Din 53455

Diunggah oleh

hasan_6764896160 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

2K tayangan9 halamanTesting of platics.Tensile test

Judul Asli

DIN 53455

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniTesting of platics.Tensile test

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

2K tayangan9 halamanDin 53455

Diunggah oleh

hasan_676489616Testing of platics.Tensile test

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 9

RE ener WO Mie ae eS

DEUTSCHE NO!

Prifung von Kunststotfen; Zugversuch

‘Supersedes 04.68 edition

As it it current practice in standards published by the International Organization for Stenderdization (/SO), the comma

has been used throughout as a decimal marker.

For connection with draft Standard ISO/DIS 527 ~ 1978 issued by the International Organization for Standardization

{1S0), s@ Explanations.

Dimensions in mm

1 Purpose and field of application ,

1.1. The tensile test in accordance with this standard is

used to assess the behaviour of plastics under uniaxial

tensile stress. The testing is carried out on selected

dependent on the manufacturing conditions for the

specimens and on the test conditions and are thus only

transferable to the behaviour of plastic products under

tensile stress when the stresses occurring at the products

conform to the test conditions for the specimen. The

tensile test in accordance with this standards primarily

tended for quality control. A coniprehensive assess:

ment of the behaviour of plastics under tensile stress is

only possible if physical properties and tensile strength

of testing, temperature, preconditioning).

1.2. The properties which can be de:

with this standard are:

— tensile strength

tensile stress at breake

= yield stress or offset yield stress

— tensile stress at given elongation

= strain at maximum load

= strain at break

— strain at yield stress

Note: The occurrence of a yield stress is dependent on.

the type of material and test conditions,

2 Concepts

the test and is based on the original gauge length Lo of

the specimen,

1) If the type of stress is not obvious from the context,

the symbol o shall be given the subscript z (see also

DIN 1602).

specimens under specific conditions for preconditioning,

test atmosphere and speed of testing. The test results are

are determined under different test conditions (e.g. speed

2.1 Strain ¢ is the elongation SL at any moment during

ex fepresents the strain at maximum load, tg the strain

at break, cg the strain at yield stress and eg, the strain

at offset yield stress.

2.2. Tensile stress 01) within the meaning of this stand

ard is the tensile force at any moment during the test.

based on the smallest initial cross section of the specimen

measured.

22.1

force.

Tensile strength o

the tensile stress at maximum.

2.2.2 Tensile stress at break ox is the tensile stress which

occurs at break of the specimen.

2.2.3 Yield stress os is the tensile stress at which the

slope of the stress-strain curve (see figure 1) is equal to

zero for the first time. {In this respect, see also the con-

cept “yield point” in DIN 50 148},

In the case of materials without a pronounced yield stress,

the offset yield stress may be taken as a substitute

quantity for the yield stress,

2.2.4 Offset yield stress os, is the tensile stress at which

the force:elongation curve departs from initial linearity

AL, and the stress-strain curve by a strain of x % (see

figure 1).

2.2.5 Tensile stress at given elongation a, is the partic-

ular tensile stress o which is measured when a particular

strain ¢ = 1% is reached.

3. Designation of the method

Designation for the tensile test on plastics, e.9. for 2 speed

of testing of 10 mm/min (3); testing of specimen No. 8:

Tensile test DIN 53455 —~ 3-5

“ EL etiSHELest mm OLS

Term____]

Standard number.

Speed of testing (see table 2)

‘Shape of specimen (see figure 3)

Continued on pages 2 t0 9

Sele sale nghts of German Sianoares(D-lormen)are wit Bevin Ver

oa?

