Sulphur Production

Diunggah oleh

Vinita Kumari0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan2 halamansingle contact process for sulphur production.

Judul Asli

sulphur production

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inisingle contact process for sulphur production.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

12 tayangan2 halamanSulphur Production

Diunggah oleh

Vinita Kumarisingle contact process for sulphur production.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

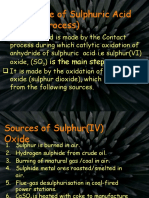

Single Contact Process for sulfur production:

Four stages involved:

Sulfur Burning: Sulfur is fed in the burner where it reacts

with dry air to produce sulfur dioxide (SO2). The air is dried

using concentrated sulfuric acid.

S(s) + O2(g) ==>SO2(g)

H= -297 kj/mol

Oxidation: The sulfur dioxide is oxidised to sulfur trioxide by

oxygen using vanadium(V)oxide as a catalyst.

2SO2(g) + O2(g)

2SO3(g) H= -197 kj/mol

Absorption: Concentrated sulfuric acid is used to dissolve

sulfur trioxide where it forms oleum (H2S2O7) in an absorption

tower.

SO3(g) + H2SO4(l) ==> H2S2O7(l)

Cooling: Oleum is then mixed with water to obtain sulfuric

acid.

H2S2O7(l) + H2O(l) ==> 2H2SO4(l)

Overall Reaction:

SO3(g) + H2O(l) ==> H2SO4(l)

Key points:

Single SO3 absorption tower

Can be operated at low SO2 concentration(6-10% by volume)

Does not meet emission regulation of SO2

Maximum conversion 97.5-98 %

Simple and easy to start up and operate therefore preferred

for new plants

Anda mungkin juga menyukai

- Sulfuric Acid Manufacture: Analysis, Control and OptimizationDari EverandSulfuric Acid Manufacture: Analysis, Control and OptimizationPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Uses of Sulphuric AcidDokumen1 halamanUses of Sulphuric AcidCyrus JethroBelum ada peringkat

- Folio ChemistryDokumen1 halamanFolio ChemistryCayep CullenBelum ada peringkat

- Contact Process: Manufacture of Sulphuric AcidDokumen3 halamanContact Process: Manufacture of Sulphuric AcidfatahleeBelum ada peringkat

- Uses of Sulphuric Acid: SulphurDokumen6 halamanUses of Sulphuric Acid: SulphurHumphrey JinuinBelum ada peringkat

- Manufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessDokumen14 halamanManufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessDian Eka FajriyantoBelum ada peringkat

- Sulfuric AcidDokumen14 halamanSulfuric AcidAkh KreshnaBelum ada peringkat

- Sulphuri C Acid: Manufacturing Substances in IndustryDokumen17 halamanSulphuri C Acid: Manufacturing Substances in IndustryAinin Akasyah AzizBelum ada peringkat

- Non - MetalsDokumen3 halamanNon - MetalsAlex noslenBelum ada peringkat

- Manufactor Acid SulfuricDokumen12 halamanManufactor Acid SulfurictdnguyenBelum ada peringkat

- DCDADokumen23 halamanDCDARushikesh Dhapse80% (5)

- Unit 5Dokumen17 halamanUnit 5JokerBelum ada peringkat

- IntroductionDokumen10 halamanIntroductionAmith Singh J100% (1)

- Sul Phu Ric Aci DDokumen24 halamanSul Phu Ric Aci DBukhari ShafiqBelum ada peringkat

- Chapter 2: Sulfur & Sulfuric Acid Chapter 2: Sulfur & Sulfuric AcidDokumen20 halamanChapter 2: Sulfur & Sulfuric Acid Chapter 2: Sulfur & Sulfuric AcidabichedBelum ada peringkat

- K01587 - 20200217130414 - Chapter 9 - Industrial ChemicalsDokumen54 halamanK01587 - 20200217130414 - Chapter 9 - Industrial ChemicalsAbdulRahim059Belum ada peringkat

