0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous Motor

Diunggah oleh

Anonymous hWj4HKIDOFJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous Motor

Diunggah oleh

Anonymous hWj4HKIDOFHak Cipta:

Format Tersedia

2013 International Conference on Electrical Machines and Systems, Oct.

26-29, 2013, Busan, Korea

Design by Optimization of an Axial-Flux

Permanent-Magnet Synchronous Motor Using

Genetic Algorithms

R. Benlamine1, 2, F. Dubas2, S-A. Randi1, D. Lhotellier1, C. Espanet2

1

Renault SA, Guyancourt, France

Energy Department, Femto-st Institute, University of Franche-Comte, France

E-mail: raouf.benlamine@renault.com

Abstract In this paper, a genetic algorithm (GA) is used to

optimize a motor for an automotive application. This motor is a

double stator axial permanent-magnet (PM) machine, and the

optimization uses a simplified analytical model. The solution

obtained with the tool is compared to three-dimensional (3-D)

finite-elements method (FEM) to confirm the validity of the

model.

Keywords Optimization, genetic algorithms, axial-flux PM

synchronous motor, embedded PM, analytical model.

NOMENCLATURE

0 , vacuum permeability.

r , relative permeability.

Dint , internal diameter.

Dext , external diameter.

Rm , average radius of the

Bm , PM flux density.

air-gap.

H m , PM magnetization.

Br , PM remanent flux density. e g , air-gap depth.

S g , two poles air-gap

B g , air-gap flux density.

Bst , stator yoke flux density.

Bt , stator tooth flux density.

p , number of pole pairs.

N sl , number of slots.

n , number of slots per phase.

K s , linear current density.

J s , current density

surface.

L pm , PM length in the

axial direction.

e pm , PM thickness.

d sl , slot depth.

Lst , stator yoke thickness.

M pm , PM weight.

optimization problems. The advantage of multi-objective

optimization is to obtain a Pareto Front of optimal solutions

for several optimization criteria (such as total weight, PM

weight, maximal torque, efficiency). The choice of the

solution can thus be a compromise between different

optimization criteria. Design by optimization of axial-flux PM

machines using GAs is not widely studied. Axial-flux surfacemounted PM machines, for their simple analytical design,

comparatively to axial-flux embedded PM, are mostly studied.

In [4], the authors studied a design of a 10 kW AFPMS

Generator (AFPMSG) with two rotors surface-mounted PM

and internal stator using GA optimization. Electromagnetic,

thermal and mechanical models are used in the optimization

process. The multi-objective optimization function consists in

minimizing the PM volume and maximizing the efficiency. In

[5], the machine studied is a 30 kW AFPMSG with two stators

and rotor surface-mounted PMs. In this case, the objective

function is only the cost of the active materials. The authors in

[6] applied different optimization methods to design

AFPMSM with two rotors surface-mounted PM and internal

stator. The results show that stochastic algorithms are more

interesting than deterministic algorithms when applied to

complex problems. The design of electric machines can be a

combination between optimization design using a simple

analytical model based on sizing equation and FEM. In [7], an

AFPMSM with internal stator and two external surfacemounted PM rotors is studied. The authors used GA

optimization to obtain motor dimensions and 3-D FEM to

obtain motor characteristics.

Lmot , axial motor length.

Tnom , nominal torque.

I. INTRODUCTION

Considering automotive applications, the electric machines

have severe constraints in terms of size and weight. Due to its

high torque density [1-2], a double stator axial-flux PM

synchronous motor (AFPMSM) is chosen. To satisfy the

complex specifications (in particular in terms of specific

torque and specific power), a design by optimization using an

analytical model and a genetic algorithm (NSGA-II) is

performed [3]. The GAs enable to solve multi-objective

Fig. 1. Axial-flux embedded PM synchronous machine.

978-1-4799-1447-0/13/$31.00 2013 IEEE

13

Using FEM, motor parameters are re-optimized to improve the

machine performances, such as reduction of cogging torque by

PM skewing and modification of winding configuration.

