Top 25 Lean Tools

Diunggah oleh

Anonymous dv2IR074Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Top 25 Lean Tools

Diunggah oleh

Anonymous dv2IR074Hak Cipta:

Format Tersedia

Lean Tool

What Is It?

How Does It Help?

5S

Organize the work area:

Eliminates waste that results from a poorly organized

work area (e.g. wasting time looking for a tool).

Sort (eliminate that which is not needed)

Set In Order (organize remaining items)

Shine (clean and inspect work area)

Standardize (write standards for above)

Sustain (regularly apply the standards)

Andon

Visual feedback system for the plant floor that indicates

production status, alerts when assistance is needed, and

empowers operators to stop the production process.

Acts as a real-time communication tool for the plant floor

that brings immediate attention to problems as they

occur so they can be instantly addressed.

Bottleneck

Analysis

Identify which part of the manufacturing process limits the

overall throughput and improve the performance of that part of

the process.

Improves throughput by strengthening the weakest link in

the manufacturing process.

Continuous Flow

Manufacturing where work-in-process smoothly flows through

production with minimal (or no) buffers between steps of the

manufacturing process.

Eliminates many forms of waste (e.g. inventory, waiting

time, and transport).

Gemba (The Real

Place)

A philosophy that reminds us to get out of our offices and spend

time on the plant floor the place where real action occurs.

Promotes a deep and thorough understanding of realworld manufacturing issues by first-hand observation

and by talking with plant floor employees.

Heijunka (Level

Scheduling)

A form of production scheduling that purposely manufactures in

much smaller batches by sequencing (mixing) product variants

within the same process.

Reduces lead times (since each product or variant is

manufactured more frequently) and inventory (since

batches are smaller).

Hoshin Kanri

(Policy

Deployment)

Align the goals of the company (Strategy), with the plans of

middle management (Tactics) and the work performed on the

plant floor (Action).

Ensures that progress towards strategic goals is consistent

and thorough eliminating the waste that comes from

poor communication and inconsistent direction.

Jidoka

(Autonomation)

Design equipment to partially automate the manufacturing

After Jidoka, workers can frequently monitor multiple

process (partial automation is typically much less expensive than stations (reducing labor costs) and many quality issues

full automation) and to automatically stop when defects are

can be detected immediately (improving quality).

detected.

Just-In-Time (JIT)

Pull parts through production based on customer demand

instead of pushing parts through production based on projected

demand. Relies on many lean tools, such as Continuous Flow,

Heijunka, Kanban, Standardized Work and Takt Time.

Highly effective in reducing inventory levels. Improves

cash flow and reduces space requirements.

Kaizen

(Continuous

Improvement)

A strategy where employees work together proactively to

achieve regular, incremental improvements in the

manufacturing process.

Combines the collective talents of a company to create an

engine for continually eliminating waste from

manufacturing processes.

Kanban (Pull

System)

A method of regulating the flow of goods both within the

factory and with outside suppliers and customers. Based on

automatic replenishment through signal cards that indicate

when more goods are needed.

Eliminates waste from inventory and overproduction. Can

eliminate the need for physical inventories (instead

relying on signal cards to indicate when more goods need

to be ordered).

KPI (Key

Performance

Indicator)

Metrics designed to track and encourage progress towards

critical goals of the organization. Strongly promoted KPIs can be

extremely powerful drivers of behavior so it is important to

carefully select KPIs that will drive desired behavior.

The best manufacturing KPIs:

Are aligned with top-level strategic goals (thus helping to

achieve those goals)

Are effective at exposing and quantifying waste (OEE is a

good example)

Are readily influenced by plant floor employees (so they

can drive results)

Muda (Waste)

Anything in the manufacturing process that does not add value

from the customers perspective.

Eliminating muda (waste) is the primary focus of lean

manufacturing.

Have questions? Call Vorne at +1.630.875.3600

Lean Tool

What Is It?

How Does It Help?

