Din 17221

Diunggah oleh

hasan_676489616100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

3K tayangan9 halamanHot Rolled Steels for Quenched and Tempered Springs Quality Specifications

Judul Asli

DIN 17221

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHot Rolled Steels for Quenched and Tempered Springs Quality Specifications

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

3K tayangan9 halamanDin 17221

Diunggah oleh

hasan_676489616Hot Rolled Steels for Quenched and Tempered Springs Quality Specifications

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 9

Deoeader 1972

Hot Rolled Btesle

for Quenched ané Tespered Springs

uality Specifications

Varagevelate Btinle fOr verpitbare Feern; Gltevorschriften

qnnsction vith Buropora 09.71 and the Standard prepared by tbe Intornationsl Organisatt

Jor Soaeetatation (150), see Replanations. reread ad

soe aevaqnoted by a dot (o) contain inforaation regarding agresnents vhich are to be sale,

sathent, “Senate, when ordering.

the, gongerning Gatte of egmarnant of Zul Zely 1263 tnt the ATgzea"s ry

oocerning Unite on Sune ag70 the unit edopted in this Standard for, t

ig Act ane tated ie) an Band (Hovtons per oquare millinetre). ie values

ee ase defiastive

sage te 8 3, pare CD;1 of tie Act, tbe unite end values appearing in Drackete elonge

according to 8 2ralttads since the hg isthe base unit for

ta Scone

1a Beate standard applin te the apring steels accorfing to Table 7 in the for of

gt relied end eubeequentiy, where pecessar7s Centreless-turned or ground bar steel (round or

fiat steel),

Set welled sibbed spring stow

Bot rolled wire,

Vide’ nates or

, Delica and plate

ae roars procensed to make quenched and tenpered leaf, torsion Der;

Wpringe, spring lock vashers es well lepring-Like componente of ail Ei

srrings Miguck quaitey stenterda exiet in respect of :

ead polled steel strip, fo ( Btentert))

eaked degen pring Toes Best 4},

cree ety vite made of unailoys

‘DIN 17226 (Preliminary Btenderd)) and

eB Seth Atay BianaacelS

Bheet 2),

jo steel vize and strip’ for

Rign-texperature steele for springs

sei lots, Sie auetiiepee ©

To metals iosding within « given Fane

required of the

walk enblen

wane che Joe te Eenore Do eontente, end eliay! ertees such ap eliicony maneest

siane eo carbontcoktente, ane lioyi0e, 2 spas as eliicon

cpleuned through Bienes cozton,coMtSDTy Hives turcugh best-trentaent, ine~ Bardening 48 of Gr

chrontutes eubeequen®. tenperine- E

sae eeperisitions and technical teras relating to Dest-trestuent,

Dim 1 sop ver!

seasraeeticn standards covering the majority of the products

Rte NMP vee a peesaatae

She ond of "hit facneion atandarde for particular forms of product, the perais

ene" os GoMhe agreed when ordering.

3 s rt

tee delaity of the steele covered by thie Standard is reckoned ae 7.05 xg/en?,

Sor De deletes cfeied co the contrary in the dimension standards listed, the pereiesible weteht

SaHaLSEE REDS greed aben ordering

yo DIN 47018.

yationed in Section 1.4 are

vie

fgreten Listed in Table 4 are divided into quality atecls and Bigh-grade ste)

fe chffer from tbe qualiy steele not ony in tele Lovey Be porus

ec da" the undforalty of shed properties > particularly op vie" 2°

eo in tht the fact that they are largely free from nonaeteliic 1o-

turface condsti

5.4.3. 0 The wade de the purchaser's responsibility. It ie advisable that

the manufacturer szould be consulted.

»_ (condi t3 if aeli very,

eraliy supplied 4p the not Folded. cope

wat conditions indicate: ¢

on. They are also aveileble in one

0 ordered.

to 8

Continued op pager

8 ant 9

Explanations on pet

Page 2 DIN-17224

tie 38

__| sala!

g} gasltl 3

1s sss z

a] 388|,!

