Tasks For Completion: Quality Objectives

Diunggah oleh

Amit PintoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tasks For Completion: Quality Objectives

Diunggah oleh

Amit PintoHak Cipta:

Format Tersedia

16-12-2014

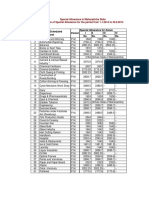

As per the discussion held at 1600 hrs in the presence of Mr. Arun Zope, Mr. Tushar

Patil, Mr. Vikram Pinto and Mr. Amit Pinto, it has been decided that the following

work is to be plan has to be designed in order to facilitate efficient practices.

TASKS FOR COMPLETION

Quality Objectives

1. Preliminary draft prepared by Mr. Arun Zope

2. Secondary draft by Amit Pinto & Vikram

Pinto

3. Final review by Arun Pinto & Reynold Pinto

Training Records

4. Certificates to be issued

5. An attendance sheet

6. Documentation of trainer and

topic for

trainees

Rejection Records

7. To find an average number of rejections

from both casting and machining centers

8. Design of a report for rejection

9. Supplementary tracking documentation and

reasons for rejection

10.To design a method of rectification of

rejected materials

11.To design a method for determining a

rejection

Root Cause Finding of

Customers Rejection

12.List of all the non corformance pointed out

by the customer

13.A systematic procedure and standards

estabilished by Siemens for checking said

products

Machine breakdown/

Maintainence report

Mr.

Arun

Zope

Mr.

Tushar

Patil

Mr.

Vikram

Pinto

Mr.

Amit

Pino

14.List of all the machines and the contracts of

services for the machines

15.Average time for repair/servicing

16.Design of a breakdown report

17.Design of maintenance report

Measurement of molten metal

18.Training of personnel for operating

measuring equipment

19.Documentation of readings weekly

20.Report to be generated for

21.Method of measuring is to be documented

Delivery Reliability to Siemens

22.A list of DPPs sent by Siemens and their

delivery dates

23.Our supply dates

24.Procedure of scheduling in order to meets

customer requirement

25.Focus on separate procedure when orders

priority is shifted by Siemens

Supplier Reliability

26.A list of all the purchase orders and vendor

supply against said POs

27.A method established for amendments

28. Documentation of supply-raw and

outsourced material

Traceability

29.Designations and colour coding at different

sections of the work place

30.Application of labels for tracibility

31.Stenciling of nameplates for identification of

locations

Any further amendments can be done with suffix

1,2,3, after the title of the document with

highlighted areas of change in yellow

Anda mungkin juga menyukai

- Script - Freebitco - Working 100 %Dokumen18 halamanScript - Freebitco - Working 100 %Mohammad Arnold28% (25)

- Productivity and Reliability-Based Maintenance Management, Second EditionDari EverandProductivity and Reliability-Based Maintenance Management, Second EditionBelum ada peringkat

- Analog Man Guide To Vintage Effects EbookDokumen3 halamanAnalog Man Guide To Vintage Effects EbookEmmanuel Ramirez100% (1)

- Digital MP3 Player - User ManualDokumen18 halamanDigital MP3 Player - User ManualdelmarioBelum ada peringkat

- Designing The Best Maintenance OrganizationDokumen5 halamanDesigning The Best Maintenance Organizationmanu_chatBelum ada peringkat

- Inventory MGMTDokumen35 halamanInventory MGMTPawan Vintu71% (7)

- Class 15 - Aggregate Planning 2Dokumen17 halamanClass 15 - Aggregate Planning 2lhaterus100% (1)

- Acad98 004R1Dokumen66 halamanAcad98 004R1michael1971Belum ada peringkat

- Maintenance ConceptDokumen4 halamanMaintenance Conceptsomjit saranaiBelum ada peringkat

- Predictive Maintenance A Complete Guide - 2021 EditionDari EverandPredictive Maintenance A Complete Guide - 2021 EditionBelum ada peringkat

- Business FunctionsDokumen88 halamanBusiness Functionsmurali dhanunjay0% (2)

- Service Oriented Enterprises (PDFDrive)Dokumen465 halamanService Oriented Enterprises (PDFDrive)Robby alazizBelum ada peringkat

- InventoryDokumen13 halamanInventoryAdityaBelum ada peringkat

- Initial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDokumen5 halamanInitial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDamianBelum ada peringkat

- Handbook of Industrial EngineeringDokumen24 halamanHandbook of Industrial EngineeringRanachetan SinghBelum ada peringkat

- TPM OverviewDokumen13 halamanTPM OverviewjesusmemBelum ada peringkat

- Chap 06 Inventory Control ModelsDokumen112 halamanChap 06 Inventory Control ModelsFatma El TayebBelum ada peringkat

