Grit Chamber

Diunggah oleh

gaur_shashikant4432Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Grit Chamber

Diunggah oleh

gaur_shashikant4432Hak Cipta:

Format Tersedia

GRIT CHAMBER

Grit Chambers

Grit chambers are basin to remove the inorganic particles to prevent damage to the pumps, and to prevent

their accumulation in sludge digestors.

Types of Grit Chambers

Grit chambers are of two types: mechanically cleaned and manually cleaned. In mechanically cleaned

grit chamber, scraper blades collect the grit settled on the floor of the grit chamber. The grit so collected is

elevated to the ground level by several mechanisms such as bucket elevators, jet pump and air lift. The

grit washing mechanisms are also of several designs most of which are agitation devices using either

water or air to produce washing action. Manually cleaned grit chambers should be cleaned at least once a

week. The simplest method of cleaning is by means of shovel.

Aerated Grit Chamber

An aerated grit chamber consists of a standard spiral flow aeration tank provided with air diffusion tubes

placed on one side of the tank. The grit particles tend to settle down to the bottom of the tank at rates

dependant upon the particle size and the bottom velocity of roll of the spiral flow, which in turn depends

on the rate of air diffusion through diffuser tubes and shape of aeration tank. The heavier particles settle

down whereas the lighter organic particles are carried with roll of the spiral motion.

Principle of Working of Grit Chamber

Grit chambers are nothing but like sedimentation tanks, designed to separate the intended heavier

inorganic materials (specific gravity about 2.65) and to pass forward the lighter organic materials. Hence,

the flow velocity should neither be too low as to cause the settling of lighter organic matter, nor should it

be too high as not to cause the settlement of the silt and grit present in the sewage. This velocity is called

"differential sedimentation and differential scouring velocity". The scouring velocity determines the

optimum flow through velocity. This may be explained by the fact that the critical velocity of flow 'vc'

beyond which particles of a certain size and density once settled, may be again introduced into the stream

of flow. It should always be less than the scouring velocity of grit particles. The critical velocity of scour

is given by Schield's formula:

V = 3 to 4.5 (g(Ss - 1)d)1/2

A horizontal velocity of flow of 15 to 30 cm/sec is used at peak flows. This same velocity is to be

maintained at all fluctuation of flow to ensure that only organic solids and not the grit is scoured from the

bottom.

Types of Velocity Control Devices

1. A sutro weir in a channel of rectangular cross section, with free fall downstream of the channel.

2. A parabolic shaped channel with a rectangular weir.

3. A rectangular shaped channel with a parshall flume at the end which would also help easy flow

measurement.

Design of Grit Chambers

Settling Velocity

The settling velocity of discrete particles can be determined using appropriate equation depending upon

Reynolds number.

Stoke's law:

Stoke's law holds good for Reynolds number,Re below 1.

Re=vd/

For grit particles of specific gravity 2.65 and liquid temperature at 10C, =1.01 x 10-6m 2/s. This

corresponds to particles of size less than 0.1 mm.

Transition law: The design of grit chamber is based on removal of grit particles with minimum size of

0.15 mm and therefore Stoke's law is not applicable to determine the settling velocity of grit particles for

design purposes.

where, CD= drag coefficient Transition flow conditions hold good for Reynolds number,Re between 1

and 1000. In this range CD can be approximated by

Primary Sedimentation

Primary sedimentation in a municipal wastewater treatment plant is generally plain sedimentation without

the use of chemicals. In treating certain industrial wastes chemically aided sedimentation may be

involved. In either case, it constitutes flocculent settling, and the particles do not remain discrete as in the

case of grit, but tend to agglomerate or coagulate during settling. Thus, their diameter keeps increasing

and settlement proceeds at an over increasing velocity. Consequently, they trace a curved profile.

The settling tank design in such cases depends on both surface loading and detention time.

Long tube settling tests can be performed in order to estimate specific value of surface loading and

detention time for desired efficiency of clarification for a given industrial wastewater using recommended

methods of testing. Scale-up factors used in this case range from 1.25 to 1.75 for the overflow rate, and

from 1.5 to 2.0 for detention time when converting laboratory results to the prototype design.

