Control Engine - 1kd-Ftv and 2kd-Ftd

Diunggah oleh

Eulicer ArmengolJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Control Engine - 1kd-Ftv and 2kd-Ftd

Diunggah oleh

Eulicer ArmengolHak Cipta:

Format Tersedia

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-147

ENGINE CONTROL SYSTEM

1. General

The engine control system of the 1KD-FTV and 2KD-FTV engines has the following system.

2KD-FTV

1KD-FTV 2KD-FTV

High

Version

System

Outline

Fuel Injection

Volume Control

(See page EG-156)

Based on the signals received from the sensors, the engine ECU

determines the fuel injection volume in accordance with the engine

condition.

Fuel Injection

Timing Control

(See page EG-157)

Based on the signals received from the sensors, the engine ECU

determines the fuel injection timing in accordance with the engine

condition.

During Starting

Control

(See page EG-158)

To facilitate startability, the engine ECU optimally controls the injection

volume and injection timing during starting.

Idle Speed

Control

(See page EG-159)

The engine ECU determines the idle speed in accordance with the engine

condition, and controls the fuel injection volume in order to maintain the

target idle speed.

Fuel Pressure

Control

(See page EG-160)

Pilot Injection

Control

(See page EG-163)

Glow Plug

Control

Based on the signals received from the sensors, the engine ECU

determines the fuel pressure via SCV (Suction Control Valve) in

accordance with the engine condition.

Based on the signals received from the sensors, the engine ECU

determines pilot injection volume/timing, and interval (between pilot

injection and main injection) in accordance with the engine condition.

Controls the length of time when the current is applied to the glow plugs,

in accordance with the coolant temperature.

Intake Shutter

Control

(See page EG-164)

Controls the intake shutter valve (throttle valve) opening angle in

accordance with the engine condition.

Fully close the intake shutter valve (throttle valve) in order to reduce the

vibration when the engine is stopped.

Swirl Control

(See page EG-164)

Based on the signals received from the sensors, the engine ECU controls

the vacuum that is directed to the actuator via the VSV, in order to open

and close the valve.

Turbocharger

Control

(See page EG-165)

Based on the signals received from the sensors, the engine ECU controls

the actuator in accordance with the engine condition.

EGR Control

(See page EG-169)

Controls the EGR volume via EGR valve in accordance with the engine

condition.

Air Conditioner

Cut-Off Control*1

By controlling the air conditioner compressor ON or OFF in accordance

with the engine condition, drivability is maintained.

Engine

Immobilizer*2

Prohibits fuel injection if an attempt is made to start the engine with an

invalid ignition key.

Diagnosis

(See page EG-171)

When the engine ECU detects a malfunction, the engine ECU diagnoses

and memorizes the failed section.

Fail-Safe

(See page EG-171)

When the engine ECU detects a malfunction, the engine ECU stops or

controls the engine according to the data already stored in the memory.

*1: Models with Air Conditioner

*2: Models with Engine Immobilizer System

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-148

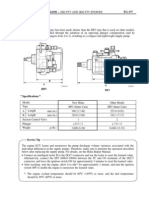

2. Construction

The configuration of the engine control system in the 1KD-FTV and 2KD-FTV engines is as shown in

the following chart.

INTAKE SHUTTER VALVE

POSITION SENSOR

#1

VLU

#2

#3

CAMSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR

FUEL PRESSURE SENSOR

#4

INJF

No.1 INJECTOR

E

D

U

No.2 INJECTOR

No.3 INJECTOR

No.4 INJECTOR

NE

PCV

SUCTION CONTROL VALVE

PCR1

INTAKE SHUTTER CONTROL

LUSL

PIM

Torque Motor (Rotary Solenoid type)

TURBO PRESSURE SENSOR

EGR CONTROL

THA

INTAKE AIR TEMP. SENSOR

WATER TEMP. SENSOR

ACCELERATOR PEDAL

POSITION SENSOR

EGR

THW

Engine

ECU

EGRC

GLOW PLUG CONTROL

VPA2

THF

SCV

INTAKE AIR TEMP. SENSOR*2

Glow Plug Relay

VG

IREL

FUEL TEMP. SENSOR

VSV (for EGR Valve Close)*1

VPA

GREL

AIR FLOW METER*1

Vacuum Regulating Valve

(for EGR Valve Control)

THIA

EDU RELAY

VSV (for Swirl Control Valve)*1

Close)

TURBOCHARGER CONTROL*1

EGR VALVE

POSITION SENSOR*3

EGLS

VNTO

Turbo Motor Driver

VNTI

STOP LIGHT SWITCH

ALTERNATOR

STP

ST1ALT

Nozzle Vane

Position Sensor

DC Motor

271EG132

(Continued)

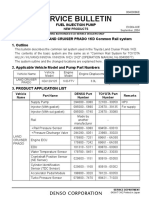

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-149

A/C AMPLIFIER*7

IGNITION SWITCH

STA

Starting Signal (ST Terminal)

Ignition Signal (IG Terminal)

