46 RegionalMaterials

Diunggah oleh

mullanji0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

86 tayangan8 halamanregional material

Judul Asli

46.RegionalMaterials

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniregional material

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

86 tayangan8 halaman46 RegionalMaterials

Diunggah oleh

mullanjiregional material

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 8

REGIONAL MATERIALS

[creat

THR Credt 5 MR Credit 5

[Points

1.2 points

1-2 points

Intent

‘To increase demand for building materials and products that are extracted and manufactured.

within the region, thereby supporting the use of indigenous resources and reducing the

environmental impacts resulting from transportation.

Requirements

Use building materials or products that have been extracted, harvested orxecovered, a8 well

‘as manufactured, within soo miles of the project site for a minimum of 10% or 20%, based

‘on cost, of the total materials vali. If only a fraction of a product or material is extracted,

harvested, or recovered and manufactured locally, then only that percentage (by weight)

‘must contribute tothe regional value. The minimum percentage regional materials for each

poirit threshold iss follows;

Beainal Mote

10%

20%, 2

‘Mechanical, electrical and plumbing components, and specialty items such as elevators and.

equipment must not be included in this calculation. Include only materials permanently

installed in the project. Furniture may be included ifitis included consistently inMR Credit,

3: Materials Reuse through MR Credit 7: Certified Wood (MR Credit 6 in Core & Shell).

2009 EDITION LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND,

ion

MR CREDIT 5

379

ae) 1. Benefits and Issues To Consider

{ { scnoors

380

Credit 5

credit

Credit 5

Environmental Issues

The use of regional building materials reduces transportation activities and associated pollution.

‘Trucks, trains, ships, and other vehicles deplete finite reserves of fossil fuels and generate air

pollution. Tealso is important to address the source of raw materials used to manufacture building

products; someare harvested or extracted far from the point of manufacture, alsocontributing toair

and water pollution associated with transportation,

Economic Issues

The availability of regionally manufactured building materials depends on the project location.

In some areas, the majority of products needed for the project can be obtained within a s00-mile

radius. Inotherareas, only a small portion or no building materials can be sourced locally. However,

the purchase of regional building materials is generally more cost-effective because of reduced

transportation costs, Also, the support of regional manufacturers and labor forces retains capital

in the community, contributing to a more stable tax base and a healthier local economy, as well as

showcases the resources and skills ofthe region.

2, Related Credits

Specifying regional materials to achieve this credit may affect the levels of achievement for the

following credits:

= MR Credit 3: Materials Reuse

= MR Credit 4: Recyeled Content

= MRCredit 6: Rapidly Renewable Materials

Set goals carly for materials use; assess the availability of regional materials and determine the best,

available products to minimize the project’s environmental impact. The use oflife-cycleassessment

tools may be employed in the decision-making process.

‘The project materials costs used in this credit need to be consistent with those used in the following

credits:

= MR Credit: Materials Reuse

= MR Credit 4: Recycled Content

= MR Credit 6: Rapidly Renewable Materials

3. Summary of Referenced Standards

There are no stanclards referenced for this credit.

4, Implementation

‘The point of manufacture is considered the place of final assembly of components into the building

product that is furnished and installed by the tradesworkers. For example, ifthe hardware comes

from Dallas, the lumber comes from Vancouver, and the joist is assembled in Kent, Washington,

then the location of the final assembly is Kent, Washington.

Tt may require careful research to determine what local products are available, so evaluate this

credit early in the design process. This credit is achieved by summing the cost of all materials that

are extracted and manufactured within soo miles of the construction site. Ifthe material contains

components that were sourced from a place within 500 miles but the final assembly was farther

away, the product cannot be counted toward the cvedit. In cases where products and construction

LEED REFERENCE GUIDE FOR GREEN BUILOING DESIGN AND CONSTRUCTION 2009 EDITION

‘components are assembled on-site, the individual components that are extracted within 500 miles

of the site will be counted toward this credit

‘The general contractor should work with subcontractors and suppliers to verify availabilty of

materials that are extracted, harvested, or recovered and manufactured locally. The contractor

should run preliminary calculations based on the construction budget or schedule of values during

the preconstruction phase. This will allow the construction team to focus on those materials with

the greatest contribution to this credit as earlyas possible,

5. Timeline and Team

Run preliminary calculations, as soon as a project budget is available, to set appropriate regional

‘materials targets. Architects should specify in the construction documents products that are

extracted/harvestedjrecovered and manufactured within 500 miles and work with the general

contractor on approved alternatives that meetthe requirements of this credit. During construction,

‘the general contractoris typically responsible for documentingtheamountsandvalues of regionally

harvested and manufactured materials used on the project. The general contractor must track.