For primary settling tanks treating municipal or domestic sewage, laboratory tests are generally not

necessary, and recommended design values given in table may be used. Using an appropriate value of

surface loading from table, the required tank area is computed. Knowing the average depth, the detention

time is then computed. Excessively high detention time (longer than 2.5 h) must be avoided especially in

warm climates where anaerobicity can be quickly induced.

Design parameters for settling tank

Anda mungkin juga menyukai

- Evidence Based Practice in Nursing Healthcare A Guide To Best Practice 3rd Edition Ebook PDFDokumen62 halamanEvidence Based Practice in Nursing Healthcare A Guide To Best Practice 3rd Edition Ebook PDFwilliam.tavares69198% (50)

- Service Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckDokumen26 halamanService Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckEduardo Reis100% (1)

- 4.9 Design of Compression Members: L 4.7 UsingDokumen22 halaman4.9 Design of Compression Members: L 4.7 Usingctc1212100% (1)

- Tech City-STP 100 KLD Price Comparison (03092016)Dokumen10 halamanTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseBelum ada peringkat

- Enviraj MBBR CalculatorDokumen3 halamanEnviraj MBBR Calculatorankur100% (2)

- ASP - Process Design CalculationDokumen21 halamanASP - Process Design Calculationvishu100% (1)

- MBR Vs SBRDokumen2 halamanMBR Vs SBRSanjeev Kachhara100% (1)

- Pepsi Mix Max Mox ExperimentDokumen2 halamanPepsi Mix Max Mox Experimentanon_192325873Belum ada peringkat

- LhiannanDokumen6 halamanLhiannanGreybornBelum ada peringkat

- Grit ChamberDokumen29 halamanGrit Chamberazcomp100% (1)

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsDari EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsBelum ada peringkat

- Design of Tanks and ChambersDokumen13 halamanDesign of Tanks and Chamberschariot1729Belum ada peringkat

- 250mld WTPDokumen6 halaman250mld WTPeepmcjayal2Belum ada peringkat

- Primary TreatmentDokumen22 halamanPrimary TreatmentEmil AbdoBelum ada peringkat

- Chapter 1 Basic Design ConsiderationDokumen38 halamanChapter 1 Basic Design ConsiderationAce ThunderBelum ada peringkat

- Mohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesDokumen104 halamanMohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesAnish Ghimire100% (1)

- Activated Sludge Calculations With Excel QuizDokumen2 halamanActivated Sludge Calculations With Excel Quiztrantrunghoa290784Belum ada peringkat

- Cost Analysis of Activated Sludge ProcessDokumen19 halamanCost Analysis of Activated Sludge ProcessDevendra Sharma100% (1)

- Equipment Design - Aeration TankDokumen6 halamanEquipment Design - Aeration TankKENGERALDBelum ada peringkat

- Operator - Book-StpDokumen113 halamanOperator - Book-StpAce Dynamics India100% (1)

- Hospital Waste Water TreatmentDokumen5 halamanHospital Waste Water TreatmentNP100% (1)

- Calculations Used in Daily Operations of An EtpDokumen9 halamanCalculations Used in Daily Operations of An Etpnguyen an100% (1)

- Journal of Water Process Engineering: SciencedirectDokumen8 halamanJournal of Water Process Engineering: SciencedirectOmar GameelBelum ada peringkat

- Tube Settler Systems For ClarificationDokumen7 halamanTube Settler Systems For Clarificationtrdakshayani100% (1)

- DesignDokumen3 halamanDesigntata_77Belum ada peringkat

- MBBR AgraDokumen44 halamanMBBR Agrasanjeevsharma9999100% (1)

- Principle of Working of Grit ChamberDokumen11 halamanPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- 40 KLD MBR QuoteDokumen15 halaman40 KLD MBR QuoteV Narasimha RajuBelum ada peringkat

- Anaerobic Treatment Systems Technical DesignDokumen64 halamanAnaerobic Treatment Systems Technical DesignJizzlmanizzlBelum ada peringkat

