Unasylva - No. 101-102-1... Eir Use in Construction

Diunggah oleh

Baguma Grace Gariyo0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan32 halamanuses of wood

Judul Asli

Unasylva - No. 101-102-1...Eir Use in Construction

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniuses of wood

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan32 halamanUnasylva - No. 101-102-1... Eir Use in Construction

Diunggah oleh

Baguma Grace Gariyouses of wood

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 32

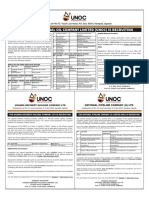

e12015 Unasylva No. 101-102-103 - Werld conutation onthe use of wood inhousing - Secton 3: Wood praduets and their useincorstrction

- Produced by: Forestry

Department

Title: World consultation on the use of wood in housing.

Espafiol Francais More details

: Wood products and their use in

construction

Section

ALAN D. FREAS

ALAN D. FREAS IS chief of the Solid Wood Products Research, Forest Products

Laboratory, Forest Service, U.S. Department of Agriculture, Madison, Wisconsin,

United States. This paper is based largely on the background papers, which are listed

at the end, and acknowledgement is made to their authors.

WOOD IN SOME FORM has always been a primary housing construction material

Once man left the natural shelter of caves and began to build his own shelter where he

wanted it, the most universally available material was, usually, wood

The nature of wood use has, of course, varied from region to region and changed with

time. Log structures have been common in many areas; and sapling-size supports for

coverings of hide, cloth or leaves have been used by many different cultures,

particularly nomads, because of easy transportability.

‘AS man has developed, so has his use of wood for shelter. Modern man in some areas.

still uses a great deal of wood in housing, but he now has it available in a variety of

forms which have resulted from technological advances. He has, further, a

considerable scientific background which permits greater structural efficiency, and

more effective protection from heat and cold, and from destructive elements such as

fire, fungi, insects and weather.

The objective of this paper is to provide a broad-scale review of the modern use of

wood as a basis from which adaptations can be made to fit conditions in any specific

area.

WOOD USE VARIES.

For one reason or another, the extent of wood use varies greatly from area to area.

Blomauist (15), in a paper prepared for a conference sponsored by the United Nations

Industrial Development Organization, speculated on some of these reasons.

He points out that in many countries there is considerable concern over the possibility

of fungi and insect attack, and that not all wood species are resistant to such attack.

Treatment with preservatives and the incorporation of special design features can

reduce the hazard, but the facilities (and knowledge) for using these preservatives are

not always available, The use of open fires for cooking and heating in some areas

introduces a fire hazard which is a deterrent,

Blomquist points out also that, while many developing countries have a liberal supply of

timber, a commonly serious lack of knowledge of timber characteristics creates

Itpuhwwr faccorgdocrenic3edselesB48e06 rim

e12015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

problems in the choice of species and in their application.

Not mentioned by Blomquist, but undoubtedly a factor, is the matter of tradition. In

many instances masonry is the accepted material for housing and the use of wood is

looked on with more or less disfavour. These and other aspects which tend to militate

against the use of wood are treated in detail in Section 4.

WOOD USE IN THE UNITED STATES AND CANADA

The extent of wood use in housing varies substantially from area to area. Wood houses

are probably far more common in Canada and the United States than in any

comparable area. House construction practices in these countries have thus been

drawn on heavily in the preparation of this paper.

Canadian and United States methods may not be directly applicable in other areas.

They do, however, cover a variety of climatic conditions and provide a base for

adaptation to specific areas, and this section reviews successful techniques in the use

of wood and wood-based materials in these countries.

In the United States, an average of | to 1.5 million new housing units are built each

year. While an increasing proportion are apartment units-both high- and low-rise-more

than half are single-family houses. Most of these are wood-framed, as are many of the

low-rise apartment units. A good share are site-buil; that is, most elements are

assembled at the housing site. An increasing percentage, however, utilizes

prefabrication to some degree. Even with site-built units, for example, the use of

prefabricated roof trusses is becoming more common.

Factory-built housing units are likewise becoming increasingly important. One recent

estimate was that nearly half of the units to be built annually will soon be factory-built,

with a substantial portion of these in the form of mobile homes. The use of modular

(three-dimensional) units is limited because of problems in transportation and erection.

The closest approach to this is the use of half-width mobile homes which are joined at

the site,

A report by the U.S. Forest Service (17) indicates the magnitude the market for wood

products represented by residential construction. The report points out that

Construction activities account for about three quarters of the lumber and plywood

consumed annually in the United States. Not all of this, of course, is used in residential

construction, but about three quarters of the construction lumber is used in new

construction or in maintenance of residential units, together with about half of the

plywood and substantial volumes of fibreboard, hardboard, and particle board

Total use in 1962 and estimates for 1970 are:

1962 [1970

Lumber

Million board feet [13 960/14 390)

Million cubic metres [32.9 [34.0

Plywood (2/8.inch basis)

Million square feet [4 170 |[5 250

Million cubic metres a7 46

Building board (insulation board, hardboard, particle board)

Million square feet [1 650 |[1 990

The typical home in the United States has a supporting framework (floor, roof and wall)

ty we fo crdcreesbablesase0m

evans Unesyva- No. 101-102-100 Werld srt onthe use of wont nhousing- Secfon 3: Wood prods ands se incorst ten

of lumber nominally 2 inches thick, commonly called "dimension" lumber. The framing

accounts for about two thirds of this lumber, the rest going to flooring, exterior covering

and the like. Only about one house in ten in 196X had masonry walls, the rest being

wood-frame (25)

Lumber use in certain applications is being largely superseded by panel products. For

example, subfloors and wall and roof sheathing were usually built of lumber in the past,

but plywood is now used increasingly for subfloors and roof sheathing, and plywood or

fibreboard for wall sheathing,

Exterior surfaces in wood, usually bevelled siding (lumber), were typical until recent

years. Other wood materials, including plywood and hardboard, are becoming more

important, but nonwood materials now fil a fairly large proportion of the market.

Hardwood strip flooring accounts for about half the floor surface material. The use of

other materials, including flexible tile and carpeting, is growing, particularly in houses

built on a concrete slab

Particle board utilization is increasing, particularly as underlay for flexible flooring and

carpets and as the core for countertops and cabinets.

The typical roof covering in the United States is the asphalt shingle, largely because it

enjoys an advantage in fire endurance ratings.’ Asphalt shingles are, in large part,

wood, since the felt from which they are made is wood-based. Wood shingles and

shakes are used to some degree, and increased use may be expected as improved

methods for imparting fire resistance are developed

Wood-frame construction in the United States is described in detail in a handbook by

Anderson (10). It presents basic principles of wood-frame house construction and is

designed to serve as a guide for those without experience. It is profusely illustrated

RECENT DEVELOPMENTS

A number of recent developments in the field of housing at the U.S. Forest Products

Laboratory are described briefly here, with details covered in the references,

Nu-Frame house. The U.S. Forest Products Laboratory continually searches for new

ways to utilize wood and wood-based materials with greater structural efficiency. At

times, houses or other structures have been erected to demonstrate the performance

Potential of these concepts. Very recently the Nu-Frame concept was developed as the

result of research objectives to answer diverse problems: too many low-grade boards

remained unused; costs of labour for on-site construction were rising rapidly; enclosing

a house required too many different operations and was too time-consuming; pre-

finished or dual-purpose components could have construction advantages; adhesives

might provide added rigidity and ease of construction.

