Munir DP

Diunggah oleh

kanchanabalaji0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan53 halamanjhhj

Judul Asli

MUNIR_DP

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inijhhj

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan53 halamanMunir DP

Diunggah oleh

kanchanabalajijhhj

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 53

NOT RAINING PROGRAM

STUDENT'S GUIDE

LUO PENETRANT METHOD

INTRODUCTION To THE LIQUO PENETRANT TRAINING PACKAGE

The tang meters ms packane ate denned fo crovde 2 Dasle Knowledge of he fundamentals of

auc senerantYesing. The waning progam mal you ate panceatng wh cinta ie Tolower,

Setrcom hous olnstcton Yo race’ Ine inlomaten suggasieg tne ASH psteaton SNT-7C-14

Love raring wil ude echres on af x lessons wt an average of sepionrly one hour ber

Tesson Ereraas wil begun oscars 4

Leva rang wll ace lectures on al lessons whan verge of anetonaely to hours Der

Tetson Soa wilbe gen fo lessone 6:7

‘The siusent Sheu assume the reSs0rsBA lar reading al assigeants, ening ects, nd par

hcpatng n ease decvesure. Shon exams wi be sare ser each lesson fe prowae the alos

‘ath afelornsibr progres nto stmuste sy

CONTENTS OF TRAINING PACKAGE

‘Yur tong package wil conan ine lolowng maleate win speclc mstucters ane assignments 0 be

ven bye course ratucte

1. STUDENT'S Package

A. Students Guide wicn wit cutie e purpose. conten, pa seo! he rng atonal

8. 1 Glasroom Training Handbook whch wil sare a8 the mar txt for he wang course

___ er

©. india! lecture guide packets on te hrcameniae of Iqud generar esing he lecture

‘ude mata are eroded wih each leon and ena othe tana Uses Sy he

‘tutor aumng nis were. Durng me tecture the akdent shoud use ine gud fo make 933

tonal notes. andthe ce wi Men became alti t tty om ata te

©. 1 packet of quizzes. The nsicter may eect remove the uaz Yom your Saket ono! fe

sig couse a eat yt aes tn Crees Agu wo unste o

2, INSTRUCTOR'S PACKAGE

[A The esmucr's sactage wil conan af ofthe efaion that you have wih te aden of an

ruc’ pace, lecture gage ransgarenoes ard que toys

©. Alte opton of the nsincier. a set of fnsbes may be used Yo proce aon th and

Atte ooton of the struct. the progranmed iseucion hansbocks may De wc fr atonal

ssrnanis.

Sever 668 of contests ave avaaoie ram ASNT and may be issued a tte eoton ofthe

5 OUTLINE OF L=SSONS ANO RELATED REAOING ASSIGNMENTS

Cssroom Trang nanatoor (CT-62) oles tne lesane ne traning eoerte the fooweg oer

PrLasson ‘Classroom Training Handbook Ch 1-2

(opto) P42 Penetrant Gn 1-2

Pr-.esson 2—Clasareom Trlaing Handbook Ch 9

Toatonal Pit? Panatrnt Gn

PT-Lesson 3—Cissroom Training Handbook Cr

loptonal Pie? Pnetrant On 348

Pr-Lasson 4—Clessroom Training Hanabook Cn

{ostenal P12 Penara Ch ¢S

rLesson Classroom Truning Hancbook Ch 6-6

(ootonal Pi? Peneram Ch 87

P7-Lesson 8—Classroom Truning Handbook Cn §

[oatenal Pt integucton Ch 1.7

Pr4asson 7—Clesaroom Traning Handhoos Ch

leotonal SNTTCTA, 90.110

OPTIONAL REFERENCE MATERIAL

‘The folowing mate's valle rom ASNT Hesacuaners and sugested where ne student wants at:

‘tena denn n the Luc Penetant Med (The ASNT Catalog lee ances tnd rdenng miomaton)

1 Programmed nsrucon nanatook Plt? Llguld Penetrant Testing)

2. Progranmed itstucion handbook Pt Unrodueton to NOT) 1

{3 Principles of Penetrants by Cov ate

4 Auta! course #1723 (Liguld Penetant Testing)

5. SNF-TC-1A Recommended Practice fer Personnel Qualiistion and Certietion In Non:

UGUID PeNerRANT METHOD

NOT Training Program Studenis Gude

Tavie of Conients

Page

Introduction.

Related Reading Outline wi

Lesson 1 1

Quiz 8

Lesson 2. a

‘Quiz 7

Lesson 3. 19

‘uz, 2

Lesson 4. 7 son

‘Quiz 35

Lesson 5, 37

__Quiz. : 43

Lesson 6,

Quiz

Lesson 7, 57

‘Qui oer)

LESSON |

LIQUID PENETRANT TESTING IS A NONDESTRUCTIVE MEANS OF LOCATING SUA

FACE DISCONTINUITIES BASED ON CAPILLARITY OR CAPILLARY ACTION.

IN THE LIQUID PENETRANT METHOD, THE LIQUID IS APPLIED TO “HE SURFACE OF

THE SPECIMEN, AND SUFFICIENT TIME IS ALLOWED FOR PENETRATION OF SUR:

FACE DISCONTINUITIES, IF THE DISCONTINUITY IS SMALL OR NARROW. AS IN A

CRACK OR PINHOLE, CAPILLARITY ASSISTS THE PENETRATION.

AFTER SUFFICIENT TIME HAS PASSED FOR THE PENETRANT TO ENTER THE

DISCONTINUITY, THE SURFACE OF THE PARTIS CLEANED. CAPILLARY-ACTION IS

AGAIN EMPLOYED TO ACT AS A BLOTTER TO DRAW PENETRANT FROM THE

DISCONTINUITY.

TO INSURE VISIBILITY, THE LIQUID PENETRANT CONTAINS EITHER A COLORED DYE

EASILY SEEN IN WHITE LIGHT, OR A FLUORESCENT DYE VISIBLE UNDER BLACK

(ULTRAVIOLET) LIGHT

A. PENETRANT APPLIED TO SURFACE, 8. TIME ALLOWED FOR PENETRANT TO

SEP INTO THE OPENING.

©, SURFACE PENETRANT REMOVED. 0. DEVELOPER APPLIED TO DRAW.

Saree PENETRANT OUT OF CPENING.

E. SPECIMEN VISUALLY EXAMINED. F. POST-CLEANING

DISCONTINUITIES THAT ARE SUBSURFACE IN ONE STAGE OF PRODUCTION COULO

BE OPEN TO THE SURFACE AT ANOTHER STAGE, SUCH AS AFTER GRINDING OR

MACHINING.

NONMETALLIC INCLUSIONS AND POROSITY IN THE INGOT MAY CAUSE STAINGEAS,

SEAMS, FORGING LAPS, COLD SHUTS, AND THE LIKE AS THE BILLET OR SLAB IS

PROCESSED IN THE MANNER SHOWN BELOW:

ad

Pr iectue Goce

ANYTHING THAT COULD BLOCK THE PENETRANT FROM ENTERING THE DISCON-

TINUITY MUST BE REMOVED.

A LIST OF CONTAMINANTS THAT MUST 8E REMOVED WOULD INCLUDE DIRT,

GREASE, RUST, SCALE, ACIDS, AND EVEN WATER. THE CLEANING SOLVENT USED

MUST BE VOLATILE (READILY VAPORIZED) SO THAI IT EASILY EVAPORATES OUT

OF THE DISCONTINUITY AND DOES NOT OILUTE THE PENETRANT.

SURFACE PREPARATION BY SHOT OR SANDBLASTING IS NOT RECOMMENDED

DISCONTINUMTES THAT WERE OPEN TO THE SURFACE MAY BE CLOSED BY THE

SHOT OR SANDBLASTING.

Yip

cxose-ecrion ZI

HISTORICALLY, PENETRANT INSPECTION WAS CALLED THE “OIL AND WHITING

METHOD.” AS IT USED KEROSENE AND & WHITE POWDER FOR THE NSPECTION OF

RAILROAD PARTS. HOWEVER, IN THE PAST 40 YEARS THE PROCESS HAS BEEN IM

PROVED TREMENDOUSLY TO THE POINT WHERE IT IS A AELIABLE AND ACCURATE

INSPECTION TECHNIQUE,

THE LIQUID PENETRANTS USED IN NONDESTRUCTIVE TESTING CAN BE CATEGO-

RIZED BY THE TYPE OF DYE THEY CONTAIN,

1, VISIBLE DYE PENETRANTS CONTAIN A COLORED (USUALLY FED) OVE

2. FLUORESCENT PENETRANTS CONTAIN A FLUORESCENT DYE.

3. DUAL SENSITIVITY PENETRANTS CONTAIN A COMBINATION OF VISIBLE ANO

FLUORESCENT DYES,

Fr Lecture Goce

PENETRANTS CAN BE FURTHER CATEGORIZED BY THE PROCESSES USED TO

REMOVE THE EXCESS PENETRANT FROM THE SPECIMEN

1. WATER-WASHABLE PENETRANTS ARE EITHER SELF-EMULSIFYING OR.

REMOVABLE WITH PLAIN WATER

2. POST-EMULSIFIED PENETRANTS REQUIRE A SEPARATE EMULSIFIER TO MAKE

THE PENETRANT WATER WASHABLE,

3. SOLVENT-REMOVABLE PENETRANTS MUST BE REMOVED WITH A SOLVENT

WHICH IS TYPICAL WHEN USING VISIBLE DYE IN PRESSURIZED SPRAY CANS,

THE FLOW CHART BELOW ILLUSTRATES THE PROCESSING SEQUENCE WITH VIS

‘BLE DYE AND FLUORESCENT PENETRANTS.