In this paper, the novelty is that the machine considered, for

the multi-objective optimization, is an axial-flux synchronous

machine with embedded PM, as shown in Fig. 1. To achieve

the design, a simplified analytical model of the motor is used.

The steps of the algorithm NSGA-II, the variation range of the

design parameters and the optimization constraints are

described. Then, the optimization results are discussed for the

considered multi-objective function. Finally, to verify the

validity of the analytical model, the solution obtained with the

optimization is simulated using 3-D FEM.

The expression of Sg, the section of the air-gap seen by the

rotor yoke between two poles, as shown in Fig. 3, is

given by:

D Dint

S g = ext

2

Bm = Br + 0 . r .H m

(7)

And finally, the electromagnetic torque of the motor can be

defined as:

2

Tnom

II. ANALYTICAL MODEL

The target of this simplified analytical model is to express

the torque per unit of weight. Then, firstly, the flux density in

the PM can be expressed by:

.(Dext + Dint )

e pm

4p

where

D + Dint

= .B g .K s . ext

.(Dext Dint )

2

(8)

is a constant, which depends on the winding factor.

(1)

By applying the Ampere's law to the elementary magnetic

circuit represented in Fig. 2, we can write:

H m .e pm + 2.H g .e g =

2 .Rm .K s

N sl

(2)

By considering the flux conservation in the magnetic circuit,

we can write:

Bm .

L pm Dext Dint

Sg

= Bg .

.

2

2

2

(3)

Fig. 2. Circulation of the flux produced by one PM pole.

Using (1), the PM magnetization is given by:

Hm =

Bm Br

0 . r

(4)

From (1)-(4), the expressions of the magnetic flux density in

the PM, Bm, and the air-gap, Bg, are given by:

2 .Rm .K s

N sl

0 r

Bm =

D Dint

L pm . ext

1

2

.e pm + 2.e g .

0 r

Sg

Br

Br

0 r

Bg =

1

0 r

.e pm

.e pm _

2 .Rm .K s

D Dint

L pm . ext

N sl

2

.

Dext Dint

Sg

L pm .

2

+ 2.e g .

Sg

(5)

.e pm

(6)

Fig. 3. Representation of one pair of poles according to the plan (xoy).

14

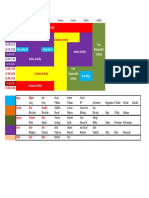

III. FORMULATION OF THE OPTIMIZATION PROBLEM

The genetic algorithm used for the optimization is the

NSGA-II algorithm described in [3]. The different

optimization steps of the algorithm are shown in Fig.4.

First, an initial population is randomly generated. Then, the

fitness of each individual (candidate solution) is evaluated. If

the required fitness is achieved, the individuals are saved.

Otherwise, the best individuals, according to their fitness, are

selected and modified to form a new population, which is used

in the next iteration. The modification of the individuals

consists in mutation and recombination operations of the

chromosomes. The new population is then evaluated and the

same operations are repeated until the target fitness level is

achieved or the maximum number of generations is reached.

The chromosomes of the individuals consist on design

parameters. In this study, external diameter, internal diameter,

stator yoke thickness, PM thickness, PM axial length, numbers

of slots per phase and slot depth are selected as chromosomes.

The constraints concern air-gap, stator yoke and tooth flux

densities, PM weight, motor axial length, nominal torque and

PM magnetization. Then, the optimization problem has seven

optimization parameters; six are continuous and one is

discrete, as shown in the Table 1.

More precisely, the geometric and electromagnetic constraints

are defined in Table 2. The multi-objective function consists

in maximizing the torque density and minimizing the PM

weight.