This unique framing system is based on five components, illustrated in Figure 1. The

wallframing system ullizes low-grade 2- by 4-inch studs set flatwise on either side of a

fibreboard diaphragm, which serves as a stiffener and as a heat and sound insulator.

An interior wall surface component utilizes foil-back gypsum board, Because the unit is

intended to span 4 feet, itis reinforced by 1-inch boards bonded to the gypsum panel.

A third component, the truss, is designed to be installed at 4-foot intervals. The

construction offers distinct advantages in manufacture and transportation. The exterior

coverings for wall and roof are combinations of materials so designed as to require only

a single layer, rather than the two normally used.

The Nu-Frame system bonds a considerable amount of surfacing material, exterior and

interior, with mastic adhesives. This greatly reduces the number of mechanical

tpstwwr fac org docreple3e4sele3B48e05 nim

evans Unesya- No. 101-102-108 Werld srsutaton onthe use of won nhousing- Secfon 3: Wood prods ands se incorstuten

fastenings (mainly nails) required for erection. A prototype house, erected on the

Forest Products Laboratory grounds, required only about 5 800 mechanical fasteners

compared with the more than 30 000 used in conventional construction, Anderson (8)

describes the development of the system and construction of the prototype.

Low-cost house designs. In response to a demand for economical but sound homes to

help alleviate the nation's housing crisis for low-income families, the Forest Service

developed a series of plans for houses of varying style and size. They have all the

essentials for families with up to 12 children and are intended primarily for rural

situations, These designs are described briefly in Designs for low-cost wood homes

(12)

Savings have been made through simplicity of design, by specifying economical but

durable wood materials, and by employing unconventional new materials, systems and

uses of wood and wood products. The fact that these homes are low-cost does not

mean that they use second-rate materials or construction methods. Strength, safety

and durability have not been sacrificed.

In many cases, construction and materials are conventional. Thus they can be built by

a small contractor using readily available materials. In many cases, too, the owner will

want to do some of the work himself. Accordingly, a well-illustrated manual has been

prepared to assist the contractor or home-owner. This publication is Low-cost wood

homes for rural America: construction manual (9).

WOOD USE IN OTHER COUNTRIES

Information on wood for housing in developing countries is difficult to obtain, Blomquist

(15) has summarized information from a few areas which suggests that wood use is

not well developed.

In Papua and New Guinea, for example, typical native housing is based on vertical

posts or poles with floor and roof framing, usually of round members fitted to flat

surfaces on the poles and attached by vines or similar fastenings. Thus itis similar to

North American pole-framing systems. In some cases a truss of round members,

occasionally sawn timbers, is used for the roof support. Small round timbers span the

trusses, with thatch or other natural materials used for roof covering. Bamboo or similar

material may be used for wall enclosures.

‘Sawn lumber may be used for door and window closures.

Typical construction in the Philippines uses the post-and-beam method, with pole-type

constructions used in some instances. Roof trusses are usually wood with steel

members used to carry tension loads. Wood roof trusses joined with nails or with metal

connector plates are being introduced. Some wood flooring is used and exterior wood

wall coverings are becoming more popular. Interior coverings are commonly fibreboard

and plywood, and prefabricated wood-frame windows are widely used

South Africa uses relatively little wood in housing, but developments by the Timber

Research Unit of the South African Council for Scientific and Industrial Research

indicate a possible increase in wood use. A recent design by the Timber Unit

incorporates preservative-treated lumber framing, together with wood siding

In India it appears that houses generally have masonry walls and nonwood floors, but

wood roof systems are well developed. The Forest Research Institute has developed a

series of truss systems which utilize the smaller pieces of secondary native species, to

reduce reliance on the four to six most popular structural species.

tpstwwr fac org docreple3e4sele3B48e05 nim

savas Unasylva No. 101-102-183 - Werld cosutation onthe use of wood inhousing- Section 3: Wood rads an hr use inconstutin

Use of sawn lumber

Early housing in North America was built of logs, but the introduction of sawmills meant

that logs could be cut into lumber. Thereafter, the abundant supply of timber and the

relative ease with which it could be converted made the lumber frame house with wood

sheathing the standard for home construction in North America. This type of

construction, with modifications resulting from the introduction of new materials such as

plywood and fibreboard, remains the most common today.

FIGURE 1. - Specific components of the Nu-Frame system: A, wall framing;

ar ee

10

rat

foesTauctes

acetal

wired

yroed ae

reat a

rake

Lassen FREE

re are Te

FIGURE 2. - Specific components of the Nu-Frame system: B. interior wall

covering

Itpuhwwr faccorgdocrenic3edselesB48e06 rim

e12015 Unasylva - No. 101-102-103 - Werld consutation onthe use of wood inhousing- Secon 3: Wood products and har use incorstruction

7 fo Bate Cree

fs0 SHEETS oe

FIGURE 3. - Specific components of the Nu-Frame system: C, dual-chord W-

truss

tputwur foo org docrepleseaselesBase0s him

e12015 Unasylva No. 101-102-103 - Werld consutation onthe use of wood inhousing- Secon 3: Wood products and har use incorstruction

FIGURE 5. - Specific components of the Nu-Frame system: E, plastic plank roof

covering.

raed dorage Pte

LUMBER TYPES AND GRADES

‘The most important lumber item in house construction is called "dimension," used

basically for the house frame. It is generally 2 inches in nominal thickness, with various

widths to suit its use as a stud, floor joist, roof rafter, and so on,

Itpuhwwr faccorgdocrenic3edselesB48e06 rim 12

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

Boards, generally of nominal Linch thickness, are now little used except in some items

of trim such as soffits, corner boards and porches. They also furnish the raw material

for patterned lumber for moulding, siding and exterior trim,

The basic descriptions of various lumber items are given in the American softwood

lumber standard (30). This standard sets limits on finished sizes, moisture content,

basic grading characteristics and methods of arriving at working stresses and modulus

of elasticity values. Detailed grade descriptions are given in grading rules issued by

regional lumber associations

TYPES OF HOUSE FRAMING

‘A method called "balloon framing" has been used to some extent. In this type of

construction, the wall studs are continuous from Sin to eaves. Joists for the second

floor are supported on a ribbon strip let into the inside edges of the studs. This

construction minimizes changes in dimension over the height of the wall and thus is

preferred where the exterior covering is masonry.

Amore common type of construction is called "platform framing" (Figure 2), where the

subfloor extends to the outside edges of the building and provides a platform on which

exterior walls and interior partitions are built. This is easier to erect in that it provides a

surface at each floor level on which to work. It is adaptable to various methods of

prefabrication and enables the wall framing to be assembled on the floor and tilted into

place.

‘An adaptation of the heavy timber system which is sometimes used in residential

construction is the "plank and beam" method (Figure 3). Beams of adequate size are

supported on posts spaced up to 8 feet apart and covered with planks or tongue and

groove decking

FIGURE 2, - Typical platform framing.

LUMBER USES IN HOUSING

House frame

The conventional house frame uses nominal 2-inch dimension for sills, plates, headers,

joists, studs, and rafters or trussed rafters. The floor consists of floor joists, of a width

determined by the span, and supported on the foundation and on an intermediate

beam. The joists are covered with subfiooring to provide a working platform for further

construction.

Walls are generally built of 2- by 4-inch studs attached to a sill at floor level and to an

upper plate. Supports at openings for windows and doors are provided by a header

(usually nominal 2-inch dimension of appropriate width).