: = ma

——

veer Sta

DUAL SENSITIVITY PENETRANTS WOULD FOLLOW & PROCESSING SEQUENCE

SIMILAR TO THAT SHOWN BELOW.

THE SELECTION OF THE SEST PROCESS, AS LISTED ON PAGES 5 ANO 8, DEPENDS.

UPON.

SENSITIVITY REQUIRED.

NUMBER OF ARTICLES TO BE TESTED.

‘SURFACE CONDITION OF PART BEING INSPECTED.

CONFIGURATION OF TEST SPECIMEN.

AVAILABILITY OF WATER, ELECTRICITY, COMPRESSED AIR, SUITABLE TESTING

AREA, ETO.

PENETRANT TESTING IS SUCCESSFULLY USED ON METALS SUCH AS’ ALUMINUM

MAGNESIUM, BRASS, COPPER, CAST IRON, STAINLESS STEEL, TITANIUM. AND

MOST OTHER COMMON ALLOYS.

IT CAN ALSO BE USED TO TEST OTHER MATERIALS, INCLUDING CERAMICS,

PLASTICS, MOLDED RUBBER, POWDERED METAL PRODUCTS, OR GLASS.

PENETRANT TESTING IS LIMITED BY ITS INABILITY TO TEST MATERIALS WITH

DISCONTINUITIES THAT ARE NOT OPEN TO THE SURFACE OR HAVING AN EX:

TREMELY POROUS SURFACE.

ane

LESSON

uz

omnis nuns a say te! como ns ng a pvarnt

“ype l panetens, according lo ou" es, st6 ase containing afhoescent dy

Because of he capilry action of peneans, his 2recess of aspecton warks wo on pais

‘wim very porous suaces

‘nen dong a aud pentane, he confit ol he specie hs ite efact on the a

{ctvenesso he test.

Luau pentrantnsoecon can be used ely on metals Such a summa and st

‘Tn penetran nepection method s used ony n he fess produc:

Ct and wing ar the names a he two men who vented the pendant test metho.

The feat meant step peneratlesing is srtce preperation.

‘one of the moat comman contaminant inte panatrant meth water.

‘The moat comenan mete of surtace preperation or penetan esi is sanding,

Chemical etting it sometmas used o remove smeared metal rom = surace to open dlscon:

Some svosurace defects cn be lcs wih te hry senave Type I panera’

‘low hoes and ges porsty may be detected wih the penstran meted

Salvent cionng ie commen method of suace Searing parts bors penetra! tesing.

‘The one major iation o peetrant esting thane pat must be net

(Grease and st woud usualy be considered a contaminant onthe sacs ofa

oleate «detect wih penerat esting, he elect must be open othe surface

is considered advantagecus fora eu penetra mater have ew tension an igh

csptoty

1 ace,

LESSON 2

THIS LESSON DISCUSSES THE EQUIPMENT AND MATERIAL REQUIRED TO PERFORM

THE VARIOUS PENETRANT TESTS AND THE REQUIRED PRE- AND POST-TEST CLEAN:

ING.

PROPER CLEANING IS ESSENTIAL TO LIQUID PENETRANT TESTING FOR TWO

REASONS

1. If THE SPECIMEN IS NOT CLEAN AND DAY, PENETRANT TESTING IS INEFFEC-

TWE.

2. IF ALL TRACES OF PENETRANT MATERIALS ARE NOT RENOVED AFTER THE

TEST. THEY MAY HAVE A HARMFUL EFFECT ON THE SPECIMEN. (CHLORINE

ANO SULFUR MAY AFFECT SOME ALLOYS }

IMMERSION TANKS AND DETERGENT SOLUTIONS ARE COMMON VEANS OF ASSUR:

ING THAT & SPECIMEN SURFACE IS SOTH PHYSICALLY ANO CHEMICALLY CLEAN.

VAPOR DEGREASING IS PARTICULARLY EFFECTIVE IN THE REMOVAL OF OlL.

GREASE, AND SIMILAR ORGANIC CONTAMINATION. HOWEVER, CERTAIN ALLOYS

HAVE AN AFFINITY FOR SPECIFIC ELEMENTS USED IN VAPOR DEGREASING AND IF

EXPOSED TO THEM MAY BECOME STRUCTURALLY DAMAGED.

‘STEAM CLEANING IS PARTICULARLY ADAPTABLE TO THE CLEANING OF LARGE, UN:

WIELOY ARTICLES

SOLVENT CLEANING MAY BE USED IN IMMERSION TANKS OR MAY BE USEO IN A

\WIPE-ON ANO WIPE.OFF TECHNIQUE. SOLVENT CLEANING IS USUALLY LESS EFFEC.

TIVE THAN THE PREVIOUS METHODS OF CLEANING a

RUST AND SURFACE SCALE CAN BE REMOVED BY ANY GOOD COMMERCIALLY

AVAILABLE ACIO OR ALKALINE RUST REMOVER FOLLOWING MANUFACTURER'S

DIRECTIONS:

PAINT REMOVAL IS OFTEN DONE IN DISSOLVING-TYPE HOT-TANK PAINT STRIPPERS,

BOND RELEASE, OR SOLVENT PAINT STRIPPERS.

ETCHING IS EFFECTIVE FOR USE ON ARTICLES THAT HAVE EEEN GROUND OR

MACHINED. THIS PROCESS USES AN ACID OR AN ALKALINE SOLUTION TO OPEN UP

GRINDING BURRS AND REMOVE METAL FROM SURFACE DISCONTINUITIES.

SURFACE CLEANING PROCESSES TO BE AVOIDED INCLUDE BLAST (SHOT, SAND,

GAIT, OR PRESSURE), LIQUID HONING, EMERY CLOTH, WIRE BRUSHES AND METAL

SCRAPERS. THESE PROCESSES TEND TO CLOSE DISCONTINUITIES BY PEENING OR

COLD WORKING THE SURFACE OF THE SPECIMEN.

PENETRANT TEST EQUIPMENT (STATIONARY)

STATIONARY EQUIPMENT USED IN LIQUID PENETRANT TESTING VARIES IN SIZE AND

IS LARGELY DEPENDENT UPON THE SIZE OF THE TEST SPECIMEN. DEPENDING ON

THE TYPE AND PROCESS USED. A STATIONARY SYSTEM COULD INCLUDE THE

FOLLOWING.

1, PRECLEANING STATION (USUALLY 7, DRYING STATION (USUALLY OVEN)

IN REMOTE AREA) 8. INSPECTION STATION (ENCLOSED

2. PENETRANT STATION (TANK) BOOTH OR TABLE WITH PROPER

3, DRAIN STATION UHTING)

|4, EMULSIFICATION STATION (TANK) 9, POSTCLEANING STATION (USUALLY

5, RINSE STATION [TANK] IN REMOTE AREA)

6. DEVELOPING STATION (TANK)

nN enon 8

PENETRANT TEST EQUIPMENT (PORTABLE)

GOTH VISIBLE AND FLUORESCENT DYE PENETRANTS ARE AVAILABLE IN KITS

WHICH CAN BE USED AT A REMOTE LOCATION OR WHEN TESTING & SMALL POR-

TION OF A LARGE AATICLE,

A VISIBLE DYE PENETRANT KIT USUALLY CONTAINS:

|. PRESSURIZED SPRAY CANS OF CLEANING OR REMOVAL FLUID.

2. PRESSURIZED SPRAY CANS OF VISIBLE DYE PENETRANT

3. PRESSURIZED SPRAY CANS OF NONAQUEOUS DEVELOPER,

4, WIPING CLOTHS ANO BRUSHES.

‘A FLUORESCENT DYE PENETRANT KIT USUALLY CONTAINS:

1. A PORTABLE BLACK LIGHT AND TRANSFORMER,

2. PRESSURIZED SPRAY CANS OF CLEANING OR REMOVAL FLUID.

3. PRESSURIZED SPRAY CANS OF FLUORESCENT DYE PENETFANT.

4. PRESSURIZED SPRAY CANS OF NONAQUEOUS DEVELOPER,

5. WIPING CLOTHS AND BRUSHES,

BLACK LIGHT EQUIPMENT IS REQUIRED IN FLUORESCENT PEN:TRANT TESTING

SINCE (T SUPPLIES LIGHT OF CORRECT WAVELENGTH TO CAUSE THE PENETRANT

TO FLUORESCE. A DEEP RED-PURPLE FILTER IS USED TO PASS ONLY THOSE

WAVELENGTHS OF LIGHT THAT WILL ACTIVATE THE FLUORESCENT MATERIAL, AT

LEAST A FIVE-MINUTE HEAT-UP TIME IS REQUIRED TO REACH THE CORRECT ARC

TEMPERATURE WHEN USING MERCURY ARC LAMPS.

THE BLACK LIGHT EMITS A SPECIAL LIGHT WITH WAVELENGTHS THAT FALL BE:

TWEEN VISIBLE AND ULTRAVIOLET. PROVIDED THAT THE FILTER IS NOT BROKEN

(OR CRACKED, THERE IS NO DANGER OF INJURY TO THE HUMAN EYE. IT IS SUG-

GESTED THAT THE FILTER 8E CHECKED PRIOR TO EACH USE.

PENETRANT TESTING MATERIALS CAN BE USED IN A VARIETY OF COMBINATIONS.

MOST MATERIALS AAE AVAILASLE IN EITHER PRESSURIZED SPRAY CANS OR IN

BULK QUANTITIES.

THE FLOW CHART BELOW ILLUSTRATES THE DIFFERENT MATERIAL COMBINATIONS.