‘the materials cost of each locally harvested and manufactured product that will be applied to this

credit,

6. Calculations

Determine the total materials cost forthe project by multiplying the total construction cost (bard

costs only in CSI Master’ormat™ 2004 Hlition Divisions 03-10, 31 (Section 31.60.00 Foundations)

and 32 (Sections 32.10.00 Paving, 32.30.00 Site Improvements, and 32.90.00 Planting) by 0.4,

Alternatively, the total materials cost may be a tally of actual materials cost in CSI MasterPormat™

2004 Bdition Divisions 03-10, 31 (Section 31.60.00 Foundations) and 32 (Sections 32.10.00 Paving,

3230.00 Site Improvements, and 32.90.00 Planting) from the project schedule of values ora similar

‘document, The benefit to using actual materials costs, as opposed tothe default 43%, is that projects

‘with less than 45% materials cost will find it easier to achieve the 10% and 20% credit thresholds,

since total materials cot is inthe denominator of the equation below. The purpose of the default

value is to streamline the documentation process, since it is often challenging to break out the

‘materials costs from labor and equipment costs forall materials on the project.

Materials costs include all expenses to deliver the material to the project site, Materials costs should

‘account forall taxes and transportation costs incurred by the contractor but exclude any cost for

labor and equipment once the material has been delivered tothe site.

List those products that are extracted, harvested, or recovered and manufactured within 500 miles

ofthe projectsite. Indicarethe manufacturer the product cost, the distancebetweenthe project site

and the manufacturer location, and the distance between the project site and the extraction site for

Calculate the percentage local materials according to Equation.

Equation 1

ercentage Loeal Cost of Local Mates

cna 8 x wo

a bl Matra os)

‘The project achieves 1 point when the percentage of local material is 10% or greater, and 2 points

when the percentage of local material is 20% or greater,

‘Table: lists sample materials and components eligible for this credit.

2009 EDITION LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION

Credit 5

reait 5

credit 5

382

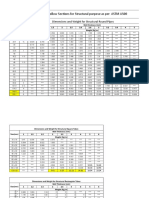

Table 1. Sample Regional Materials

Bian FORE of Hen oO oP NST in Sao?

ing Tn ares 50 as [ Pg a is =

ewe erctin, 00 mos [ i it 0 is Ye

Cent Cone 650 er Cana lt, 60 ake Tole comet

ree, 10 ine aes tr Des ves epee ans

Dnel p ty 200 is Dalle, 600 les te

Furniture and furnishings (GSI Division 12) are excluded from the calculations for this credit,

‘unless they are considered consistently across MR Credits 3-7. This credit applies primarily to CSI

MasterFormat" 2004 Raition Divisions 03-10, 31 (Section 31.60.00 Foundations) and 32 (Sections

32.10.00 Paving, 32.30.00 Site Improvements, and 32.90.00 Planting).

Do not include mechanical, electrical, and plumbing components or appliances and equipment

in the calculations for this credit. Compared with structural and finish materils, mechanical and

clectrical equipment tends to have a high dollar value relative to the amount of material it contains

and thet high dollar value would skew the results of the calculation,

Reused and Salvaged Materials

Reused and salvaged materials that satisfy the requirements of MR Credit 3 may also contribute

‘to MR Credits, Use the location from which they were salvaged as the point of extraction, and use

‘te location of the salvaged goods vendor as the point of manufacture. On-site salvaged materials

automatically qualify.

For materials with more than 1 point of manufacture or extraction, all within the so0-mile radius,

list the component with the greatest distance. I' portion ofthe material was either manufactured

or extracted beyond the 5oo-mile radius, list only that portion and associated cost satisfying the

credit requirement.

Forassemblies orproducts manufactured withinthe 500-mile adiusthat containsome components

extracted farther away, use multiple lines when listing purchases. Base the proportionality of such

produets’ costs on the weight oftheir various components (see the example for concrete in Tables

2and3)

‘Table 2. Sample Assembly Percentage Regionally Extracted Calculation for Concrete

Sane wit on _| tt Se fe) | mega ent

cot me 1230 °

Aah 22 15 28

ve 25 i 25

Sie 780 wo 750

cj Gis Agpegte | __,000 8 1000

Sond 1.200 m3 1.200

conse 23789 NA 3507

rot Reo aio Nata 5070.70) Bam

LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION 2009 EDITION

Table 3. Sample Spreadsheet for Regional Materials,

ne | Oc

‘between Mine: Value’ a!