Overall Equipment

Effectiveness

(OEE)

Framework for measuring productivity loss for a given

manufacturing process. Three categories of loss are tracked:

Availability (e.g. down time)

Performance (e.g. slow cycles)

Quality (e.g. rejects)

Provides a benchmark/baseline and a means to track

progress in eliminating waste from a manufacturing

process. 100% OEE means perfect production

(manufacturing only good parts, as fast as possible, with

no down time).

PDCA (Plan, Do,

Check, Act)

An iterative methodology for implementing improvements:

Applies a scientific approach to making improvements:

Poka-Yoke (Error

Proofing)

Design error detection and prevention into production

processes with the goal of achieving zero defects.

It is difficult (and expensive) to find all defects through

inspection, and correcting defects typically gets

significantly more expensive at each stage of production.

Root Cause

Analysis

A problem solving methodology that focuses on resolving the

underlying problem instead of applying quick fixes that only

treat immediate symptoms of the problem. A common

approach is to ask why five times each time moving a step

closer to discovering the true underlying problem.

Helps to ensure that a problem is truly eliminated by

applying corrective action to the root cause of the

problem.

Single Minute

Exchange of Die

(SMED)

Reduce setup (changeover) time to less than 10 minutes.

Techniques include:

Enables manufacturing in smaller lots, reduces inventory,

and improves customer responsiveness.

Plan (establish plan and expected results)

Do (implement plan)

Check (verify expected results achieved)

Act (review and assess; do it again)

Plan (develop a hypothesis)

Do (run experiment)

Check (evaluate results)

Act (refine your experiment; try again)

Convert setup steps to be external (performed while the process

is running)

Simplify internal setup (e.g. replace bolts with knobs and levers)

Eliminate non-essential operations

Create standardized work instructions

Six Big Losses

Six categories of productivity loss that are almost universally

experienced in manufacturing:

Provides a framework for attacking the most common

causes of waste in manufacturing.

Breakdowns

Setup/Adjustments

Small Stops

Reduced Speed

Startup Rejects

Production Rejects

SMART Goals

Goals that are: Specific, Measurable, Attainable, Relevant, and

Time-Specific.

Helps to ensure that goals are effective.

Standardized

Work

Documented procedures for manufacturing that capture best

practices (including the time to complete each task). Must be

living documentation that is easy to change.

Eliminates waste by consistently applying best practices.

Forms a baseline for future improvement activities.

Takt Time

The pace of production (e.g. manufacturing one piece every 34

seconds) that aligns production with customer demand.

Calculated as Planned Production Time / Customer Demand.

Provides a simple, consistent and intuitive method of

pacing production. Is easily extended to provide an

efficiency goal for the plant floor (Actual Pieces / Target

Pieces).

Total Productive

Maintenance

(TPM)

A holistic approach to maintenance that focuses on proactive

and preventative maintenance to maximize the operational time

of equipment. TPM blurs the distinction between maintenance

and production by placing a strong emphasis on empowering

operators to help maintain their equipment.

Creates a shared responsibility for equipment that

encourages greater involvement by plant floor workers. In

the right environment this can be very effective in

improving productivity (increasing up time, reducing cycle

times, and eliminating defects).

Value Stream

Mapping

A tool used to visually map the flow of production. Shows the

current and future state of processes in a way that highlights

opportunities for improvement.

Exposes waste in the current processes and provides a

roadmap for improvement through the future state.

Visual Factory

Visual indicators, displays and controls used throughout

manufacturing plants to improve communication of

information.

Makes the state and condition of manufacturing

processes easily accessible and very clear to everyone.

ITASCA, IL USA | +1.630.875.3600

www.vorne.com | www.leanproduction.com | www.oee.com

Anda mungkin juga menyukai

- 25 Essential Lean Tools ExplainedDokumen3 halaman25 Essential Lean Tools ExplainedsansagithBelum ada peringkat

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsDari EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Gemba Overview - Sheena Butts - IIESHS - WEBINAR v1Dokumen35 halamanGemba Overview - Sheena Butts - IIESHS - WEBINAR v1Bryan OrdialesBelum ada peringkat

- 1 2017 CEO Standard Work ShortDokumen44 halaman1 2017 CEO Standard Work ShortRahardian Faizal Zuhdi100% (1)