ACT

IGSW

Magnetic Clutch Actuation Signal

AC1

Engine Idle-Up Signal

4

CRUISE CONTROL MAIN SWITCH*

CCS

BATT

BATTERY

COMBINATION METER

MREL Engine ECU

MAIN RELAY

+B

TRANSPONDER KEY ECU*5

IMO

IMI

TC

SIL

DLC3

WFSE

W

GIND

PI

SPD

DM

TACH

TRANSMISSION CONTROL ECU*

CAN+

ECT CONTROL

CAN-

THWO

*1: Only for 1KD-FTV Engine

*2: Only for Models with Intercooler

*3: Only for 2KD-FTV Engine

*4: Only for Models with Cruise Control System

*5: Only for Models with Engine Immobilizer System

*6: Only for Models with Automatic Transmission

*7: Only for Models with Air Conditioner System

*8: Only for Models with Multi Information Display

Check Engine

Warning Light

Glow Indicator Light

Cruise MAIN

Indicator Light*4

Vehicle Speed Signal

Injection Volume Signal*8

Tachometer

Water Temp. Signal

271EG133

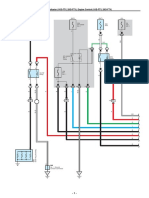

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-150

3. Engine Control System Diagram

Accelerator Pedal

Position Sensor

Ignition Switch Signal

Stop Light Switch Signal

Air conditioner Signal*1

Glow Relay

Vehicle Speed Signal

Suction Control

Valve

Engine

ECU

Fuel Temp.

Sensor

Supply Pump

Atmospheric

Pressure Sensor

VSV*2

(EGR Valve Close)

Common-Rail

Fuel Pressure

Sensor

Intake Air

Temp. Sensor*2

Intake Air

Temp.

Sensor*3

Intercooler*3

E-VRV

EDU

Relay

EDU

Intake

Shutter

Assy.

EGR Valve

Position Sensor*4

Turbo Pressure

Sensor

Air Flow Meter*2

Intake Air

Temp. Sensor*4

DC Motor*2

Nozzle Vane

Position Sensor*2

Glow Plug

VSV*2

(Swirl

Control

Valve)

Injector

Turbo Motor

Driver*2

Water

Temp.

Sensor

Camshaft

Position Sensor

Crankshaft

Position Sensor

*1: Only for Models with Air Conditioner

*2: Only for 1KD-FTV Engine

*3: Only for Models with Intercooler

*4: Only for 2KD-FTV Engine

271EG134

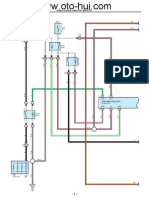

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-151

4. Layout of Main Components

EDU

E-VRV

Turbo Pressure Sensor

Air Flow Meter*1

Intake Air

Temp. Sensor*2

Glow Plug

Injector

Intake Air

Temp. Sensor*3

Intake Shutter Valve

Position Sensor

Fuel

Pressure

Sensor

Torque Motor

(Rotary Solenoid type)

VSV*1

(EGR Valve Close)

EGR Valve

Position Sensor*2

Water

Temp.

Sensor

Check Engine

Warning Light

Glow

Indicator Light

VSV*1

(Swirl Control

Valve)

Engine ECU

Transmission

Control ECU*4

Common-Rail

Crankshaft

Position Sensor

Camshaft Position

Sensor

Fuel Temp.

Sensor

Stop Light

Switch

SCV

Supply Pump

DLC3

Accelerator Pedal

Position Sensor

LHD Model

*1: Only for 1KD-FTV Engine

*2: Only for 2KD-FTV Engine

*3: Only for Models with Intercooler

*4: Only for Models with Automatic Transmission

271EG135

Turbo Motor

Driver*1

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-152

5. Main Components of Engine Control System

General

The main components of the 1KD-FTV and 2KD-FTV engine control system are as follows:

Components

Engine ECU

Outline

32-bit CPU

Quantity

Function

The engine ECU effects overall control of the engine

control system to suit the operating conditions of the

engine in accordance with the signals provided by

the sensors.

EDU

DC/DC Converter

The EDU is used to drive the injector at high speeds.

The EDU has realized high-speed driving under high

fuel pressure conditions through the use of a DC/DC

converter that provides a high voltage, quickcharging system.

Turbo Pressure

Sensor

Semiconductor

Silicon Chip Type

This sensor uses built-in semiconductors to detect

the intake manifold pressure.

Atmospheric Pressure

Sensor

Semiconductor

Silicon Chip Type

This sensor, which is built into the engine ECU, uses

semiconductors to detect the atmospheric pressure.

Fuel Pressure Sensor

Semiconductor

Strain Gauge Type

This sensor uses built-in semiconductors to detect

the internal pressure of the common-rail.

Crankshaft

Position Sensor

Pick-up Coil Type

(Rotor Teeth /36-2)

This sensor detects the engine speed and performs

the cylinder identification.

Camshaft

Position Sensor

Air Flow Meter

(1KD-FTV Engine)

Water Temperature

Sensor

Pick-up Coil Type

(Rotor Teeth /5)

This sensor performs the cylinder identification.