Roof framing has commonly consisted of roof rafters supported at the walls and joined

at the centre to a ridge board (Figure 4). The rafters are nailed to the ceiling joists. This

construction is now often supplanted by light trusses (trussed rafters) made from

dimension lumber, The use of trussed rafters simplifies construction since they can be

set in place as a unit and do not require interior walls to support the ceiling joists.

Sheathing

Wall and roof sheathing and subfloors are intended to stiffen the walls and to provide a

nailing base for the coverings. In the past, sheathing commonly consisted of 1-inch

boards applied either diagonally or at right angles to the framing members. When

diagonally applied, board sheathing imparts considerable stifiness and thus resistance

tpstwwr fac org docreple3e4sele3B48e05 nim

eats Unasyiva - No. 101-102-108 - World consultation onthe use of wood inhexsing- Secton 3 Wood pradcts and her use in construction

to hurricane and earthquake forces.

Following the second world war, panel products of structural plywood and fibreboard

began to replace lumber sheathing and subflooring. Now a typical house consists of a

sawn lumber frame with plywood roof sheathing and subflooring and with wall

sheathing of fibreboard or a combination of fibreboard and plywood

Finish carpentry

Although style changes have eliminated or reduced some items of wood finish, sawn

lumber is still used extensively for exterior and interior trim, finish carpentry and

flooring. Among these are fascia, soffits, trim, corn” boards, porches, decks and wood

siding

Probably no other siding material is available in the variety of patterns and textures in

which sawn lumber is regularly produced. Horizontal bevel siding is perhaps the most

common, but other patterns for both horizontal and vertical application are available.

Latest statistics (25) indicate that the use of lumber siding (in houses insured by the

Federal Housing Administration) had declined from approximately 12 percent in 1959

to 5 percent in 1968, with increases shown for plywood, fibreboard and nonwood

sidings, Continued improvement in exterior finishes may reverse this trend,

FIGURE nk and bean framing for one-storey house.

Wood roofing

‘Asphalt shingles are by far the most common roof covering in the United States.

Available statistics indicate only a limited use of sawn shingles and spit shakes.

Development of suitable fire-retardant treatments may result in increased use of wood

shingles. Not only do wood shingles and shakes have an important aesthetic appeal,

but they offer better insulating qualities and thus reduce heating and am-conditioning

costs.

Panelling

Only a minor amount of sawn lumber is now used in panelling. The lower cost and

greater ease of handling and application of plywood account for this change. Provision

of sawn panelling in lesser thicknesses than the standard 3/4-inch and in greater

widths may increase its application.

Millwork and flooring

‘Sawn lumber provides the basic raw material for windows, cabinets, and flooring. For

these uses wood continues to maintain its position considerably, except that resilient

tile and carpeting are becoming popular as flooring materials at its expense.

Observations on the use of wood in millwork and flooring are given on page 65.

NEW DEVELOPMENTS

Lumber sizes

History suggests that cross-sectional dimensions of sawn lumber for use in house

construction evolved from the sawing and resawing of cants into even-inch increments.

Finished sizes have gone through considerable evolution with respect to the nominal

sizes, with the latest American softwood lumber standard (30) being the first to deal

explicitly with the problem of shrinkage from surfaced-green dimensions to those which

prevail after some period in service. That is, they specify finished dimensions for both

tpstwwr fac org docreple3e4sele3B48e05 nim

savas Unesyva- No. 101-102-100 Wer srsutaton on the use of wont inhousing- Secfon 3: Wood prods andi seincorstuten

surfaced-green and surfaced-dry material. Comparison of former 2-inch framing

lumber sizes with new PS 20-70 dimensions can be summarized as follows

(measurements in inches):

Nominal reference [Former sizes, green or dry |New sizes PS 20-70 19% m.c.

2x4 15/8 x 35/8 112x312

2x6 15/8 x 5 1/2 112 x 5 112

2x8 15/8 x 71/2 11/2 x7 14,

2x10 16/8 x 9 112 11/2 x 9 114

2x12 15/8 x 11/2 1112 «14-114.

Working stresses

‘The current softwood lumber standard specifies that where working (design) stresses

are to be assigned, they shall be developed in accordance with technically adequate

standards. Principal among these are Standards D 2555 and D 245 of the American

Society for Testing and Materials. These are constantly under review.

FIGURE 4,- Typical rafter framing,

Design criteria

Design criteria in terms of floor, sidewall and roof loads referenced in building codes

and construction standards have sometimes been regarded as constraints to the more

efficient use of wood framing in house construction. That is, they have been considered

tpstwwr fac org docreple3e4sele3B48e05 nim swe

savas Unesyva- No. 101-102-100 Werld srt onthe use of wont nhousing- Secfon 3: Wood prods ands se incorst ten

unduly conservative in relation to methods of structural analysis. Full-scale tests have

indicated performance superior to that assumed under current design criteria (19). On

this basis, representatives of the four model building codes in the United States (the

Federal Housing Administration, the National Association of Home Builders, and the

forest products industries), met and developed new and uniform design criteria, These

criteria, which are shown in Table |, have been incorporated into the new National

Building Code for One- and Two-family Dwellings and into standards of the Federal

Housing Administration. Simpiified span tables based on the new criteria are available.

TABLE 1. - DESIGN CRITERIA FOR WOOD FLOORS, CEILINGS AND ROOFS

Siructural assembly _|[Deflection’]Live load?|[Dead load] Total load

Pounds per square foot

Floors - heavy 360 40 10 50

Floors -light® 360 30 10 40

Ceiling joists 240 20 10 30

Limited altic storage

Ceiling joists 240 10 5 15

No atic storage

Low slope roof joists || 240 20 5 35

‘Supporting ceiling* 5 (30) (15) (45)

@o_ |__|)

Low slope roof joists || 240 20 10 30

Not supporting ceiling a0 | eo

@o)_|[_(10)_|_ 60)

Rafters - heavy roof ||__180 20 5 35

G0) 5 5)

(4) 15 65)

Rafters - light roof 180 20 7 27

G0) 7 )

(40) 7 Co)

* Spans divided by number shown. For plaster ceilings divided by 360 throughout. -

Live load used only in computing spans based on deflection -* Attic floors and sleeping

rooms. - 4. Also rafters supporting ceiling-® Loads in parentheses are alternate

loadings to accommodate climatic conditions.

