Slag Defects in Grey Iron

Diunggah oleh

arnaldorcr8646100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

993 tayangan1 halamanHak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

993 tayangan1 halamanSlag Defects in Grey Iron

Diunggah oleh

arnaldorcr8646Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

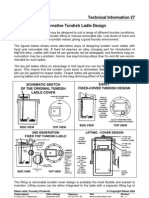

Technical Information 33

Slag Defects in Grey Iron

Slag defects in grey iron is typically found in the cope side or dispersed due to turbulent

mold filling. Grey iron slag inclusions are typically a result of improper separation of base

metal slag or oxidation of the metal during processing. Defects can also occur as a result

of reactions between metal and mold materials.

Grey iron slag inclusions are typically high in manganese, silicon and iron, and sometimes

other slag forming constituents such as Ca and Al from alloy additions can be found. Slag

inclusions common also coexist with sand grains from reactions with the mould.

Example of grey iron slag inclusion cluster. Close-up of slag cluster showing various phases.

Possible causes: Possible cures:

• Inadequate slag separation from melting • Improve slag removal procedures.

and pouring systems. • Proper draining of ladles and received to

• Cold metal heels in ladles and receivers. avoid cold metal heels.

• Lack of slag traps or filters. • Review gating system and avoid

• Low pouring temperature. turbulent mould filling.

• Excess addition of slag forming • Use filters in the gating system.

materials. • Increase pouring temperature.

• Turbulent mould filling. • Use an inoculant with low contents of

slag forming elements such as Ca and

Al.

• Use inoculants with fast dissolution

characteristics and the correct sizing.

• Avoid adding silicon carbide at a late

stage of processing.

Elkem ASA, Foundry Products © Copyright Elkem ASA

Postal address Office address Telephone Web Revision

P.O.Box 5211 Majorstuen Hoffsveien 65B +47 22 45 01 00 www.foundry.elkem.com No. 1.1

NO-0302 Oslo Oslo Telefax Org. no. 20.03.2004

Norway Norway +47 22 45 01 52 NO 911 382 008 MVA

Anda mungkin juga menyukai

- Technical InformationDokumen78 halamanTechnical InformationCarlos Barrachina Martínez100% (2)

- 26-ELKEM - Poster-Graphite Structures in Cast IronsDokumen1 halaman26-ELKEM - Poster-Graphite Structures in Cast IronsSalvador Rocha100% (2)

- Fading of Nodularity in Ductile IronDokumen2 halamanFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- ELMAGDokumen2 halamanELMAGthomazfabricioBelum ada peringkat

- Hot Topics: Effect of Magnesium in Ductile IronDokumen3 halamanHot Topics: Effect of Magnesium in Ductile Ironsidharth saraswatBelum ada peringkat

- Common Metallurgical Defects in Ductile Cast IronDokumen10 halamanCommon Metallurgical Defects in Ductile Cast IronsateeshkoriBelum ada peringkat

- Common Metallurgical Defects in Ductile Cast IronDokumen10 halamanCommon Metallurgical Defects in Ductile Cast IronsateeshkoriBelum ada peringkat

- Common Metallurgical Defects in Ductile Cast IronDokumen10 halamanCommon Metallurgical Defects in Ductile Cast IronsateeshkoriBelum ada peringkat

- Elkem 19 Aluminum in Cast IronDokumen2 halamanElkem 19 Aluminum in Cast Ironmarcotulio123Belum ada peringkat

- Hydrogen PinholesDokumen1 halamanHydrogen Pinholesarnaldorcr8646Belum ada peringkat

- Fading of Nodularity in Ductile IronDokumen2 halamanFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- Flash On English For Mechanics, Electronics and Technical Assistance - Answer Key and TranscriptsDokumen11 halamanFlash On English For Mechanics, Electronics and Technical Assistance - Answer Key and TranscriptsRe A.100% (1)

- Copper 2010 ProgramDokumen44 halamanCopper 2010 ProgramCecilia Iter100% (1)

- Magnesium Slag Defects in Ductile IronDokumen1 halamanMagnesium Slag Defects in Ductile Ironarnaldorcr8646100% (1)

- Carbon Monoxide Blowholes in Grey IronDokumen1 halamanCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646Belum ada peringkat

- Poor Nodularity in Ductile IronDokumen2 halamanPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- Selection of Inoculants For Ductile Cast IronDokumen1 halamanSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- SG Iron ProductionDokumen20 halamanSG Iron ProductionShreyashri Nayak100% (1)