HOWEVER, CARE SHOULD ALWAYS BE TAKEN TO ASSURE THAT MANUFACTURERS

SPECIFICATIONS OR COMPANY PROCEDURES ARE CLOSELY FOLLOWED

[

Pr Leste Gace

Cesson 2

PENETRANT TESTING MATERIALS

PENETRANT MATERIALS ARE OFTEN AESTRICTED TO SPECIFC GROUPS, THE

ESTABLISHED GROUPS OF PENETRANT MATERIALS WILL USE THE FOLLOWING IN A

VARIETY OF COMBINATIONS TO OBTAIN THE 8EST RESULTS:

1. WATER-WASHABLE PENETRANTS—CONTAIN AN EMULSIFYING AGENT WHICH

MAKES THEM EASILY REMOVABLE BY A WATER AINSE OR WASH, THIS

PENETRANT MATERIAL CAN BE OBTAINED WITH EITHER A VISIBLE OR

FLUORESCENT OVE

2. POST-EMULSIFIABLE PENETRANTS—ARE HIGHLY PENETRATING, OILY VISIBLE

OR FLUORESCENT PENETRANTS WHICH ARE NOT SOLJBLE IN WATER,

THESE PENETRANTS MUST BE TREATED WITH AN EMULSIFER BEFORE THEY

CAN BE REMOVED BY A WATER RINSE OR WASH

3, SOLVENT-REMOVABLE PENETRANTS—ARE OILY PENETRANTS THAT DO NOT

CONTAIN AN EMULSIFYING AGENT AND ARE REMOVABLE ONLY BY

SOLVENTS SPECIFICALLY DESIGNED FOR THAT PURPOSE.

4, EMULSIFIERS—WHEN APPLIED TO A PENETRANT-COATED SPECIMEN MAKE

THE RESULTANT MIXTURE REMOVABLE BY WATER RINSE OR WASH

EMULSIFIERS HAVE LOW PENETRANT CHARACTERISTICS AND UO NOT

REMOVE INDICATIONS FROM THE SPECIMEN SURFACE.

5. REMOVERS (SOLVENT)—ARE DESIGNED TO BE USED IN CONJUNCTION WITH

‘SPECIFIC_PENETRANTS.-TYPICAL-REMOVERS -ARE-AVAILABLE IN-BULK-OR

PRESSURIZED SPRAY CONTAINERS.

6. DRY DEVELOPERS—ARE A FLUFFY, ABSORBENT WHITE FOWDER THAT IS

USED IN BOTH FLUORESCENT AND VISIBLE DYE PENETRANT TESTS. IT FUNC.

TIONS TO DRAW THE PENETRANT INDICATIONS TO THE SURFACE THUS MAK-

ING THEM VISIBLE

7. WET DEVELOPERS—FUNCTION SIMILARLY TO ORY DEVELOPERS EXCEPT

THAT THEY ARE A MIXTURE OF A DEVELOPING POWDER AND WATER,

Teston 2

8 NONAQUEOUS WET DEVELOPERS—OIFFER FROM WET DEVELOPERS IN THAT

THE DEVELOPER POWDER IS MIXED WITH A AAPIO-CRYING LIQUID SOLVENT

9. LIQUID OXYGEN (LOX) COMPATIBLE MATERIALS—MUST BE USED WHEN AR-

TICLES INSPECTED ARE SUBJECTED TO CONTACT WITH ETHER LIQUID OR

GASEOUS OXYGEN. THESE MATERIALS ARE SPECIFICALLY DESIGNED TO BE

INERT WHEN IN THE PRESENCE OF LOX.

10. LOW SULFUR AND LOW CHLORINE—PENETRANT MATERIALS MUST E

SPECIFICALLY DESIGNED TO AVOID THE HARMFUL EFFECTS CAUSEO ON

‘SOME NICKEL AND TITANIUM ALLOYS BY THE SULFUR ANC CHLORINE CON.

TENT.

SAFETY PRECAUTIONS.

IN GENERAL, THE MATERIALS USED IN PENETRANT INSPECTION CAN BE FLAM-

MABLE AND CAN CAUSE SKIN IRRITATIONS.

IN ADDITION, THE ULTRAVIOLET SPECTRUM OF LIGHT RAYS GENERATED FROM THE

MERCURY ARC LAMP CAN CAUSE SUNBURN AND MAY BE INJURIOUS TO THE EVES

HOWEVER, IF THE PROPER FILTER FOR FLUORESCENT DYE INSPECTION IS USED,

THE HARMFUL RAYS WILL BE FILTERED OUT.

FIRE—MANY PENETRANT MATERIALS ARE FLAMMABLE, SAFE PRACTICE REQUIRES

THAT PENETRANT MATERIALS USED IN OPEN TANKS HAVE 4 FLASHPOINT OF

GREATER THAN 120° F - —

SKIN IRRITATION-SKIN IRRITATION CAN BE AVOIDED BY PREVENTING UN

NECESSARY CONTACT AND BY THE USE OF GLOVES. APRONS.

AND PROTECTIVE HAND CREAMS.

AIR POLLUTION—THE DEVELOPING POWDERS ARE CONSIDERED NONTOXIC BUT EX:

CESSIVE INHALATION MUST BE AVOIDED, EXHAUST FANS SHOULO

SE INSTALLED IN ANY CONFINED AREA WHERE DRY DEVELOPERS

OR VAPORS FROM THE PENETRANTS ARE PRESENT

awe.

Lesson 2

enon a aecetate method 0! sutace cleming a tet pata to be

‘good exhaust aystsm is ecommended whan working with cleaning solvents.

\Yanercegreasing' ctlen usd remove oxton, ust, and acne Deore a pat panetant

Pars iat nave been painted ususty cannot be inepacied wih pensrants because sub ein

‘removing techniques Fave not been develope.

Detergent sng is accesaie lor posing but should never e use lor pracieaning

because tim ast the emulster gurng ne penetra est,

ona ie olen alive Beclring a par tat has ben machired fo apecilciclerance by

sautace ging

Cony waible aye penarants ae avaible portble Ks because Murescent des wilt fe:

Dry eeveloers are usualy only used wih vsble dye penevants

Enmulsiors and solvents are both commony ued in penevant esty es postcleanee

Wet dveionars should neve be used when hay wil come nto coract wih gaseous or fauié

‘nigen becouse ofthe rele eaoted by oxygen and water mixing,

[Emusilers must have high penevatng cheracanstes lo ema penetants Ina ein lets and

tne covet ers pace an no broken or wacked,

Peneirnt materi ae often placed in grouings tat wl assure aad lst wh materi that

Noraqueo -

Postemusiiable poneans are usualy soubien wale aller he soeiaton olan musi.

Water washable pencvants ae cammoly uted wih either a vita of rescence,

Fasnoont rele othe lonest tenperaie at which vapors wit ile when expose to tne

ogee

APPLICATION OF PENETRANTS

ALMOST ANY LIQUIO COULD BE CONSIDERED A PENETRANT, BUT MODERN

PENETRANTS MUST HAVE:

1, THE ABILITY TO HOLD A DYE MATERIAL IN SUSPENSION.

THE ABILITY TO SPREAD THE DYE EVENLY OVER THE SURFACE

THE ABILITY TO CARRY THE DYE INTO ANY DISCONTINUITY OPEN TO THE SUR-

FACE,

4. THE ABILITY TO BRING UP THE DYE AS IT IS “COAXED” BACK TO THE SUR.

FACE.

5. THE ABILITY, WHEN DESIRED, TO BE EASILY REMOVED.

THERE ARE TWO TYPES OF DYE USED IN MODERN PENETRANTS

1. VISIBLE—A BRIGHTLY COLORED DYE THAT IS HIGHLY VISIBLE JNDER NORMAL

LIGHTING CONDITIONS, THIS TYPE OF OYE IS NORMALLY CALLED

VISIBLE OYE.

2. FLUORESCENT—AN ALMOST COLORLESS OYE WHICH EMITS VISIBLE LIGHT

RAYS WHEN REVIEWED UNDER BLACK LIGHT

A DYE WITH DUAL SENSITIVITY CONTAINS BOTH A VISIBLE DYE FOR EXAMINA:

TION IN WHITE LIGHT AND A FLUORESCENT DYE FOR A MORE SENSITIVE EVALUA-

TION OF SMALL DISCONTINUITIES.

PENETRANTS. EITHER FLUORESCENT OR VISIBLE, CAN 8E APPLIED BY ANY ONE OF _

THE FOLLOWING MEANS:

1. SPRAYING—USUALLY USING A LOW PRESSURE CIRCULATION 2UMP OR FROM

PRESSURIZED SPRAY CANS,

BRUSHING—USUALLY APPLIED WITH RAGS, COTTON WASTE, OR GRUSHES

IMMERSION—THE ENTIRE PART IS DIPPED INTO A TANK OF PENETRANT

POURING—THE PENETRANT IS SIMPLY POURED OVER THE SURFACE

PENETRATION (OWELL) TIME

THE PERIOD OF TIME OURING WHICH THE PENETRANT IS PERMITTED TO REMAIN

ON THE SPECIMEN IS A VITAL PART OF THE TEST

TIGHT CRACKLIKE DISCONTINUITIES MAY REQUIRE IN EXCESS OF 30 MINUTES FOR

PENETRATION THAT WILL GIVE AN ADEQUATE INDICATION. HOWEVER, GROSS

DISCONTINUITIES MAY BE SUITABLY PENETRATED IN 3 TO 5 MINUTES

THE TEMPERATURE OF THE SPECIMEN AND TEMPERATURE OF THE PENETRANT

CAN AFFECT THE REQUIRED DWELL TIME

WARMING THE SPECIMEN TO 70°F OR HIGHER ACCELERATES PENETRATION AND

SHORTENS OWELL TIME. HOWEVER, CARE SHOULD BE TAKEN NOT TO

OVERHEAT THE SPECIMEN SINCE TOO MUCH HEAT MAY CAUSE EVAPORATION

(OF THE PENETRANT FROM THE DISCONTINUITY.