Modular coordination

‘A development in modular coordination for the more effective use of wood is the

Unicom system developed from studies sponsored by the National Forest Products

Association, Using the 4-inch module and the 16- or 24-inch spacing, the house

designer has complete design flexibility and the builder or component manufacturer

uses standard materials with minimum waste. In addition to the saving from a

standardized design and fabrication discipline, the system also eliminates bridging

between floor joists, doubling of headers under parallel partitions, blocking between

studs, and other features which contribute little structurally. In two housing projects

analysed, it has been reported that use of the Unicom system resulted in savings of

U.S.$63 000 for one (250-house) project and $20 600 for the other (23)

Low-profile floor system

tpstwwr fac org docreple3e4sele3B48e05 nim wea

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

The increasing use of concrete slab foundations, which began in the early 1950s and

has stabilized over the past 10 years at about 43 percent of all single-family houses,

resulted in a significant reduction in the volume of lumber and related wood products

used for floor construction

Conventional wood floor construction over a craw! space places the floor level well

above the exterior grade. To combine the advantage of the low silhouette, the lower

construction costs of the concrete slab and the comfort and appearance of a wood

floor, a low-profile floor system was developed (22). This low-profile system permits

shorter spans of smaller size lumber through intermediate supports. It also utilizes the

narrow under-floor space as a plenum chamber for heating and air-conditioning. This

floor system provides a workable solution in wood for those areas where builder and

consumer preference dictates a low house silhouette

All-weather wood foundation

Weather is one of the problems frequently cited by builders in explaining increasing

construction costs. In many areas of the country, adverse weather conditions make it

difficult or impossible to excavate and construct conventional masonry foundations, A

new all-weather wood foundation system has been developed to overcome this

problem. This system is the product of a three-year effort by the National Association of

Home Builders Research Foundation, the Federal Housing Administration, the Forest

Products Marketing Branch of the Forest Service, the American Wood Preservers

Institute, and the National Forest Products Association. It can be erected in 9 man-

hours, at a saving of $250 per house compared with the conventional masonry

foundation (7)

The all-weather wood foundation system consists of a wood frame with plywood-

sheathed panels pressure-treated against termites and decay. It provides for fully

insulated below-ground habitation and enables the industrialized home builder to

provide a complete house package which can be totally assembled by carpenters.

This system and its low-profile counterpart overcome major deficiencies in conventional

foundation construction for low- and middle-income housing

FUTURE USES OF SAWN LUMBER IN HOUSING

Conventional wood-frame house construction has remained essentially unchanged for

centuries. The widespread adoption of the trussed rafter and panel sheathing products

is the only significant modification of the standard system of joists, studs and rafters

covered by sheathing and siding.

Since the wood frame has proved adaptable to industrialized construction, it seems

unlikely that the trend to factory fabrication will substantially modify the sheathed frame

system. This appears to be borne out by the fact that new steel and aluminium house

frames have copied the wood system.

Factory fabrication and the increasing trend toward building with three-dimensional

modules should place greater emphasis on weight reduction in the house frame, With

its favourable ratio of strength to weight, sawn lumber can be more adaptable to such

efforts than the metal frames.

Although reductions have been made in the standard dimensions of wood members,

these changes were based upon each member acting independently. However, full-

scale performance testing has revealed that interaction of members and sheathing in

the completed house adds significantly to the strength and rigidity of the system. Efforts

to develop a reliable design procedure to reflect such interaction are presently under

way. Such a design technique, in combination with improved fastenings and structural

tpswwr fac org docreple3e4Bele3B48e0 nim eee

erava01s Unasyiva - No. 101-102-108 - World consultation onthe use of wood inhexsing- Secton 3 Wood pradcts and her use in construction

adhesives, should make further economies in the wood-frame system possible

While sawn lumber for sheathing purposes will continue to dectine in use, development

of a composite design procedure and better fastening methods may well lead to new

and more efficient uses of board lumber for structural frame applications.

Use of poles and posts

A building system increasing in popularity for house construction uses preservative-

treated wood poles as the foundation and the structural framework (Figure 5). While

round poles are generally used, sawn timbers are occasionally employed. In either

case, they are embedded in the earth and serve as the principal supporting elements of

the structure. Thus the poles serve two basic functions-that of the foundation and of the

framework supporting the floor members, the walls and the roof framing

Conventional foundations are not required, so that there is less site preparation and,

more important, less soil disturbance and a reduced possibility of erosion. The lack of

soil disturbance also reduces the possibility of extensive soil movement on steep

slopes. This system is thus more adaptable to rough topography than constructions

with conventional foundations. With the poles properly embedded in the earth, and with

adequate joining of all elements, this type of construction is especially effective in

resisting major structural damage in high-wind areas, including those where wave

action may accompany high winds (2, 5, 11, 26).

PRESERVATIVE TREATMENT

Pole construction depends upon the abilty of the poles to resist deterioration from

wood-destroying organisms, such as fungi and insects in the soil in which they are

embedded. Since the sapwood of even resistant wood species has little durability, this

implies that poles must be preservatively treated to ensure long life,

FIGURE 5. - Pole construction has been used successfully in reducing the cost

of housing. It is especially adaptable to steep hillsides and rough terrain.

Round poles are most common in house construction, although rectangular members

are sometimes used for simplicity in framing. Rectangular members require greater

care in treatment, because frequently the sapwood is partially or completely removed

and the heart-wood of many species is difficult to treat.

The treatment of wood to protect it from wood-destroying organisms is well developed,

tpn fo ordre seAbeles48e05r4m we

savas Unesyva- No. 101-102-100 Werld srs onthe use of wont nhousing- Secfon 3: Wood prods ands se incorstuten

and chemicals and treatment processes are well known and described in a variety of

references, including (4) and (7). Itis beyond the scope of this paper to describe

chemicals and processes in detail. Pressure processes are most common, although

other processes may be used. The choice of preservative chemical rests on a variety of

factors, but paintabilty, freedom from odour, as well as permanence and effectiveness,

are important factors. Government regulations may, in some areas, limit or prohibit

their use and such regulations should be consulted before making a choice

STRUCTURAL DESIGN

The design of a pole house entails nothing unusual, except for considerations related to

soil characteristics affecting depth of pole embedment, and soil-bearing strength. In

areas of hurricane hazard, special attention must be paid to the connexions between

elements, and between the various elements and the poles. Design features are

covered in (4) and (5)

CONSTRUCTION

Foundation

One of the advantages of pole construction on sloping sites is the reduced likelihood of

erosion, as compared with foundations which require extensive excavation, The

preparation of the holes for pole embedment, however, stil requires care to avoid soil

disturbance. While the holes can be dug by hand, machine driling is much faster if

equipment is available and if the site permits it.

Figure 6 illustrates several methods of pole embedment. In certain types of soils,

backfiling with the original soil is satisfactory. Where this is not feasible because of lack

of adequate support, backiiling may be done with sand or gravel or with soil-cement

mixture. The latter may be especially important in developing countries where self-help

methods would be convenient.

FIGURE 6. - Pole placement - soil type and topography will generally dictate the

method of pole embedment.

mk wach

Se

= kel

mies

Where the bearing strength of the soil is inadequate to support the imposed loads, it

may be necessary to provide a concrete pad at the bottom of the hole to provide

greater bearing area than would result from the base of the pole alone. Pads may be

Poured in place or precast and placed in the base of the holes. Backillng can be as

suggested earlier or, for shallow holes or for certain soil types, it may be desirable to

backfill around the poles with concrete

tpstwwr fac org docreple3e4sele3B48e05 nim wee

savas Unesyva- No. 101-102-100 Werld srt onthe use of wont nhousing- Secfon 3: Wood prods ands se incorst ten

Before backfling it is necessary to position the poles exactly and to plumb them, It may

be desirable to attach some of the framing and square and plumb the whole structure

before backfiling, particularly if concrete is used.

Support beams

Three common attachment systems for support beams are shown in Figure 7. Bolts or

spiked grids are commonly used in connecting floor beams to poles because of the

higher loads imposed by floors, while nails may be suitable for attaching roof beams

Design data for connexions are given in (24) and (29).

FIGURE 7. - Three methods of attaching beams to the poles.

wih te-pleces bosert attagthedd fo

end hart nai, | Pole sith boii

Bor attaybing Flow

eal ttm bere 11

Sawn beams for supporting floor joists and wall framing are attached to the poles as

indicated in Figure 8. Where joists are used, or where poles are cut off at floor level,

the beams must also be designed to carry roof loads transmitted through the wall

framing. Normally, however. roof framing is supported on roof beams at the top of the

poles,

Good practice suggests that the support beams be attached in pairs, one on each side

of the pole. Where. as is frequently the case, floor support beams are exposed to

weather, itis best that they be treated with a preservative.