- Nitrogen FissuresDokumen1 halamanNitrogen Fissuresarnaldorcr8646100% (1)

- Selection of Inoculants For Grey Cast IronDokumen2 halamanSelection of Inoculants For Grey Cast Ironarnaldorcr8646Belum ada peringkat

- Common Metallurgical Defects in Ductile IronDokumen1 halamanCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- Common Metallurgical Defects in Grey Iron English (1Dokumen1 halamanCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- Fading of InoculationDokumen2 halamanFading of Inoculationarnaldorcr8646Belum ada peringkat

- Chunky GraphiteDokumen16 halamanChunky GraphitesachinguptachdBelum ada peringkat

- Mould & Core Material for the Steel FoundryDari EverandMould & Core Material for the Steel FoundryPenilaian: 5 dari 5 bintang5/5 (2)

- Nitrogen in Cast IronDokumen4 halamanNitrogen in Cast IronFaizan TahirBelum ada peringkat

- Selection of NodularizersDokumen2 halamanSelection of Nodularizersarnaldorcr8646100% (2)

- Inoculation of Heavy Section CastingsDokumen2 halamanInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Effects of Minor and Trace Elements in Cast IronDokumen2 halamanEffects of Minor and Trace Elements in Cast Ironarnaldorcr864667% (3)

- Magnesium Contents in Ductile IronDokumen2 halamanMagnesium Contents in Ductile Ironarnaldorcr8646Belum ada peringkat

- Composition of Grey Cast IronDokumen2 halamanComposition of Grey Cast IronPranil GhatageBelum ada peringkat

- S.G. Iron : MouldingDokumen11 halamanS.G. Iron : MouldingsureshbabuamalaBelum ada peringkat

- Foundry DefectsDokumen12 halamanFoundry DefectsVirendra Gupta100% (1)

- Shrinkage in Ductile IronDokumen5 halamanShrinkage in Ductile Ironkarthikkanda100% (1)

- Recommended Target Analysis For Ductile IronDokumen2 halamanRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- Common Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageDokumen1 halamanCommon Metallurgical Defects in Grey Iron: Hydrogen Blowhole Nitrogen Fissure Compaction of Graphite Flakes ShrinkageJoao LuisBelum ada peringkat

- Effect of Minor and Trace Elements in Cast IronDokumen2 halamanEffect of Minor and Trace Elements in Cast IronsachinguptachdBelum ada peringkat

- Effects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsDokumen5 halamanEffects of Alloying Elements On The Micro Structures and Mechanical On Ductile Cast IronsCharlie Chong100% (6)

- Shrinkage in Iron CastingsDokumen10 halamanShrinkage in Iron CastingskarthikkandaBelum ada peringkat

- Alternative Tundish Ladle DesignDokumen2 halamanAlternative Tundish Ladle Designarnaldorcr8646Belum ada peringkat

- Late Metal Stream InoculationDokumen2 halamanLate Metal Stream Inoculationarnaldorcr8646Belum ada peringkat

- Effect of Minor and Trace Elements in Cast IronDokumen2 halamanEffect of Minor and Trace Elements in Cast IronsachinguptachdBelum ada peringkat

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDokumen2 halamanPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Belum ada peringkat

- Surface Graphite Degeneration in Ductile Iron CastDokumen8 halamanSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarBelum ada peringkat

- Nitrogen Fissures Defects in Iron Castings: Back ToDokumen2 halamanNitrogen Fissures Defects in Iron Castings: Back ToJustin DixonBelum ada peringkat

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDokumen8 halamanRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazBelum ada peringkat

- Sampling of Liquid Cast IronDokumen2 halamanSampling of Liquid Cast Ironarnaldorcr8646Belum ada peringkat

- Elkem 05 Inoculation MechanismsDokumen2 halamanElkem 05 Inoculation Mechanismsmarcotulio123Belum ada peringkat

- Elkem 07 Magnesiun Contents in Ductile IronDokumen2 halamanElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Belum ada peringkat

- Elkem 13 Compacted Graphite IronDokumen2 halamanElkem 13 Compacted Graphite Ironmarcotulio123Belum ada peringkat

- Ductile Dross Formation MonitoringDokumen27 halamanDuctile Dross Formation MonitoringsachinguptachdBelum ada peringkat

- Common Metallurgical Defects in Grey Cast Irons 2Dokumen1 halamanCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiBelum ada peringkat

