine (Pneumatic) Assembly PistonDokumen1 halamanInventorwizard: Miniature Model Engine 6 Cylinder - Radial Engine (Pneumatic) Assembly PistonHans ManriqueBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- CB3033BS66,1MI4P LS71 0,09kW 365V 87HzDokumen4 halamanCB3033BS66,1MI4P LS71 0,09kW 365V 87Hzmagda_biricaBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- High Pressure Gear Pump GuideDokumen12 halamanHigh Pressure Gear Pump GuideMauricio Ariel H. OrellanaBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Inlet of Foam Box Dwg.Dokumen1 halamanInlet of Foam Box Dwg.solquihaBelum ada peringkat

- Spec Sheet for Steam Globe ValveDokumen3 halamanSpec Sheet for Steam Globe ValveGastonBalcarcelBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Bombinha de Óleo (Exploded View)Dokumen13 halamanBombinha de Óleo (Exploded View)Fábio EstevamBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- MR HUSSAIN g7 DSTDokumen4 halamanMR HUSSAIN g7 DSTcamdenclaimsBelum ada peringkat

- Rawmill LubricationDokumen22 halamanRawmill Lubricationsivareddy143Belum ada peringkat

- Wind Turbine Nacelle Datasheet Pack ENGDokumen16 halamanWind Turbine Nacelle Datasheet Pack ENGMamelucoBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Modificaiton Bulletin AF200Dokumen47 halamanModificaiton Bulletin AF200Amer RafiqueBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- 100-155 Filter and Heater UnitDokumen3 halaman100-155 Filter and Heater Unitapi-290859192Belum ada peringkat

- Pradi 000000Dokumen1 halamanPradi 000000pchannagoudarBelum ada peringkat

- Corrosion Damage Report (CDR)Dokumen4 halamanCorrosion Damage Report (CDR)diaccessltd_17172961Belum ada peringkat

- Pump Price BreakdownDokumen3 halamanPump Price BreakdownAlejandro GilBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold DrawnDokumen3 halamanMCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen34 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Ga 9017 M Etp Mes Pu 01Z A02 074Dokumen1 halamanGa 9017 M Etp Mes Pu 01Z A02 074Sabir NasimBelum ada peringkat

- Gestamp Monthly Action PlanDokumen3 halamanGestamp Monthly Action Planapi-273257329Belum ada peringkat

- CustomerDokumen4 halamanCustomerapi-273257329Belum ada peringkat

- 8d Gestamp Ak 4 Lamination and Inclusions Rev 2Dokumen4 halaman8d Gestamp Ak 4 Lamination and Inclusions Rev 2api-273257329Belum ada peringkat

- Ak-2 Class A Release Criteria Rev 3Dokumen4 halamanAk-2 Class A Release Criteria Rev 3api-273257329Belum ada peringkat

- f-15 Rear Door Inner LH 8875 B BlankDokumen7 halamanf-15 Rear Door Inner LH 8875 B Blankapi-273257329Belum ada peringkat

- Corrective Action Request (CAR) 8-Discipline Steps: Form DescriptionDokumen3 halamanCorrective Action Request (CAR) 8-Discipline Steps: Form Descriptionapi-273257329Belum ada peringkat

- f-15 Rear Door Inner LH 8875 A BlankDokumen7 halamanf-15 Rear Door Inner LH 8875 A Blankapi-273257329Belum ada peringkat

- HP 2Dokumen10 halamanHP 2api-273257329Belum ada peringkat

- F 15 Front Door Inner LH 8855 A BlankDokumen7 halamanF 15 Front Door Inner LH 8855 A Blankapi-273257329Belum ada peringkat

- f-15 Front Door Inner LH 8855 B BlankDokumen8 halamanf-15 Front Door Inner LH 8855 B Blankapi-273257329Belum ada peringkat

- HP 1Dokumen12 halamanHP 1api-273257329Belum ada peringkat

- HSM Gouges and Scratches: Continuous Improvement Action ItemsDokumen1 halamanHSM Gouges and Scratches: Continuous Improvement Action Itemsapi-273257329Belum ada peringkat

- Gestamp - Eg Body Side - Surface FeaturesDokumen9 halamanGestamp - Eg Body Side - Surface Featuresapi-273257329Belum ada peringkat