Tae fret appended number, vhieh according to

ton of Di

004s

Onas

nas

nas

0935

|

|

jeraational Rativay Federation (UC) are reformulat

ones

ons

onus

ons

nas

nas

6.1.2. The code number or the materiel number

tter or the

for’ the

1 grade and the code

\guation)according to

Couparable steet

4 88, 828

q zes| 338

5 338] §88)2:.

q 3222/2 333/7 qa | Ste poe

£28 2/0 S32 as aunt ere” sccording to

3 B22)3 222/82435 § 2."20 The Golde nuaber must be

2 | adele PTET ny, the code letter, and to

i é Hii 5 eee ac

3233/3 3232/3 ip

z fof) 22 dlaks 9 Ea setae agte tanealsd cosdition Ce or 02)+

BSS) FSS[FFas, S| 54 1°70 or 1.0903.02.

©1855 -5 $| appended numbers for identifying eee t

8 ease on] comgition (in confanction with

Z Eyre ich, according to

nooltzesd § 7

28255 3] ota ccrreaieton natetia’ the arp

a

i

z Zed] appended nusber for the treataent condition are

<3 Eu) 'be sopgnded to the ayabete for the product

2 z] as given in the examples 0 tion in the

Sés 5g] afatosion steatarae. a

B85 de

a feriel sunber 1.0905) in thet bot

terial sunber 4. 2

285 Folled condition:

Eee 80 x 40 DIN 4570 - $1 81.70

AER 80 X 10 DIE 4570 - 4.0903.00

eds of. F

6.2.4. The exasple quoted in Section 6.1.2 for

a'code desiguetion fe to be written ss follows

when combined sith particulars apecifying «

5 Mode of delivery (eng. 3 ble 3):

z Spring t.01 80 x10 DIN 1570 - 51.51 7 U-

<3 node of delivery 3.0

os? or Bpring ateel 80x 10 DIN 1570 - 1.0903.00 =

$36 node of delivery 3.8

Bas

Table 4. Grade classification and cheat.

76

DIN 47221 Page 5

2. Bequiremente

eda Pepduction procveses

Tete oboice of production pro

of

ft saeaistig

2.2: Moden.of Se eats) tea a the not

i214. Stools jing to, andar are 12 one of the modes of delivery (combina-

72s gePetehtattes proberticn) accordane to ante: aaa

denaeentepat contivion (eee Table 2) and the node of fete, {

ine trantnent coery ie usuliy sade in the untreeted (Dor ots

raeTebenieel couposition and through bard

Tresponde to mode of deliv

re ugually delivered to the purcbaser

ae ere ufecturing conditions the purchaser

a te left to the manufacturer

work unless agreed to the con-

1e Table 3) must be

3 condition with

according to beats. Por the

a’beat basis.

Shen:

sree regard to the chemical composition

3a. Manet apalzeie values are guaranteed for odes of Se3t2077 1 and 40 ad

the pagtect SROs Values for the otner podee of deliver > to "1X.

7.3.2+.0 In the cas ee delivery 1 end 1 4 it may de agreed vhen ordering thas.

Porieteat ion 4 povided oat, tbe product analysis upholds, the edie enel7~

Ts2 Tubshet tot the permiasibie varietions fros tbe lisit values © ated 4p Table 4.

perniseibie Uelivery 5 to 11 2 ainor variations fre theee 140lt yeioes for

eee eete a are peraiteed provided that the properties to be Saar”

‘of delivery are maintained:

for round

canard through barfenability 1s, quarente

eangard Ghrougl pe iguicetes dn Mabie 5+

nor Pui through bargening ie genoted DY &

2 el eens gelue of Se Hae (47 HEC in the

mae a eo*SS Sii7) in he core of apeciael

MIT) Dud in water or ofl.

Gprough hardensbiliey is verified only

f specially agreed wher ordering (see Section

‘and ayebole for,

jode of delivery?)

chemical composition

Pernieaibie wexinus

feontent in Ladle ab]

hardness in the core

‘after quenching?)

hardness tn the soft

‘tunecled condition (0)

ae meena (©)

Sa

Wepaataas

HG

100

10

esas =

3100 5

1) mre ef

wre piven ip b

2) me numbers and letters

ment with the sdent:

Cernational stander:

3) bee Section 7-4 and Table 5+

4) see Table 6 and Section 745+

Exanpiee of application:

fue order apecifien the node of delivery

T tyubol t's the following must del

el eospoeition from the prt

ih the core after

yrénese ip the soft an

wetere are tov

‘the product analys:

je analy

2) vnan two or wore protuct analyse!

neck the vardati

cording to the

b) If the chenten) cow

the he

yoge * DIN -47224

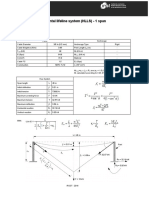

qeple 5. Limiting dinenstone for throwsh bardepadility of the steele

es Tasos Vins fs

| mene | umes | onlay

{ate ser [tetera mater

77 ores C 7

si ‘ 7

sosicr? “os ‘ =

550r3 on % s

soca a

sremove ‘a A °

1) Valid for the quenching temperatur

2) the ateel 518i 7 1a aot weed Sn the fore of round steel for springs.