(Gmba Benin 90

GIN 53455 Engl. Price group 7

‘Sales No. 0107

raged DIN SS 455

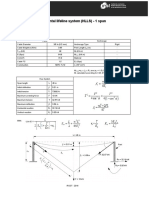

Force F —=

Where:

Fx

Sky

“y= Aly

my |

[|

|

Als nas : |

ite Abs= Sta) |

ena i

LL Als | if

L au, | i i

bah i

ie Alena oe i

Ala |

i 3bmn

at te Suse ta)

Figure 1. Force-elongation curve

Maximum force

Force at break

Force at yield stress

Force at offset yield stress

Force at i% strain

Elongation at meximum force

Elongation at breaking force; . 5

Elongation at the force corresponding to the yield stress

Elongation at the force corresponding to offset yield stress

Elongation specitied for determining the‘ottset viele stress

lo *

100

Elongation at /% strain

4ly=

DIN 53.455 Page 3

4. Tést equipment

4,1. Testing machi

As testing machine, any tensile testing machine of class 1

in accordance with DIN 51221 Part 1 may be used which

indicates the load to which the specimen is subjected at

any moment of the test and the speed of testing selected

in accordance with subclause 8.4.1. It shall, as far as

possible, be free from inertia lag in respect of force mea-

surement and indication.

4.2. Ektensometer

For elongations up to 10 mm, the use of an electrical

Measuring instrument is recommended, which can give

@ scaled-up recording of the elongation of the gauge

length and which will allow the recording of elongations

of 0,5 mm with an error not greater than 5%.

Elongations greater than 10 mm to 50mm must be deter-

‘mined from the elongation of the gauge length with an

accuracy of at least 0,5 mm or better.

Elongations greater than 50 mm can be determined with

suificient accuracy from the movement of the grips, e.9.

from the force-longation curve plotted, in which the

distance between the grips before the testis used as the

reference length

When using specimen No. 5 for flexible film, the gauge

and clamping lengths may be the same fot easier deter-

mination of strain values and may 8e 100 mm.

Note 1: To calculate a reference length which takes into

account the shape of thesspecimen, the following

equation can be used:

aressin

2

Note 2: If a stress-strain curve is to be plotted, then to

determine the inclination of the original tangents,

the use of a precision extensometer is required

2s is also used for the measurement of the elastic,

modulus (DIN 53.457).

4.3 Clamping device

The clamping device must meet the following require-

ments:

— The longitudinal axis of the specimen must be able to

be adjusted free of load in the direction of the tensile

force.

— Fractures caused by the grips shall be able to be

largely avoided.

— The specimen must not slip relative to the grips.

Note: Slipping of the specimen can be avoided, for

‘example, by using automaticaly self-tightening

rips or by fitting a crosswise mounted rod.

4.4 Micrometer

‘The micrometer must allow measurement of the thick-

ness of the specimens No. 3 to 5 to t 0,01 mm and of

specimen No. 5 for film to + 0,003 mm. ;

4.5 Width measuring instrument

‘The width-measuring instrument must allow measure.

ment of the width of the specimens to + 0,05 mm.

Note: Micrometers and width measuring instruments

shall exert a pressure from 0,01 to 0,03 Nimm?

fon the specimen.

5 Specimens

5.1 Preparation of the specimens

Preparation of the specimen depends on the product to

be tested and is governed by the details in the standards,

for the product concerned.

If such details are not available, preparation of the

specimen must be agreed between the parties concerned

for the specimens must be prepared as follows (the con-

ditions must be stated in the test report)

suawysads “f aunbiy

5 2G asneysans 685 (y seb ussmeq wnbuay (@ wnbuay a6nep (y

“vontpe 2661 2890320 ‘ssp es NIG ul uami6 z pue | sadeus

uowoads yu uoysnjuod prone 0 s9ps0 uy ¢ aunty ul sualuzeds ayn Asap Of pasn UReG aney Geb SlAGUUTN,

1 oe |

(02h i bt

! 001 | { | s

,

: Ost 6

ar eset iT

a et

a~ TF alt

Ty eo e

Ta0S

suorsuawip pue adeys ‘vawoeds, . ON

“(1 a10N 85) suoseas Eursas jeo}uyoer 105 Azess300U 51 s1yt

a1aym WU Q} 04 uMOD paUIYDeU aq UD sBUIPINOW ¥OIK

SSaUYOYL BuLUMDE;NUEW 1e Palsar aq j[eUs sBUIpINOw!