WELL TIMES ARE BASED ON THE ASSUMPTION THAT THE PENETRANT WILL RE:

MAIN WET ON THE PART SURFACE, ADDITIONAL PENETRANT MAY BE APPLIED

DURING DWELL TIME,

‘THE PENETRANT MANUFACTURER WILL PROVIDE SUGGESTED OWELL TIMES FOR

THE VARIOUS PENETRANTS THAT IT PRODUCES.

PENETRANT TESTING PROCESSES

WE PREVIOUSLY MENTIONED THE TWO TYPES OF PENETRANTS, VISIBLE AND

FLUORESCENT. FOR BOTH CATEGORIES THERE IS A FURTHER BREAKDOWN:

1. WATER-WASHABLE (VISIBLE OR FLUORESCENT)

2, POST-EMULSIFICATION (VISIBLE OR FLUORESCENT)

3, SOLVENT-REMOVABLE [VISIBLE OR FLUORESCENT)

WATER-WASHABLE PENETRANTS HAVE A BUILT-IN EMULSIFIER ANO THE

PENETRANT IS EASILY REMOVED BY A WATER RINSE, CARE MUST BE TAKEN

TO INSURE THAT THE SPRAY VOLUME AND FORCE DOES NOT WASH

PENETAANT OUT OF THE DISCONTINUITY.

WATER TEMPERATURES ABOVE 110° F ARE NOT RECOMMENDED SECAUSE

THIS MAY SPEED UP THE EVAPORIZATION OF THE PENETRANT

Coston

THE SKETCH BELOW REPRESENTS THE STEPS IN A WATER-WASHABLE PENETRANT

Test.

WATER-WASHABLE PENETRANTS ARE USUALLY PREFERRED FOR USE ON AR.

TICLES WITH A ROUGH SURFACE OA IF THEY CONTAIN THREADS OR KEYWAYS.

THE BUILTN EMULSIFIER PROVIDES THE BEST PENETRANT REMOVAL FROM

BLIND HOLES AND OTHER HARD-TO-REACH LOCATIONS SUT HAS THE DISADVAN.

TAGE OF POOR RELIABILITY IN DETECTING WIDE OR SHALLOW DISCONTINUITIES.

(SEE PAGE 6 FOR ADVANTAGES AND DISADVANTAGES)

SOLVENT-REMOVABLE PENETRANTS—THEY HAVE THE ADVANTAGE OF PORTABIL:

ITY AND CAN BE USED OUTDOORS WITHOUT USING HEAVY. COMPLEX EQUIPMENT

THEY ARE EXCELLENT FOR MANY MAINTENANCE INSPECTIONS AND FOR CHECK.

ING PORTIONS OF A LARGER STRUCTURE

PENETRANT IS OFTEN APPLIED FROM A rican

PRESSURIZED SPRAY CAN WHICH MAKES .

THE SYSTEM VERY PORTABLE

AFTER THE SPECIFIED OWELL TIME, THE

EXCESS PENETRANT IS FIRST REMOVED é

BY WIPING WITH ABSORBENT TOWELS =

AND THEN CLEANED WITH TOWELS

DAMPENED WITH SOLVENT.

SOLVENT IS NEVER APPLIED DIRECTLY TO THE SPECIMEN AS IT MIGHT WASH

(OUT OA DILUTE THE PENETRANT IN THE DISCONTINUITY.

(SEE PAGE 6 FOR ADVANTAGES AND DISADVANTAGES OF SOLVENT-REMOVASLE

PENETRANTS)

POST-EMULSIFICATION PENETRANTS AEQUIRE A TWO-STEP REMOVAL PROCESS,

THE EMULSIFIER IS USUALLY APPLIED BY DIPPING OR IMMERSION. THE AMOUNT OF

DOWELL TIME IN THE EMULSIFIER IS IN THE RANGE OF ONE TO FOUR MINUTES IN AC-

CORDANCE WITH MANUFACTURERS’ RECOMMENDATIONS AND THE TYPE OF

DEFECTS EXPECTED

THE RESULTANT EMULSIFIER-PENETRANT MIXTURE IS REMOVED 8Y WATEA RINSE

(EMULSIFICATION WILL BE COVERED IN MORE DETAIL IN LESSON 4)

1_WATER-WASHABLE

Tessar 3

| seuvwevemsrene

2. SOLVENT-REMOVABLE

JA Aaa

3. POST-EMULSIFICATION

LEAK-THROUGH TECHNIQUE—THE USE OF LIQUID PENETRANT IN THIS METHOD IS

‘SUITED FOR FINDING LEAKS IN SUCH ARTICLES AS TANKS. PIPING, TUBING, AND,

HOLLOW CASTINGS. THE SKETCH BELOW ILLUSTRATES THE LEAK-THROUGH

TECHNIQUE

FIXING AND RECORDING INDICATIONS.

1. PHOTOGRAPHS—TYPICAL BLACK AND WHITE AND COLOR FILM ARE USED

WITH THE SELF-DEVELOPING FILMS PROVIDING THE MOST CONVENIENCE

2, SPECIAL WAX AND PLASTIC FILM DEVELOPERS HAVE SEEV DEVELOPED TO

ABSORB AND FIX THE PENETRANT INDICATION TO FORM A PERMANENT

RECORD,

A, STRIPPABLE LACQUERS ARE SPRAYED IN SEVERAL COATS OVER THE IN:

DICATION AND WHEN ORY CAN BE “LIFTED” TO PROVIDE A PERMANENT

RECORD,

B, SPECIAL “FIXERS” ARE SPRAYED OVER THE INDICATION ANO WHEN DAY

ARE LIFTED WITH TRANSPARENT TAPE

LESSON 3

uz,

2 chal sensitty panetant conlahs 8 spec ye Ia sible whe Hoh and wi Roresc®

‘etnout he ee o blak hh

A par being penetantmspacted must stay Immersed hth pera ank fr te eniro

peeled due ime

The qu penetra’ eakstvough lst rare fo he aby of «pene

ry ceveloper every.

Viable dye penetans are usvsly considered lobe lets sane than herent pentrants.

‘Walerwashatio poneiranis havea buit-n enusiier that permis 900 resus penetra

removal Wom parts suapeced of hing wide e slow Gacontvuts,

Sohventemovabie penetanis are aveate m both vin and Murescent dye,

Excess poat-eruisiibia penetra! i commonly removed by spreyng the ata ole pr

wih leaner (sven) and then wing wah n-eelowel

Waterwasnabe penetant ays ar usutly very porate because ne materials are com-

monly used in pressurized spray cane

Waring ihe soecimen lo temperatures upto about 70°F tds to accelerate penetration and

shortens de ine,

For the dw tne lobe accurate, he sacs ol the soecimen must say wet with penarat for

the ene inspected

he typical awa tne for mos! penetra iapecton Is About 20-20 minutes.

12, Ust two (2) of he conmenty used methods of aopyeg penetrant lo specimen

‘halt to Be mapecie,

{o sereag rrough the

18. Lst-towr ofthe -commeny uted: methods of preciearing the spechnen bere

penetrantinspacion

oboe, each XX 3 inches wit fled hres, whic

11 you were asked lo examine 200

natant method would you chooes?

(2) post emuttestin (b) water washable

LESSON 4

THIS LESSON DISCUSSES EMULSIFICATION, PENETRANT REMOVAL, AND DEVEL.

OPER APPLICATION

POST-EMULSIFICATION PENETRANT [P. £, PENETRANT}

THIS TYPE OF PENETRANT EMULSIFICATION IS ACCOMPLISHED BY DIPPING THE

PART IN A CHEMICAL EMULSIFIER PRIOR TO WASHING. THE EMULSIFIER WILL

BREAK DOWN THE PENETRANT AND MAKE IT WATER SOLUBLE.

THE EMULSIFIER CAN SE APPLIED BY DIPPING OR SPRAYING, BUT NOT BY

BRUSHING. THE BRISTLES OF THE SRUSH MAY ENTER THE DISCONTINUITY

SN XD

SSD)

=

vip

Dp cin

IF TOO SHORT AN EMULSIFICATION TIME IS USED. NOT ALL PENETRANT WILL BE

REMOVED, WHICH WILL CLOUD OVER CISCONTINUITIES,

IF TOO LONG A TIME IS USED, PENETRANT WITHIN THE DISCONTINUITIES WILL

ALSO BECOME WATER SOLUBLE AND BE WASHED AWAY WITH EXCESS

PENETRANT.

THE PE PENETRANT MAKES THE WATER WASH LESS CRITICAL,

THE SKETCHES BELOW COMPARE THE EFFECTS OF WATER-WASHABLE ANO POST-

EMULSIFICATION PENETRANTS

Wow ss isconTINuIcs. A SOOM

-

merece

«eae

(A) WATER-WASHABLE. (8) POST-EMULSIFICATION

DEVELOPER APPLICATION

‘SOME INDICATIONS MAY BE VISIBLE PRIOR TO THE APPLICATION OF & DEVELOPER,

SUT THIS STEP WILL ENSURE THAT ALL DISCONTINUITIES ARE VISIBLE TO THE

NAKED EYE,

DEVELOPING IS ACCOMPLISHED WHEN A HIGHLY ABSORBENT POWDER IS APPLIED

TO THE ITEM BEING TESTED AFTER EXCESS PENETRANT IS REMOVED.

THE PENETRANT IS ACTUALLY DRAWN QUT OF THE DISCONTNUITY BY THE

STRONG CAPILLARY ACTION OF THE DEVELOPER

AS SHOWN ABOVE, THE IMAGE OF THE DISCONTINUITY IN THE OEVELOPER WILL

ACTUALLY BE LARGER THAN THE ACTUAL SIZE OF THE DISCONTINUITY

THERE ARE TWO COMMON TYPES OF DEVELOPERS IN USE TODAY—WET AND DRY.