TABLE 1

DOMAIN OF VARIATION OF THE OPTIMIZATION PARAMETERS

Design

Parameters

Symbols

Units

Type

Variation

Range

External Diameter

Dext

[mm]

Continuous

[180, 230]

Internal Diameter

Dint

[mm]

Continuous

[120, 160]

Stator Yoke

Thickness

Lst

[mm]

Continuous

[10, 30]

PM Thickness

epm

[mm]

Continuous

[1, 50]

PM Axial Lenght

Lpm

[mm]

Continuous

[1, 50]

Number of Slots

per Phase

Discrete

Slot Depth

dsl

[mm]

Continuous

2,38

[5,50]

TABLE 2

THE OPTIMIZATION CONSTRAINTS

Optimization

Constraints

Symbols

Units

Min Value

Max Value

Airgap flux density

Bg

[T]

0.6

0.9

Stator yoke flux density

Bst

[T]

0.7

1.7

Stator tooth flux density

Bt

[T]

PM weight

Mpm

[kg]

Motor axial length

Lmot

[mm]

Nominal torque

Tnom

[N.m]

55

PM magnetization

Hm

[A/m]

Hcj

1.8

0.8

1.3

TABLE 3

OPTIMIZATION TOOL PARAMETERS

Number of individuals

Number of generations

Number of chromosomes

Number of constraints

Number of criteria

102

100

100

7

7

2

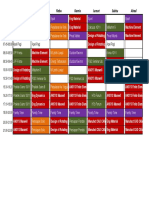

IV. RESULTS OF THE OPTIMIZATION

Fig. 4. Representation of the GA optimization steps.

The number of individuals and the number of generations

are defined in Table 3. To save a solution, it is necessary to

satisfy all constraints.

In Figure 5, the solutions obtained with the optimization

show that the maximization of the torque density can be

15

achieved by minimizing the PM weight if the best solutions

are chosen. The constraint on the axial length of the machine

and on the rated torque involves very different dimensions of

the PMs. Thus, as shown in Fig. 6-7, if the PM axial length

decreases, the PM thickness must increase to satisfy the torque

constraint. The external diameter increases also, which

increases the PM weight and the total machine weight. Thus,

the torque density decreases when PM weight becomes higher.

Otherwise, if the axial length of the machine increases, the

ratio between the air-gap surface seen by one pole and the

surface of one pole becomes larger. Thus, the torque

performance of the machine is improved. In addition, the

motor weight decreases, which increases the torque density.

Thereby, the proposed tool can help to find the best solution

for a minimum PM weight and a maximum torque density.

Fig. 7. Torque density as function of PM thickness.

Rated Torque

Torque [p.u]

1.2

1

0.8

0.6

Instantanous Torque (FEM)

0.4

Average Torque (FEM)

0.2

0

Average Analytical Torque

0

0.5

1.5

2.5

Time [ms]

Fig. 5. Evolution of the optimization criteria.

Fig. 8. Torque as function of the time.

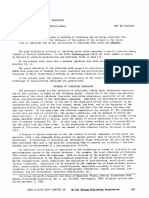

V. 3-D FINITE-ELEMENT METHOD

The optimal solution obtained with the design by

optimization is simulated using a 3-D FEM software [8]. The

evolution of the motor torque is illustrated in Fig. 8 (for the

rated operating point).

The error in the calculation of the nominal torque by the

analytical model, compared to the average torque obtained

with 3-D FEM, is less than 5 %. It confirms the reliability of

the developed approach.

VI. CONCLUSION

Fig. 6. Torque density as function of PM axial length.

In this work, the authors have proposed the optimal design

of an original motor topology, consisting in an axial-flux

synchronous machine with embedded PM. The optimal design

is based on a simplified analytical model combined with a

genetic algorithm. The analytical model is as simple as

possible in order to improve the convergence speed, unless we

use a stochastic optimization algorithm. The advantage of the

optimization based on GAs is to reach a global optimum and

to follow the evolution of solutions based on design

parameters. However, the GAs are all the more interesting

when the model is complex and multi-physic (electromagnetic,

16

thermal and mechanical models) and when the parameters are

numerous and hybrid (i.e. continuous, discrete and possibly

Boolean). However, this first order approach is satisfying in

the sense that it enables to provide an interesting design that is

confirmed by 3D FEM refined model.