‘wou wayei suawisads “sjersarew BuIpjnow wos, paredaid

‘ue suawiseds ayi asaya Wi » 03 € 03 1UNOWE AiGe

“i9yaid [184s G ‘ON PL2 € “ON suawIDads jorssauyaIND ay,

“suijy J Gunnsar ay2 40} papuaruy

$1 G “ON UawDads “paussouod saried ay) Usemiag

avi6e aq isnw 31 ‘spuepuers jeriareus aye1sdoudde ay) U!

Payoeds 10u s1 aceys ayn azaym “Paisal aq 01 1nposd

aul Uo spuadap uawilzads ay jo Uo!I2—|9g “suaWoads

‘a1g{ss0d aya 40 suojsuawip pu edeys ayn smoys ¢ ain6, 3

suauijpeds oy2 Jo suo}suaunp pue sdeus z's

“snoaBequeape aq Aew sseooud Buntino ay Bulsnp

ano aun Buoje saBuey> Aituersuoa tujod Burnin sip yoy

Ur pue ano mesp e seanpoud yoryas s9raNs e “s—se0 aulOs UW}

289 Bunsno a04-yoiou “yioows ‘1yByens e seanpo:d pue

WW 10 ¥ ©} ueUU}Dads aya jo YpIM pasinbas ay2 i> UED I}

epyaoid Burnin 10} pasn oq ues sersno Jaded 40 wy, AU

> “{asned yu aauepsozce us) Susuenspucde.,

Jaye Ajaiepawust so azaydsoune Buiuopuozaid ay us

ajaissod 41 zarano wy @ uum ino aq isnt SuaUsDads ay

é “parser tou a1e sa6pe aur ve pue saaejins

1941 uo sme 9191514 yum suaLs}dadg “dis Wl} 94) 40,

suonseup assaqsues pue jeuspm6uo} ay yroq ut dis

24 Jo ipim au sano a1q)580d se painqusip Atwi0}!un

se sled wouy patoajas ave sous wy, Wo1y suausidedg

“Adononue ays 40 wonveuIp patzadxe

‘242 04 Ajannadsou sejnoypuadiad pue jaljeved a4e you4in

layer aq ienus susuioeds siesedas ‘peizadxa 9q 0} +1

‘Adontostue j) uawoeds aut jo uonoa.1p jeuipeus6u0} 243

Uy ano paysieo aq jeys suonesedo Buluiyoeus aay [Ty

“aoejins ay Gu\Sewep Indy panowies aq asnus S142

aujzeds ay 4o uonevedaud ayn uy peonpoud 51 ys) 51

“uns 40 082 “ON 2216 afd) saded aniseige Yala ‘89

‘sa6pa pue sazejins ays jo Bulysiuly njaea ino Alse9 04

+ aigesynpe aq Aeus 3] 129342 YBlOU picae Ob se os sme),

ue sSewiep wos, 294s aq jjeys #882 pue saoezans jy

“L'L asnejaqns or pred aq isnwi uopuanie sejnoyiaed YoIYM

‘uy “Buyulypews Aq 10 “Bulpinow uonaafuy J0 oyssasd.u09

Aq “8-2 ‘Anooup soyye paredesd 9q eo va

pads aut 7

a

SSPESNIG.

If necessary, @ specimen can be prepared so that its

dimensions represent a constant ratio to those of speci-

‘mens No. 3 and No. 4. This must be stated in the test

report. Test results obtained on this type of specimen

can deviate from results obtained on dumb-bell type

specimens.

If the product to be tested is available as film material in

sufficiently wide strips, specimen No. 5 is taken from it

‘in the longitudinal as well as transverse direction.

If the product to be tested is avaitable as film stri

idth << 15 mm and if the maximum deviation from

‘the meah width is not greater than + 0,1 mm, sections

from it are used which have the length of the specimen

No. 5 but the width of the strip.