Walll and floor frame

Conventional framing is common. In general, however, floor joists are positioned on top

of the floor support beams, which creates some problems in attachment, While

toenailing may be satisfactory in many instances, special joist connexions (Figure 8)

are recommended where wind loads are high (26).

Wall framing is usually placed inside the pole line to simplify construction, leaving the

poles exposed (see Figure 5). Occasionally the design calls for the poles to be fully or

Partially exposed inside the house. This complicates final framing and finishing and may

add substantially to labour costs.

Roof frame

Three general types of roof frame are encountered in pole construction. The first,

which might be called " post and beam," requires a line of poles down the centreline of

the house to support ridge beams to which the rafters are attached. A different

tpwwr fac org docreple3e4sele3B48e05 him 12

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

arrangement would stil require a line of poles down the centre of the house but would

ulilze large-dimension rafters, more widely spaced, to which purlins would be attached.

More commonly, conventional rafter construction or trussed rafters are used.

POST CONSTRUCTION

Short posts are used to some degree in house construction, terminating at first-floor

level, with floor beams attached to their upper ends. Such posts may be set as

described earlier for poles, Within the past few years, however, a technique has been

developed for driving highway guardrail posts (18), and this technique could be used

for embedding foundation posts for houses.

Glued and composite elements

‘A glued wood element may be considered an assembly of parts (primarily wood)

bonded together by an adhesive to serve a particular structural function. For example.

a stressed-skin wall of floor panel, consisting of plywood facings bonded to lumber

framing, would fit such a definition, as would a glued-laminated wood beam, For this

discussion, a composite element is considered to fit the same definition except that

some parts may be of a material other than wood. For example, a sandwich panel

could consist of plywood facings with paper honeycomb or plastic foam core.

Such elements have had some use in construction for three decades or so, Experience

has shown that factory fabrication is nearly always required to ensure proper control of

dimensions, proper curing of the adhesive, and so on.

‘A growing number of wood-frame buildings use prefabricated elements such as roof

trusses. The majority of these have been assembled with mechanical fastenings, but

adhesives are now being used increasingly.

Glued elements are used, for example, for box beams used as clear-span floor beams

or as ridge or roof frame beams (often exposed for appearance), or as lintels over

openings in walls. Stressed-skin and sandwich panels have been used for floors, walls,

and roofs in place of more conventional construction.

POTENTIAL

Advantages

A glued prefabricated element offers certain advantages over conventional

construction, primarily increased speed of construction as labour requirements are

reduced on the site. Construction speed may also be enhanced by reducing delays due

to weather.

Shop fabrication can resutt in higher quality components, with better control over

moisture content and thus dimensions of individual parts. Closer control of element size

may also result in more efficient use of materials.

Thermal insulation can be built in during shop fabrication; in foam-core sandwich

panels itis an integral part of the assembly. Similarly, electrical, plumbing and

mechanical systems can be built in.

Many of these advantages of prefabrication apply also to nonglued elements. Glueing,

however, generally develops a greater proportion of the structural potential and can

give a permanently tight joint.

Limitations

tpstwwr fac org docreple3e4sele3B48e05 nim 902

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

Glued prefabrication also has limitations. For example, considerable investment in

manufacturing facilities and organization is required. This is justified only when

requirements of a substantial volume are foreseen. When one considers transportation

and erection costs for prefabricated elements, cost in place may be greater than for an

equivalent unit built on site. Individual instances differ so greatly, however, that no

general statement can be made and each case should be analysed separately

Unconventional or nonstandard elements generally require special structural and

architectural attention. Building code acceptance may be a problem.

Elements built off-site require careful coordination with the builders who will assemble

them at the site, as well as control of dimensions to ensure fit after they arrive,

FIGURE 8.- Con

TYPES OF ELEMENT

‘A number of elements are used primarily in engineered light-frame construction,

although they find some place in ordinary residential construction, These include glued-

laminated timbers, plywood box beams, trusses, stressed-skin panels and sandwich

panels,

Glued-laminated timbers

Glued-laminated timbers are made up of layers of lumber, the grain direction of each

layer parallel to the long dimension of the member, bonded with a rigid adhesive, They

can be made either straight or curved and of any length or cross section

These versatile members find some use in residential construction as long-span floor or

roof beams. In general, though, they are limited to relatively high-cost residences.

Plywood box beams

These box beams consist of a top and bottom lumber flange, either solid or laminated,

connected with one or more vertical plywood webs, usually glued to the flanges. Such

members are lighter in weight and more efficient than solid lumber, as well as being

more stable dimensionally.

They are used occasionally for floor and roof framing, and sometimes in small

dimensions to span openings such as windows or garage doors.

Trusses

Trussed rafters are commonly used in house construction in the United States, They

are generally at conventional spacings-16 or 24 inches-and roof and ceiling panels are

attached directly to them, Usually they are made of 2-inch dimension lumber with the

truss members joined with metal plates, although glued gusset plates are also used,

Trusses having large, rigidly glued plywood gusset plates are substantially stiffer than

those made with light metal plates because the joints resist rotation of the truss

members,

Most trusses do not have space for storage in the attic of the completed house. With

proper design, however, this can be provided

Stressed-skin panels

A stressed-skin panel consists of a covering glued to one or both sides of framing

members so that all parts act integrally. The coverings resist flexural and direct

tpstwwr fac org docreple3e4sele3B48e05 nim 2

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

stresses, thus adding to the load-carrying capacity of the framing and permitting a

reduction in its size. The framing resists shear as well as flexural forces. Attaching the

skins to the framing with adhesive is the most effective system, although mechanical

fastening may be used.

Panel skins may be on one or both sides of the framing. One-sided panels facilitate

installation of utilities, Two-sided panels, however, are more efficient, because both

skins contribute to load-carrying capacity.

Stressed-skin panels may have blanket insulation installed at the factory. Because of

their otherwise tight construction, it is common practice to provide vents by notching or

driling end headers, Special means for connecting panels on the job must be provided.

This is usually done by setting out the framing at one side of the panel and nailing it

through the projecting skin of the adjacent panel.

Wall panels are generally 4 by 8 feet in size with floor panels 4 feet wide but 12 to 14

feet long. Such panels are light enough to be handled manually. With the advent of on-

the-job handling equipment, larger sizes have been used. Wall panels, for example,

may be full length, while floor panels may be shop-fabricated in sizes up to 8 by 28

feet.

Sandwich panels

‘A sandwich panel is similar to a stressed-skin panel in that skins act together with a

lightweight core to resist loads. However, instead of a spaced framework, the core is

essentially continuous, such as foamed plastic or paper honeycomb. Skins can be

thinner than for a stressed-skin panel because they have more continuous support. A

variety of materials may be used including wood-based materials such as plywood and

hardboard skins and paper honeycomb cores. Frequently, wood strips are glued to the

perimeters to strengthen the core and to facilitate attachment to adjacent panels.