[4]

REFERENCES

[6]

[1]

[2]

[3]

M. Aydin, S. Huang and T.A. Lipo, Axial Flux Permanent Magnet Disc

Machines: A Review, in Conf. Record of SPEEDAM, pp. 61-71, May

2004.

R. Qu, M. Aydin, T.A. Lipo, Performance Comparison of Dual-Rotor

Radial-Flux and Axial-Flux Permanent Magnet BLDC Machines, in

International Electric Machines and Drives Conference, 2003

K. Deb, A.Pratap, S. Agarwal, and T. Meyarivan, A Fast and Elitist

Multiobjective Genetic Algorithm: NSGA-II, IEEE Transactions on

Evolutionary Computation, vol.6, no.2, April 2002.

[5]

[7]

[8]

J. Azzouzi, N.A. Karim, G. Barakat, B. Dayko, Axial flux PM

synchronous generator design optimization: robustness test of the

genetic algorithm approach, on Power Electronics and Applications,

2005.

N. Rosatami, M.R. Feyzi, J. Pyrhonen, A. Parviainen, V. Behjat,

Genetic Algorithm Approach for Improved Design of a Variable Speed

Axial-Flux Permanent-Magnet Synchronous Generator, IEEE

Transactions on Magnetics, vol.48, no.12, pp. 4860-4865, December

2012.

C. Boccaletti, S. Elia, E. Nistico, Deterministic and Stochastic

Optimisation Algorithms in Conventional Design of Axial Flux PM

Machines

A. Mahmoudi, S. Kahourzade, N. A. Rahim and W.P. Hew, Design,

Analysis, and Prototyping of an Axial-Flux Permanent-Magnet Motor

Based on Genetic Algorithm and Finite Element Analysis, IEEE

Transactions on Magnetics, vol.49, pp. 1479-1492, November 2012.

http://www.cedrat.com

17

Anda mungkin juga menyukai

- Study of a reluctance magnetic gearbox for energy storage system applicationDari EverandStudy of a reluctance magnetic gearbox for energy storage system applicationPenilaian: 1 dari 5 bintang1/5 (1)

- Electrical Overstress (EOS): Devices, Circuits and SystemsDari EverandElectrical Overstress (EOS): Devices, Circuits and SystemsBelum ada peringkat

- Physics of Dielectrics and DRAMDokumen31 halamanPhysics of Dielectrics and DRAMUdai SinghBelum ada peringkat

- 1 IntroductionDokumen61 halaman1 Introductionfiraol temesgenBelum ada peringkat

- Cognitive RadioDokumen65 halamanCognitive Radiousman_arain_lhr0% (1)

- 3 3 1 Optical Applications With CST MICROWAVE STUDIODokumen36 halaman3 3 1 Optical Applications With CST MICROWAVE STUDIOmsajjad_68Belum ada peringkat

- Fundamentals of Electric Propulsion: Ion and Hall ThrustersDari EverandFundamentals of Electric Propulsion: Ion and Hall ThrustersBelum ada peringkat

- Submitted By: Rajat Garg C08541 EECE, 7th SemDokumen22 halamanSubmitted By: Rajat Garg C08541 EECE, 7th Semrajatgarg90Belum ada peringkat

- Axial PErmanent MAgnetDokumen6 halamanAxial PErmanent MAgnetSatyam Swarup100% (1)

- Design and Development of Medical Electronic Instrumentation: A Practical Perspective of the Design, Construction, and Test of Medical DevicesDari EverandDesign and Development of Medical Electronic Instrumentation: A Practical Perspective of the Design, Construction, and Test of Medical DevicesBelum ada peringkat

- Jones Tutorial 2 On Stepping MotorsDokumen125 halamanJones Tutorial 2 On Stepping MotorsVictor UrbinaBelum ada peringkat

- Wood Pole KN RatingsDokumen3 halamanWood Pole KN Ratingsjobpei2Belum ada peringkat

- IQ2010 For LabVIEW Quick Start GuideDokumen4 halamanIQ2010 For LabVIEW Quick Start GuideRicardo PaivaBelum ada peringkat