- Common Metallurgical Defects in Grey Cast IronDokumen9 halamanCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Elkem 10 Tundish Cover Ladle NodularizationDokumen2 halamanElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Belum ada peringkat

- S.G IronDokumen6 halamanS.G IronQasim BarkatBelum ada peringkat

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDokumen23 halaman1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Defects in Ductile IronDokumen12 halamanDefects in Ductile IronSerdar çevikBelum ada peringkat

- Metallurgical Defects of Cast Steel: SeminarDokumen26 halamanMetallurgical Defects of Cast Steel: SeminarAndré RibeiroBelum ada peringkat

- Effect of Bismuth in Ductile IronDokumen4 halamanEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Ductile Cast IronDokumen9 halamanDuctile Cast Ironander_sarettaBelum ada peringkat

- 26-ELKEM Poster-Graphite Structures in Cast IronsDokumen1 halaman26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENBelum ada peringkat

- Carbon Monoxide Blowholes in Grey IronDokumen1 halamanCarbon Monoxide Blowholes in Grey IronAmnartBelum ada peringkat

- Secondary Steelmaking: Topics To Discuss ..Dokumen11 halamanSecondary Steelmaking: Topics To Discuss ..Mir RafsanBelum ada peringkat

- Type of InclusionDokumen58 halamanType of Inclusionravindra191274Belum ada peringkat

- Casting DefectsDokumen57 halamanCasting DefectsFajar SiradzBelum ada peringkat

- Chunky GraphiteDokumen16 halamanChunky GraphitesachinguptachdBelum ada peringkat

- Casting DefectDokumen90 halamanCasting DefectNayan PatelBelum ada peringkat

- Determining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004Dokumen8 halamanDetermining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004arnaldorcr8646Belum ada peringkat

- Heat Conservation in Liquid Iron, 2005-07-10Dokumen5 halamanHeat Conservation in Liquid Iron, 2005-07-10arnaldorcr8646100% (1)

- Compacted Iron ElkemDokumen20 halamanCompacted Iron ElkemAmol ThakurBelum ada peringkat

- Inoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesDokumen12 halamanInoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesZody YtuBelum ada peringkat

- Inoculation of Heavy Section CastingsDokumen2 halamanInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Magnesium Versus Sulphur in Ductile IronDokumen2 halamanMagnesium Versus Sulphur in Ductile Ironarnaldorcr8646100% (2)

- In The Mould Nodular Is IngDokumen2 halamanIn The Mould Nodular Is Ingarnaldorcr8646Belum ada peringkat

- Nitrogen FissuresDokumen1 halamanNitrogen Fissuresarnaldorcr8646100% (1)

- Internal Shrinkage PorosityDokumen1 halamanInternal Shrinkage Porosityarnaldorcr8646100% (2)

- Factors Influencing The Recovery and Addition of MagnesiumDokumen4 halamanFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Belum ada peringkat

- Late Metal Stream InoculationDokumen2 halamanLate Metal Stream Inoculationarnaldorcr8646Belum ada peringkat

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDokumen2 halamanPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Belum ada peringkat

- Selection of NodularizersDokumen2 halamanSelection of Nodularizersarnaldorcr8646100% (2)

- Factors Influencing The Recovery and Addition of MagnesiumDokumen4 halamanFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Belum ada peringkat

- Heat Conservation in Liquid IronDokumen2 halamanHeat Conservation in Liquid Ironarnaldorcr8646Belum ada peringkat

- Alternative Tundish Ladle DesignDokumen2 halamanAlternative Tundish Ladle Designarnaldorcr8646Belum ada peringkat

- Selection of Inoculants For Grey Cast IronDokumen2 halamanSelection of Inoculants For Grey Cast Ironarnaldorcr8646Belum ada peringkat

- The "Sandwich Pocket Process"Dokumen2 halamanThe "Sandwich Pocket Process"arnaldorcr8646Belum ada peringkat

- Recommended Target Analysis For Grey IronDokumen2 halamanRecommended Target Analysis For Grey Ironarnaldorcr8646Belum ada peringkat

- G9 Metals and Reactivity TESTDokumen4 halamanG9 Metals and Reactivity TESTMiral AlasbahiBelum ada peringkat

- Debinding and Sintering Solutions For Metals and CeramicsDokumen8 halamanDebinding and Sintering Solutions For Metals and CeramicsdtkraeutBelum ada peringkat