‘A sandwich panel is lighter in weight than a stressed-skin panel, and the foam-core

panels are better insulators. Sandwich panels generally cost more and must be

prefabricated

There are a number of proprietary systems of wall. floor and roof panels currently in

use, generally in 4-foot widths. Wall panels use foam cores from 11/2 inches thick,

while roof and floor panels are generally 4 to 6 inches thick, depending on span. House

systems have been produced with whole walls 8 by 20 feet or more in size.

Three-dimensional units

Complete residential units may be assembled at the factory and may employ one or

more of the glued elements described earlier. Typical units are mobile homes and

modular structures.

Mobile homes are self-contained, box-shaped residential units on a wheeled

undercarriage. Many units are moved only once-from the factory to a site. In some

instances they need not comply with established building code regulations. They are

produced on an assembly line. The method of construction varies, but one common

feature is the frequent use of adhesives for assembly.

Modular structures are box-shaped units which can be transported on a trailer and set

on foundations to form part of a permanent structure. They are often sectionalized.

Two or more units may be joined side by side, with one side of each section open, or

fully enclosed units may be joined horizontally in various configurations. The fully

enclosed units may also be stacked one on the other or in a separately built frame.

tpstwwr fac org docreple3e4sele3B48e05 nim 902

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

Transportation and erection loads impose stresses not normally encountered in house

construction. The increased rigidity provided by glued elements is essential to resist

such dynamic stresses.

FIELD GLUEING

Structural bonding with adhesives on the site, not easy or practical in the past because

of work and weather limitations, is now possible thanks to a new class of adhesives.

These elastomeric adhesives come ready to use and are easy to apply, They fill gaps

and do not require extra sanding of commercially produced surfaces. They set with

only moderate pressure and will quickly withstand impact construction loads without

breaking, They are relatively tolerant of weather conditions and can be applied to wet

or frosty surfaces over a range of temperature conditions. They are not, however,

recommended for use under severe exposure conditions. A main limitation is their

tendency to creep under load.

The elastomeric adhesive is coming into common use for attaching plywood floors to

joists. This gives partial stressed-skin action and the system is stiffened. Nailing

problems are minimized, since the adhesive holds the panels tight to the joists. Thus,

field glueing combines many of the advantages of shop fabrication with those of field

construction. Other applications could include attachment of wall or roof sheathing to

the frame. This has been done experimentally with the Nu-Frame system described

earlier

SPECIAL DESIGN FEATURES

Recognized design methods exist for the elements discussed earlier (1). When these

elements are assembled in a building, the structure can be analysed for resistance to

horizontal forces, such as those resulting from hurricanes and earthquakes.

Wood structures are recognized as being outstanding in their resistance to

earthquakes and, with proper anchorage and connexions, to high winds. The glued

elements described here add to this capacity.

Fire performance of wood structures can be improved in various ways, Fire-resistant

components can be incorporated into a composite element, As an example, a stressed-

skin floor-ceiling panel has been tested and rated as " one-hour fire resistant.” It

consists of 2- by 6-inch joists with 5/8-inch top skin (floor) glued to them, while the

ceiling is a layer of 1/2-inch fibreboard covered with 1/2-inch gypsum board.

Treatment with fire-retardant chemicals can drastically reduce the rate of surface flame

spread, but has little effect on fire resistance. However, such treatment, combined with

Suitable construction features, can improve the fire performance of wood structures.

Panel products

Income has an important effect on what materials are used for housing; where incomes

are low, housing is minimal also. Wood-based panel products, the results of improving

technology, are relative latecomers in the field of building materials. Because plants

needed to produce them require considerable capital investment and highly skilled

labour and technology, they find most use in the more developed and affluent areas of

the world. About 75 percent of world production of plywood, insulation board,

hardboard, particle board, and panel products of lesser volume, is used in the United

States and Europe

The main uses for wood-based panel products are in construction. As a group, they

have shown a phenomenal growth since the second world war. There are significant

tpstwwr fac org docreple3e4sele3B48e05 nim 1902

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

reasons for this which suggest that further growth in consumption may be expected if

the world's housing needs are to be met. These include:

Maintaining a reasonable ratio of labour to material costs. The costs for fixing panel

products in place are less per unit area. With increasing labour costs, this factor

becomes increasingly important, for itis cost in place rather than material cost that

should govern choice of material.

Panel products are frequently developed for specific uses. The panel products industry

has a number of products developed for specific uses in housing

Elimination of "wet-wall" construction. Past practice has been to plaster interior wall

surfaces, There is now a transition to" dry-wall” construction which opens the way to

increasing use of all types of panel products for interior surfaces.

Development of factory fabrication of housing. Increasing prefabrication of housing

elements and mobile homes takes advantage of the characteristics of panel products.

While the 4- by 8-foot size is common in on-site construction because of the ease with

which it can be handled, larger sizes can be used in factories where mechanical

handling is possible, Panel products withstand transportation and erection stresses

better

Prefinishing and special surfaces. Factory-applied finishes and special surfaces not

only provide attractive and durable finishes but reduce on-site labour. Special methods

are needed for attaching prefinished panels.

Code regulations frequently limit or prohibit the use of combustible materials in high-

rise housing. These limitations apply to wood-based panel products as well as to

lumber. Some use of panel products for nonstructural purposes may be permitted, but

fire-retardant treatment is generally required. Restrictions on wood use are often less

in single-family housing

CONSTRUCTION PLYWOOD

The construction plywood industry is concentrated in four main areas: North America,

with softwood plywood; Finland, with birch plywood, and its developing spruce-core,

birch-face plywood: Australia, with radiata pine; and Japan, with both lauan and

‘American softwood, France uses tropical and other hardwood plywood and the United

Kingdom substantial amounts of both Finnish and British Columbian plywood,

Construction plywood is used considerably for concrete forms because it provides a

smooth surface and may be used again. For repeated use, plywood with a high-density

overlay is desirable.

Foundations

‘Some use is being made of plywood for foundations, and this is likely to expand

Preservative treatment is necessary.

Floor systems

Plywood is commonly used as the subfloor in housing. Thicknesses of 5/e to 3/4 inch

are generally used on usual joint spacings. Thicker plywood is required for greater

spans, as in post and beam construction.

Wall sheathing and exterior covering

The major functions of wall sheathing are to prevent air infiltration and to provide

tpstwwr fac org docreple3e4sele3B48e05 nim

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

racking resistance. Properly fastened plywood provides excellent racking resistance. In

some instances, part plywood sheathing and part fibreboard are used.

Plywood is used increasingly for siding (cladding). It is frequently applied vertically,

sometimes with grooves or other working for appearance. It is supplied in 12-inch-wide

strips for horizontal application as lapped siding It is sometimes applied in full panels as

a combination sheathing and siding When this is done the nailing must be frequent to

furnish the desired racking resistance, and this may detract from appearance.

Roof sheathing

In North America plywood is the most frequently used roof-sheathing material

Sheathing grades in thicknesses of 3/8 or 1/2 inch are commonly used for spans up to

24 inches, a common spacing for roof trusses. As for subfloors, greater thicknesses are

required for wider spacing as in post and beam construction

Miscellaneous uses

Considerable amounts of plywood are used for incidental purposes in housing, such as

soffits and returns at roof edges; shelving; porch and carport ceilings; and

miscellaneous builtins

DECORATIVE PLYWOOD

Decorative plywood is used in panelling and for the skins of flush doors. The mobile

home industry uses substantial amounts of decorative plywood for interior surfaces.

Kitchen cabinets and other built-in items are commonly made of decorative plywood for

appearance.