- 002 5956Dokumen62 halaman002 5956Dipen K. DasBelum ada peringkat

- Position Sensing: Angle and Distance Measurement for EngineersDari EverandPosition Sensing: Angle and Distance Measurement for EngineersBelum ada peringkat

- Assembling An HRPT SystemDokumen5 halamanAssembling An HRPT Systembill_crews100% (1)

- Hands-on TinyML: Harness the power of Machine Learning on the edge devices (English Edition)Dari EverandHands-on TinyML: Harness the power of Machine Learning on the edge devices (English Edition)Penilaian: 5 dari 5 bintang5/5 (1)

- Advanced Computational and Design Techniques in Applied Electromagnetic Systems: Proceedings of the International ISEM Symposium on Advanced Computational and Design Techniques in Applied Electromagnetic Systems, Seoul, Korea, 22-24 June, 1994Dari EverandAdvanced Computational and Design Techniques in Applied Electromagnetic Systems: Proceedings of the International ISEM Symposium on Advanced Computational and Design Techniques in Applied Electromagnetic Systems, Seoul, Korea, 22-24 June, 1994Belum ada peringkat

- Hollow State in A Solid State WorldDokumen1 halamanHollow State in A Solid State Worldapi-3701386Belum ada peringkat

- Electronics 3 Checkbook: The Checkbooks SeriesDari EverandElectronics 3 Checkbook: The Checkbooks SeriesPenilaian: 5 dari 5 bintang5/5 (1)

- Implementation of Autonomous Control System of The Chain Wheel Robot Using The Backpropagation Artificial Neural Network (ANN) MethodsDokumen6 halamanImplementation of Autonomous Control System of The Chain Wheel Robot Using The Backpropagation Artificial Neural Network (ANN) MethodsInternational Journal of Innovative Science and Research Technology100% (1)

- Water Cooled Axial Flux Motor High TorqueDokumen7 halamanWater Cooled Axial Flux Motor High TorqueSteven SullivanBelum ada peringkat

- Shortwave DiathermyDokumen40 halamanShortwave DiathermyPraneethaBelum ada peringkat

- Permanent Magnet Technology in Wind Power GeneratorsDokumen6 halamanPermanent Magnet Technology in Wind Power GeneratorsPaulius BruneikaBelum ada peringkat

- Resonant Inductive Coupling WPTDokumen83 halamanResonant Inductive Coupling WPTABHIJIT CHANDRA100% (1)

- Specialty Optical Fibers HandbookDari EverandSpecialty Optical Fibers HandbookAlexis MendezBelum ada peringkat

- 6360 LV User InstructionsDokumen11 halaman6360 LV User InstructionsPrasanth MenonBelum ada peringkat

- PIFA Planar Inverted F AntennaDokumen4 halamanPIFA Planar Inverted F AntennaAhsan AltafBelum ada peringkat

- Mathematical Theory of Connecting Networks and Telephone TrafficDari EverandMathematical Theory of Connecting Networks and Telephone TrafficBelum ada peringkat

- Sound From UltrasoundDokumen9 halamanSound From UltrasoundNakul NemaBelum ada peringkat

- Tesla Coil ProjectDokumen58 halamanTesla Coil Projectvdahiya007Belum ada peringkat

- Micro-nanoelectronics Devices: Modeling of Diffusion and Operation ProcessesDari EverandMicro-nanoelectronics Devices: Modeling of Diffusion and Operation ProcessesBelum ada peringkat

- Magneto Hydro Dynamic Power Generation MHDDokumen29 halamanMagneto Hydro Dynamic Power Generation MHDSubin JamesBelum ada peringkat

- Grounding Basics 3 - Solar Panel GroundingDokumen9 halamanGrounding Basics 3 - Solar Panel GroundingCarolBelum ada peringkat

- Transistorized Series Voltage RegulatorDokumen4 halamanTransistorized Series Voltage RegulatorIpsita MishraBelum ada peringkat

- Acoustical Transducers - Lecture 5Dokumen25 halamanAcoustical Transducers - Lecture 5Anonymous W9zlG22RBelum ada peringkat