- Go 5 Ammonia, Sulphuric Acid, Nitric AcidDokumen21 halamanGo 5 Ammonia, Sulphuric Acid, Nitric AcidcikaifaBelum ada peringkat

- 1.11 CHEM FINAL Chapter 11 Sulfuric AcidDokumen21 halaman1.11 CHEM FINAL Chapter 11 Sulfuric AcidSudhanshuBelum ada peringkat

- All Chemical Reactions 2023Dokumen29 halamanAll Chemical Reactions 2023Aryan MishraBelum ada peringkat

- Sulphuric AcidDokumen21 halamanSulphuric AcidFabian SealeyBelum ada peringkat

- Properties of Sulphuric AcidDokumen3 halamanProperties of Sulphuric AcidTian YinBelum ada peringkat

- Folio Chemistry: Sulphuric AcidDokumen6 halamanFolio Chemistry: Sulphuric AcidmissyunnaBelum ada peringkat

- The Contact Process in The Production of Sulphuric Acid in Chemistry. Additionally There Are Environmental Impacts and The Ways To Prevent Pollution.Dokumen6 halamanThe Contact Process in The Production of Sulphuric Acid in Chemistry. Additionally There Are Environmental Impacts and The Ways To Prevent Pollution.nickola traceyBelum ada peringkat

- 7.8.1 Sulphur Chemistry NotesDokumen6 halaman7.8.1 Sulphur Chemistry NotesbhartiyaanujBelum ada peringkat

- Contact ProcessDokumen12 halamanContact ProcessAdil Yaqub - 74665/TCHR/CNTBBelum ada peringkat

- Sulfuric Acid Obtaining: Ricardo Ocampo SánchezDokumen7 halamanSulfuric Acid Obtaining: Ricardo Ocampo SánchezAgueda ZuñigaBelum ada peringkat

- Ostwald ProcessDokumen2 halamanOstwald ProcessBiru GanBelum ada peringkat

- Fundamentals of Sulfur Recovery by The Claus ProcessDokumen8 halamanFundamentals of Sulfur Recovery by The Claus ProcessAram IbrahimBelum ada peringkat

- Sulfur and Sulfuric AcidDokumen20 halamanSulfur and Sulfuric AcidZakia LuthfianaBelum ada peringkat

- Basic Raw Material For Sulphur Acid ProductionDokumen13 halamanBasic Raw Material For Sulphur Acid ProductionGrace Oluchi0% (1)

- Contact ProcessDokumen4 halamanContact Processlinachouli7654Belum ada peringkat

- Manufacture of Sulfuric Acid Using Contact Process: Prepared By: Moncatar, Merry Marielle MDokumen5 halamanManufacture of Sulfuric Acid Using Contact Process: Prepared By: Moncatar, Merry Marielle MYsabelle JimeneaBelum ada peringkat

- Sulphuric Acids: U O S ADokumen10 halamanSulphuric Acids: U O S AMuhamad Dzul MuazzemBelum ada peringkat

- Sulphuric Acid (H SO4)Dokumen44 halamanSulphuric Acid (H SO4)Faisal Azis RamadhanBelum ada peringkat

- SulfurDokumen6 halamanSulfurSyed HashmiBelum ada peringkat

- Sulphuric Acid: - Poorv, Anya, Maanya, Shruti, Keyur, PrarthanaDokumen7 halamanSulphuric Acid: - Poorv, Anya, Maanya, Shruti, Keyur, PrarthanaKeyur KadiwarBelum ada peringkat

- Stage 1: Preparation of Sulphur DioxideDokumen2 halamanStage 1: Preparation of Sulphur Dioxidenajwasyafiqah_1Belum ada peringkat

- Chemistry Sulphuric Acid SolutionsDokumen7 halamanChemistry Sulphuric Acid SolutionsGurjapsingh SandhuBelum ada peringkat

- (Chapter 9) Manufactured Subtances in Industry: Ravien Alvin Yoges Chan Wai HonDokumen8 halaman(Chapter 9) Manufactured Subtances in Industry: Ravien Alvin Yoges Chan Wai HonSharvien RajamanikamBelum ada peringkat