OTH USE A WHITE POWDER AND THE PRIMARY DIFFERENCE IS IN THE METHOD OF

APPLICATION, oe es

1. WET DEVELOPERS:

‘A, THE NONAQUEOUS DEVELOPER IS HELO IN SUSPENSION IN A SOLVENT.

BASE AND IS USUALLY SUPPLIED IN PRESSURIZED CANS,

ANOTHER TYPE OF WET DEVELOPER HOLDS THE WHITE POWDER IN

SUSPENSION IN A WATER BASE.

THIS TYPE OF WET DEVELOPER IS GENERALLY USED WITH WATER:

WASHABLE OR P. E. PENETRANTS ANO IS APPLIED BY DIPPING OR SPRAY.

ING. AFTER APPLICATION, A SHORT TIME 1S ALLOWED FOR THE WATER TO

EVAPORATE LEAVING A THIN LAYER OF WHITE POWDER IF AN OVEN IS

USED, THE TEMPERATURE SHOULD NOT EXCEED ABOUT 225 F AS THIS

COULD EVAPORATE PENETRANT IN THE DISCONTINUITY

2. DRY DEVELOPERS

[A DRY DEVELOPER IS A FLUFFY WHITE POWDER THAT (S NOT CARRIED IN A

uu,

DRY DEVELOPERS ARE APPLIED DIRECTLY TO THE ARTICLE AS A POWDER.

THIS IS USUALLY CONE WITH SLIGHT AIR PRESSURE OR ARTICLES MAY BE

DIPPED INTO A CONTAINER OF DRY DEVELOPER,

ITIS VERY NECESSARY TO HAVE A DRY SURFACE PRIOR TO APPLICATION OF

‘A DRY POWDER. A WET SURFACE WILL RESULT IN UNEVEN LAYERS OF

POWDER -

DRY DEVELOPER IS USUALLY USED ON FLUORESCENT PENETRANTS.

‘ADVANTAGES OF ““WET"" DEVELOPERS

BETTER ON SMOOTH SURFACES WHERE THE ORY DEVELOPER WILL NOT

ADHERE.

WHEN A WIDE, SHALLOW DISCONTINUITY IS SOUGHT, A WET DEVELOPER WILL

LEAVE A MORE EVEN COAT OF DEVELOPER

ADVANTAGES OF "DRY" DEVELOPERS

ON ROUGH SURFACES, AND ON SHARP FILLETS, HOLES, AND THREADED AR.

TICLES, THE WET DEVELOPER TENDS TO LEAVE TOO MUCH DEVELOPER,

LESSON 4

mung seamed onan too kng ane sadam, ptt

uring the rns cycle, an emus ie ace lo &savenremovabb penetant 0 make it water

Waler-washable peneants havea bull envi

Pos emulsification penetrants are commonly avaabe n bol vable and WMorescent dyes

‘Te penevan removal oracess win waterwashable peneirans i very ec! because of he

anger suowensah salle

SoWvaniramonatie penetans ae common utes because tay wl withstand & very force

water wash winou! Ie cenge of over wasn,

7 lpeng the pal a tank o soventsouon,

Wet daveloners are usualy chosen ove a dry dovelope or use cma smooth sce

A major advaniage one ory developer over wet fat i wil no owe the sre arti of ex:

ets buloup m Bveads and

‘The emsteaion me requred io dete! wid or shalow cicontndes is wsuaty lenge ha

To avoid overwash whan usig water washable peetrans the wale soraynozl is wsialy

nel a 3 80" angi tothe srlace.

len using a waterwashablepereanl the pat must be completes died # a oven ino

‘rcets of 226° F belore the wet dveope Care apmies

‘A mejor edvniage of 2 nonaqueous developer i al # can be spo 0 stats heated

shove 225" FwiPou! evaporation on he devloze vehcl

Soventremowable horescent pentrants reque he ute o 2 ater me-corsumng meth of

Posters visti dye penevants commonly ute both wel and oy developers

LESSON 5

THIS LESSON DISCUSSES THE FINAL STEPS IN THE PENETRANT PROCESS: INSPEC.

TION, EVALUATION, POSTCLEANING, AND MATERIAL CONTROL.

INSPECTION

PROPER LIGHTING SHOULO BE

AN ARTICLE,

|. IF A FLUORESCENT DYE PENETRANT IS USED, A ROOM OR BOOTH WITH DIM

LIGHT AND A BLACK LIGHT WITH PROPER INTENSITY ARE REQUIRED,

2. IF A VISIBLE DYE PENETRANT IS USED, ADEQUATE NORMAL LIGHTING IS

NECESSARY.

{E FIRST CONSIDERATION IN THE INSPECTION OF

TYPICAL INDICATIONS IN PENETRANT INSPECTION

__ALL INDICATIONS FOUND WITH THE LIQUID. PENETRANT. METHOD WILL BE SUR-

FACE DISCONTINUITIES, BUT THE INDICATIONS MAY OR MAY NOT AFFECT THE

USEFULNESS OF THE ARTICLE,

FALSE INDICATIONS.

THE MOST COMMON SOURCE OF FALSE INDICATIONS IS POOR WASHING.

THE OPERATOR CAN EASILY TELL WHEN A GOOD RINSE IS OBTAINED BY US-

ING A BLACK LIGHT DURING AND AFTER THE FLUORESCENT PENETRANT

REMOVAL PROCESS,

seentason §

TO AVOID FALSE INDICATIONS, CARE SHOULD BE TAKEN SO THAT NO OUTSIDE

CONTAMINATION SUCH AS THE FOLLOWING OCCURS.

1. PENETRANT ON OPERATOR'S HANDS,

2. CONTAMINATION OF DEVELOPER.

3. PENETRANT TRANSFERRED TO CLEAN SPECIMEN FAOM OTHER INDICATIONS

4 PENETRANT ON INSPECTION TABLE,

‘Typleal False ts

NONRELEVANT INDICATIONS,

NONAELEVANT INDICATIONS ARE ACTUAL SURFACE DISCONTINUITIES THAT IN

MOST CASES ARE THERE BY DESIGN. THEY ARE CAUSED BY SOME FEATURE OF

ASSEMBLY SUCH AS ARTICLES THAT ARE PRESS-FITTED, KEYED. SPLINED, OR

IVETED,

NONRELEVANT INDICATIONS COULD ALSO INCLUDE LOOSE SCALE OR A ROUGH

‘SURFACE ON A FORGING OR CASTING,

TRUE INDICATIONS

(SOME TYPICAL INDICATIONS ARE SHOWN IN CHAPTER 6, PAGES 8-19 IN THE

TRAINING HANDBOOK)

TRUE INDICATIONS ARE THOSE CAUSED BY SURFACE DISCONTINUITIES THAT

HAVE BEEN INTERPRETED AS NOT BEING FALSE OR NONRELEVANT.

TRUE INDICATIONS ARE SUBJECT TO EVALUATION AS TO THE CAUSE AND THE

EFFECT THEY WILL HAVE ON THE SERVICE LIFE OF THE ARTICLE

TRUE INDICATIONS-COULD -8E-DIVIDED INTO FIVE-BASIC-CATEGORIES:

1. CONTINUOUS LINE—THIS TYPE OF INDICATION IS OFTEN CAUSED BY CRACKS,

‘COLD SHUTS, FORGING LAPS, SCRATCHES, OR DIE MARKS.

2, INTERMITTENT LINE—THESE INDICATIONS COULD BE CAUSED BY ANY OF THE

DISCONTINUITIES MENTIONED ABOVE PROVIDED THEY WERE VERY TIGHT OR.

WHERE THE PART HAD BEEN PEENED, MACHINED, OR GROUND.

3, ROUND—USUALLY CAUSED 8Y POROSITY OPEN TO THE SURFACE.

4. SMALL DOTS—TINY ROUND INDICATIONS CAUSED BY THE 20ROUS NATURE

OF THE SPECIMEN, COARSE GRAIN STRUCTURE, OR MICRCSHRINKAGE,

5, DIFFUSED OR WEAK—THESE INDICATIONS ARE DIFFICULT TO INTERPRET AND

OFTEN THE PART MUST BE CLEANED AND RETESTED. IN MANY CASES THE

DIFFUSED OR WEAK INDICATIONS TURN OUT TO BE FALSE INDICATIONS

CAUSED BY AN IMPROPER PENETRANT PROCEDURE,

DEPTH DETERMINATION OF PENETRANT DISCONTINUITIES

THE GREATER THE DEPTH OF A DISCONTINUITY, THE MORE PENETRANT IT WILL.

HOLD AND THE LARGER AND BRIGHTER THE INDICATION.

POSTCLEANING

AFTER THE SPECIMEN HAS BEEN INSPECTED IT |S VERY IMPORTANT THAT IT BE

THOROUGHLY CLEANED, POSTCLEANING USUALLY WILL INVOLVE THE SAME

TYPES OF CLEANING OPERATIONS AS WERE USED IN PRECLEANING.

son's

QUALITY CONTROL OF PENETRANT TEST MATERIALS

ALUMINUM TEST BLOCKS—THEY PROVIDE & GOOD MEANS 2F EVALUATING

GENERAL PURPOSE PENETRANTS. THEY SHOULD BE USED FOR COMPARISONS

ONLY AND NOT FOR ABSOLUTE EVALUATIONS,

THESE 8LOCKS ARE NONUNIFORM, AND THE OEPTH AND WIDTH OF CRACKS ARE

UNCONTROLLED THE SIZE OF THE BLOCKS MAY VARY BUT ARE ABOUT 3/8 BY 2

INCHES OF 2024.T-3 ALUMINUM, ABOUT 3 INCHES LONG.