Hot-wire Type

Thermistor Type

Thermistor Type

Thermistor Type

Thermistor Type

Intake Shutter Valve

Position Sensor

No-contact Type

Accelerator Pedal

Position Sensor

No-contact Type

Contact Type

Intake Air

Temperature Sensor

Intake Air

Temperature Sensor

(for Intercooler)

Fuel Temperature

Sensor

EGR Valve

Position Sensor

(2KD-FTV Engine)

SCV

Suction Control

Valve

Injector

Linear Solenoid

Valve

8-hole Type

(1KD-FTV Engine)

6-hole Type

(2KD-FTV Engine)

This sensor uses a built-in hot-wire to directly detect

the intake air volume.

This sensor detects the engine coolant temperature

by means of an internal thermistor.

This sensor, which is provided at the air cleaner

outlet, detects the intake air temperature by means

of an internal thermistor.

On the 1KD-FTV engine, this sensor is built into

the airflow meter.

This sensor, which is provided only on the models

with an intercooler, detects the intake air

temperature past the intercooler.

This sensor detects the fuel temperature in the

supply pump by means of an internal thermistor.

This sensor detects the intake shutter valve (throttle

valve) opening angle.

This sensor detects the amount of pedal effort

applied to the accelerator pedal.

The basic construction and operation of this sensor

are the same as in the 1TR-FE and 2TR-FE

engines. For details, see page EG-46.

This sensor detects the actual amount of the EGR

valve opening.

The SCV position is controlled by the signals from

the ECU, and a fuel volume that suits the SCV

position is drawn into the pumping portion (plunger

portion).

The injector contains a solenoid valve that opens and

closes to increase or decrease the pressure in the

control chamber. This causes the nozzle needle to

open and close the valve, which results in fuel

injection.

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-153

Engine ECU

The 32-bit CPU of the engine ECU is used to increase the speed for processing the signals.

Each of the 2KD-FTV engine and the 2KD-FTV High Version engine is equipped with an engine

ECU that contains an engine control program that differs from each other. However, both engine

models share the same mechanical components.

On the models equipped with the A340E and A340F automatic transmissions, the engine ECU

maintains communication with a separate, independent ECT ECU through CAN (Controller Area

Network). Thus, engine control is effected in coordination with ECT control.

Turbo Pressure Sensor

The turbo pressure sensor consists of a semiconductor which utilizes the characteristic of a silicon chip

that changes its electrical resistance when pressure is applied to it. The sensor converts the intake air

pressure into an electrical signal, and sends it to the engine ECU in an amplified form.

Sensor Unit

(V)

5

Output

Voltage

(kPa)

100

250

Intake Manifold Pressure

271EG136

Fuel Pressure Sensor

The fuel pressure sensor consists of a semiconductor which utilizes the characteristic of a silicon chip

that changes its electrical resistance when pressure is applied to it. This sensor is mounted on the

common-rail, outputs a signal that represents the fuel pressure in the common-rail to the engine ECU, in

order to constantly regulate the fuel at an optimal pressure.

Detection Portion

(V)

Output

Voltage

(MPa)

Fuel Pressure

271EG137

EG-154

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

Crankshaft Position Sensor and Camshaft Position Sensor

The timing rotor of the crankshaft consists of 34 teeth, with 2 teeth missing. The crankshaft position

sensor outputs the crankshaft rotation signals every 10, and the missing teeth are used to determine

the top-dead-center.

To detect the camshaft position, a protrusion that is provided on the timing pulley is used to generate 5

pulse for every 2 revolution of the crankshaft.

Camshaft

Position Sensor

Camshaft Position Sensor

34 Pulse/360 CA

5 Pulse/720 CA

224EG41

Sensor Output Waveforms

5 Pulse/720 CA

180 CA

180 CA

34 Pulse/360 CA

180 CA

34 Pulse/360 CA

271EG138

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-155

Intake Shutter Valve Position Sensor

The intake shutter valve position sensor is mounted on the intake shutter assembly, to detect the opening

angle of the intake shutter valve (throttle valve), the intake shutter valve position sensor converts the

magnetic flux density that changes when the magnetic yoke (located on the same axis as the intake

shutter valve shaft) rotates around the hall IC into electric signals to operate the intake shutter valve

control motor.

Hall IC

Output

Voltage

(V)

Magnet

271EG82

Intake Shutter Valve

(Throttle Valve)

100

Intake Shutter Valve Position Ratio ()

271EG83

258AE62

EG-156

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

6. Fuel Injection Volume Control

The engine ECU calculates two types of values: the basic injection volume and the maximum injection

volume. Then, the engine ECU compares the basic and maximum injection volumes, and determines the

smaller calculated value to be the final injection volume.

Basic Injection Volume

Accelerator Pedal

Position Sensor

Crankshaft

Position Sensor

Engine Speed

Engine ECU

Calculation of

Basic Injection

Volume

ISC* Correction

Water Temp. Sensor

*: Idle Speed Control

224EG44

Maximum Injection Volume

Engine ECU

Basic/Maximum

Injection Volume

(Map data inside of ECU)

Crankshaft

Position Sensor

Engine Speed

Water Temp. Sensor

Maximum Injection

Volume Correction

Fuel Temp. Sensor

Intake Air

Temp Sensor

Turbo Pressure

Sensor

Air Flow Meter*

Intake Air Volume*

224EG46

*: Only for 1KD-FTV Engine

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-157

Final Injection Volume Decision

Engine ECU

Basic Injection Volume

Fuel Pressure

Comparison

Final

EDU

Maximum Injection

Volume

Injector

224EG48

7. Fuel Injection Timing Control

Fuel injection timing is controlled as shown below.