- Smed PDFDokumen17 halamanSmed PDFVinay BansalBelum ada peringkat

- Six Sigma Green Belt Project Purchasing ProcessDokumen18 halamanSix Sigma Green Belt Project Purchasing ProcessKrish0% (1)

- Eng Oee Industry StandardDokumen30 halamanEng Oee Industry Standardjoseparra100% (1)

- Kaizen For Lean ManufacturingDokumen11 halamanKaizen For Lean ManufacturingTonmok SonBelum ada peringkat

- Lean Six Sigma Project CharterDokumen1 halamanLean Six Sigma Project CharterPedro KBelum ada peringkat

- HeijunkaDokumen6 halamanHeijunkajosegarreraBelum ada peringkat

- Kaizen Case StudyDokumen44 halamanKaizen Case StudyTanmoy ChakrabortyBelum ada peringkat

- Kaizen Event OverviewDokumen1 halamanKaizen Event OverviewOscar Gonzalez CastroBelum ada peringkat

- Toyota Culture HRD ArticleDokumen18 halamanToyota Culture HRD ArticleCandra WinataBelum ada peringkat

- Heijunka: Toyota's Production Leveling Principle. A Key TPS Tool To Increase ProductivityDokumen10 halamanHeijunka: Toyota's Production Leveling Principle. A Key TPS Tool To Increase ProductivityRajpandian SelvamBelum ada peringkat

- Master Scientific Thinking with Toyota Kata Starter KataDokumen27 halamanMaster Scientific Thinking with Toyota Kata Starter KataRoberto SacconiBelum ada peringkat

- Assembly Line BalancingDokumen5 halamanAssembly Line Balancingabhijitsamanta1100% (1)

- Sample SOP Template GuideDokumen1 halamanSample SOP Template GuideMahmoud DomourBelum ada peringkat

- Simulation-based Lean Six-Sigma and Design for Six-SigmaDari EverandSimulation-based Lean Six-Sigma and Design for Six-SigmaPenilaian: 3 dari 5 bintang3/5 (2)

- Shanin Techniques Jo MoorenDokumen3 halamanShanin Techniques Jo MoorenAnonymous X0iytQQYJ6Belum ada peringkat

- Process Improvement Explained - What Is Lean Six SigmaDokumen21 halamanProcess Improvement Explained - What Is Lean Six SigmaSunilBelum ada peringkat

- Line Balancing: An Overview ofDokumen27 halamanLine Balancing: An Overview ofSpremkumar SpremkumarBelum ada peringkat

- The Lean Toolbox - 25 Essential Lean ToolsDokumen3 halamanThe Lean Toolbox - 25 Essential Lean ToolsGyogi MitsutaBelum ada peringkat

- Lean Implementation GuideDokumen52 halamanLean Implementation GuideSantosh S MyageriBelum ada peringkat

- Introducing The Schneider Production SystemDokumen13 halamanIntroducing The Schneider Production SystemIndra Kusumajati Raj Suweda100% (3)

- FEIGENBAUM + Ishikawa + TaguchiDokumen7 halamanFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiBelum ada peringkat

- Lean OutlineDokumen2 halamanLean OutlineTee Hor ChangBelum ada peringkat

- Poka Yoke: Presented By: Darpan Shah (24) Prinka Mittal (01) Priyanka ChaudharyDokumen45 halamanPoka Yoke: Presented By: Darpan Shah (24) Prinka Mittal (01) Priyanka ChaudharyanshuldceBelum ada peringkat

- The DefinitionDokumen9 halamanThe DefinitionRitesh ChoudharyBelum ada peringkat

- 12 Pecb Whitepaper Iso 13053Dokumen9 halaman12 Pecb Whitepaper Iso 13053João Paulo Rolim SampaioBelum ada peringkat

- Six Sigma Project Charter FormDokumen3 halamanSix Sigma Project Charter Formapi-3760226100% (1)

- Leader Standard Work V1.0Dokumen3 halamanLeader Standard Work V1.0SudhagarBelum ada peringkat