THE BLOCKS ARE HEATED AND QUENCHED TO PRODUCE AN OVERALL CRACK PAT:

TERN. THEY CAN BE REUSED BY REHEATING, QUENCHING. ANO CAREFUL CLEAN.

ING

PENETRANT

2

PENETRANT

SLOT IN

Test BLOCK

SENSITIVITY TESTS—WHILE THERE HAVE SEEN NO SIMPLE QUANTITATIVE TESTS.

DEVELOPED FOR MEASURING PENETRANT SENSITIVITY, A SIMPLE COMPARATIVE

TEST IS USUALLY ADEQUATE,

‘A SMALL SAMPLE OF THE PENETRANT FROM THE TESTING AREA IS PLACED ON

ONE SIDE OF AN ALUMINUM TEST BLOCK. AND A SMALL SAMPLE OF NEW

PENETRANT ON THE OTHER SIDE. BY VISUAL OBSERVATION IT IS DETERMINED IF

THE OLD PENETRANT IS CONTAMINATED TO THE POINT WHERE iT MUST BE

DISCARDED.

tesisn §

MENISCUS TEST—FROVIDES A PRACTICAL TEST FOR EVALUATING THE DYE CON:

(CENTRATION IN THIN-LIQUIO FILMS.

THE TEST UTILIZES A FLAT GLASS PLATEN AND A CONVEX LENS WHEN A OROP OF

SOLUTION IS PLACED BETWEEN THE LENS AND PLATEN, A COLORLESS OA

NONFLUORESCENT SPOT IS FORMED AROUND THE POINT OF CONTACT. THE

RESULTANT CONTACT ANGLE SIMPLY INDICATES THE ABILITY OF A LIQUID TO WET

[A SURFACE,

‘THE DIAMETER OF THE REMAINING “SPOT” OF COLORLESS PENETRANT PROVIDES

‘A MEASURE OF FILM THICKNESS WHICH CAN BE USED TO COMPARE THE DYE

~~ GONCENTRATION OF PENETRANTS. PROLONGED EXPOSURE OF A FILM TO

ULTRAVIOLET LIGHT OR ACCIDENTAL CONTAMINATION BY ACIOS OR ALKALIS WILL

AFFECT THE DYE CONCENTRATION AND THEREFORE CHANGE THE SPOT

DIAMETER,

contact spot,

angle Tens

a Tater

CERAMIC BLOCK TEST—CONSISTS OF AN UNGLAZED CERAMIC DISC WHICH HAS

THOUSANDS OF MICROPORES AND CRACKS ON ITS SURFACE

A PENCIL MARK IS MADE ON THE BLOCK AND A SMALL AMOUNT OF A TEST

~PENETRANT IS PLACED ON ONE SIE AND A REFERENCE PENE-RANT IS APPLIED

TO THE OTHER SIDE. AFTER THE CORRECT DWELL TIME, THE TWO PENETRANTS

ARE COMPARED IN A SIDE-BY-SIDE VISUAL EXAMINATION.

‘A REDUCTION’IN THE NUMBER OR APPARENT BRIGHTNESS OF PORE INDICATIONS

SHOULD BE OBSERVED WHEN COMPARING A FRESH AND OLD BATCH OF

PENETRANT.

WATER CONTENT TEST—THE ASTM STANDARD 0-95 DESCRIBES A TEST WHERE

100 ML OF PENETRANT IS PLACED IN A BOILING FLASK WITH A SMILAR QUANTITY

(OF MOISTURE-FREE XYLENE. THE CONDENSATE IS COLLECTED IN A GRADUATED

TUBE TO SHOW PERCENT OF WATER BY VOLUME

IF PERCENT OF WATER EXCEEDS MANUFACTURERS’ RECOMMENDATIONS, THE

PENETRANT IS DISCARDED.

VISCOSITY TEST—A VISCOMETER TUBE IS USED TO MEASURE THE VISCOSITY IN

CENTISTOKES TO DETERMINE IF THE PENETRANT IS WITHIN THE RANGE RECOM:

MENDED BY THE MANUFACTURER. A TYPICAL STANDARD IS ASTM 0-445.

FLUORESCENT PENETRANT FADE TEST—THIS TEST INVOLVES THE USE OF THE

ALUMINUM TEST BLOCKS IN A SIDE-BY-SIDE COMPARISON TEST

"THE FLUORESCENT PENETRANT IS PLACED ON BOTH SIDES OF THE BLOCK AND

PROCESSED NORMALLY. ONE HALF OF THE BLOCK IS THEN EXPOSED TO A STAN:

DARD BLACK LIGHT FOR ONE HOUR, WHILE THE OTHER SIDE 1S COVERED WITH

PAPER,

THE FLUORESCENT BRILLIANCE OF THE TWO SIDES IS OBSERVED AND, IF ONE

SIDE IS NOTICEABLY LESS BRILLIANT, THE PENETRANT IS DISCARDED.

WATER WASHABILITY TEST—THIS TEST EVALUATES THE EFFICIENCY OF THE

EMULSIFIER BY COMPARING TWO DIFFERENT PERCENTAGE BLENDS OF

PENETRANT AND EMULSIFIER

A SPECIAL STEEL BLOCK IS PLACED AT A 75° ANGLE AND THE TWO BLENDS ARE

ALLOWED TO FLOW SEPARATELY DOWN THE BLOCK, AFTER A FIVEMINUTE

"WAITING PERIOD. THE BLOCK IS WASHED AND EXAMINED FOR TRACES OF REMAIN.

ING PENETRANT.

DEVELOPERS—DRY DEVELOPERS ARE SIMPLY VISUALLY INSPECTED TO SEE THAT

THEY ARE NOT LUMPY OR CAKED INSTEAD OF FLUFFY ANO LIGHT.

WET DEVELOPERS ARE OFTEN CHECKED USING A HYDROMETER TO ASSURE THAT

THE DENSITY OF THE POWDER IN THE VEHICLE IS WITHIN THE RANGE RECOM.

MENDED BY THE MANUFACTURER,

FILTERED PARTICLE METHOD OF PENETRANT INSPECTION—WHEN TESTING &

POROUS SURFACE WITH FILTERED PARTICLES, THE INCREASED AREA CREATED BY

A CRACK WILL “FILTER" THE PENETRANT, LEAVING THE PARTICLES ON THE SUR

FACE

7)

aa

ane

Lesson 5

‘type! face inca could be cause By an assemay tht requres in component o be

Nenvelvantneiotons cous be caused by he rough surtace ona easing

Postlering necessary eny when the part mus Be rlesed by te quid penerant mato,

[A typcal te incaton producing round ication common ceed by nora,

Diluted or weak indeatens ere ton causes by subsurace lsconinuties, andthe pat must

be ralesieg using a ighy seraive pnelan hl wit penetrate gra true,

rue iniceons ar usualy hase el requ evaluation Yo delorine Wer act onthe wervies

He othe pa

“Te aun tes Blocks uses penevant evasion are ested ra avenchad wale 0 ro:

‘The senaivy tests used in enetrant inpecton ar riatvely imo, nanquanistve, and

ure sie-by sce viva observation,

The meniscus ost utes lt glass ten and convex len fo determine the ae concent:

ton of vise o Huorescentpenevant

‘Te ceramic block lest uses an unfired ceramic dsc le deteming the apcerent brightness o he

| spac steel block, paced ata 7 angi

Dry developers ae often checkad with a nyerometer one tal hay are ei ight and lly

‘and not sete io a Gense mature

‘Te tuorscont penetran tide ist usualy makes use ofthe amin aa blocks 10 pet

he tered partie meio of penevant inspection used eta fa INorescent patil na wil

not pass tough a #120 seve,

‘The daptn oa dlscontnuty can be comoared by cbservng the relate iz or beghiness of he

incaton

Penetrant that has been wransfered to a clean ari rom the cation on anata aie can

cause ase ateaton

Nenslevantneeation olten are ati! scace dscontenies,

If ascominaty i avatisted 98 being a Yue hatin, the ate shoud auomacahy bere:

inci

a used 1 check the actvaness ofthe

LESSON 6

THIS LESSON DISCUSSES TYPES OF DISCONTINUITIES THAT CAN BE EVALUATED

WITH THE LIQUID PENETRANT METHOD.

DISCONTINUITIES CAN BE DIVIDED INTO THREE GENERAL CATESORIES: INHERENT.

PROCESSING, AND SERVICE.

1. INHERENT—THEY ARE USUALLY RELATED TO DISCONTINUITIES FOUND IN THE

MOLTEN METAL.

INHERENT WROUGHT DISCONTINUITIES RELATE TO THE MELTING AND

SOLIDIFICATION OF THE ORIGINAL INGOT BEFORE IT IS FORMED INTO SLABS,

BLOOMS, AND BILLETS.

INHERENT CAST DISCONTINUITIES RELATE TO THE MELTING, CASTING, AND

SOLIDIFICATION OF A CAST ARTICLE. USUALLY CAUSED BY INHERENT

VARIABLES SUCH AS INADEQUATE FEEDING, GATING, EXCESSIVE POURING

TEMPERATURE, AND ENTRAPPED GASES,

2. PROCESSING DISCONTINUITIES—THEY ARE USUALLY RELATED TO THE

VARIOUS MANUFACTURING PROCESSES SUCH AS MACHINNG, FORMING, EX:

TRUDING, ROLLING, WELDING, HEAT TREATING, AND PLATING

3. SERVICE DISCONTINUITIES—THEY ARE RELATED TO THE VARIOUS SERVICE

CONDITIONS SUCH AS-STRESS- CORROSION: FATIGUE” ANO-EROSION-—

REMEMBER, WHEN YOU USE THE LIQUID PENETRANT METHOD. YOU CAN FIND

ONLY THOSE DISCONTINUITIES WHICH ARE OPEN TO THE SURFACE.