Product | Manutactuer| Proecta | Prost& |. Product | ativngas | infomation Souce

vrata | amet | aac | Re :

one {eniles)

ro | oe |e 5 | s57 | 3677 | ctr ia

mee | ote | as 6 | se1000 | serge | conc simina

oS e-—“—i—tié‘C_CSC_CSs—s—sCSCSC

pam [nama us| 75 [256 | ano | a0 aon manor

cine fbr ne [a8 [rar sisa29 atom mace

cars| Toscan | 16 | 380 | sao | 2200 | Gmc

tuner [aya [ato | se | fon 350 | tan 80 | ta ita

es eC

Tot er $810

"a i ol One 270) 751.09

Pact en iin 1

a ad 1

7. Documentation Guidance

‘Asa first step in preparing to complete the LEED-Online documentation requirements, work

through the following measures, Refer to LEED-Online for the complete descriptions ofall required

documentation.

= Compile alist of product purchases manufactured, extracted, or harvested regionally.

* Recordimanufacturers' names, productoosts,distancesbetweentheprojectandmanufacturer,

and distances between the project and the extraction site

‘= Where appropriate, retain cutsheets that document material originand manufacture within a

‘500-mile radius ofthe project sie.

* Where appropriate, maintain alist of terials costs, exeludinglabor and equipment, for CST

Divisions 03-10, 31 (Section 31.60.00 Foundations) and 32 Sections 32.10.00 Paving, 32.30.00

Sie improvements, and 32.90.00 Planting) only; including Division 12s optional

8, Examples

EXAMPLE 1

Figure 2 illustrates an example for a hypothetical slag concrete material that is extracted,

processed, and manufactured within so0 miles ofa projec site.

2009 EDITION LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION,

PR 108% 2000 a Mamutactsing Location of Fy Ash Concrete

a

SCHOOLS | Credit 5

a.

A Pepsin

© conor scan ttartictng

EXAMPLE 2

‘The total construction costs for a library building are $600,000. Using the default materials

calculations, the total cost of materials excluding labor and equipment is $600,000 x 0.45 =

$270,000. "Table lists the regional materials purchased forthe projec. In this example, the cost

‘of regionally harvested and manufactured products asa percentage ofthe total cost of materials

s2789%. The project earns 2points,

384 LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION 2009 EDITION

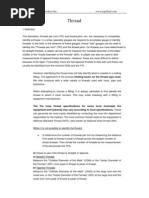

Table 4, Sample Calculation for Regional Material

“Total constriction cost ‘Fe00000] | NC __ Credit 5

a a a io $eaoen0] /Scro0ts | — creat 5

Pie lial xt ce eb cand $2700] (03 | Greats)

1] Bist between | Distance Between ~~

Pract ate | vendor | PROS | prota | pret and wercon | Ren net

raters | "sta | ton

Piant Materies | fanutacturer

vecuous [Ome | taz70 2% 3 tt

Geawe [wer —

segregate Concrote 21.000 . 8 manufacturer

pu st | cpa noe | a oa it

vo tears ut | sagos0 no 0 vn

ead a tie ao pena Tamsss

i lo ly ce! da ‘72310

tel bu ined paw pee a aE 759%

Ft etd

105 ep ts i

2 ng os 1

Total points documented 7

EXAMPLE 3

Concrete dry mixis provided bya subcontractor. The dry mix contains cement, aggregate, sand,

‘water, and acimixtures with a definite proportion. While the concrete is manufactured within

20 miles from the project site, the aggregate is mined from a town 100 miles away, the cement

plants 600 mites away, and the sand is from s50 miles away. In this case, onlythe aggregate will

qualify for the regional material credit. The cost of the aggregate material can either be provided

by the subcontractor or calculated on the basis ofthe percentage of aggregate and total cost of

the concrete mix. Ifthe concrete mix was $100,000 and the aggregate was 10% by weight of the

concrete, te aggregate cost will be assumed to be $10,000. Therefore, the concrete will account

for $10,000 to the regional material credit.

9. Exemplary Performance

Project teams may earn an Innovation in Design credit for exemplary performance by achieving a

total value of regionally harvested, extracted, and manufactured materials of 30% or mote.

10. Regional Variations

Local availability of materials will vary by region, Regional building materials are often consistent

‘with regional design aesthetics and may be more stable in the local climate than materials from

other regions, Consider thelocal architecture and adopta design that incorporates locally produced

‘materials wherever possible. Those project sites near sources for material origin and manufacture

‘will have an advantage in the achievement of this credit.