LAMINBOARD AND BLOCKBOARD

Laminboard and blackboard are basically European products, used in the same way in

construction as thick plywood. Made of thick laminated lumber or vertically laminated

veneer core, they appear in 3- and 5-ply configurations between 12 and 25 millimetres

(1/2 to 1 inch) in thickness, The grain of the face plies of the 5-ply board may be either

parallel or perpendicular to that of the core. Their major uses are in structural flooring,

shelving, free-standing partitions and doors or sides in cabinets, They are similar to the

lumber-core plywood manufactured in the United States.

INSULATING BOARD

Two basic qualities of insulating board are available A for interior and exterior use.

Water resistance is imparted to the exterior quality by incorporating asphalt in the

furnish, by an asphalt coating on the finished board, or both:

The major exterior products are sheathing and shingle backer. Sheathing is made in

three qualities and densities: regular, about 18 pounds per cubic foot; intermediate,

about 22 pounds per cubic foot; and nail-base, about 25 pounds per cubic foot

Regular density is made in 2- and 4-foot widths, but to provide desired racking

resistance the 4-foot width in a 3/,-inch thickness must be applied with the long

dimension (8 or 9 feet) vertical. The two higher densities are supplied only in a V2-inch

thickness. When properly applied, they provide good racking resistance.

Shingle backer is used under coursed wood shingles or sidewalls to provide a deep

shadow line. It has the required nail-holding power, when the shingles are applied with

special deformed nails, and eliminates the need for wood nailing strips.

Interior-quality insulating board has long been used for acoustical tiles. When holes or

tpstwwr fac org docreple3e4sele3B48e05 nim ire

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

fissures are drilled or machined in it, the board absorbs sound and reduces

reverberation in a room. insulating board in tile or board form is usually painted with a

fire-retardant paint to reduce the rate of flame spread. Some basic boards are treated

with a fire retardant. These find most use in commercial buildings where regulations

are restrictive, Increasing emphasis on quiet areas in homes will undoubtedly lead to

more use of sound-absorbent boards,

Such boards, however, do not reduce sound transmission in multifamily dwellings, A

special sound-deadening board is produced for light-framed construction,

Plain insulating board (undrilled or unmachined for sound absorption) is used in tle

form or as lay-in panels for suspended ceilings. It is usually prefinished, It is sometimes

overlaid with a washable nonabsorbent film for use in kitchens and bathrooms.

HARDBOARD

While hardboard has a large number of industrial uses, its main importance lies in

housing, A number of these uses parallel those for plywood, where a relatively thin,

dense and hard product is needed.

Itis used for lining of concrete forms, particularly for curved surfaces, because it can be

bent to fairly sharp radii in single curvature. Usually a special quality double-tempered

board is provided for this use

‘A major use is for prefinished panelling, which is usually provided in the 4- by 8-foot

size, either embossed or printed with a wood-grain figure. Prefinished accessory

mouldings are commonly fumished with the panels.

Hardboard is also used for floor underlay, where it serves to mask minor irregularities

in the subfloor surface and provides a base for resilient floor coverings.

Medium-density hardboard is used mainly for house siding This relatively new product

has a density of about 40 pounds per cubic foot and is usually about 3/8-inch thick. Itis

either primed at the factory or completely prefinished or stained. It may be applied

either in panel form or as lapped siding. Where it is furnished prefinished, outside and

inside comers and nails are provided in matching colours.

The engineering data for new applications such as skins for stressed-skin panels and

gusset plates for trusses are being compiled.

Considerable amounts of hardboard are used as skins for flush doors and as bases for

decorative plastic laminates, Properly manufactured hardboard tends to reduce show-

through from the base on which it is applied.

PARTICLE BOARD

Particle board is a relatively new product and uses for it are still developing. There is

considerable variation in application in different areas. For example, in the United

States relatively little particle board goes into exteriors while in France exterior use is

more common.

Particle board may be made by pressing (sometimes classified as mat-formed) or by

extrusion. The greatest proportion is mat-formed. Mat-formed particle board is used in

Europe not only as core stock for furniture and cabinets, but as wall lining, roof

sheathing and finish flooring. The major use in the United States is as floor underlay for

resilient coverings, which accounts for some 40 percent of production.

Particle board goes into shelving, concrete form lining (to a limited degree), and core

tpstwwr fac org docreple3e4sele3B48e05 nim

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

stock, Structural uses such as sheathing and subflooring are uncommon, although

recent developments indicate future expansion in this field,

A special product called mobile home decking has been developed for mobile homes. It

is somewhat stiffer and stronger than the usual underlay or core stock. When bonded

with urea-formaldehyde resin, itis protected from ground moisture and has adequate

durability for this use. A similar product bonded with phenolic resin is gaining

acceptance for factory-buill housing designed for longer life than mobile homes.

EXAMPLES OF USE IN DEVELOPING COUNTRIES

In the Philippines, consumption of plywood and hardboard in housing is low, although

the industries are well developed. This appears to result from a traditional preference

for lumber. It has been reported, however, that corrugated hardboard sometimes

replaces corrugated steel for roofing.

The production and use of panel products in Latin America are low, with Brazil

producing about half of the total. Brazil is reported to have two large producers of

phenolic-bonded plywood for use in concrete forms. Most other plywood produced in

the area is for door skins

Some wood-based panel products go into prefabricated housing in Latin America. For

example, it has been reported that several thousand single-storey houses have been

constructed of extruded-type particle board in Chile. One company in Colombia has

reportedly used hard-board, coated with asphalt, for exterior wall cladding on a

thousand low-cost housing units. A large plant in Surinam produces prefabricated

houses in the middle-cost range; plywood is used for interior surfaces and particle

board for ceilings and built-in furniture

A particle board manufacturer in Brazil has designed and carried out a pilot project

consisting of a thousand prefabricated houses based on elements of phenolic-bonded

board. If the first houses are successful, the producer has plans for 15 000 additional

units.

Use of wood flooring and millwork in housing

MILLWORK

The term millwork is used in North America to designate a group of produets including

such items as windows, doors and trim. Elsewhere, the term joinery is common. In the

United States, however, the terms woodwork and millwork have been used

interchangeably. The largest association of millwork manufacturers in the United States

carries the title National Woodwork Manufacturers’ Association

The list of items which can be classified as millwork is long. The principal ones from the

standpoint of quantity are: mouldings, door frames and entrances, blinds and shutters,

sash and window units, doors, stairwork, kitchen cabinets, mantels, and china or

corner cabinets

Millwork has two specific classes: stock and custom. Stock millwork is manufactured in

a standard size, pattern and layout ready for use and is available from distributors.

Because of standardization it is less expensive than custom millwork. The term stock

millwork does not mean monotonous similarity; there is a sufficient variety of sizes and

designs to meet a range of demands.

Custom millwork, as the term implies, is made to order to St specific applications. It is

sometimes called " architectural woodwork." The principal association of manufacturers

tpstwwr fac org docreple3e4sele3B48e05 nim 22

eu2015 Unasylva No. 101-102-108 - Werld consultation onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

of custom millwork in the United States is the Architectural Woodwork Institute,

Custom millwork is, of course, more expensive because it is not produced in quantity

and requires special manufacturing setups. It is used largely in schools, churches,

expensive housing, and public buildings, where it satisfies the requirements of the

architectural design

On the whole, millwork does not serve in a structural capacity in the sense of carrying

imposed loads. Stair-work is an exception. Millwork, however, may serve an important

protective function, as in window and door units.