Plastic film is understood to mean flat, laminar plastic

products with a thickness up to about 0,5 mm for rigid »

film and up to about 2 mm for flexible film.

Flexible plastic film is understood to be

that which has a shear modulus 5) equal to or less than

500 Nimm?.

Rigid plastic film is understood to be that

which has @ shear modulus greater than 500 N/mm?

{see Note 2).

Note 1: It is pointed out that in the case of specimens

with increasing thickness, the tensile behaviour

is influenced due to restriction of the transverse

contraction.

Note 2: When testing film with a width <15 mm, the

condition of the edges produced during prepa

ration of the strips is also included in the test

result, This is therefore not a test of the film but

a test of a specific film strip. .

If, when testing very ductile film, the tensile

‘testing machine will not allow sufficient elonga-

tion of the specimen for the specimen to break,

shorter clamping and gauge lengths must be

agreed and these stated in the test report.

5.3. Application of the reference marks

Reference marks to determine the strain are applied in

2a suitable way to the specimen as in figure 3. This must

not damage the surface of the specimen, i.e. the refer-

lence marks must not be scratched, punched or impressed

‘on the specimen.

‘When using marking instruments or adhesive, it must be

ensured that the substance used will not affect the

material to be tested. :

6 Quantity of specimens :

according to test conditions

6.1 If the product to be tested consists of isotropic

material, at least 5 specimens are tested.

6.2. Hf the product to be tested consists of anisotropic

material, at least 5 specimens are tested per sampling

irection (see subclause 5.1).

5) For determining shear modulus, see DIN 53.445,

DIN 53455

Film

ection

6.3 If the product to be tested is in the form of

strip, at least 5 specimens are tested for each

{see note 2 on subclause 5.2).

6.4. If the product to be tested is in the form of fiim

strip, at least 5 specimens are tested.

Note on subclauses 6.3 and 6.4: Experience hes shown

that the scatter of the measured values increases

with reducing thickness of the film material.

A different number of speci recommended

for thin films as follows: :

Table 1.

Mi

imum number

Film thickness of specimens

0,04 100,1 10

less than 0,04 15

7 Preconditioning

Unless otherwise agreed or specified in the technical delivery

conditions for the product to be tested, the specimens

are stored for at least 16 hours, for arbitration cases

96 hours, in standard atmosphere DIN 50014 — 23/50-2

8 Test procedure

8.1. Thickness and width of the specimen are measured

at a minimum of 5 places within the gauge length (see

figure 3),

Specimens whose maximum and minimum thickness differs

by more than 0,1 mm {ivith film by more than 10%) or

whose maximum and minimum widths differ by more

than 0,1 mm, are not tested.

B82 Test atmosphere

Where not otherwise agreed or contained in the technical

delivery conditions for the product to be tested, the testing

iscarried out in standard atmosphere DIN 50014 — 23/50-2

8:3 Clamping the specimen

The specimen is clamped in the clamping device so that

its longitudinal axis is in the direction of the tensile force

‘and that the specified clamping length (see figure 3) is

observed.

Tighten the grips uniformly and firmly to prevent the

specimen from slipping in the grips (see note on subclause 4 3

8.4 Tensile test

8.4.1. The specimen is subjected to strain at a uniform

speed of testing in accordance with table 2 to determine

the strength and strain, The test speed is the speed at

which the two grips move away from each other during

the test, The speed of testing to be selected must be taken

from the standards for the product concerned or must

be agreed between the parties concerned, Those speeds,

of testing to be preferred ar

48 DIN 53455

Table 2.