- Revista de Confiabilidad de MantenimientoDokumen69 halamanRevista de Confiabilidad de MantenimientoghoyarbideBelum ada peringkat

- 2018 SMRP Solutions Issue 3 PDFDokumen17 halaman2018 SMRP Solutions Issue 3 PDFAndres NoriegaBelum ada peringkat

- 12 TPMDokumen50 halaman12 TPMGatut SulianaBelum ada peringkat

- Otal Roductive Aintenance: Designed by Danish Zakria Hafiz Abdul MananDokumen11 halamanOtal Roductive Aintenance: Designed by Danish Zakria Hafiz Abdul MananManan IFtikharBelum ada peringkat

- The 14 Principles of the Toyota WayDokumen7 halamanThe 14 Principles of the Toyota Wayraydiamond4uBelum ada peringkat

- TLT dEC 2013 PDFDokumen36 halamanTLT dEC 2013 PDFJorge Cuadros BlasBelum ada peringkat

- Optimizing Production Processes Using SMED AnalysisDokumen9 halamanOptimizing Production Processes Using SMED AnalysishajiBelum ada peringkat

- Leanmap FREE Six Sigma DMAIC ProcessDokumen1 halamanLeanmap FREE Six Sigma DMAIC ProcessdrustagiBelum ada peringkat

- Introduction to Mineral Processing and Ore HandlingDokumen8 halamanIntroduction to Mineral Processing and Ore HandlingJake AJBelum ada peringkat

- Maintain Continuous Improvement SystemDokumen76 halamanMaintain Continuous Improvement SystemJaleto sunkemoBelum ada peringkat

- A Method For TPT ReductionDokumen114 halamanA Method For TPT ReductionEbrahim HanashBelum ada peringkat

- Lean ClassDokumen425 halamanLean ClassElena Montero CarrascoBelum ada peringkat

- Audit Process - How ToDokumen144 halamanAudit Process - How ToVenkateswarlu BharathulaBelum ada peringkat

- Work Study, Time StudyDokumen21 halamanWork Study, Time StudyShashank SrivastavaBelum ada peringkat

- 1 Overview 01 APR 2014Dokumen20 halaman1 Overview 01 APR 2014Denis CBelum ada peringkat

- CMRP OverviewDokumen2 halamanCMRP OverviewBabatunde Abiodun OluboriBelum ada peringkat

- Reliability Solutions For Mechanical Equipment DataDokumen20 halamanReliability Solutions For Mechanical Equipment DatatohemaBelum ada peringkat

- World Class Manufacturing ManagementDokumen2 halamanWorld Class Manufacturing ManagementShashank BurdeBelum ada peringkat

- Intro-The Nature of FailureDokumen14 halamanIntro-The Nature of FailureIsnan RivaniBelum ada peringkat

- A Total Productive Maintenance (TPM) Approach To Improve Overall Equipment EfficiencyDokumen4 halamanA Total Productive Maintenance (TPM) Approach To Improve Overall Equipment EfficiencyIJMERBelum ada peringkat

- Strategies and Success Factors For Overcoming Challenges in TPM ImplementationDokumen25 halamanStrategies and Success Factors For Overcoming Challenges in TPM Implementationdeepak_manjunath_1100% (1)

- Short Interval Control Executive SummaryDokumen2 halamanShort Interval Control Executive Summaryaminos85Belum ada peringkat

- Lean Manufacturing & TPMDokumen2 halamanLean Manufacturing & TPMEdward GermánBelum ada peringkat

- 5 Steps To Implementing A Lean Material Handling SystemDokumen3 halaman5 Steps To Implementing A Lean Material Handling SystemGovind AgarwalBelum ada peringkat

- Cost of Poor MaintenanceDokumen14 halamanCost of Poor MaintenanceSaulo CabreraBelum ada peringkat

- Five Steps To Improve ProductivityDokumen2 halamanFive Steps To Improve ProductivityManojBelum ada peringkat

- Set Up TimeDokumen23 halamanSet Up TimemuneerppBelum ada peringkat

- Assessment Criteria - MaintenanceDokumen14 halamanAssessment Criteria - MaintenanceTin NguyenBelum ada peringkat

- World Class ManufacturingDokumen36 halamanWorld Class ManufacturingDilfaraz KalawatBelum ada peringkat

- Implement Six Sigma PlanDokumen27 halamanImplement Six Sigma PlanYuvanesh Yuvan100% (1)

- D5 - Introduction To Lean ThinkingDokumen50 halamanD5 - Introduction To Lean ThinkingAzer Asociados Sac100% (1)