Accelerator Pedal

Position Sensor

Crankshaft

Position Sensor

Engine Speed

Engine ECU

Basic Injection Timing

Water Temp. Sensor

Intake Air Temp.

Sensor

Correction

Turbo Pressure Sensor

Injection Timing

EDU

Injection

201EG45

EG-158

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

8. During Starting Control

Injection Volume Control

The starting injection volume is determined by adjusting the basic injection volume in accordance with

the starter ON signals (ON time) and coolant temperature sensor signals and engine speed signal. When

the engine is cold, the coolant temperature will be lower and the injection volume will be greater.

Engine ECU

Basic Injection

Volume

+

Starter Signal

Correction

Water Temp.

Sensor

Crankshaft

Position Sensor

224EG50

Injection Timing Control

To determine the starting injection timing, the target injection timing is corrected in accordance with the

starter signals, water temperature, and engine speed.

When the water temperature is low, if the engine speed is high, the injection timing is advanced.

Engine ECU

Starter Signal

Target Injection

Timing Correction

Water Temp.

Sensor

Crankshaft

Position Sensor

224EG51

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-159

9. Idle Speed Control

Fuel injection timing is controlled as shown below.

Engine ECU

Accelerator

Pedal Position

Sensor

Water Temp. Sensor

Target Speed

Calculation

Vehicle Speed Sensor

Starter Signal

A/C Signal*

Idle-up Signal

Comparison

Actual Engine Speed

Injection Volume

Correction

Crankshaft

Position Sensor

*: with Air Conditioner

233EG14

EG-160

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

10. Fuel Pressure Control

General

Engine ECU calculates the target injection pressure (32~160MPa/1KD-FTV, 30~160MPa/2KD-FTV)

base on the engine conditions, that are the signals from the acceleration pedal position sensor and the

crankshaft position sensor.

To control fuel pressure, signals sent to SCV (Suction Control valve) of the supply pump regulate the

pumping volume, so that the pressure detected by the pressure sensor matches the target injection

pressure.

Fuel Pressure Sensor

Pressure Limiter

Common-rail

Injector

Supply Pump

SCV

Fuel Temp. Sensor

EDU

Calculation of

target injection

pressure

Engine ECU

Crankshaft

Position

Sensor

Accelerator Pedal

Position Sensor

271EG139

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-161

System Operation

1) General

The engine ECU controls the opening of the SCV in order to regulate the volume of fuel that is

pumped by the supply pump to the common-rail. Consequently, the fuel pressure in the common-rail is

controlled to the target injection pressure.

2) SCV Opening Small

(a) When the opening of the SCV is small, the fuel suction area is kept small, which decrease the

transferable fuel quantity.

(b) The plunger strokes fully, however, the suction volume becomes small due to the small suction area.

Therefore, the difference of the volume between the geometry volume and the suction volume is in

vacuum condition.

(c) Pumping will start at the time when the fuel pressure has become higher than the common-rail

pressure.

Fuel Pumping Mass

Plunger TDC

Plunger BDC

Pumping

Starting Point

Cam

Stroke

SCV

Small Suction

Area

(a)

(b)

(c)

245EG13

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-162

3) SCV Opening Large

(a) When the opening of the SCV is large, the fuel suction area is kept large, which increase the

transferable fuel quantity.

(b) If the plunger strokes fully, the suction volume will increase because the suction area is large.

(c) Pumping will start at the time when the fuel pressure has become higher than the common-rail

pressure.

Fuel Pumping Mass

Pumping

Starting Point

Cam

Stroke

Large Suction

Area

(a)

(b)

(c)

245EG14

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-163

11. Pilot Injection Control

Pilot injection is a method that provides an auxiliary fuel injection before the main fuel injection takes

place. The purpose of pilot injection is to gently start the combustion of the fuel of the main injection in

order to reduce combustion noise.

State

Pilot Injection

Pilot Injection

Ordinarily Injection

Main Injection

Fuel Injection

Combustion

Pressure

168EG23

During pilot injection, the pilot injection volume, timing, and interval (Between pilot injection and

main injection) are controlled as shown below.

Accelerator Pedal

Position Sensor

Crankshaft

Position Sensor

Engine Speed

Engine ECU

Basic Pilot Injection

(Volume, Timing, Interval)

Intake Air Temp.

Sensor

Correction

Water Temp. Sensor

Turbo Pressure Sensor

Pilot Injection

(Volume, Timing, Interval)

EDU

Injection

201EG45

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-164

12. Intake Shutter Control

The opening of the intake shutter valve (throttle valve) that is installed on the intake manifold is

controlled by the engine ECU in accordance with engine condition.

As a result, the noise that is generated during idling and deceleration, as well as the noise and vibration

that are generated when the engine is stopped, have been reduced and this control makes it possible to

re-circulate the exhaust gas in accordance with the driving condition.

Intake Shutter

Valve Position

Sensor

Intake Shutter Valve

Control Motor

Engine Speed

Vehicle Speed

Water Temp.

Intake Shutter

Valve

Engine

ECU

Intake Air Temp.