Code

Corre

Speed | number for sponding to

of the desig- | mm/min sO +

testing ration of . 527 - 1976

the method

1 1 150%

Ja ta 2+20% aste

0 2 5+ 20%

nm 3 10+ 10%

wv loa 20+ 10%

v 8 50 10%

vi 6 100+ 10%

vil 7 200+ 10% | Speed

vu 8 500+ 10% | Speed H ‘

\eF speeds are permissible and shall be gradusted in

‘the same way.

fa specimen is used which is modified in proportion to

rabclause 5.2 or shortened in accordance with note 2

7), subclause 5.2, then the speed of testing must be

wy 21tered in the same ratio,

value

xe

ALR

8.4.2 During the test, note the tensile force and/or the SLs

maximum force as well 9 the force at break and the associ-

ated changes in gauge length. If necessary, measure the ise

test duration. Where possible, plot the force: elongation

curve. Lo

A

8.4.3 With tests in which the specimens do not break 4o

within the gauge length, the tensile stress at break cannot

be determined. 7

Yield stress and yield strain can only be determined

when the reduction in cross-sectional area begins within

the gauge length,

‘The strain at maximum force and the strain at break can

‘only be determined when the area of strain is wholly

within the gauge length (see DIN 50 145).

8.4.4 To determine the offset yield stress, a force:

elongation curve must be plotted.

*3 Evaluation

o

9.1 The smallest initial cross section Ag is determined

from the individual values for thickness and width of the

specimen.

Key to the symbols in subclauses 9.2 to 9.5:

Fimax Maximum force in N

FR Force at break in N :

Fs Force corresponding to yield stress in N

Fs, Force corresponding to offset yield stress in N

Ag Initial cross section of the specimen in mm?

9.5 The offset

Key to the symbols used in sube!

AL pmax elongation in mm at maximum force

Id stress og, is determined by drawing

2 parallel to the initial tangent of the force-elongation

curve through the abscissa value AL, cofresponding to

in of x %. The point of intersection of this line with

the force-elongation curve produces the force Fs, Cor- |

responding to the offset yield stress. 5

Foy 2

os. = — in Nim

Ao

In the offset yield stress and the symbolsos,, AL, F sx,

Als, and ese, x must be replaced by the numerical

of the specified strain deviation x %, e.g. for

1% strain, O55, AL4,Fs1,ALgy and egy

se5 9.6 to 9.10:

elongation in mm with force at break

elongation in mm at yield stress

elongation in mm at the force corresponding

to offset yield stress

initial gauge length in mm

forge at i% strain N

initial cross section of the specimen in mm?

9.6 Tensile stress at given elongation o, in Nemm2

A

Ao

The symbol 0; must be provided with the numerical value

of the appropriate strain ¢ as subscript, e.g. 0109 for

e= 100%,

2.7 Yield strain ey in %

Abr

9.9 Strain at yield stress es in %

9.2. Tensile strength op in N/mm?

9.3. Tensile stress at break og in N/mm?

Fa

care

9.10

3:

Lo

ts 100

Strain at offset yield stress eg, in %

Sksy

Lo

ts + 100

9.11 If the test results are statistically evaluated, the

‘est report shall contain the following details (in this,

respect see also DIN 53598 Part 1):

= all individual values ~ x;

= number of measurements n

— arithmetic mean value x

= standard deviation 5

Confidence intervals of the mean value at a confidence

‘evel (formerty statistical certainty) P = 95 %.

10. Test report

With reference to this stands

2) type, form on delivery and designation of the product

b) date of manufacture and method of manufacture of

the specimens

©) position of the specimens in the product

¢) shape of the specimens (in accordance with figure 3)

€) thickness of the specimens in mm

f) mean value

49) width of the specimens in mm

|, the test report must state:

Standards referred to and further standards

DIN 53455 Page 7

hy mean value ‘

j) number of specimens

i). preconditioning of the sp

k) test atmosphere where this d

1) speed of testing

rm) tensile strength og in N/mm?

1) tensile stress at break og in N/mm?

©) yield stress og in N/mm2

) where necessary offset yield stress ogy i’ N/mm?

4) where necessary tensile stress at given elongation,

in N/mm?