- TLT Magazine Aug10 PDFDokumen76 halamanTLT Magazine Aug10 PDFDanLorenaBelum ada peringkat

- A3 Problem Solving Training Course OutlineDokumen1 halamanA3 Problem Solving Training Course OutlineNedra DebbechBelum ada peringkat

- Lean IntroDokumen27 halamanLean Introjitendrasutar1975Belum ada peringkat

- Developing an MPM Framework Using ANP for Maintenance Performance Indicator SelectionDokumen14 halamanDeveloping an MPM Framework Using ANP for Maintenance Performance Indicator SelectionAlejandro100% (1)

- Inventory Management and ControlDokumen52 halamanInventory Management and ControlAshish MalhanBelum ada peringkat

- FEIGENBAUM + Ishikawa + TaguchiDokumen7 halamanFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiBelum ada peringkat

- Project Report On Maynard Operation Sequence TechniqueDokumen9 halamanProject Report On Maynard Operation Sequence TechniqueEditor IJTSRDBelum ada peringkat

- Stage Step (Nakajima's 12 Steps) : Decision To Introduce TPMDokumen16 halamanStage Step (Nakajima's 12 Steps) : Decision To Introduce TPMKarisma Lumban GaolBelum ada peringkat

- Committing To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbDokumen36 halamanCommitting To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbCarlos Delgado NietoBelum ada peringkat

- QP 2010 June IssueDokumen84 halamanQP 2010 June IssueyengzuluetaBelum ada peringkat

- Operations Intelligence Complete Self-Assessment GuideDari EverandOperations Intelligence Complete Self-Assessment GuideBelum ada peringkat

- Reliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsDari EverandReliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsBelum ada peringkat

- Diesel - Monthly Price (..., and News - IndexMundiDokumen1 halamanDiesel - Monthly Price (..., and News - IndexMundiAmit PintoBelum ada peringkat

- Data Science For Business Level 1 Badge20220613-46-3c60pi-1Dokumen1 halamanData Science For Business Level 1 Badge20220613-46-3c60pi-1Amit PintoBelum ada peringkat

- Diesel - Daily Price - C..., and News - IndexMundiDokumen1 halamanDiesel - Daily Price - C..., and News - IndexMundiAmit PintoBelum ada peringkat

- Certifications To Be Added To ListDokumen12 halamanCertifications To Be Added To ListAmit PintoBelum ada peringkat

- Maharashtra Special Allowance Rates 2014Dokumen2 halamanMaharashtra Special Allowance Rates 2014Amit PintoBelum ada peringkat

- How To Pick An Internet Connection in IndiaDokumen1 halamanHow To Pick An Internet Connection in IndiaAmit PintoBelum ada peringkat

- CPI-INDIA Avg CPI 2014Dokumen1 halamanCPI-INDIA Avg CPI 2014Amit PintoBelum ada peringkat

- GRN-Incomming Inspection Report ModifiedDokumen4 halamanGRN-Incomming Inspection Report ModifiedAmit PintoBelum ada peringkat

- Timetable 2018Dokumen16 halamanTimetable 2018Amit PintoBelum ada peringkat

- CPI-INDIA Inds Workers 2014Dokumen2 halamanCPI-INDIA Inds Workers 2014Amit PintoBelum ada peringkat

- How To Pick An Internet Connection in IndiaDokumen1 halamanHow To Pick An Internet Connection in IndiaAmit PintoBelum ada peringkat

- Timetable 2018Dokumen15 halamanTimetable 2018Amit PintoBelum ada peringkat

- How To Pick An Internet Connection in IndiaDokumen1 halamanHow To Pick An Internet Connection in IndiaAmit PintoBelum ada peringkat

- Resignation HR LETTERDokumen1 halamanResignation HR LETTERAmit PintoBelum ada peringkat

- Internal Audit ProcedureDokumen2 halamanInternal Audit ProcedureAmit Pinto100% (1)

- Coat Thickness Measuring InstrumentsDokumen1 halamanCoat Thickness Measuring InstrumentsAmit PintoBelum ada peringkat

- Theory Notes RacDokumen12 halamanTheory Notes RacAmit PintoBelum ada peringkat

- HVOF Coatings PDFDokumen36 halamanHVOF Coatings PDFRadu HaiducuBelum ada peringkat

- Training Conducted On PDFDokumen1 halamanTraining Conducted On PDFAmit PintoBelum ada peringkat

- Module-1 - Preferred SeriesDokumen4 halamanModule-1 - Preferred SeriesAmit PintoBelum ada peringkat

- Mech FM May10Dokumen2 halamanMech FM May10Amit PintoBelum ada peringkat

- Minutes 02: Article Allocation, Draft DeadlinesDokumen1 halamanMinutes 02: Article Allocation, Draft DeadlinesAmit PintoBelum ada peringkat