Mechapicel_propertis

ia Meble 6 for hardness in the untreated (hot rolled) condition are ref-

Fe pot binding.

‘of nodes of delivery 1 a and 3a the maximus hardness values in the soft

jceording to Table 6 are guarent

livery 3, 3 a and 11k the mechanical p:

Tcording to the pert

28: rebiliey

. Teles 2 and 3) ali the steele according to this Standard are available

SFE GRASEECESS cold cheareviaity. Ordering in this way is recommended for steels vhich may

tee"), 2 8.

Treataent condition

untreated | aoft anneats quenched and

(uot ro1lga)

Code nusber| Matersed hardness") dardec yield point elongation

auster | HB30 or HVS | HB30 or HVS Nimo? Nimmt Ly = 5dq

(aime) (eat) %

sexinus ainieue sain

3Bsi7 1.0970 =u 27 1000 1180 ee 1370, ‘

(105) (120 to 140),

sisi7 1.0903 =70 us 0 waters | 6

ms (135 to 160)

sosicey | 1.0960 ~310 25 m0, | wei | 6

A (is | (135 t0 160)

sscra | >m0 Py W809 1370 to 1620 ‘

. (120) (140 to 165)

socwa | 1.8159 >30 mo 1189 1370 to 1670 ‘

: (029) (149 te 170)

‘S51 CrMoV4 V7701 >n0 2s 1180, 1370 to 1670 6

(12) (149 te 170)

ye yieid point (0.2 Lisit) te = 90% of the

) It can be asmuned that on through hardening of the a

ile atrengths

Le Strengths city of the ateele is © 200 000 N/aa™ (20 000 ke/aaé), whilet the

12 (8000 ke/en?)

eodutes

3). Tf auch a species

eterained

pproxinately from the Brinell hardness by multiplying by the

jainery Standard). Tbe teat to definite

ified on eyecinene vith a dt of 10 na (Cove

seaptred fron the product its diameter ebeuld be the largest,

Tivery éinenstons.

5) The tensile etret

factor 0.35 (e

an be calculets

‘Sige DIN 50130 (Prel

DIN-47221 Page 5

for wot

2 ebearing is envisaged (:

5.2).

‘ales

have 2 snooth surface

That produces by rolling; they

‘cracks, deep pits or other

Iapeiring the durability of Dinweter

3<

ertance of th =

fatigue strengtb, zw <0

ject te toretonsl er

ite apecifies in the

rewne condition, special | 230 <9

Ween ordering 20 50

3:

ste correcting of surface defect vieiaeas | Profacte with ect

Ee le ip Fes eons wuss oe Teteraeee | Tenncacetion’y

<7 on

7<15 0x

15 <3 ow

3 <3 O55

ws 080

Digh-erade

1's covered in thie Standard

50 Grv 4 and $1 CrffoV 4) the maxi-

of decarburisation depth in the

Condition according to Table 7 are

‘unless agreed to the contrary

jog. Toe values quoted apply to

‘Gecarburi vation (incomplete removal

Subtotal decarburization (virtu-

fe Fesovel of carbon) ie pot persissible for bigh-grei

‘in Table 7 apply to the diameter in the case of products witb rou

ction they relate only to the thickne:

7.0.34 9 Feating for decarburisetion depth (eee Section @.4.6) muat de separately agreed when

ordering.