#) strain at maximum load ¢p in %

5} strain at break cp in %

1) yield strain eg in %

1) where necessary, strain egy in % at offset yield stress

ens,

jates from this standard

V1 if available, force-elongation curve or stress-strain

curve

wl appearance of the specimens after testing

x] conditions deviating from this standard

Y¥) date of testing

DIN 1602 Strength testing on metallic materials; definitions

DIN 50014 Atmospheres and its technical application; standard atmospheres

DIN 50 145 Testing of metallic materials; tensile test

DIN 51.220 Material testing machines; general directions

DIN 51.221 Part 1 Material testing machines; tensile testing machines, general requirements

DIN 51.221 Part 2 Material testing machines; tensile testing machines; large tensile testing machines and universal testing

DIN 51221 Part3

DIN 53.430

DIN 53.457

DIN 53504

DIN 53571

DIN 53.598 Part 1

DIN EN61

Former editions

machines

Material testing machines; tensile testing machines, small tensile testing machines

Testing of rigid cellular plastics; tensile test

Testing of plastics; determination of the modulus of elasticity in tensile, compression and bending

tests

Testing of elastomers; determination of ultimate tensile strength, tensile strength, elongation at tear

and stress values ine tensile test

Testing of flexible cellular materials; tensile test

Statistical evaluation of random samples, with examples taken from elastomers and plastics testing

Glass-fibre reinforced plastics; tensile test

DIN 53371: 10.55, 09.59

DIN 53.455: 10.52, 04.68

Amendments

Compared with the April 1968 edition, it must be noter

{In addition to an editorial revision, the stipulations in t

is standard have been changed to take into account the provisions

of ISO Standard ISO 527, in this respect, see also the Explanations.

eS DINS3455

Explanations

This standard largely conforms in substance to the draft ISO 7)/DIS 527 — 1978 “Plas — Determination of tensile

properties” — and ISO Recommendation ISO/R 1184 [Plas ics — Determination of tensile properties of films”.

In departure from ISO 527, measurement of the elastic modulus is not included, since Standard DIN 53 457 is available

for this, Also compared with ISO 527, specimen No. 5 is included for the testing of film. Specimens No. 3 and No. 4

conform to ISO 527 and the same applies to the speeds of testing.

lar attention must be drawn to the fact that in the case of materials exhibiting creepage or orientation effects

test, the test temperature of 23°C otherwise easy to achieve experimentally is often difficult to produce,

or orientation effects can be associated with considerable intrinsic heating of the specimen. Because the

dispersal of excess heat is not always easy to achieve experimentally and an appropriate specification would go beyond

the scope of a standard, this point has been disregarded.

‘The specifications of European Standard DIN EN 61 “Glassibre reinforced plastics; tensile test” must be observed for

the testing of glass-fibre reinforced plastics.

With all materials, the test conditions in each case must be selected to conform to the particular properties of the mate

rials taking into account the product standards.

‘The particular test results obtained can be supplemented by 8 tabular display of the details of the test procedure (test

parameters), The details to be included are given in the following table

Example:

ow ‘Shape Initial Gauge-| Speed | Maximum

Br | samt ne | wets | TM Jerson |fenan | ot [ond

seinen ee eT astng | Rese

No. °c mm mm mm? mm mm/min N

Tensile stress

at max. load 3 23 tor | 38 38.4

op = 45 Nimm?

50 50 1730

7) 130: International Organization for Standardization

DIN 5345S Page 9

“aLw | foe [aca | fore | Ata | forces | aba,

Jasin} at | teak | ty} vii fe ile

orce | treat | force | Suess | stem | svess |” stest

Fr |Otee| A | Stn | Fox | Abr

me [fom [oe fm [stm

ese st

opin

x |=|PERE

i

Tene sess

abe

on nNina?

Yates

osama?

mar

Yo sia

cain’

Bren sain

cain

‘stant

yield ess

fam

x|x}x|x{x| x |x]

‘Shaina tise

vides

Esa Ls44] bot til i

x} xixixlxlx| x | xl] E

x |x |x|x|x|x| x [x78

x

x |x lx) x) x,x)| x [x

x

x |x| x|x}x] x |x

x

During the revision of DIN-58 485, it was proposed that the symbols andor terms should be used as in DIN 50145

“Testing of metallic materials; tensile test” .