- World Class Manufacturing, An IntroDokumen12 halamanWorld Class Manufacturing, An IntroNishanth C Mohan100% (1)

- Lean Leadership - TopDokumen49 halamanLean Leadership - TopafmmarquesBelum ada peringkat

- Lean Six Sigma Green Belt OrientationDokumen18 halamanLean Six Sigma Green Belt OrientationJyoti Thonte-BukkapatilBelum ada peringkat

- Quiz Answers Kaizen Leadership PDFDokumen1 halamanQuiz Answers Kaizen Leadership PDFJose OrtegaBelum ada peringkat

- Implement Lean ManufacturingDokumen11 halamanImplement Lean ManufacturingRafael GrippBelum ada peringkat

- Minitab GuideDokumen21 halamanMinitab GuideBlazieBelum ada peringkat

- Lean Six Sigma in The Service Industry by Alessandro Laureani PDFDokumen14 halamanLean Six Sigma in The Service Industry by Alessandro Laureani PDFnaacha457Belum ada peringkat

- Shanin DOE - Six SigmaDokumen7 halamanShanin DOE - Six SigmaBennett Matthews100% (1)

- Standard Work For Leaders - YescoDokumen43 halamanStandard Work For Leaders - YescoPavel Collado100% (3)

- Visual Factory (Actually Used in Factories)Dokumen19 halamanVisual Factory (Actually Used in Factories)monu9999100% (2)

- 9 Key Strategies To Minimize The Cost of Poor Quality - Insights PDFDokumen6 halaman9 Key Strategies To Minimize The Cost of Poor Quality - Insights PDFAlsayed DiabBelum ada peringkat

- Click To Edit Master Title Style: Lean 101Dokumen60 halamanClick To Edit Master Title Style: Lean 101imamBelum ada peringkat

- 7 QC Tools PresentationDokumen115 halaman7 QC Tools Presentationsumeetsaini88Belum ada peringkat

- Module 3 Matl - Measure PhaseDokumen75 halamanModule 3 Matl - Measure PhaseHannah Nicdao TumangBelum ada peringkat

- Root Cause AnalysisDokumen7 halamanRoot Cause AnalysisAsley AlbertoBelum ada peringkat

- Gemba KaizenDokumen64 halamanGemba KaizenJohnson Gitonga Nderi100% (3)

- Minitab TrainingDokumen15 halamanMinitab TrainingJulius SiburianBelum ada peringkat

- Value Stream Mapping: Dr. Richard E. WhiteDokumen19 halamanValue Stream Mapping: Dr. Richard E. WhiteSamir ChaudhariBelum ada peringkat

- Six SigmaDokumen13 halamanSix Sigmashafvan_786Belum ada peringkat

- Primer On Lean Six Sigma - NRCDokumen54 halamanPrimer On Lean Six Sigma - NRCJim WolfeBelum ada peringkat

- Design For Six Sigma - An OverviewDokumen50 halamanDesign For Six Sigma - An OverviewDiana BlueseaBelum ada peringkat

- TQM & Quality Circles: Improving Products Through Employee EngagementDokumen16 halamanTQM & Quality Circles: Improving Products Through Employee EngagementEnna GuptaBelum ada peringkat

- On Campus Recruitment Drive of OSMOSYSDokumen3 halamanOn Campus Recruitment Drive of OSMOSYSNag ReddyBelum ada peringkat

- Human Bio Jan 16 p1Dokumen24 halamanHuman Bio Jan 16 p1boho14Belum ada peringkat

- Cranial Manipulative TherapyDokumen6 halamanCranial Manipulative Therapypurple112650% (2)

- Sumit B.sc. 1st Year ResultDokumen1 halamanSumit B.sc. 1st Year ResultAmit kumar YadavBelum ada peringkat

- Maths - Race#054Dokumen2 halamanMaths - Race#054PkrBelum ada peringkat

- St. Paul University Manila Offers Music Therapy CoursesDokumen3 halamanSt. Paul University Manila Offers Music Therapy CoursesRosemarie Dela Rosa TabayagBelum ada peringkat