Accelerator Pedal

Position

Intake Air Pressure

Ignition Switch

271EG140

13. Swirl Control (Only for 1KD-FTV Engine)

The engine ECU determines the swirl control valve position (open or closed) based on the engine

conditions (engine speed and accelerator pedal effort). Then, it switches the vacuum that is applied to the

actuator diaphragm via the VSV, in order to open and close the swirl control valve.

In the low engine speed range, the engine ECU closes the swirl control valve to strengthen the swirl in

the combustion chamber, thus promoting the mixture of fuel and air and stabilizing combustion. When

the engine speed increases to the medium or high-speed range, the engine ECU fully opens the swirl

control valve. On a cold engine, the engine ECU fully closes the swirl control valve to reduce the amount

of white smoke emissions.

Intake Port

Vacuum

Swirl Control Pump

Valve

Accelerator Pedal Position

Combustion Chamber

Engine Speed

Actuator

Engine ECU

VSV

271EG90

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-165

14. Turbo Charger Control (Only for 1KD-FTV Engine)

General

The engine ECU controls the nozzle vane position using the turbo motor driver, in order to obtain the

calculated target turbo pressure appropriate to the engine operating condition.

The engine ECU calculates the optimal nozzle vane position in accordance with the driving conditions

(engine speed, injection volume, atmospheric pressure, and water temperature etc), and sends a target

nozzle vane position signal to the turbo motor driver. The turbo motor driver controls the nozzle vane

position in accordance with this signal and the actual nozzle vane position signal provided by the

nozzle vane position sensor.

DC Motor

Turbo Pressure

Sensor

Nozzle Vane

Position

Sensor

Actual Nozzle

Vane Position

Atmospheric

Pressure

Sensor

Nozzle Vane

Position Control

Crankshaft

Position Sensor

Injector

Engine ECU

Water Temp.

Sensor

Target Nozzle Vane Position Signal

Turbo Motor

Driver

Intake Air Temp.

Sensor

Turbocharger Control Status

271EG141

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-166

Construction

1) General

Variable nozzle vane device is established on the turbine (exhaust) side, and consisted of a DC motor,

nozzle vane position sensor, linkage, drive arm, unison ring, driven arms and nozzle vanes.

DC Motor

Nozzle Vane

Position Sensor

Turbine

Wheel

Linkage

Nozzle Vane

Full-Close Stopper

Driven Arm

Unison Ring

Drive Arm

271EG142

Service Tip

To control the nozzle vane position, the turbo motor driver renders the contact position of the

linkage with the full-close stopper (thus fully closing the nozzle vane) as the zero point for the

nozzle vane position sensor.

If the turbocharger has been reinstalled or replaced, turn the ignition switch from ON to OFF

once, and make sure that the linkage comes in contact with the full-close stopper.

The full-close stopper position, which is adjusted at the factory at the time of shipment, is not

serviceable in the field. For this reason, if the linkage does not come in contact with the full-close

stopper during an inspection, the turbocharger assembly must be replaced.

Never attempt to loosen or tighten the locknut of the full-close stopper because it will adversely

affect the performance of the engine.

For details, see the Hilux Repair Manual.

Linkage

Open

Full-Close

Stopper

Close

Lock Nut

271EG143

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-167

2) Nozzle Vane Position Sensor

The nozzle vane position sensor consists of a Hall IC and a magnetic yoke that rotates in unison with

the movement of the linkage that actuates the nozzle vane. The nozzle vane position sensor converts

the changes in the magnetic flux that are caused by the rotation of the DC motor (hence, the rotation of

the magnetic yoke) into electric signals, and outputs them to the turbo motor driver. The turbo motor

driver determines the actual nozzle vane position from the electric signals in order to calculate the

target nozzle vane position.

Hall IC

4.5

Magnetic Yoke

Full Close

Output

Voltage

(V.)

Sensor Vane

0.5

Full Open

Nozzle Vane Position

Full Close

Full Open

271EG148

Sensor Vane

271EG147

System Diagram

Nozzle Vane Position Sensor

Magnetic

Yoke

Magnet

VCX1

VSX1

Hall IC

Sensor Vane

E2X1

Turbo Motor

Driver

Magnet

271EG149

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-168

Operation

1) At Engine Low Speed Range

When the engine is running in a low speed range, the DC motor presses down the linkage by a signal

from the turbo motor driver. The tip of the linkage rotates the unison ring counterclockwise through a

drive arm.

The unison ring contains a driven arm, which is placed through the cutout portion of the unison ring.

This driven arm also moves in the direction of the rotation of the unison ring. The fulcrum of the

driven arm is an axis that is integrated with the nozzle vane behind the plate. When the driven arm

moves counterclockwise, the nozzle vane moves toward the closing direction. This results in

increasing the velocity of the exhaust gas flowing to the turbine, as well as the speed of the turbine. As

a result, torque is improved when the engine is running at low speeds.

DC Motor

Nozzle Vane

Linkage

Linkage

Gas Flow

Fulcrum

Unison Ring

Plate

Drive Arm

Driven Arm

Cutout Portion

Driven Arm

271EG144

2) At Engine Medium-to-High Speed Range

When the engine is running in a medium-to-high speed range, the DC motor pulls up the linkage by a

signal from the turbo motor driver. With this, the driven arm moves clockwise and this opens the

nozzle vane and holds the specified supercharging pressure. Thus, lowering the back pressure and

improving the output and fuel consumption.