- Magnetic Levitation SystemDokumen9 halamanMagnetic Levitation SystemArjun SreenivasBelum ada peringkat

- IntroductionToTheArduinoMicrocontroller PDFDokumen3 halamanIntroductionToTheArduinoMicrocontroller PDFNikhilesh ThatipamulaBelum ada peringkat

- Virtual WireDokumen13 halamanVirtual WirePedro Nuno Sabugueiro OliveiraBelum ada peringkat

- A New Computer-Based Ferromagnetic Metal Detector For Security ApplicationsDokumen8 halamanA New Computer-Based Ferromagnetic Metal Detector For Security ApplicationsJalalBelum ada peringkat

- Introduction To Linear Integrated CircuitsDokumen12 halamanIntroduction To Linear Integrated CircuitsAnil Kumar YernintiBelum ada peringkat

- Unit IDokumen37 halamanUnit IDINESH KUMAR DRAVIDAMANIBelum ada peringkat

- An-MPU-9250A-03 MPU-9250 Accel Gyro and Compass Self-Test Implementation v1 0 - 062813Dokumen14 halamanAn-MPU-9250A-03 MPU-9250 Accel Gyro and Compass Self-Test Implementation v1 0 - 062813Herry WijayaBelum ada peringkat

- Schedule PlanDokumen3 halamanSchedule PlanAnonymous hWj4HKIDOFBelum ada peringkat

- The Speed of Trust: Based On The Book by Stephen MR CoveyDokumen34 halamanThe Speed of Trust: Based On The Book by Stephen MR CoveyAnonymous hWj4HKIDOF100% (1)

- Tedy Kuswara: A StorytellerDokumen1 halamanTedy Kuswara: A StorytellerAnonymous hWj4HKIDOFBelum ada peringkat

- Jadwal Juli - Oktober 2016 HarianDokumen1 halamanJadwal Juli - Oktober 2016 HarianAnonymous hWj4HKIDOFBelum ada peringkat

- Jadwal Persiapan S2 v2Dokumen1 halamanJadwal Persiapan S2 v2Anonymous hWj4HKIDOFBelum ada peringkat

- 5716159Dokumen34 halaman5716159Anonymous hWj4HKIDOFBelum ada peringkat

- Goldstein R J Fluid Mechanics MeasurementsDokumen1 halamanGoldstein R J Fluid Mechanics MeasurementsAnonymous hWj4HKIDOFBelum ada peringkat

- UPM University Petru Major 13 183 PaperDokumen3 halamanUPM University Petru Major 13 183 PaperAnonymous hWj4HKIDOFBelum ada peringkat

- Chapter 2 - Macromechanical Analysis of A Lamina Exercise SetDokumen12 halamanChapter 2 - Macromechanical Analysis of A Lamina Exercise SetAnonymous hWj4HKIDOFBelum ada peringkat

- 3241 Lecture 2Dokumen8 halaman3241 Lecture 2Anonymous hWj4HKIDOFBelum ada peringkat

- Vehicle Dynamics: Instructor: Ashok Kumar Pandey EmailDokumen6 halamanVehicle Dynamics: Instructor: Ashok Kumar Pandey EmailAnonymous hWj4HKIDOFBelum ada peringkat

- Automating Battery Pack Design AA V9 I2Dokumen4 halamanAutomating Battery Pack Design AA V9 I2Anonymous hWj4HKIDOFBelum ada peringkat

- MSC Development Planning and MSC Development Planning Research ScholarshipsDokumen2 halamanMSC Development Planning and MSC Development Planning Research ScholarshipsAnonymous hWj4HKIDOFBelum ada peringkat

- Presentation 1Dokumen4 halamanPresentation 1Anonymous hWj4HKIDOFBelum ada peringkat

- Section 133123Dokumen11 halamanSection 133123Dian Aplimon JohannisBelum ada peringkat

- Semikron Datasheet Skiip 23ac126v1 25231080Dokumen4 halamanSemikron Datasheet Skiip 23ac126v1 25231080Antonio Carlos CardosoBelum ada peringkat