Proposed in

accordance with

DIN 50145

Tensile stress ° °

Tensile strength ow Roy

Tensile stress at break ou Rx

Yield stress os Rs

Offset yield stress Os, Rs

Stress value 9 R

Swain e e

Strain at maximum force on Am

Strain at break : ‘ee. Au

Strain at yield . fs AS

Strain at offset yield sires + a on As.

Initial cross section . Ao So

Maximum force Fras Fa

Elongation at maximum force Lema Lew

Inclusion of the symbols in the above list — proposed in relation to DIN 50 145 —

mittee since standard use of symbol R for strength or stress and symbol A for stra

from metals.

If international standardization of the symbols used is introduced, the Plastics Standards Committee wi

accordingly.

fas not able to be agreed by the com-

thas not yet been introduced apart

revise DIN 53.455

Anda mungkin juga menyukai

- 2014 68 Eu PDFDokumen96 halaman2014 68 Eu PDFAlienshow100% (1)

- Delayed PWHTDokumen4 halamanDelayed PWHThasan_676489616Belum ada peringkat

- API 5L - 43rd and 44th Ed - Comparison r1Dokumen68 halamanAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Cross Cut TestDokumen1 halamanCross Cut Testhasan_676489616Belum ada peringkat

- Method of Statement Piping Fab. ErectionDokumen22 halamanMethod of Statement Piping Fab. Erectionhasan_676489616Belum ada peringkat

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Acid PipingDokumen1 halamanAcid Pipinghasan_676489616Belum ada peringkat

- Duty CycleDokumen1 halamanDuty Cyclehasan_676489616Belum ada peringkat

- Celex:02014l0068 20140717:en:txtDokumen118 halamanCelex:02014l0068 20140717:en:txtedwinBelum ada peringkat

- LNG Tank Dismantling MS RevCDokumen14 halamanLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Paul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDokumen438 halamanPaul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDavor Katunarić100% (1)

- PNFJ8000Dokumen71 halamanPNFJ8000seenu189100% (1)

- Horizontal Life Line CalculationDokumen1 halamanHorizontal Life Line Calculationhasan_676489616100% (1)

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Europe steel standards overviewDokumen14 halamanEurope steel standards overviewhasan_676489616Belum ada peringkat

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDokumen24 halamanPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishBelum ada peringkat

- Tank Construction Quality ProceduresDokumen36 halamanTank Construction Quality ProceduresJagdish Busa100% (2)

- Fall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public ConsultDokumen40 halamanFall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public Consultlwin_oo2435100% (3)

- Solar Power Plant ReportDokumen1 halamanSolar Power Plant Reporthasan_676489616Belum ada peringkat

- OSHA - 29CFR - Construction StandardsDokumen22 halamanOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- E SN854Dokumen2 halamanE SN854hasan_676489616Belum ada peringkat

- 1926.501 - Duty To Have Fall ProtectionDokumen4 halaman1926.501 - Duty To Have Fall Protectionhasan_676489616Belum ada peringkat

- FITTINGS ButtweldDokumen5 halamanFITTINGS ButtweldThamaraikani ManiBelum ada peringkat

- Stainless Steels For H2SO4Dokumen4 halamanStainless Steels For H2SO4Marshel LeninBelum ada peringkat

- E SN882Dokumen2 halamanE SN882hasan_676489616Belum ada peringkat

- Din 2614Dokumen11 halamanDin 2614hasan_676489616Belum ada peringkat

- German test point system standardDokumen3 halamanGerman test point system standardhasan_676489616Belum ada peringkat

- E SN883Dokumen2 halamanE SN883hasan_676489616100% (1)

- ASME B16.47 Series B FlangeDokumen4 halamanASME B16.47 Series B Flange41h189Belum ada peringkat

- Din 2461-66Dokumen7 halamanDin 2461-66hasan_676489616Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)