271EG145

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-169

15. EGR Control System

General

The table below lists the differences between the EGR system on the 1KD-FTV and 2KD-FTV engines,

as well as the differences in their control contents.

Engine

Differences

1KD-FTV

A VSV (Vacuum Switching Valve) is provided for EGR valve close

control.

2KD-FTV

2KD-FTV High Version

An EGR valve position sensor is provided for detecting the EGR valve

position.

EGR Control for 1KD-FTV Engine

By sensing the engine driving conditions, the engine ECU electrically operates both the E-VRV (for

EGR valve control) and VSV (for EGR valve close), which controls the magnitude of vacuum

introduced into diaphragm of EGR valve and intake shutter valve (throttle valve) opening position

with intake shutter valve control motor and the amount of recirculating exhaust gas is regulated. EGR

valve opening lift is controlled by modulated negative pressure.

On the 1KD-FTV engine, the VSV (for EGR valve close) is activated when the EGR control is

stopped, in order to introduce the atmospheric pressure to the EGR valve diaphragm and improve

EGR valve closure response.

Intake Shutter

Valve Position

Sensor

Intake

Shutter

Valve

Intake Shutter

Valve Control Motor

EGR

Valve

Vacuum

Pump

Vacuum

Damper

Engine

ECU

Atmospheric

Pressure

Sensor

Intake

Manifold

Crankshaft

Position Sensor

Accelerator Pedal

Position Sensor

Water Temp. Sensor

Turbo Pressure

Sensor

Intake Air

Temp Sensor

Air Flow Meter

E-VRV

(for EGR Valve Control)

Engine

VSV

(for EGR Valve Close)

Exhaust Manifold

271EG150

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-170

EGR Control for 2KD-FTV Engine

By sensing the engine driving conditions and actual amount of EGR valve opening, the engine ECU

electrically operates the E-VRV (for EGR valve control), which controls the magnitude of vacuum

introduced into diaphragm of EGR valve and intake shutter valve (throttle valve) opening position with

intake shutter valve control motor and the amount of recirculating exhaust gas is regulated. EGR valve

opening lift is controlled by modulated negative pressure.

Intake Shutter

Valve Position

Sensor

Intake

Shutter

Valve

Intake Shutter

Valve Control Motor

EGR Valve

Position Sensor

Vacuum

Damper

Vacuum

Pump

Crankshaft

Position Sensor

Engine

ECU

Intake

Manifold

EGR

Valve

Atmospheric

Pressure

Sensor

Accelerator Pedal

Position Sensor

Water Temp.

Sensor

Turbo Pressure

Sensor

Intake Air

Temp Sensor

E-VRV

(for EGR Valve Control)

Engine

Exhaust Manifold

271EG131

ENGINE 1KD-FTV AND 2KD-FTV ENGINES

EG-171

16. Diagnosis

The diagnosis system of the 1KD-FTV and 2KD-FTV engines uses the M-OBD (Multiplex On-Board

Diagnosis).

When the Engine ECU detects a malfunction, the engine ECU makes a diagnosis and memorizes the

failed section. Furthermore, the check engine warning light in the combination meter illuminates or

blinks to inform the driver.

The 2-digit DTCs (Diagnostic Trouble Codes) can be accessed by connecting the SST (09843-18040)

to the DLC3 terminals TC and CG, and reading the blinking of the check engine warning light.

By using the intelligent tester II, the 5-digit DTCs and ECU data can be read out. Moreover, the

ACTIVE TEST can be used to drive the actuator by means of the intelligent tester II.

The Engine ECU can output freeze-frame data to the intelligent tester II. This data is stored in the

engine ECU at the very moment when the engine ECU has detected its last data of malfunction.

All the DTCs have been made to correspond to the SAE controlled codes. Some of the DTCs have been

further divided into smaller detection areas than in the past, and new DTCs have been assigned to them.

For details, see the Hilux Repair Manual.

Service Tip

To clear the DTC that is stored in the engine ECU, use a intelligent tester II or disconnect the battery

terminal or remove the EFI fuse for 1 minute or longer.

17. Fail-Safe

When a malfunction is detected by any of the sensors, there is a possibility of an engine or other

malfunction occurring if the ECU were to continue to control the engine control system in the normal

way. To prevent such a problem, the fail-safe function of the ECU either relies on the data stored in

memory to allow the engine control system to continue operating, or stops the engine if a hazard is

anticipated. For details, see the Hilux Repair Manual.