- Jenish PatelDokumen12 halamanJenish PatelHirenBelum ada peringkat

- Chemistry-Folio Form 4Dokumen45 halamanChemistry-Folio Form 4Ahmad Izzat Mohd HanafiBelum ada peringkat

- 2 Sulphur and Sulphuric Acid IndustriesDokumen39 halaman2 Sulphur and Sulphuric Acid IndustriesChuka OmeneBelum ada peringkat

- Contact ProcessDokumen16 halamanContact ProcessOmar Almonte100% (1)

- Sulphur: Sulphur: Sources and UsesDokumen4 halamanSulphur: Sulphur: Sources and UsesDavies MasumbaBelum ada peringkat

- All Chemical ReactionsDokumen29 halamanAll Chemical ReactionsManeet SinghBelum ada peringkat

- Topic 13 EquilibrumDokumen6 halamanTopic 13 EquilibrumalskdfjpoiuwekljBelum ada peringkat

- Sulphur Recovery UnitDokumen1 halamanSulphur Recovery UnitKmt_AeBelum ada peringkat

- Chemistry - SulphurDokumen2 halamanChemistry - Sulphurwebsurfer755Belum ada peringkat

- Sulphuric Acids: Group Members: Samoi Oladipo Alliyah LindsayDokumen11 halamanSulphuric Acids: Group Members: Samoi Oladipo Alliyah Lindsaysamoi oladipoBelum ada peringkat

- ChemistryDokumen11 halamanChemistryEttaBelum ada peringkat

- Selina Sol Concise Chem Class 10 CH 11Dokumen7 halamanSelina Sol Concise Chem Class 10 CH 11StBelum ada peringkat

- Crude OilDokumen8 halamanCrude OilAathifa ThowfeekBelum ada peringkat

- StageDokumen1 halamanStageJenice ChongBelum ada peringkat

- Haber Process and Contact ProcessDokumen4 halamanHaber Process and Contact Processmya thet htar sweBelum ada peringkat

- Acid BaseDokumen18 halamanAcid BasechaitanyaBelum ada peringkat

- Uses of Sulphuric AcidDokumen14 halamanUses of Sulphuric AcidFaizul FaiiziBelum ada peringkat

- Production of Sulfuric AcidDokumen29 halamanProduction of Sulfuric Aciddeshaka11Belum ada peringkat

- Chemistry Manufactured Substances in IndustryDokumen81 halamanChemistry Manufactured Substances in Industrynabiellahuda88% (8)

- 2016 New 1Z0 803 Exam Dumps For Free VCE and PDF 61 90 PDFDokumen15 halaman2016 New 1Z0 803 Exam Dumps For Free VCE and PDF 61 90 PDFVinita KumariBelum ada peringkat

- HTML Multiple Choice QuestionsDokumen49 halamanHTML Multiple Choice QuestionsVinita Kumari100% (1)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Diffusion of Water Inside Legume SeedsDokumen2 halamanDiffusion of Water Inside Legume SeedsVinita KumariBelum ada peringkat

- Emission Characteristics of Alternative FuelsDokumen14 halamanEmission Characteristics of Alternative FuelsVinita KumariBelum ada peringkat

- Ce MC AssertionDokumen3 halamanCe MC Assertionapi-3739994Belum ada peringkat

- CH 9Dokumen13 halamanCH 9Tr Mazhar PunjabiBelum ada peringkat

- Acids and BasesDokumen2 halamanAcids and Basesishi.chopra08Belum ada peringkat

- CationsDokumen6 halamanCationsPierce MoralesBelum ada peringkat

- Chem Test No. 4 (Alkyl Halides, Alcohol and Phenols)Dokumen4 halamanChem Test No. 4 (Alkyl Halides, Alcohol and Phenols)fahadmustafa100% (1)