- Gravity - Rapid Sand FiltrationDokumen12 halamanGravity - Rapid Sand FiltrationBrudel_c100% (1)

- Interim Report 150 MLDDokumen112 halamanInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenBelum ada peringkat

- Preliminiary TreatmentDokumen22 halamanPreliminiary TreatmentIsmail toro100% (1)

- Microsoft Word - Festo Rain Water Harvesting Flow ChartDokumen5 halamanMicrosoft Word - Festo Rain Water Harvesting Flow Chartjeykumar.BalannairBelum ada peringkat

- Lesson Plan: How Do We Clean Polluted Water?Dokumen15 halamanLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyBelum ada peringkat

- The F To M RatioDokumen6 halamanThe F To M Ratiojokish100% (2)

- FiltrationDokumen23 halamanFiltrationsaefasd100% (1)

- Daf PDFDokumen10 halamanDaf PDFHRK65Belum ada peringkat

- Lesson 17 - Activated SludgeDokumen8 halamanLesson 17 - Activated SludgeShane RodriguezBelum ada peringkat

- SBR Sewage Treatment Plant Clear WaterDokumen12 halamanSBR Sewage Treatment Plant Clear WaterAndreea CalcanBelum ada peringkat

- Activated Sسمعيلثludge Calculation SheetDokumen14 halamanActivated Sسمعيلثludge Calculation SheetYasser Fathy Aly100% (1)

- Sewage Treatment WorksheetDokumen18 halamanSewage Treatment WorksheetRemedanBelum ada peringkat

- Concept of Zero DischargeDokumen4 halamanConcept of Zero DischargeShesharam Chouhan67% (3)

- EE-2 Mini Project ReportDokumen7 halamanEE-2 Mini Project Report63GANESH SINGHCIVILBelum ada peringkat

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDokumen47 halamanDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALABelum ada peringkat

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDokumen8 halaman04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyBelum ada peringkat

- 5m3d MBR Packaged STP 2017.3.28Dokumen13 halaman5m3d MBR Packaged STP 2017.3.28DevBelum ada peringkat

- Ate Huber-1Dokumen47 halamanAte Huber-1Ravena RemaditaBelum ada peringkat

- ClarifierDokumen1 halamanClarifiergroup2sd1314Belum ada peringkat

- Effluent Treatment PlantDokumen16 halamanEffluent Treatment PlantVishal guptaBelum ada peringkat

- Advanced Activated Sludge ProcessDokumen5 halamanAdvanced Activated Sludge ProcessDileep C DileepBelum ada peringkat

- ETP Design CalculationDokumen6 halamanETP Design Calculationmanuel.hernandez100% (2)

- Wastewater Reuse FinalDokumen36 halamanWastewater Reuse FinalAshraf RefaatBelum ada peringkat

- Efficiency Comparison of Various Sewage Treatment Plants in BangaloreDokumen36 halamanEfficiency Comparison of Various Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- Design of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana StateDokumen6 halamanDesign of 125 KLD Sewage Treatment Plant at Dundigal Village, Medchal Distrct, Telanagana Statedeepak kumarBelum ada peringkat

- UASB-Process Design For Various Types of WastewatersDokumen21 halamanUASB-Process Design For Various Types of WastewatersapitbhuBelum ada peringkat

- Slow Sand Filtration Dwfsom40 PDFDokumen4 halamanSlow Sand Filtration Dwfsom40 PDFjose03Belum ada peringkat

- STP AdequacyDokumen5 halamanSTP AdequacyenvsandyBelum ada peringkat

- Design of WTP and STPDokumen14 halamanDesign of WTP and STPVenu Ch100% (1)

- Sequencing Batch Reactor Technology For Biological Wastewater Treatment: A ReviewDokumen9 halamanSequencing Batch Reactor Technology For Biological Wastewater Treatment: A ReviewDiliptiwariBelum ada peringkat