2:29:23

oir +1)

Content of nonmetallic inclusions, special

ordering.

stendards ip regard to mexinun pernissible

Peopent to this effect must be reached whea

8, Texting

Delivery testings

#'For ail the a en in thie Standard the purchaser can arrange delivery teatings watch

SiifF bhereily be eagriee. out by iuapectors belonging to the menufacturer’s vorks, but gubject

fo separa iyien ordering way aleo be performed by outeide inspectors appointed by

tof testing

erificetion of the. pra ° apecizen por

heat and bestetreataent for sball be taken for each t

pose of the product analysis, cuttings shell be taken uniformly from the en-

‘the product to be tested.

cimen preparation for verifying through bardensbility (see Section

1 be Peached vben ordering (see also Section &.4.2).

reining surface hardness (see Section 7.5.2) sball be

8.3.2. 0 With re

‘7:A) epectal sgres

8.3.5, @ Toe

Ythod of saxpling for

. ecinen for the tensile test (see Section 7.5.3) shall de taken fron the core of

the product in the Girection of fibre flo

or eeternining decarburization depth consists of an adequate length of the

So the deteiia in Section 8.4.6 in the ae Folled condition.

Feet ete cedure for taking epecisens for deteraining the content of ponsetallic inclusions

£526, Tes Bvegevay Lets tas efseb in the Stani-Eisen Tost Sheets atated in Section 6.8.7.

a1 be determined by the methods") given by the Cherists’ Com-

eabUttenleute (Association of Gerssn Ferrous Metallurgists).

ining through bardenability must have the cross-section di-

se hetle $ and a length of not less then 24 (¢ is the diameter or thick”.

Dene) ize apecizen ia quescbed 4a voter or of} from the hardening tesperature stated in Tapie 6

eels cetn zat in tuo Centrally at right angles to the direction of fibre flow. The Rockvel

ction (longitudinal axie of the

pean, (Hae) wbould be seesured in the middle of he eros

spectnen)-

6.4.2.4. @ Toe choice of quench oil shell be agreed separately.

a ip to be determined according to DIN $0103.

2: Die Unterauchung der eetaltischen Stoffe (In~

(arbitration analyses), Ducseldorf, Verlag

79

Page 6 DIM17221

0.4.3. Toe 18 te to be determined according to DIM 50351 and Vickers hardness

sccording to DIA

8.4.4, The tensile te Section 7.5.3) 4 to be carried out according to DIN 50145) us

the short proportional bar with a get <-ogth of 10 = 5 do,

EP'efere 12 bo propounced piel poltts tne G.r '='e “narl°be determined a

DIN 50145*).

ordering recarding the

tallogrepbically at a aagaifi

Fron a specimen in the a

‘epecia

the average of four

F, two thirds of the depth of the decarburized

ting products with other eros

ig inclusions (;

cording to the following Stebl-Ei: ‘Test Sheeta¢), depending

Sok de tenting of high-grade at

BEET Eicroncopie testing of high-erade «

900 = Gee edition 197036 *

1500" Step Seve

Gis saves

asou = Mus Seite

Git sated

Gntess, Screed te the contrary wien ordering, the testing abould be perforned accordiag to Stabl-

Blue’ aeet’ Sheet 1380,

with (1lustrations

o for nonetallic inclustor

eeroscopic nonsetallic inclusions

1a for macroscopic nonetallic inclusions

8. Bee

6.5.4, If the unsatiafactory result of « testing is obviously due to deficiencies in the test

procedure or to defective preparation of a species: viich, bovever, must not ate from Geficien-

Glen dn the steel iteelf, then, much unsatiafactory rewuit aball be set aside when the decision

{e'being made regarding fulfilent of the requ renente, and the teat concerned aball be repeats

8.5.2. If the unsatisfactory result of a testing ie dus to incorrect heat-treataent, &

imen may be heat-treated and the testing repeated on it.

8.5.5, If the results of a properly conducted testing do not

eried’ out. The procedure for thts purpo

sy

tthe specifi

fe that for

ie

requirements, «

sh unsatisfactory

‘the sane test

4 to be in conforaity with the conditions if both reteatings have

‘rejected if one of the retestings ie unsatisfactory.

‘certificated by one of the certificates according to DIM 50089. The type

‘egreed when ordering.