- Retina 2016 SyllabusDokumen217 halamanRetina 2016 Syllabuscmircea0% (1)

- Effective Learning Techniques Revealed in University Entrance Exam TextDokumen1 halamanEffective Learning Techniques Revealed in University Entrance Exam TextlorenuchiBelum ada peringkat

- The ADDIE Instructional Design Process ExplainedDokumen14 halamanThe ADDIE Instructional Design Process ExplainedjasmineBelum ada peringkat

- FEMFAT Flyer e WebDokumen8 halamanFEMFAT Flyer e Webfkaram1965Belum ada peringkat

- UntitledDokumen4 halamanUntitledTafadzwa MurwiraBelum ada peringkat

- Scrum PDFDokumen222 halamanScrum PDFvive_vt_vivasBelum ada peringkat

- 2019 MM Unit 2 Exam 2 FinalDokumen20 halaman2019 MM Unit 2 Exam 2 FinalSarah NavarroBelum ada peringkat

- 2015 SJCSAA Annual ReportDokumen36 halaman2015 SJCSAA Annual ReportAldrin Derrick ChuaBelum ada peringkat

- Maestro in Absencia Module/Activity Sheet: Subject: Learning CompetencyDokumen2 halamanMaestro in Absencia Module/Activity Sheet: Subject: Learning CompetencyJff ReyesBelum ada peringkat

- Course Information Course Number Course Title Degree Program Module N0 and Code Coordinator Lecturer ETCTS Credits Contact Hours (Per Week)Dokumen3 halamanCourse Information Course Number Course Title Degree Program Module N0 and Code Coordinator Lecturer ETCTS Credits Contact Hours (Per Week)zemeBelum ada peringkat

- Candy Gunther Brown, Excerpt and InterviewDokumen12 halamanCandy Gunther Brown, Excerpt and InterviewBill CosbyBelum ada peringkat

- WorkPermitReceiver PDFDokumen2 halamanWorkPermitReceiver PDFAbu sufyanBelum ada peringkat

- Satellite Instructional Television ExperimentDokumen57 halamanSatellite Instructional Television ExperimentmariarunaBelum ada peringkat

- Activity Completion Report First Homeroom Pta Meeting (Grade 9 - Actinium)Dokumen3 halamanActivity Completion Report First Homeroom Pta Meeting (Grade 9 - Actinium)CATHERINE FAJARDO100% (1)

- Course - Data Science Foundations - Data MiningDokumen3 halamanCourse - Data Science Foundations - Data MiningImtiaz NBelum ada peringkat

- Karnataka Neet 2017 State Merit ListDokumen936 halamanKarnataka Neet 2017 State Merit Listkaushik ghosh40% (5)

- FlutterDokumen2 halamanFlutterjuniormj1Belum ada peringkat

- Schema Theory Explains Reading ComprehensionDokumen3 halamanSchema Theory Explains Reading ComprehensionBlezel Mae AlzagaBelum ada peringkat

- Kalle Miller - Prometheus Camps As An Alternative To Finnish Confirmation CampsDokumen7 halamanKalle Miller - Prometheus Camps As An Alternative To Finnish Confirmation CampsconstantinecartmanBelum ada peringkat

- EDU501 Assignment CompletedDokumen3 halamanEDU501 Assignment CompletedMusdiq AwanBelum ada peringkat

- Familias de RevitDokumen2 halamanFamilias de RevitEdder Ñahui PeñaBelum ada peringkat

- The 38 Bach RemediesDokumen20 halamanThe 38 Bach RemediesSriram Bharat100% (1)

- URICA ChangeDokumen3 halamanURICA Changeclaudiaolareanu100% (1)

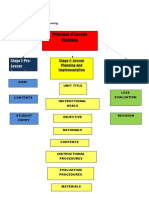

- Principal of Lesson Planning: Stage 1: Pre-Lesson PreparationDokumen6 halamanPrincipal of Lesson Planning: Stage 1: Pre-Lesson Preparationjaysel86Belum ada peringkat