Anda mungkin juga menyukai

- Control Engine 1kd FTV and 2kd FTDDokumen41 halamanControl Engine 1kd FTV and 2kd FTDMuxumad Cabdulahi0% (1)

- Toyota 2kd Engine ContrlDokumen25 halamanToyota 2kd Engine ContrlKamal Semboy67% (3)

- 1kd-Ftv and 2kd-Ftv FipsDokumen8 halaman1kd-Ftv and 2kd-Ftv FipsSultan Ahmed Khan100% (23)

- Hilux 1kd 2kdDokumen5 halamanHilux 1kd 2kdmiguelcastillo91% (35)

- 1KD FTVDokumen10 halaman1KD FTVnicamarcos100% (7)

- 1kd FTVDokumen2 halaman1kd FTVGregory Ashley87% (15)

- Engine 1KD, 2KDDokumen72 halamanEngine 1KD, 2KDjimmy_huamancayo97% (60)

- Common Rail System (CRS) : Toyota 1Kd/2Kd EngineDokumen31 halamanCommon Rail System (CRS) : Toyota 1Kd/2Kd EngineJuan Alberto Bucaro100% (30)

- Toyota 1kd 2kdDokumen31 halamanToyota 1kd 2kdMispa Serv100% (2)

- F7 A2 F8 B1 E1 F6 F5 G1 E4: Position of Parts in Engine CompartmentDokumen3 halamanF7 A2 F8 B1 E1 F6 F5 G1 E4: Position of Parts in Engine CompartmentEtienne van Tonder100% (3)

- 1kd FTV OverhaulDokumen37 halaman1kd FTV OverhaulJehuty8897% (34)

- Denso Toyota Hilux Common RailDokumen68 halamanDenso Toyota Hilux Common RailRonald Yanes93% (71)

- HiluxDokumen11 halamanHiluxCarlos Eduardo Zelidon100% (2)

- TOYOTA Hi Lux FaultCodes 0692Dokumen1 halamanTOYOTA Hi Lux FaultCodes 0692yargen100% (1)

- ECT and A/T Indicator (1KD-FTV, 2KD-FTV), Engine Control (1KD-FTV, 2KD-FTV)Dokumen33 halamanECT and A/T Indicator (1KD-FTV, 2KD-FTV), Engine Control (1KD-FTV, 2KD-FTV)Erick Lizana Neyra100% (4)

- Wiring Diagram ECU 2KD-FTVDokumen13 halamanWiring Diagram ECU 2KD-FTVDam Nguyen87% (95)

- Hilux GD SeriesDokumen17 halamanHilux GD SeriesNging Yu100% (6)

- 2004-2015 Toyota Hilux Fuse Box Diagram Fuse DiagramDokumen12 halaman2004-2015 Toyota Hilux Fuse Box Diagram Fuse DiagramJunior Salazar100% (2)

- 1KD-FTV and 2KD-FTV EnginesDokumen25 halaman1KD-FTV and 2KD-FTV EnginesSergio Olivares Cortes100% (6)

- 04 Engine ProperDokumen5 halaman04 Engine Properwilliam_senati20057051Belum ada peringkat

- Spill Control Valve InspectionDokumen1 halamanSpill Control Valve InspectionArdi AgusmanBelum ada peringkat

- 1K 2KD Fuel Injection Volume ValueDokumen12 halaman1K 2KD Fuel Injection Volume ValueJimmy100% (2)

- 1ktze Pinin-PinoutDokumen11 halaman1ktze Pinin-PinoutKooked100% (9)

- 1zzVS2zz 6Dokumen16 halaman1zzVS2zz 6Ofi de Mo100% (1)

- 9913 Ap 34Dokumen108 halaman9913 Ap 34احمدميدوBelum ada peringkat

- 06imvpu Eg ControlDokumen44 halaman06imvpu Eg Controlvuongspkt12007Belum ada peringkat

- Engine Control System DiagramDokumen8 halamanEngine Control System DiagramGowher QadriBelum ada peringkat

- 1MZ-FE Engine Control SystemRX300 99Dokumen11 halaman1MZ-FE Engine Control SystemRX300 99Jose Calle100% (1)

- Sfi SystemDokumen96 halamanSfi SystemWawan SatiawanBelum ada peringkat

- 3grfse 1Dokumen42 halaman3grfse 1Zoli Borbely100% (3)

- Sistema de Control de EmisionesDokumen45 halamanSistema de Control de EmisionesDavid ParariBelum ada peringkat

- Engine - 1VD-FTV EngineDokumen33 halamanEngine - 1VD-FTV EnginePablo Pérez100% (3)

- GR00001100 13B PDFDokumen342 halamanGR00001100 13B PDFNicu PascalutaBelum ada peringkat

- ASE 2010 L2 Composite VehicleDokumen20 halamanASE 2010 L2 Composite VehicleSeven See67% (3)

- GDIDokumen7 halamanGDIlinhda561Belum ada peringkat

- E - Theory/Operation - Efi: 1991 Mitsubishi MonteroDokumen7 halamanE - Theory/Operation - Efi: 1991 Mitsubishi MonteroAnimemanuel MuñozBelum ada peringkat

- Exhaust Gas RecirculationDokumen15 halamanExhaust Gas RecirculationJesus FloresBelum ada peringkat

- 13a Mfi 1.5LDokumen164 halaman13a Mfi 1.5LDian Zahari Zainal AbidinBelum ada peringkat

- Engine PADokumen49 halamanEngine PAlartsim115Belum ada peringkat

- Toyota Avensis DPFDokumen22 halamanToyota Avensis DPFCarl Anthony Chamberlain100% (3)

- Multiport Fuel System (Mfi) : Group 13ADokumen64 halamanMultiport Fuel System (Mfi) : Group 13Ajagjitemir6014Belum ada peringkat

- V 3 Aac02v3d PDFDokumen48 halamanV 3 Aac02v3d PDFFred Fredy100% (1)