- Getting Graphite Prices RightDokumen5 halamanGetting Graphite Prices RightMochammad AdamBelum ada peringkat

- A Guide To Weapon SmithDokumen41 halamanA Guide To Weapon SmithYato LeoBelum ada peringkat

- Chemistry ClassX AssignmentDokumen6 halamanChemistry ClassX AssignmentBharatiyaNaariBelum ada peringkat

- Chapter 1 - Introduction To Material Science and EngineeringDokumen31 halamanChapter 1 - Introduction To Material Science and EngineeringImran Rizal100% (2)

- Component Shelf Life 8a GEDokumen35 halamanComponent Shelf Life 8a GEpapplionBelum ada peringkat

- RecyclingDokumen87 halamanRecyclingMashrurSamit 17Belum ada peringkat

- Charadva Bhavin: Summer Internship Project ON Shree Mahavir Metalcraft Pvt. LTDDokumen100 halamanCharadva Bhavin: Summer Internship Project ON Shree Mahavir Metalcraft Pvt. LTDrinkuchheda100% (1)

- Edema 1Dokumen9 halamanEdema 1Edema O. GregoryBelum ada peringkat

- Snake Plant (Sanseviera Trifasciata) Extract As Corrosion Inhibitor To Galvanized Iron Sheet and Copper Slab BarDokumen26 halamanSnake Plant (Sanseviera Trifasciata) Extract As Corrosion Inhibitor To Galvanized Iron Sheet and Copper Slab BarGerelizza anggaBelum ada peringkat

- Definitions - Topic 3 Atoms Elements and Compounds - CAIE Chemistry IGCSEDokumen2 halamanDefinitions - Topic 3 Atoms Elements and Compounds - CAIE Chemistry IGCSEAtif BakhshBelum ada peringkat

- Emtak 2008Dokumen232 halamanEmtak 2008Kotova AminaBelum ada peringkat

- Wire Design Basics - Jewelry Making With Beads, JewelryDokumen52 halamanWire Design Basics - Jewelry Making With Beads, JewelryLuna Serpaggi100% (2)

- Corrosion ProtectionDokumen95 halamanCorrosion ProtectionNestor Mijares100% (1)

- Allot RopesDokumen6 halamanAllot RopesAmira katkhudaBelum ada peringkat

- Guidelines On Materials Requirements For Carbon and Low Alloy Steels For H S-Containing Environments in Oil and Gas ProductionDokumen55 halamanGuidelines On Materials Requirements For Carbon and Low Alloy Steels For H S-Containing Environments in Oil and Gas ProductionramaniBelum ada peringkat

- SilberlineBrochure2011 SmallDokumen18 halamanSilberlineBrochure2011 SmallJuan Angel DechimaBelum ada peringkat

- Unit - I: Classes of Engineering Materials & Conducting MaterialsDokumen18 halamanUnit - I: Classes of Engineering Materials & Conducting MaterialsDeependra SinghBelum ada peringkat

- GCSE Chemistry Revision Notes (4-6)Dokumen4 halamanGCSE Chemistry Revision Notes (4-6)Promise OjoBelum ada peringkat

- Key Criteria For Matching Filler Metals To Your Base MaterialDokumen3 halamanKey Criteria For Matching Filler Metals To Your Base MaterialchowhkBelum ada peringkat

- Dgca Question Module 6 and 7Dokumen29 halamanDgca Question Module 6 and 7Kusum chaurasiaBelum ada peringkat

- Sae Ams-W-6858Dokumen46 halamanSae Ams-W-6858Luis HernandezBelum ada peringkat

- Fallas Boiler (Babcock and Wilcox)Dokumen8 halamanFallas Boiler (Babcock and Wilcox)scofiel1Belum ada peringkat

- Code of Practice For SuperintendentsDokumen74 halamanCode of Practice For Superintendentsprionus2002Belum ada peringkat

- Development of The Matching Filler Metal For MARBN - New Advanced Creep Resisting Alloys For Thermal Power PlanDokumen10 halamanDevelopment of The Matching Filler Metal For MARBN - New Advanced Creep Resisting Alloys For Thermal Power PlanBurag HamparyanBelum ada peringkat

- The History of WeldingDokumen18 halamanThe History of WeldingMalcolm Diamond100% (1)

- Polyaniline Coatings For Corrosion ProtectionDokumen4 halamanPolyaniline Coatings For Corrosion ProtectionAnonymous T02GVGzBBelum ada peringkat