- 2085 Rev 6Dokumen1 halaman2085 Rev 6api-273257329Belum ada peringkat

- 14-7-15 f25 Bodyside Outer LH 2122Dokumen10 halaman14-7-15 f25 Bodyside Outer LH 2122api-273257329Belum ada peringkat

- 05aDokumen1 halaman05aapi-273257329Belum ada peringkat

- Lamination Ci Update Nov 2014Dokumen6 halamanLamination Ci Update Nov 2014api-273257329Belum ada peringkat

- 10-2-2014 Gestamp Part 2302Dokumen7 halaman10-2-2014 Gestamp Part 2302api-273257329Belum ada peringkat

- Defectmanual 2Dokumen37 halamanDefectmanual 2api-273257329Belum ada peringkat

- Method statement for box culvert constructionDokumen10 halamanMethod statement for box culvert constructionTAMILBelum ada peringkat

- 18.5200 MUS KS01 Foam SeparatorDokumen32 halaman18.5200 MUS KS01 Foam SeparatorIndra KushwahaBelum ada peringkat

- Neptune Orthopaedics Standard Operating Procedure-ProductionDokumen3 halamanNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurBelum ada peringkat

- DONE ElectSpeciBook PDFDokumen35 halamanDONE ElectSpeciBook PDFMaulik RavalBelum ada peringkat

- Chap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetDokumen2 halamanChap 4 Wastewater Effluent Treatment Plant ETP Operation Manual FactsheetAhmedBelum ada peringkat

- 350 MW Power Plant Technical SpecificationsDokumen7 halaman350 MW Power Plant Technical SpecificationsEricGaringanaoBelum ada peringkat

- Diagnostic Exam for Aeronautical Engineering StudentsDokumen4 halamanDiagnostic Exam for Aeronautical Engineering StudentsBerns DulamBelum ada peringkat

- FF8.5GX Universal Compressor R134a 115V 60Hz: GeneralDokumen2 halamanFF8.5GX Universal Compressor R134a 115V 60Hz: GeneralWin FloresBelum ada peringkat

- Waste Water Treatment Using Electrocoagulation TechnologyDokumen4 halamanWaste Water Treatment Using Electrocoagulation TechnologyKetan V. JoshiBelum ada peringkat

- P 329E ContinuousCastingPlantsForCopperDokumen24 halamanP 329E ContinuousCastingPlantsForCopperI SinhrooBelum ada peringkat

- South African Cotton Textile Pipeline Statistics 2016-2020Dokumen16 halamanSouth African Cotton Textile Pipeline Statistics 2016-2020Siphumelele QithiBelum ada peringkat

- Unit 3 Production and Cost AnalysisDokumen6 halamanUnit 3 Production and Cost Analysismanjunatha TK100% (1)

- Crane Packing ListDokumen2 halamanCrane Packing Listmanas3sBelum ada peringkat

- Click Bond Nutplate, Install and RemovalDokumen35 halamanClick Bond Nutplate, Install and RemovalBlack SkyBelum ada peringkat

- List of Proposed Electrical Building MaterialDokumen2 halamanList of Proposed Electrical Building MaterialLaila AzreenBelum ada peringkat

- Grundfosliterature 145813Dokumen2 halamanGrundfosliterature 145813Sudhakar Murugesan100% (1)

- Sub Title IodoformDokumen3 halamanSub Title IodoformReni whynBelum ada peringkat

- Changes in Matter Education Presentation in Orange Light Yellow Hand Drawn StyleDokumen20 halamanChanges in Matter Education Presentation in Orange Light Yellow Hand Drawn StyleYam YrrehcBelum ada peringkat

- GTDMC ReportDokumen11 halamanGTDMC ReportOwais AhmedBelum ada peringkat

- FEC Problem Set 1Dokumen4 halamanFEC Problem Set 1Buğra MertolBelum ada peringkat

- AMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsDokumen23 halamanAMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsLuongBelum ada peringkat

- Smart' Polymers and What They Could Do in Biotechnology and MedicineDokumen6 halamanSmart' Polymers and What They Could Do in Biotechnology and MedicineAlexander KritikopoulosBelum ada peringkat

- Marten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsDokumen391 halamanMarten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsJed MansouriBelum ada peringkat