- Trickling FilterDokumen7 halamanTrickling FilterTasirmistBelum ada peringkat

- Anaerobic FilterDokumen7 halamanAnaerobic FilterdlunaoneBelum ada peringkat

- Biomod: Packaged Moving Bed Biofilm ReactorDokumen4 halamanBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- Sanitary Engineer II: Passbooks Study GuideDari EverandSanitary Engineer II: Passbooks Study GuideBelum ada peringkat

- Design of Shopping ComplexDokumen110 halamanDesign of Shopping Complexgaur_shashikant4432100% (1)

- Mohd Fakri Muda MFKA2009 ABSDokumen5 halamanMohd Fakri Muda MFKA2009 ABSgaur_shashikant4432Belum ada peringkat

- Time Table JAN 2016 CIVILDokumen1 halamanTime Table JAN 2016 CIVILgaur_shashikant4432Belum ada peringkat

- Time Table JAN 2016 CIVILDokumen1 halamanTime Table JAN 2016 CIVILgaur_shashikant4432Belum ada peringkat

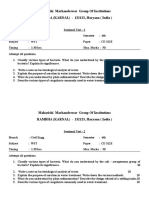

- Oup of Institutions, Rambha (Karnal) Course: B.Tech, Session: 2013-14 Time Table Civil 3Rd SemDokumen1 halamanOup of Institutions, Rambha (Karnal) Course: B.Tech, Session: 2013-14 Time Table Civil 3Rd Semgaur_shashikant4432Belum ada peringkat

- Maharishi Markandeswar Group of Institutions RAMBHA (KARNAL) - 132123, Haryana (India)Dokumen3 halamanMaharishi Markandeswar Group of Institutions RAMBHA (KARNAL) - 132123, Haryana (India)gaur_shashikant4432Belum ada peringkat

- Maharishi Markandeswar Group of Institutions RAMBHA (KARNAL) - 132123, Haryana (India)Dokumen3 halamanMaharishi Markandeswar Group of Institutions RAMBHA (KARNAL) - 132123, Haryana (India)gaur_shashikant4432Belum ada peringkat

- Applications of Bituminous Emulsions in Road ConstructionDokumen27 halamanApplications of Bituminous Emulsions in Road Constructionravi1625Belum ada peringkat

- A Study On Properties of Concrete With The Use of Jute FiberDokumen22 halamanA Study On Properties of Concrete With The Use of Jute Fibergaur_shashikant4432Belum ada peringkat

- Notification HSSC JobsDokumen13 halamanNotification HSSC JobsUpamanyu ChauhanBelum ada peringkat

- Ece Labs DetailDokumen7 halamanEce Labs Detailgaur_shashikant4432Belum ada peringkat

- Outline 03Dokumen14 halamanOutline 03Carlos Rene Mamani TrujilloBelum ada peringkat

- Hpu II Je 2015Dokumen15 halamanHpu II Je 2015gaur_shashikant4432Belum ada peringkat

- Advertisement No. DLG RC 2015 1 Dated 01 July 2015Dokumen7 halamanAdvertisement No. DLG RC 2015 1 Dated 01 July 2015gaur_shashikant4432Belum ada peringkat

- Civil 13Dokumen5 halamanCivil 13gaur_shashikant4432Belum ada peringkat

- Himachal Pradesh Public Service Commission: Principal (ITI) - 2014Dokumen1 halamanHimachal Pradesh Public Service Commission: Principal (ITI) - 2014gaur_shashikant4432Belum ada peringkat

- Handbook QFD ServicesDokumen25 halamanHandbook QFD ServicesMoeshfieq WilliamsBelum ada peringkat

- JFR Final Project ReportDokumen78 halamanJFR Final Project Reportgaur_shashikant4432Belum ada peringkat

- Structural Safety CertificateDokumen1 halamanStructural Safety Certificategaur_shashikant4432100% (1)

- M TechDokumen33 halamanM Techgaur_shashikant4432Belum ada peringkat

- IV SemesterDokumen12 halamanIV SemesterShashikant GaurBelum ada peringkat

- Return FormDokumen1 halamanReturn Formgaur_shashikant4432Belum ada peringkat

- Foundation 2Dokumen74 halamanFoundation 2gaur_shashikant4432Belum ada peringkat