Itis not practical to attempt to describe here the more common types of millwork,

because of the great diversity of items and the variations within each type. A

comprehensive review of United States millwork practice lists for sashes and windows

alone four principal and seven miscellaneous types (21). Instead, a number of general

considerations are discussed.

Species used

The report on a survey conducted by the International Working Group on Timber

Information (20) lists some 55 species used for millwork in the 11 countries from which

replies were received. The extent of use of individual species, however, was not

indicated. Itis probable that certain species find only limited, somewhat localized use.

The range of species listed is large, including softwoods and hardwoods and both

temperate-zone and tropical species.

A paper prepared for presentation at a meeting of the Study Group on Production

Techniques in Wooden Houses Under Conditions Prevailing in Developing Countries

(14) presents a list of species used for joinery in three tropical areas, covering: Brazil,

Paraguay; Congo, Ivory Coast, Kenya, Nigeria; Philippines, Malaysia. This list also

gives an indication of use and brief remarks on important characteristics of these

species.

Selection of species for millwork will depend on a number of characteristics. Among the

more important are: suitability for working with tools; dimensional stability with respect

to moisture changes; ease with which it can be dried without serious defects; ease with

which it can be fastened (by nailing, for example); natural durability (for exterior use) or

ease with which it can be treated; abilty to take finishes; and, of course, its availabilty

in sufficient quantity in the necessary quality.

Standards

Standards are usually available for the quality of the finished product. These may be

prepared by private standard-making bodies, or by or under the sponsorship of a

government agency. In the United States, for example, commercial or product

standards are prepared by a sponsoring group, subject to the review of a broadly

based committee. Coordination is provided by the National Bureau of Standards of the

USS. Department of Commerce.

Besides defining product quality, most standards will also define standard dimensions

and describe " standard" products. Standards of dimensioning are needed to promote

ease of construction, so that the builder may standardize the framing around window

and door openings. Illustrative of a quality standard prepared by an industry association

is the book Quality standards of the architectural woodwork industry (13)

Treatment

The survey mentioned earlier (20) surprisingly indicates that not all exterior millwork is

treated to inhibit attack by fungi and insects. It appears, however, that treatment is fairly

tpstwwr fac org docreple3e4sele3B48e05 nim

evans Unesyva- No. 101-102-100 Werld srt onthe use of wont nhousing- Secfon 3: Wood prods ands se incorst ten

common, although chemicals may differ.

One of the most common treatments involves the use of pentachlorophenol in an

organic solvent, usually mineral spirits. In the United States, the finished product is

dipped in the preservative for three to five minutes, and frequently some degree of

water repellency is imparted by including a repellent (such as paraffin wax) in the

treating solution.

Moisture content

Recommended moisture contents seem to vary considerably. For example, the survey

mentioned earlier shows, for products for interior use, recommended moisture contents

ranging from as low as 4 percent to as high as 8 to 17 percent. Some of these

differences may be accounted for by variations in climatic conditions and in the degree

to which homes are heated in cold ciimates. Apparently, however, a moisture content

limitation of some sort is universal.

Its clear that moisture content should be as close as possible to that expected in

service. Lacking this, dimensional changes will occur with resultant warping and poor

performance.

Use of adhesives

‘Adhesives are used in a variety of ways in the manufacture of windows, doors, trim

and similar items. For example, narrow pieces may be glued edge to edge to provide

needed widths. Finger joints are increasingly used for stock of the necessary length

Panel materials such as plywood and hardboard are bonded to the framework of

panel-type doors.

Neither of the previously cited references covers this point in detail. It should be

obvious, however, that any product destined for exposure to the weather requires the

use of a waterproof or, at the very least, a highly water-resistant adhesive if there is

any likelihood of free water getting to the glue bond

FLOORING

Wood flooring is common in housing. A survey of wood use in houses in the United

States indicates that, in houses not built on slabs, wood flooring accounted for about 53

percent of the finish flooring used (25). For houses built on a concrete slab, however,

only about 5 percent of the finish flooring was of wood (strip, lumber, parquet or

plywood parquet).

Types

Wood flooring is made in a variety of types (16, 27), but by far the most common is

strip flooring. In 1968, it constituted some 52 percent of the finish flooring of homes

inspected by the Federal Housing Administration (25) not built on slabs, while other

types of wood flooring amounted to less than 1 percent.

Strip flooring is normally made with tongue and groove on edges and ends to permit

blind nailing. A small percentage is square-edged and nailed through the faces. Plank

flooring is similar in pattern to strip flooring but is wider. It may be blind-nailed but

frequently is fastened with screws, the heads of the screws being recessed and

covered with wood plugs.

Block flooring is available in squares in two varieties, unit and laminated. Unit block

flooring is made of strips, splined or otherwise fastened together. Laminated block

flooring is cross-laminated like plywood and thus shrinks and swells less with moisture

tpstwwr fac org docreple3e4sele3B48e05 nim 202

eu2015 Unasylva No. 101-102-103 - Werld consutatin onthe use of wood inhousing - Secton 3: Wood praduets and their use incorstrction

change than do other flooring types. The block edges are usually tongue and groove. A

variety of special pattems are available.

Installation

In the United States, a wood subflooring of boards or, more commonly, of plywood, is

used over the joists in nonslab construction. The use of subflooring does not seem to

be so widespread in other countries.

As noted earlier, most strip flooring is blind-nailed to the joists, with the flooring length

at right angles to the joists, Over concrete slabs, itis usual to lay down sleepers to

which the flooring is nailed. Block flooring is also usually nailed. Over concrete slabs,

block flooring may be laid in a mastic.

Detailed descriptions of installation practices are given in several references (9, 10, 16,

27)

Species used

Because of its greater hardness and generally greater beauty, hardwood is used for

most wood flooring. In the United States, oak, maple, beech, birch and pecan are the

most important species (16).

In other areas, a wide variety are used. Suggested species are shown in the two

Timber Development Association publications (27) and (28). Selection will be

conditioned by stability, tool-working potential and appearance.

Moisture content

Moisture content at the time flooring is laid is important because of the large expanses.

covered. It should be as close as possible to that expected in service. Too high a

moisture content can result in shrinkage and thus the opening of cracks between strips

or blocks. Too low a moisture content can result in buckling

Recommendations on this point vary. In the United Kingdom, for example.

recommendations are for somewhat higher moisture content than in the United States.

This may well be because of inherent differences in beating practices.

The Timber Development Association suggests 14 percent for buildings heated

intermittently and 12 percent for buildings heated continuously (27). United States

practice is considerably different, with a suggested average of 7 percent over most of

the country, and with averages as high as 11 percent in the damper areas and as low

as 6 percent in the drier areas (16).

Standards

Standards for flooring are available. In the United States, for example, industry

standards are published, and some types of flooring are covered by commercial

standards issued by the U.S. Department of Commerce.

Use of adhesives

Adhesives are not commonly used in flooring except for the laminated block type.

United States manufacturers tend to use melamine-urea adhesives as a compromise

between cost and durability. The type used, however, should be adequate to withstand

service conditions.

Finishing

tpstwwr fac org docreple3e4sele3B48e05 nim

evans Unesyva- No. 101-102-108 Wer srsutaton onthe use of wont inhousing- Secfon 5: Wood prods ands se incest uten

Wood sealers and varnishes are most commonly used. The former have the advantage

of penetrating the wood and not forming a surface coating. Floors finished with sealers