HOWEVER, DURING THE MANUFACTURING PROCESS, MANY DISCONTINUITIES THAT

WERE SUBSURFACE CAN BE MADE OPEN TO THE SURFACE SY NACHINING, GRIND:

ING, ANO THE LIKE,

REMEMBER THAT DISCONTINUITIES ARE NOT NECESSARILY DEFECTS. ANY INDICA.

TION THAT IS FOUND BY THE INSPECTOR IS CALLED A DISCONTINUITY UNTIL IT CAN

BE IDENTIFIED AND EVALUATED AS TO THE EFFECT IT WILL HAVE ON THE SERVICE

OF THE PART.

LISTED BELOW ARE SOME TYPICAL DISCONTINUITIES THAT SHOULD SE RECOG.

NIZED WHEN OOING ANY TYPE OF NONDESTRUCTIVE TEST. (& MORE DETAILED

STUDY OF TYPICAL DISCONTINUITIES CAN BE OBTAINED EY READING PRO.

GRAMMED INSTRUCTION HANDBOOK Pi-4-1.)

DISCONTINUITIES-TRAPPED-IN-THE-INGOT-OURING-THE-STEELMAKING PROCESS

MAY CAUSE ADDITIONAL TYPES OF DISCONTINUITIES AS THE STEEL IS USED IN THE

MANUFACTURE OF AN ARTICLE,

THERE ARE THREE MAIN TYPES OF DISCONTINUITIES FOUND IN INGOTS.

1. PoRosiTy—causED ay

ENTRAPPED GAS IN THE MOLTEN

a a

2. NONMETALLIC INCLUSIONS—CAUSED fnfcitsows

BY IMPURITIES ACCIDENTALLY IN-

CLUDED IN THE MOLTEN METAL.

IPE—CAUSED BY SHRINKAGE AT THE

‘CENTER OF THE INGOT AS THE

MOLTEN METAL SOLIDIFIES.

THE "HOT TOP" IS USUALLY CROPPED OFF TO REMOVE MOS" OF THE ABOVE

DISCONTINUITIES,

WHEN AN INGOT IS FURTHER PROCESSED INTO SLABS, SLOOMS, AND BILLETS, 1T

'S POSSIBLE FOR THE DISCONTINUITIES TO CHANGE SIZE AND SHAPE.

AS A BILLET IS FLATTENED AND SPREAD OUT, NONMETALLIC INCLUSIONS MAY

CAUSE A LAMINATION. PIPE AND POROSITY COULD ALSO CAUSE LAMINATIONS INV

THE SAME MANNER AS SHOWN BELOW:

AS A BILLET IS ROLLED INTO BAR STOCK, NONMETALLIC INCLUSIONS ARE

SQUEEZED OUT INTO LONGER AND THINNER DISCONTINUITIES CALLED STRINGERS,

Pr Lecture cuce

AS A BILLET IS ROLLED INTO ROUND BAR STOCK, SURFACE IRAZGULARITIES MAY

CAUSE SEAMS. SEAMS ARE CAUSED BY FOLDING OF METAL OUE TO IMPROPER,

ROLLING OR BY A CRACK IN THE BILLET AS SHOWN BELOW:

‘A SEAM COULD ALSO OCCUR WHEN THE BILLET IS FORMED INTO A RECTANGULAR

BAR AS SHOWN BELOW:

Pr Leche Gace

FORGING DISCONTINUITIES OCCUR WHEN METAL IS HAMMERED OR PRESSED INTO

SHAPE, USUALLY WHILE THE METAL IS VERY HOT.

‘A FORGED PART GAINS STRENGTH OUE TO THE GRAIN FLOW TAKING THE SHAPE

OF THE DIE, AND THE PROCESS IS SHOWN BELOW.

‘A FORGING LAP IS CAUSED BY FOLDING OF METAL ON THE SUFACE OF THE

FORGING, USUALLY WHEN SOME OF THE FORGING METAL IS SQUEEZED OUT

BETWEEN THE TWO DIES.

GZ

A FORGING BURST IS A RUPTURE CAUSED BY FORGING AT IMPROPER

TEMPERATURES. BURSTS MAY. BE EITHER INTERNAL OR-OPEN-"O-THE SURFACE

|AS SHOWN BELOW.

“or cer on eta

CASTING DISCONTINUITIES OCCUR WHEN MOLTEN METAL IS POURED INTO A MOLD.

AND ALLOWED TO SOLIDIFY.

A COLD SHUT IS CAUSED WHEN MOLTEN METAL IS POURED OVER SOLIDIFIED

METAL AS SHOWN BELOW:

HOT TEARS (SHRINKAGE CRACKS) OCCUR WHEN THERE IS UNEQUAL SHRINKAGE

BETWEEN LIGHT AND HEAVY SECTIONS AS SHOWN BELOW:

SHRINKAGE CAVITIES ARE USUALLY CAUSED BY LACK OF ENOUGH MOLTEN

METAL TO FILL THE SPACE CREATED BY SHRINKAGE, SIMILAR “O PIPE IN THE IN

Gor.

[esse

MICROSHRINKAGE IS USUALLY MANY SMALL SUBSURFACE HOLES THAT APPEAR

AT THE GATE OF THE CASTING.

MICROSHRINKAGE CAN ALSO OCCUR WHEN. THE MOLTEN METAL MUST FLOW

FROM A THIN SECTION INTO THICKER SECTION OF A CASTING.

BLOW HOLES ARE SMALL HOLES AT THE SURFACE OF THE CASTING CAUSED BY

GAS WHICH COMES FROM THE MOLD ITSELF, MANY MOLDS ARE MADE OF SAND,

AND WHEN MOLTEN METAL COMES INTO CONTACT WITH THE MOLD, THE WATER

IN THE SAND IS RELEASED AS STEAM.

POROSITY IS CAUSEO BY ENTRAPPED GAS. POROSITY IS USUAL.Y SUBSURFACE

BUT CAN OCCUR ON THE SURFACE DEPENDING ON THE DESIGN OF THE MOLD.

GRINDING CRACK. ARE A PROCESSING-TYPE DISCONTINUTY CAUSED BY

STRESSES WHICH ARE QUILT UP FROM EXCESS HEAT CREATED BETWEEN GRINO-

ING WHEEL AND METAL.

GRINDING CRACKS WILL USUALLY OCCUR AT RIGHT ANGLES TO THE ROTATION

OF THE GRINDING WHEEL

HEAT TREAT CRACKS ARE OFTEN CAUSED SY THE STRESSES BUILT LS OURING

HEATING AND COOLING. UNEQUAL COOLING BETWEEN LIGHT AND HEAVY SEC.

TIONS MAY CAUSE HEAT TREAT CRACKS.

HEAT TREAT CRACKS HAVE NO SPECIFIC DIRECTION AND USUALLY START AT

SHARP CORNERS WHICH ACT AS STRESS CONCENTRATION POINTS.

FATIGUE CRACKS ARE SERVICE-TYPE OISCONTINUITIES THAT ARE USUALLY OPEN

TO THE SURFACE WHERE THEY START FROM CONCENTRATION POINTS,

FATIGUE CRACKS ARE POSSIBLE ONLY AFTER THE PART IS PLACED INTO SERVICE,

BUT MAY BE THE RESULT OF POROSITY, INCLUSIONS OR OTHER OSCONTINUITIES

IN A HIGHLY STRESSED METAL PART.

=

WELDING DISCONTINUITIES—THE FOLLOWING ARE TYPES OF “PROCESSING

DISCONTINUITIES.

CRATER J ceaysverse

cracks

STRESS CRACK

POROSITY

SLAG INCLUSIONS

TUNGSTEN

INCLUSIONS

SSS

SE

Lack oF

PENETRATION

S&S

LACK OF FUSION CL EE

UNDERCUT LLL os DA

estan ?

AFTER REVIEWING THE PHOTOGRAPHS AND DESCAPTIONS OF TYPICAL DISCON-

TINUTIES I> SHOULD BE OBVIOUS THAT LIQUD PENETRANT INSPECTION 18 NOT

THE BEST METHOD IN ALL CASES.

THE SELECTION OF ONE TESTING METHOD OVER ANOTHER IS BASED UFON

VARIABLES SUCH AS

{TYRE AND ORIGIN OF DISCONTINUITY

2. MATEFIAL MANUFACTURING PROCESS.

9. ACCESSIBILITY OF ARTICLE

4. LEVEL OF ACCEPTABILITY DESIRED

5. EQUIPMENT AVAILABLE

6. cost

TRAINING AND CERTIFICATION

IT IS IMPORTANT THAT THE TECHNICIAN AND SUPERVISOR SE QUALIFIED IN THE

UQUID PENETRANT METHOD SEFORE THE TECHNIQUE IS USED ANC TEST RESULTS

EVALUATED,

THE AMERICAN SOCIETY FOR NONDESTRUCTIVE TESTING RECOMMENDS THE USE

OF ITS DOCUMENT RECOMMENDED PRACTICE NO. SNT-TC-1A.

THIS DOCUMENT PROVIDES THE EMPLOYER WITH THE NECESSARY GUIDELINES

TO PROPERLY QUALIFY AND CERTIFY THE NOT TECHNICIAN IN ALL METHODS,

TO COMPLY WITH THIS DOCUMENT THE EMPLOYER MUST ESTABLISH A ““WRIT-

TEN PRACTICE” WHICH DESCRIBES IN DETAIL HOW THE TECHNICIAN WILL BE

‘TRAINED, EXAMINED, AND CERTIFIED,

THE STUDENT IS ADVISED TO STUDY PAGE 6 OF THE JUNE 1975 EDITION OF SNT-

TO-18 TO DETERMINE THE RECOMMENDED NUMBER OF HOURS OF CLASSROOM

INSTRUCTION AND MONTHS OF EXPERIENCE NECESSARY TO BE CERTIFIED AS A

LIQUID PENETRANT TESTING TECHNICIAN.