- Adavances in Positioning and FramesDokumen407 halamanAdavances in Positioning and Framesoliwia.tolloczkoBelum ada peringkat

- Modified Moment Estimation For A Two Parameter Gamma DistributionDokumen9 halamanModified Moment Estimation For A Two Parameter Gamma DistributionInternational Organization of Scientific Research (IOSR)Belum ada peringkat

- Nortje Desiree 2002 PDFDokumen328 halamanNortje Desiree 2002 PDFAtul KulkarniBelum ada peringkat

- Materials and Approaches For On Body Energy HarvestingDokumen8 halamanMaterials and Approaches For On Body Energy HarvestingShotech EngineeringBelum ada peringkat

- Wave Propagation in Shallow Water: Ert - C WDokumen24 halamanWave Propagation in Shallow Water: Ert - C WMarco QuirozBelum ada peringkat

- Self Assessment ASPDokumen104 halamanSelf Assessment ASPTarek San100% (1)

- Isolation and Purification of AlkaloidsDokumen14 halamanIsolation and Purification of AlkaloidsLuděk SpurnýBelum ada peringkat

- Introductory Circuit Theory by Guillemin ErnstDokumen580 halamanIntroductory Circuit Theory by Guillemin ErnstJunaid IqbalBelum ada peringkat

- Experiences of ISFOC On Concentration Photovoltaic: Francisca RubioDokumen49 halamanExperiences of ISFOC On Concentration Photovoltaic: Francisca RubioHikary AcevesBelum ada peringkat

- Abbreviated Piping TermsDokumen7 halamanAbbreviated Piping TermsZulkeefal DarBelum ada peringkat

- Chem Lab 12 IndicatorsDokumen2 halamanChem Lab 12 IndicatorsZaleBelum ada peringkat

- Disturbance-Rejection vs. SetpointDokumen5 halamanDisturbance-Rejection vs. SetpointravaraeBelum ada peringkat

- Session - 5 FEA of Grids: Module Code: 19STC502A-2021Dokumen34 halamanSession - 5 FEA of Grids: Module Code: 19STC502A-2021rajaBelum ada peringkat

- Strength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, MalaysiaDokumen7 halamanStrength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, Malaysiaqidunk ipsiBelum ada peringkat

- A History of PhotographyDokumen49 halamanA History of PhotographyderghalBelum ada peringkat

- Conclusion and Recommendations HTDokumen1 halamanConclusion and Recommendations HTAdiel AdrieBelum ada peringkat

- Division 2 - Site WorkDokumen14 halamanDivision 2 - Site WorkWincelet CelestinoBelum ada peringkat

- Press Tool ReportDokumen40 halamanPress Tool ReportIshu Bassan100% (2)

- En Jkm320pp (4bb)Dokumen2 halamanEn Jkm320pp (4bb)Ronal100% (1)

- CV 101Dokumen4 halamanCV 101frco1504Belum ada peringkat

- Drop of Water On Penny - HandoutDokumen7 halamanDrop of Water On Penny - Handoutapi-240932330Belum ada peringkat

- RT Finalpresenatation08 161118104713Dokumen56 halamanRT Finalpresenatation08 161118104713sajay2010Belum ada peringkat

- Formsat 5Dokumen6 halamanFormsat 5gramuiitmBelum ada peringkat

- t9 PDFDokumen21 halamant9 PDFselvaganapathy1992Belum ada peringkat

- Engine Control SystemDokumen7 halamanEngine Control SystemFaisal Al HusainanBelum ada peringkat

- Mayan Calendar ExplainedDokumen9 halamanMayan Calendar Explainedbresail40% (1)

- Reservoir Management Session 3 W Solutions PDFDokumen39 halamanReservoir Management Session 3 W Solutions PDFEmad ZakiBelum ada peringkat

- The Hubbard Coil MatrixDokumen4 halamanThe Hubbard Coil MatrixAna Luisa Lynce100% (1)