8 to the upper

temperature linits indicated in Table 6 which, hovever, must not be exceeded. Ven hardening

from forsing heat 1t Le iuportant not to go below the lower temperature limite, otbervies the

take-up of sardness will be unsatisfactory. *

9.2. Soft annealing

a held at the temperatures indicated in Table 8 for

jection, whereupon they are to be slowly cooled.

oe

The places are to be carefully heated to the tenperatures indicated in Table 8 until they have

assuned the specified tosperature in the core also, whereupon they are to be cooled in # still

and throughout, 1.0. for lengths of tine depending on the

tures indicated in Table 8 which apply to hardening aft

indicate: rature range should b

jardening fron forming heat the texpt

ined prior to quenching Hust equal to the lower terperecure of the t

ndicated in Table 8 for fc into springs.

ature, the details for which in Table 8 should be regarded as reference val

a to suit the required strength properties. To avoid gifficulty in main.

Teloing consistent strength values it is Tecossended that processing should be perforaed accord~

ing to beate. Tempering should be performed insediately after hardening othervige bardening

cracks may occur.

Following should be noted with regard to the application of the different heat-treat~

.

ry Af manufacture into eprings or sprint

te, For will’

F iiait of

fae

arburization during

found to afford adequate protection against decarburization o

7

to protect

fa vith exces

Se provent at41h etre

2) Opttinesie fr

Diu 17221 Page 7

2) vith all the steels, ea

SETAE tne Biguer annenline

a controll

>) gue hardening temperatures indicat

Riteione 7-4 and 8.4.2).

surfece, sot gscepttl

PEL TOMO eretore ©

oe eT they ste

6S hey eS ESS epee

oe ee

ft annealing ten-

tng’ aay be aeceenee

repiliey 4m oteele Bert

or260 HB in the as roll

af opringe for Fail-borae

‘ontea) eprings

condition.

pe Noraalizing for grein, reftpee

3:5;25 Noneceanary provided that the teparn.,

erally wapeceeg' for bot forming are maseresiees

Tor haghig stressed wpreas ing asf fi~

Tulty ip forming, Bowevers

be advisable pi

‘Por all springs in st

St) pkrdening and texpering BOF

c'the final heat-treatment.

20.8

Feapien aboving the uses to visen the ettel®

Dee eae taking account of tbe econons

puts enner of nardening and type Of stree!

m iiated in Table 9-

4 Gompiasote)

tia Sopnia eal and interns? defects Bay OD}T

TUNERS Urleney’tepase to an epprecyee

bsected, $2 and use of ane materiel Sn ©

e Drocemesne sare tothe stock grade and

Torn of product. concerned

17 tan. purchaonr must ive bt RABUtREST

Ths ME Bargpportuniey of courses

zn MGEE AD OPEopTeine de fustities apd wpere

aa ti Siteiteing tbe ma

ferapecinens of

Very severely

Relieal and toi

Uptinge ie Larger dimen

4) murough herdensbinity (0

Pe conesdered vben €ec

2) yor aprines tres

inet seting ateclo which offer o MED

itet the occurrence of

weight, perei

Yor hot rollet

ral pUrpo:

DIN 1045 Bt

TIE 1017 Bheet 1

erat

ase | 11n-4570 Boe rotted, 34m

P tione, evetie, valu

‘LIK 2077 Spring } bar, round; rolled for pot worked springs

san zor? pring seek SEE; Fenied For the produccion of Nesistte® aprings

1 for

aimensions, weights, pereiesible

round steel,

i pars; Bot rolded fee at

ond grooved epring steels

pan-nast, (DDH

fe dn quality standards for tren and 6

‘hte complaints 1

rae pe 1/112.

aplanetions on

Have) VoL. 80 (1961)

al

\

\

turn

Tight, round steel; dimensions, perei

yor hot rolled wires

ror Mgrt0 Bteel wire rod; dimensions, peri Able variation

Yor hot rolled flete:

guest under 3 am thickness and hot rolled #trsPi permissible variations 12

DIN 1016 Hot roll

dinensio

ple variations, weights

DIN 59200 Hot roll

fo weight

ie vide flate; dimensions, perat!

citications f

reien te full atandard sta

pentay, ©

the present teaue of DIK 17224

Tet Toreet springs vaich appear’

hes pan been delaged b7 the need:

Bitatts of tne discus

{s0/D1s 683/217")

a ateels

alloy steole ant freeneutting atgeles

reels. Set foracd and heat-treated SPFinet)

neat trated arhed and tenpered apriags! quality epecitieatiees

orks Sor mer pin sunnuard vith these internation eet tee has ven

ation of She ore and producers participating in Whe, i000)

ing conditions

rec

tana from the interna

yartettaae Gn Garaany. ibe princiyel departures from G0 6A!