Cosson?

CERTIFICATION OF NDT PERSONNEL IS THE RESPONSIBILITY OF THE EMPLOYER

AND IS USUALLY AT THREE LEVELS.

LEVEL IIS QUALIFIED TO PERFORM SPECIFIC CALIBRATIONS, SPECIFIC TESTS,

AND SPECIFIC EVALUATIONS ACCORDING TO WRITTEN INSTRUCTIONS,

I-18 QUALIFIED TO SET UP AND CALIBRATE EQUIPMENT AND TO INTER:

PRET AND EVALUATE RESULTS WITH RESPECT TO CODES, STAN.

DARDS, AND SPECIFICATIONS, MUST BE ABLE TO, PREPARE WRITTEN

INSTRUCTIONS AND REPORT TEST RESULTS.

LEVEL: I=MUST BE-CAPABLE “ANO”RESPONSIBLE FOR ESTABLISHING TECH:

NIQUES, INTERPRETING CODES, AND OESIGNATING THE TEST METHOD

AND TECHNIQUE TO BE USED. MUST HAVE A PRACTICAL BACK-

GROUND IN THE TECHNOLOGY AND BE FAMILIAR WTH OTHER COM.

MONLY USED METHODS OF NOT.

LeveL

THE SNT-TC-1A DOCUMENT RECOMMENDS THAT THE NOT TECHNICIAN BE

EXAMINED IN THE FOLLOWING AREAS:

‘A. GENERAL EXAMINATION

8. SPECIFIC EXAMINATION

. PRACTICAL EXAMINATION

ASNT PROVIDES A SERVICE TO THE INOUSTRY BY PROVIDING LEVEL Ill EXAMINA.

TIONS IN THE GENERAL AND PRACTICAL AREAS. BECAUSE OF THE INDIVIDUAL 7E.

QUIREMENTS OF THE MANY INDUSTRIES USING NOT, THE SPECIFIC EXAMINATION

'S STILL THE RESPONSIBILITY OF THE EMPLOYER, THE FOLLOWING FLOW CHART

INDICATES THE PATHS THAT CAN BE TAKEN TO BE CERTIFIED ACCORDING TO THE

‘SNT-TO-1- DOCUMENT

Lesson 7

ure

‘tod over another i usualy Ihe decision! he Level eeticisn

percrmig net

ASNT pronces a

‘he tesponsbilly of ssing a ceria fo he NDT lectin i nays given to fe employer

the SHTTC-1A documento bs comied wih,

ce ler examining Level, andl personna nthe Genera and Specie

{the SNT-TC-1A docuren! iso be used a0 a racommended guideline, he Willen Practice

‘rus be submited to ASNT lor sporva

the SNT-TC-1A guidlines ae 1s be Lowes, Ine Lovell tecnico sould havea knows

‘toler commonly used methods of NOT eventhough carillon i needed! ey fe Vad

‘A Levelt tecnica performing» laud peneban! esis permite to acepl or alec he part

povided ta wile msiuctons 2 recede we given Io hm bya Lever Lave! er

ed ina

‘To comly wih the guidelines of SNI-TC:1A, al tre levele ol tecticons must tke a General,

Practcal, and Specie lel exarinatons are used to determine cetieion

‘he June 1978 econ of SNT-TC:1A permis the employer lo waive an mxaninaion for Level

bersomel provided tal docimeniatn sn ile showing the lechnicar’squaifintons

Ni sent! hat every employer using the SNT-TC-1A document eslaish a Wien Pract,

{1 an employer does not have a Level lachien a ie company, he ea lan the services of

te eutede agency to ertrm these hnclons

LESSON 7

IDENTIFICATION AND COMPARISON OF DISCONTINUITIES THAT CAN BE FOUND

WITH THE LIQUID PENETRANT PROCESS.

THE STUDENT IS ASKED TO STUDY THE PHOTOGRAPHS AND DESCRIPTIONS OF

TYPICAL DISCONTINUITIES AS PRINTED IN THE PT CLASSROOM TRAINING HAND-

BOOK (CT-6-2),

EACH OF THE SPECIFIC DISCONTINUITIES ILLUSTRATED ARE DIVIDED INTO THREE

GENERAL CATEGORIES: INHERENT, PROCESSING, AND SERVICE. :

cou sHuT PAGE 7-10

FILLET CRACK PAGE 7-12

GRINDING CRACKS PAGE 7-15

HEAT-AFFECTED ZONE CRACKING .... PAGE 7-19

HEAT TREAT CRACKS PAGE 7-21

‘SHRINKAGE CRACKS PAGE 7.24

THREAD CRACKS PAGE 7-26

HYDROGEN FLAKE PAGE 7-31

LACK OF PENETRATION PAGE 7-40

LAMINATIONS vanes PAGE 7-42

LAPS AND SEAMS PAGE 7-44

LAPS AND SEAMS PAGE 7-46

MICROSHRINKAGE PAGE 7-49

STRESS CORROSION PAGE 7-55

HOT TEARS PAGE 7-63

INTERGRANULAR CORROSION PAGE 7-68

Lesson 6

ove

1. The genes category of processing scontmutas telat isconntis case aura

imanuactunng processes uch 88 wetng,extuag and Neal Weatng

2, Darn the staimaking arocess the to a ne mgot fuel roves 19 Mele elmeate such

Secontmutes apne, pore and nonmetlic neers

2. wana iets roted ino ba sock, @nanmetaie nlesion could be Yeed ine &nger ane

44 Porosity abit ould cause a laraon ihe metal were lores a Fat pte

5, Seams are usu subswtacesacontnutns caused by proper raing of ial no round

—— 6. Dering the roling ofa bet int ound bar stock, the gran in he metal ams perpendioula 1

the arecton of ing,

7. Inthe tering eperaten, under

©. Forging brats te conscere subeirtace eacontnuties and can never be mspectad with haus

9. Colt shuts are common decontuites found nthe lorgng process anf are caused by hace:

(uate nealing af Ihe lrged pat

10. Blow roles a0 seurace dacontuiies common found neat part

11, Because cold meta! accuses more space nan hol mata here is ne cngar of “ha ees” ou

fg the eating process

12, Porosity is often caused by entapped gBs thats expended during he nating and pressing

the orang process.

13. Meroetvinkage i often found at he gate o casing and is vel subetace.

1 Gini ace are usualy at AEN angi lo ha dracton of grncng a ae caused by ne

heal Buicup belweea the grncing whee and meta,

15, Heat eat cracks are olten associate with tess concent

16. Porosty may lado aiue crack na igh sessed part

17. crater cracks and tngsien incisions are botn aesoctee with dacontmties formes ang he

wang process

16. Lack of penetration and inc o! fusion both rlar othe same type of weksng agcontnuty

1 atl wl nt low Ihe metal to few propery and may

ito poets an the pat being Meat

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

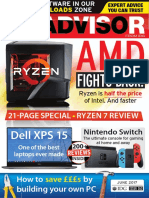

- PC Advisor - June 2017 UK PDFDokumen148 halamanPC Advisor - June 2017 UK PDFgymadniBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Machining TheoryDokumen45 halamanMachining TheorydramiltBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- CSWIP 3.1-2010 The Welding Inspection of SteelDokumen317 halamanCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Fundamentals of CNC MachiningDokumen256 halamanFundamentals of CNC Machiningdig_it100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Seerat QuizDokumen48 halamanSeerat Quizابُوالبَتُول ڈاکٹر صفدر علی قادری رضویBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- PhoneWorld Magazine Feb-March 2015 Edition PDFDokumen31 halamanPhoneWorld Magazine Feb-March 2015 Edition PDFgymadniBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- B.A Eng B Question Wise 2004 To 2014Dokumen19 halamanB.A Eng B Question Wise 2004 To 2014gymadniBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- English Tenses Book in UrduDokumen130 halamanEnglish Tenses Book in UrduMuhammad Iqbal76% (114)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- B.A Eng A Question Wise 2004 To 2014Dokumen17 halamanB.A Eng A Question Wise 2004 To 2014gymadniBelum ada peringkat

- Short Stories NotesDokumen30 halamanShort Stories NotesShahid MahmoodBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Machinist Course Book in UrduDokumen137 halamanMachinist Course Book in UrduursalibabaBelum ada peringkat

- Inspection Plan - NDTDokumen4 halamanInspection Plan - NDTgymadniBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Article EssayDokumen35 halamanArticle EssaygymadniBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- B A NotesDokumen60 halamanB A NotesBasimAhmed60% (5)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Belajar Menggambar 3d Dengan Autocad 2007Dokumen200 halamanBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Mill MaxDokumen23 halamanMill Maxgymadni100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- 5 - Rashid Baloch - Talent RetentionDokumen22 halaman5 - Rashid Baloch - Talent RetentiongymadniBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Presentation Machine Tool LatheDokumen19 halamanPresentation Machine Tool LatheFarah HumaBelum ada peringkat

- Mill MaxDokumen23 halamanMill Maxgymadni100% (1)

- Belajar Menggambar 3d Dengan Autocad 2007Dokumen200 halamanBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Yaseen's document compilationDokumen80 halamanYaseen's document compilationgymadniBelum ada peringkat

- Cone Density Formula On Different DegreesDokumen15 halamanCone Density Formula On Different Degreesgymadni50% (2)

- Cylindrical, Rectangular, and Elliptical Tank Volume CalculatorDokumen8 halamanCylindrical, Rectangular, and Elliptical Tank Volume CalculatorgymadniBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)