- CHEM1 Q2 M2-Lewis-StructuresDokumen32 halamanCHEM1 Q2 M2-Lewis-StructuresMark TerradoBelum ada peringkat

- Novo NASA (9 Coeficientes)Dokumen253 halamanNovo NASA (9 Coeficientes)bincoleto5536Belum ada peringkat

- Honors Chemistry - Chemical Bonding Practice ExamDokumen5 halamanHonors Chemistry - Chemical Bonding Practice ExamJhon Excell SanoBelum ada peringkat

- Organic Chemistry NotesDokumen24 halamanOrganic Chemistry NotesSweatBelum ada peringkat

- Chem 4Dokumen103 halamanChem 4César Arenas100% (1)

- A + B A + B: Acid Conjugate Base Conjugate Acid BaseDokumen7 halamanA + B A + B: Acid Conjugate Base Conjugate Acid BaseKatrina CagungunBelum ada peringkat

- Recent Comments: Home 01 Neet - Aipmt - Jee Main Mcqs Jee Main, Neet Mcqs Set 20Dokumen5 halamanRecent Comments: Home 01 Neet - Aipmt - Jee Main Mcqs Jee Main, Neet Mcqs Set 20sujayan2005Belum ada peringkat

- Chemical Bonding MCQ 16Dokumen4 halamanChemical Bonding MCQ 16sunBelum ada peringkat

- Chapter 7 - Carboxylic AcidsDokumen8 halamanChapter 7 - Carboxylic AcidsRoy ZahreddineBelum ada peringkat

- Qualitative Analysis Wired ChemistDokumen18 halamanQualitative Analysis Wired ChemistFrances GanotisiBelum ada peringkat

- HydrocarbonDokumen15 halamanHydrocarbonChandrika AnchanBelum ada peringkat

- Amines Jee FormulaDokumen67 halamanAmines Jee Formulanew ganesh storesBelum ada peringkat

- Protein AssignmentDokumen2 halamanProtein AssignmentFRANCISCO, QUENNIE MARIE D.Belum ada peringkat

- 9F. CH Nh2 (0.12 Mole, PK, 3.3) Is Added To 0.08 Moles of HCL and The Solution Is Diluted To SolutionDokumen14 halaman9F. CH Nh2 (0.12 Mole, PK, 3.3) Is Added To 0.08 Moles of HCL and The Solution Is Diluted To SolutionSandipan SamantaBelum ada peringkat

- Experiment 3Dokumen7 halamanExperiment 3Botlhe Kgotla SamBelum ada peringkat

- Coordination Compounds - QuestionDokumen3 halamanCoordination Compounds - Questionbest badmintonBelum ada peringkat

- Counting Atoms Part 1Dokumen14 halamanCounting Atoms Part 1api-271064836Belum ada peringkat

- 5 6091125367966269653 PDFDokumen220 halaman5 6091125367966269653 PDFTrep ChiruBelum ada peringkat

- Basic Organic Nomenclature Packet Honors Chemistry: Name: - BlockDokumen12 halamanBasic Organic Nomenclature Packet Honors Chemistry: Name: - BlockJamaica Calamno SalvadorBelum ada peringkat

- MCQ ChemistryDokumen7 halamanMCQ ChemistryNadherdaman Alshamary0% (1)

- CompleximetryDokumen29 halamanCompleximetrychamp delacruzBelum ada peringkat

- Introduction To Organic Chemistry: 5.3 Acids and BasesDokumen14 halamanIntroduction To Organic Chemistry: 5.3 Acids and BasesLemony SnickitBelum ada peringkat

- Seth Anandram Jaipuria School Revision Test (2021-22), Class-Xii (Topic - Amines)Dokumen2 halamanSeth Anandram Jaipuria School Revision Test (2021-22), Class-Xii (Topic - Amines)vedang agarwalBelum ada peringkat

- A02 355Dokumen68 halamanA02 355jaimeBelum ada peringkat

- 11th Chemistry (EM) - SampleDokumen36 halaman11th Chemistry (EM) - Samplepearlyn0% (1)