2009 EDITION LEED REFERENCE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION

385

11. Operations and Maintenance Considerations

MATE) ‘The duplication, replacement, and repair of regional materials wil be esr information about

the installed produetshas ben maintained. Bncourage the creation ofasustainablé purchasingplan

and provide building operators with ist ofthe installed products an their manufacturers, sch as

the documentation used inthe LEED application

12. Resources

Please see USGRC's LEED Registered Project Tools (att

additional resources and technical information.

iyyrwusgbe.orgiprojecttools) for

Government Resources

heck with the local chamber of commerce or regional and state economic development agencies

for building materials manufacturersin the region,

13, Defi

‘Manufacturing refers to the final assembly of components into the building product that is

furnished and installed by the tradesworkers.

Regionally extracted materials areraw materials taken fromwithinasoo-mile radius ofthe project

site

Regionally manufactured materials are assembled as finished products within a soo-mile radius

ofthe project site, Assembly does not include on-site assembly, erection, or installation of finished

components.

386 LEED REFERENGE GUIDE FOR GREEN BUILDING DESIGN AND CONSTRUCTION 1009 EDITION

Anda mungkin juga menyukai

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Zinc MTC PDFDokumen1 halamanZinc MTC PDFmullanjiBelum ada peringkat

- ANSI Pipe Lengths: Size Standard LengthDokumen2 halamanANSI Pipe Lengths: Size Standard LengthmullanjiBelum ada peringkat

- Tainjin Haigang Steel Co. Ltd. (Made in China)Dokumen2 halamanTainjin Haigang Steel Co. Ltd. (Made in China)mullanjiBelum ada peringkat

- Ex StickersDokumen3 halamanEx StickersmullanjiBelum ada peringkat

- Product Details ASTM A53Dokumen4 halamanProduct Details ASTM A53mullanjiBelum ada peringkat

- Product Specification Levels for PipesDokumen14 halamanProduct Specification Levels for PipesmullanjiBelum ada peringkat

- Astm 500Dokumen4 halamanAstm 500mullanjiBelum ada peringkat

- Pre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiameterDokumen1 halamanPre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiametermullanjiBelum ada peringkat

- NPT Thread DetailsDokumen1 halamanNPT Thread DetailsmullanjiBelum ada peringkat

- Supplier List: Supplier Name & Address Vendor Code Product / Services StatusDokumen2 halamanSupplier List: Supplier Name & Address Vendor Code Product / Services StatusmullanjiBelum ada peringkat

- Hindi English Masala TranslationDokumen10 halamanHindi English Masala TranslationmullanjiBelum ada peringkat

- API 5l Details From My SideDokumen14 halamanAPI 5l Details From My SidemullanjiBelum ada peringkat

- Inspection Check ListDokumen3 halamanInspection Check ListmullanjiBelum ada peringkat

- Inspection Check ListDokumen3 halamanInspection Check ListmullanjiBelum ada peringkat

- ANSI Coupling Weight Chart by SizeDokumen1 halamanANSI Coupling Weight Chart by SizemullanjiBelum ada peringkat

- Al-Jazera Steel Factories API 5L Pipe SpecificationsDokumen22 halamanAl-Jazera Steel Factories API 5L Pipe Specificationsmullanji50% (2)

- CSWIP-WI-6-92 14th Edition April 2017Dokumen17 halamanCSWIP-WI-6-92 14th Edition April 2017mullanjiBelum ada peringkat

- Employee training recordsDokumen10 halamanEmployee training recordsmullanjiBelum ada peringkat

- Zinc MTCDokumen1 halamanZinc MTCmullanjiBelum ada peringkat

- Hydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsDokumen1 halamanHydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsmullanjiBelum ada peringkat

- NoiceDokumen2 halamanNoicemullanjiBelum ada peringkat

- BPV Stencil MarkingDokumen2 halamanBPV Stencil MarkingmullanjiBelum ada peringkat

- Performance of Galvanized Steel ProductsDokumen16 halamanPerformance of Galvanized Steel ProductsAndy ChongBelum ada peringkat

- Oznake ČelikaDokumen8 halamanOznake ČelikaSamra DukićBelum ada peringkat

- Work at Height Safety GuideDokumen1 halamanWork at Height Safety GuidemullanjiBelum ada peringkat

- Standard Analysis UpdatedDokumen15 halamanStandard Analysis UpdatedmullanjiBelum ada peringkat

- Pipe ThreadsDokumen11 halamanPipe Threadsanac_mathBelum ada peringkat

- BS 1387/1985 Standard for Black and Galvanized Steel TubesDokumen2 halamanBS 1387/1985 Standard for Black and Galvanized Steel TubesmullanjiBelum ada peringkat

- M1 - 2 Welding Symbols and DrawingsDokumen13 halamanM1 - 2 Welding Symbols and DrawingsmullanjiBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)