preres Standards are eet out belovs

Mee only tro quality steels

[sb'at 7ivith «silicon

ft delivery 91995 of

oats considerable quantities fer #7

‘the

Neat 2, 95 84

on Ai Tonal standarde they have ceased £0

GD Bice 7 with 0.20 to 0.00 8 by vbr

cr.

orte Bigh-ere de, 6 previeushy saciuéat only 50 CFV, haa, benn,rgtsined, 25 836 MY

OF the oh Safpaeig’ tncroneed vanadion content: Sa 20 utes ody aice 6 and 58 crv & have bean Te

oe eee tae 55 Er 3 and 51 CrMe¥ & which are chee ese Gm the draft 160 Standard und in the

Eurenors.

‘Rrrometreation of the choice of eradee te DIN A720) 64

Tes iaiuah vas approved by all whe, took port, 2, Cit,

1955 seeds) gtanaara ban an saay os 1h steele teehoding see seconteining Bigi-grade tee vith

are ae nah vy chs ce and tot Lene than O-0005 57 OO 2

0-73 oY ctardn the tnfornstions on chentesl COMPoeiste BOS iS" eupplemen

earding he permianitle mations oo Chtueen the product anaizeie and the Leéhe ase

7.3)

(uot formed), bot are alee ovatzane, use

ae teeesitys oF with contrelese-tursed oF

‘of the vowel condition of de

‘out by the pring sanuracter

conaiticn

Proviets

Verified by the suppiie

Mechanical and technological propertic

DAY shove participating in the 4!

‘theations Fel bar

nev version of DIN 17221 vere of the gpanten that 0

ab test ebould sot be included, Yat

. ardening 10 guarantt Quenching in water

fi should be opect fis jon, adopt Ba rceurk hardening ves « sintwus Rerdnens valse

or Sit Sh°Uks bac For the oteel 36 84,7) ta the fs oh auitanly Sclnenn (eve Sections 7.8 ant

Fg oe eitttnc an atandard, but 8 only verified mupdect

wor

a erreettoted in the arate 150 Standard and ts toe

te eres aMhamed on a martensite cost nyons auoee tbe contre (axis) of the hardened cress

eenore are Wetgrantionsl evendards alae give guaranteed Tt? for bardne ae quench

see eieun bardawen valuen fat 88 25 00 salad. condition to be guareatert

arene tate Line vith, the sateraationa, eres ee Tor comparable ot

ee eee ibe april 1995 neue of the DUR Sesser sone’ procesncre alee gave their Pe

pine Wan Pe NS okeela for epringe re SOMceTaeS oe Soe toee Sr aanenting to. the Lovet

er na shane ter ezze at the techaical and erononts factors which ‘pple

Table 5). Tigrennent vie ordering. The 11s

Top Din» Draft Internationa standard, 140 draft

- BIN 47221 Page 9

Tas provisions relating te pechantonl propertion ta the au . ores om

ditige alee apres aleoet in thets entirety vith the international standards. Tale applies both te the tale

tos ia fabte F aad to their verification which 10 perfornet on reference apocinans sf 10 er dianster, Coos

pered with the carlior voroion of the DIX Standard the winiaun valuce of yield point and tensile etreagth

Rive bows elightiy increased.

fete 7 gives the poraisetbie maximun valuse of ourte

Seo Lio” dn the Rot ration condition, ‘These. pre

fencielons of delivery weationsd. Foe values

Righ-grede

st fron the International

sot been possible

Perforned notallograpbically according to

in the view of the majority of users and producers, Bas

the esthod described in ection 8.4.6 vbich,

proved satiafactory.

Ho apecifications relating te quality steele have been included ia the Standard. Theae cannot be required

vis. Steels alloyed vith eilicon show « aark

carbarisation and vith euch steels total 4's earburisation

In general Layout the present Standard corresponds te the nev segue of DIN 17200. The provisions relating

te the production process, the soden of delivery and the teeting have been hureccized an fur as possitie

with the interaaticnal standards. Vith ainer anendnente and the Beceseary additi

duced ateols the particulars regarding the heat-treatacnt aad weebility ef the

fron the earlier fosue of the Standard.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- ASME B16.47 Series B FlangeDokumen4 halamanASME B16.47 Series B Flange41h189Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- API 5L - 43rd and 44th Ed - Comparison r1Dokumen68 halamanAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- LNG Tank Dismantling MS RevCDokumen14 halamanLNG Tank Dismantling MS RevChasan_676489616100% (1)