- Maharishi Markandeswar Group of Institutions: RAMBHA (KARNAL) - 132123, Haryana (India)Dokumen1 halamanMaharishi Markandeswar Group of Institutions: RAMBHA (KARNAL) - 132123, Haryana (India)shashikantgaurBelum ada peringkat

- Principles of Environment ManagementDokumen2 halamanPrinciples of Environment Managementgaur_shashikant4432Belum ada peringkat

- Construction ManagementDokumen23 halamanConstruction Managementgaur_shashikant4432Belum ada peringkat

- SUMITDokumen10 halamanSUMITgaur_shashikant4432Belum ada peringkat

- ST.T FormDokumen9 halamanST.T FormPatiala BsnlBelum ada peringkat

- Chauhan For Structure-ModelDokumen1 halamanChauhan For Structure-Modelgaur_shashikant4432Belum ada peringkat

- -4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويDokumen35 halaman-4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويAboalmaail Alamin100% (1)

- Data Mining For Business Analyst AssignmentDokumen9 halamanData Mining For Business Analyst AssignmentNageshwar SinghBelum ada peringkat

- High Intermediate 2 Workbook AnswerDokumen23 halamanHigh Intermediate 2 Workbook AnswernikwBelum ada peringkat

- 7 Ways To Support Your Babys Learning Today Monti KidsDokumen19 halaman7 Ways To Support Your Babys Learning Today Monti KidsMareim A HachiBelum ada peringkat

- The Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperDokumen12 halamanThe Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperIgor SangulinBelum ada peringkat

- Math - Snowflake With ProtractorsDokumen4 halamanMath - Snowflake With Protractorsapi-347625375Belum ada peringkat

- Ethics FinalsDokumen22 halamanEthics FinalsEll VBelum ada peringkat

- 2015 Grade 4 English HL Test MemoDokumen5 halaman2015 Grade 4 English HL Test MemorosinaBelum ada peringkat

- Human Aspect Issues After Mergers and AcquisitionsDokumen4 halamanHuman Aspect Issues After Mergers and AcquisitionsA B100% (1)

- Description About Moon: Earth SatelliteDokumen6 halamanDescription About Moon: Earth SatellitePurva KhatriBelum ada peringkat

- Cryptocurrency Research PDFDokumen59 halamanCryptocurrency Research PDFAnupriyaBelum ada peringkat

- Photoshoot Plan SheetDokumen1 halamanPhotoshoot Plan Sheetapi-265375120Belum ada peringkat

- Annotated Bibliography 2Dokumen3 halamanAnnotated Bibliography 2api-458997989Belum ada peringkat

- Nodal Analysis Collection 2Dokumen21 halamanNodal Analysis Collection 2Manoj ManmathanBelum ada peringkat

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDokumen2 halamanN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueBelum ada peringkat

- Life Assessment of High Temperature HeadersDokumen31 halamanLife Assessment of High Temperature HeadersAnonymous UoHUag100% (1)

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Dokumen20 halamanHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaBelum ada peringkat

- Rfis On Formliners, Cover, and EmbedmentsDokumen36 halamanRfis On Formliners, Cover, and Embedmentsali tahaBelum ada peringkat

- SSC 211 ED Activity 4.1Dokumen4 halamanSSC 211 ED Activity 4.1bernard bulloBelum ada peringkat

- James KlotzDokumen2 halamanJames KlotzMargaret ElwellBelum ada peringkat

- Purchasing and Supply Chain Management (The Mcgraw-Hill/Irwin Series in Operations and Decision)Dokumen14 halamanPurchasing and Supply Chain Management (The Mcgraw-Hill/Irwin Series in Operations and Decision)Abd ZouhierBelum ada peringkat

- Internship (1) FinalDokumen12 halamanInternship (1) FinalManak Jain50% (2)

- Deep Sea 500 Ats ManDokumen18 halamanDeep Sea 500 Ats ManLeo Burns50% (2)

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDokumen3 halamanComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077Belum ada peringkat

- Product 97 File1Dokumen2 halamanProduct 97 File1Stefan StefanBelum ada peringkat