- Mechanical Masters ProgramDokumen2 halamanMechanical Masters ProgramAmit PintoBelum ada peringkat

- Questionnaire For Casting FoundriesDokumen10 halamanQuestionnaire For Casting FoundriesAmit PintoBelum ada peringkat

- Questionnaire For Casting FoundriesDokumen10 halamanQuestionnaire For Casting FoundriesAmit PintoBelum ada peringkat

- SWSIM-Enhanced Turbulence Modeling FlowDokumen21 halamanSWSIM-Enhanced Turbulence Modeling Flowr3155Belum ada peringkat

- Unit-2.4 Searching With Partial Observations - CSPs - Back TrackingDokumen42 halamanUnit-2.4 Searching With Partial Observations - CSPs - Back Trackingmani111111Belum ada peringkat

- Stanway: Buying Options Click & CollectDokumen3 halamanStanway: Buying Options Click & CollectPauloTavaresBelum ada peringkat

- 1 Quick Tour v1.0Dokumen33 halaman1 Quick Tour v1.0Harish KumarBelum ada peringkat

- Presentation HowTo GuideDokumen71 halamanPresentation HowTo GuideFred EneaBelum ada peringkat

- Cisco Switching Basics.Dokumen272 halamanCisco Switching Basics.Vipin AroraBelum ada peringkat

- 3D Graphics TransformationsDokumen22 halaman3D Graphics Transformationsmiryalalokesh123_971Belum ada peringkat

- 2D Thermal Analysis of Chimney Using ANSYSDokumen3 halaman2D Thermal Analysis of Chimney Using ANSYSKaustubh JoshiBelum ada peringkat

- Basic PLC Program Design ExamplesDokumen169 halamanBasic PLC Program Design ExamplesAlexCanenciaBelum ada peringkat

- IntelDokumen5 halamanIntelrAM50% (2)

- Rockwell Software RSView32 Recipe Pro Getting en 0811Dokumen34 halamanRockwell Software RSView32 Recipe Pro Getting en 0811atif010Belum ada peringkat

- Bio Data: F2004034@bits-Pilani - Ac.inDokumen5 halamanBio Data: F2004034@bits-Pilani - Ac.inSitikantha MallikBelum ada peringkat

- EpicorAFR UserGuideeBook 905605 PDFDokumen176 halamanEpicorAFR UserGuideeBook 905605 PDFleorojoahuBelum ada peringkat

- Tuning of PID Controller Using Conventional and Meta-Heuristic Technique For AVR SystemDokumen4 halamanTuning of PID Controller Using Conventional and Meta-Heuristic Technique For AVR Systemrathorsumit2006Belum ada peringkat

- Norma Iso 21500Dokumen42 halamanNorma Iso 21500Jesus Antonio Rivera Pinzon100% (1)

- Unit-Iv Hopfield Networks: As Per Jntu Your Syllabus IsDokumen48 halamanUnit-Iv Hopfield Networks: As Per Jntu Your Syllabus IsJustin CookBelum ada peringkat

- ReadmeDokumen3 halamanReadmeJorge ValdezBelum ada peringkat

- Context Diagram (DFD Level 0) : AdminDokumen7 halamanContext Diagram (DFD Level 0) : AdminAdibah BadzlinaBelum ada peringkat

- Examen de Tema de ProporcionalidadDokumen2 halamanExamen de Tema de ProporcionalidadDulce CastroBelum ada peringkat

- Excel Sheet Functions TestingDokumen206 halamanExcel Sheet Functions TestingSathish Kumar KarneBelum ada peringkat

- Unit of Competency Learning Outcome Methodology Assessment ApproachDokumen1 halamanUnit of Competency Learning Outcome Methodology Assessment ApproachEmer ArcitaBelum ada peringkat

- Material Master Data GovernanceDokumen5 halamanMaterial Master Data GovernanceManuel BarbaBelum ada peringkat

- pcsc1 v2.01.0 PDFDokumen30 halamanpcsc1 v2.01.0 PDFmg5049Belum ada peringkat

- How To Configure An Authoritative Time Server in Windows ServerDokumen7 halamanHow To Configure An Authoritative Time Server in Windows ServerJosue JuarezBelum ada peringkat

- Flexible License - 1. Server Installation and ActivationDokumen4 halamanFlexible License - 1. Server Installation and ActivationfcoipmBelum ada peringkat

- Program Literasi EdukasiDokumen6 halamanProgram Literasi EdukasiAtikah SafitriBelum ada peringkat

- Elementary Data StructuresDokumen66 halamanElementary Data StructuresAmbrose Ashok KumarBelum ada peringkat