- Method of Statement Piping Fab. ErectionDokumen22 halamanMethod of Statement Piping Fab. Erectionhasan_676489616Belum ada peringkat

- Fall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public ConsultDokumen40 halamanFall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public Consultlwin_oo2435100% (4)

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- ITP For Piping WorksDokumen91 halamanITP For Piping Workshasan_676489616100% (1)

- Construction ProcedureDokumen36 halamanConstruction ProcedureJagdish Busa100% (2)

- PNFJ8000Dokumen71 halamanPNFJ8000seenu189100% (1)

- OSHA - 29CFR - Construction StandardsDokumen22 halamanOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- Shear and Moment Diagrams - Including The 3 Moment Equation and ExamplesDokumen300 halamanShear and Moment Diagrams - Including The 3 Moment Equation and Examplessoulsell100% (7)

- FAG Bearings For Rolling Mills Application PDFDokumen69 halamanFAG Bearings For Rolling Mills Application PDFPintu SarkarBelum ada peringkat

- Steel Grades ComparisonDokumen14 halamanSteel Grades Comparisonhasan_676489616Belum ada peringkat

- Acid PipingDokumen1 halamanAcid Pipinghasan_676489616Belum ada peringkat

- Paul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDokumen438 halamanPaul K. Feyerabend - Philosophical Papers, Volume 4 - Physics and Philosophy-Cambridge University Press (2015) PDFDavor Katunarić100% (1)

- Shear Capacity of Circular Concrete SectionsDokumen14 halamanShear Capacity of Circular Concrete Sectionspatricklim1982Belum ada peringkat

- Delayed PWHTDokumen4 halamanDelayed PWHThasan_676489616Belum ada peringkat

- Horizontal Life Line CalculationDokumen1 halamanHorizontal Life Line Calculationhasan_676489616100% (1)

- Conservation of Energy Worksheet #1 Answers - 1Dokumen3 halamanConservation of Energy Worksheet #1 Answers - 1Fitz Baniqued67% (3)

- 2014 68 Eu PDFDokumen96 halaman2014 68 Eu PDFAlienshow100% (1)

- Celex:02014l0068 20140717:en:txtDokumen118 halamanCelex:02014l0068 20140717:en:txtedwinBelum ada peringkat

- Duty CycleDokumen1 halamanDuty Cyclehasan_676489616Belum ada peringkat

- Cross Cut TestDokumen1 halamanCross Cut Testhasan_676489616Belum ada peringkat

- 1926.501 - Duty To Have Fall ProtectionDokumen4 halaman1926.501 - Duty To Have Fall Protectionhasan_676489616Belum ada peringkat

- E SN854Dokumen2 halamanE SN854hasan_676489616Belum ada peringkat

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDokumen24 halamanPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishBelum ada peringkat

- Solar Power Plant ReportDokumen1 halamanSolar Power Plant Reporthasan_676489616Belum ada peringkat

- Stainless Steels For H2SO4Dokumen4 halamanStainless Steels For H2SO4Marshel LeninBelum ada peringkat

- E SN834Dokumen3 halamanE SN834hasan_676489616Belum ada peringkat

- FITTINGS ButtweldDokumen5 halamanFITTINGS ButtweldThamaraikani ManiBelum ada peringkat

- Din 2461-66Dokumen7 halamanDin 2461-66hasan_676489616Belum ada peringkat

- E SN883Dokumen2 halamanE SN883hasan_676489616100% (1)

- E SN882Dokumen2 halamanE SN882hasan_676489616Belum ada peringkat

- Din 2614Dokumen11 halamanDin 2614hasan_676489616Belum ada peringkat

- Practice 5 - Questions - CSWIPDokumen16 halamanPractice 5 - Questions - CSWIPravichandran0506Belum ada peringkat

- 8fc63d2f f6Dokumen18 halaman8fc63d2f f6Chandra MohanBelum ada peringkat

- MPD 02 - Breakdown Dan Teori PDDokumen34 halamanMPD 02 - Breakdown Dan Teori PDAriBelum ada peringkat

- Assignment - Metals and Non MetalsDokumen3 halamanAssignment - Metals and Non MetalsHayyagoBelum ada peringkat

- Materials Science and Engineering Concept Check Part3 PDFDokumen26 halamanMaterials Science and Engineering Concept Check Part3 PDF李宛芸Belum ada peringkat

- Tutorial - 2-1 - 230521 - 212904 - 230602 - 225042Dokumen8 halamanTutorial - 2-1 - 230521 - 212904 - 230602 - 225042Ajj JajBelum ada peringkat

- Extended Surface Heat TransferDokumen42 halamanExtended Surface Heat TransferAbubakkar Siddiq100% (2)

- Composite Structures: SciencedirectDokumen9 halamanComposite Structures: SciencedirectbarracudacemBelum ada peringkat

- 2018 - OL - VERY IMPORTANT - Tailoring A Nanofiber For Enhanced Photon Emission and Coupling Efficiency From Single Quantum EmittersDokumen4 halaman2018 - OL - VERY IMPORTANT - Tailoring A Nanofiber For Enhanced Photon Emission and Coupling Efficiency From Single Quantum EmittersMaslovBelum ada peringkat

- Pengaruh Penambahan Serat Bambu Terhadap Kuat Tarik Dan Kuat Tekan BetonDokumen6 halamanPengaruh Penambahan Serat Bambu Terhadap Kuat Tarik Dan Kuat Tekan Betonmuhajir mrbBelum ada peringkat

- Finite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFDokumen13 halamanFinite Element Analysis of The Direct Shear Box Test - Potts (1987) PDFAlfredo López HernándezBelum ada peringkat

- Grain-Oriented Electrical SteelDokumen11 halamanGrain-Oriented Electrical SteelMakhlouf HamideBelum ada peringkat

- Pis 45880 GB 20140526Dokumen2 halamanPis 45880 GB 20140526Linnie McleodBelum ada peringkat

- Reprap Hotend Thermistor NTC 3950 100K PDFDokumen7 halamanReprap Hotend Thermistor NTC 3950 100K PDFKaveesha DinamiduBelum ada peringkat

- Sample MCQ Mec201Dokumen10 halamanSample MCQ Mec201UjjalKalitaBelum ada peringkat

- Physics Sectionwise Analysis of PYQs (For 2023) - PDFDokumen4 halamanPhysics Sectionwise Analysis of PYQs (For 2023) - PDFShreyas manteBelum ada peringkat

- Appendix 1 2017Dokumen34 halamanAppendix 1 2017Sohrab FarmanBelum ada peringkat

- Mechanical Engineering Important MCQ PDF-Fluid Mechanics 2Dokumen8 halamanMechanical Engineering Important MCQ PDF-Fluid Mechanics 2kibrom atsbhaBelum ada peringkat

- 0B5fN9XjkYQyiNS1HTXRfc2hNYU0 PDFDokumen23 halaman0B5fN9XjkYQyiNS1HTXRfc2hNYU0 PDFVikram MBelum ada peringkat

- McGill CHEM - 110Dokumen4 halamanMcGill CHEM - 110RafaBelum ada peringkat

- Design of UFP-coupled Post-Tensioned Timber Shear WallsDokumen10 halamanDesign of UFP-coupled Post-Tensioned Timber Shear WallsRafael Arízaga BravoBelum ada peringkat

- Aluminum Alloys - Mechanical Properties PDFDokumen10 halamanAluminum Alloys - Mechanical Properties PDFMohamed NasrBelum ada peringkat

- (Doru Michael Stefanescu) Science and EngineeringDokumen413 halaman(Doru Michael Stefanescu) Science and EngineeringJayant Raj SauravBelum ada peringkat

- Drift-Diffusion Model: Introduction: Dragica VasileskaDokumen9 halamanDrift-Diffusion Model: Introduction: Dragica VasileskaLê Văn TrungBelum ada peringkat

- Experiment 1 FamiliarizationDokumen7 halamanExperiment 1 FamiliarizationSeif-El-Islam BayBelum ada peringkat

- A Practical 3D Bounding Surface Plastic Sand Model For Geotechnical Earthquake Engineering ApplicationDokumen11 halamanA Practical 3D Bounding Surface Plastic Sand Model For Geotechnical Earthquake Engineering ApplicationMiguel Angel LuceroBelum ada peringkat