- General General Information: 13A MPIDokumen91 halamanGeneral General Information: 13A MPIDiego SantanaBelum ada peringkat

- ДатчикиDokumen4 halamanДатчикиАндрей ДубовецBelum ada peringkat

- Detroit 60 Datos BásicosDokumen16 halamanDetroit 60 Datos Básicosvictorhernandezrega100% (1)

- E Theory OperationDokumen7 halamanE Theory Operationdguruge8Belum ada peringkat

- Egine Control System: GeneralDokumen18 halamanEgine Control System: GeneralAdrianoTHEBelum ada peringkat

- ASE L2 Composite Vehicle 2007Dokumen0 halamanASE L2 Composite Vehicle 2007Anil YarlagaddaBelum ada peringkat

- G32D DTCDokumen59 halamanG32D DTCPower NguyenBelum ada peringkat

- GR00000900 13a PDFDokumen402 halamanGR00000900 13a PDFNicu PascalutaBelum ada peringkat

- Mono Jetronic (Haynes)Dokumen3 halamanMono Jetronic (Haynes)pieroBelum ada peringkat

- D6CC - Fuel System PDFDokumen45 halamanD6CC - Fuel System PDFduongpn100% (12)

- SsangYong Korando / New Actyon - Engine Control SystemDokumen172 halamanSsangYong Korando / New Actyon - Engine Control Systemtroublezaur80% (5)

- Egine Control System: GeneralDokumen18 halamanEgine Control System: GeneralAnh Tu NguyenBelum ada peringkat

- Engine Control System Engine Control System System Diagram: To EsmDokumen40 halamanEngine Control System Engine Control System System Diagram: To EsmAlex RonBelum ada peringkat

- 1KR-FE Engine Control SystemDokumen346 halaman1KR-FE Engine Control SystemMortada Alsonni79% (19)

- Isuzu EngineDokumen53 halamanIsuzu EngineSmaileRun78% (18)

- 4.1 Engine Management System-R1-1 MINYI EFFADokumen24 halaman4.1 Engine Management System-R1-1 MINYI EFFARusonegroBelum ada peringkat

- Ecm Draft-6-10Dokumen5 halamanEcm Draft-6-10api-327987286Belum ada peringkat

- Case IH MX Tractor SRT ManualDokumen81 halamanCase IH MX Tractor SRT Manualhuskerchamps60% (5)

- Group 2 Specifications: 1. Major ComponentsDokumen6 halamanGroup 2 Specifications: 1. Major ComponentsYamilaBelum ada peringkat

- Q4 Science 9 Week 7 1Dokumen4 halamanQ4 Science 9 Week 7 1May LanieBelum ada peringkat

- Electronic Unit Injector - Remove: C6.6 Industrial EngineDokumen12 halamanElectronic Unit Injector - Remove: C6.6 Industrial EngineBassieBelum ada peringkat

- Future 125 1Dokumen100 halamanFuture 125 1TamPhamBelum ada peringkat

- Engine Crec Generic Scan Tool EngDokumen997 halamanEngine Crec Generic Scan Tool EngAlexandru Dumitru ZahariaBelum ada peringkat

- Peec II - Peec III Brake Engine 10 P OkDokumen10 halamanPeec II - Peec III Brake Engine 10 P OkEduardo AlvarezBelum ada peringkat

- Catalogo de Códigos Do Compressor 3CDCDokumen20 halamanCatalogo de Códigos Do Compressor 3CDCEvandro MatosoBelum ada peringkat

- Maintenance Schedules / Maintenance PartsDokumen29 halamanMaintenance Schedules / Maintenance PartsRiki Akbar100% (1)

- Mini Cooper Cooper S Clubman r55 r56 r57 Service Manual 2007 2013 Excerpt Vanos Units Removing and Installing n12 n16 n18 EngineDokumen7 halamanMini Cooper Cooper S Clubman r55 r56 r57 Service Manual 2007 2013 Excerpt Vanos Units Removing and Installing n12 n16 n18 EngineRemo OsamaBelum ada peringkat

- Kle650cbfcdf Parts List PDFDokumen115 halamanKle650cbfcdf Parts List PDFOliverBelum ada peringkat

- Psi Engines Product Sheet PDFDokumen2 halamanPsi Engines Product Sheet PDFDaniel DelgadoBelum ada peringkat

- Power Distribution Box, Rear Integrated Supply Module: Z11 F014 F011 F018 F08 F010 Z2a A361Dokumen9 halamanPower Distribution Box, Rear Integrated Supply Module: Z11 F014 F011 F018 F08 F010 Z2a A361Ninh LỗBelum ada peringkat

- Cooling System (Compatibility Mode)Dokumen28 halamanCooling System (Compatibility Mode)agvassBelum ada peringkat

- 2006 Honda CRF250R Owner'S Manual & Competition HandbookDokumen168 halaman2006 Honda CRF250R Owner'S Manual & Competition Handbookrafael grondinBelum ada peringkat

- Bwts Library 530 623Dokumen27 halamanBwts Library 530 623Tri Minh100% (1)

- Código P0171Dokumen4 halamanCódigo P0171Transmisiones Automáticas ChepeBelum ada peringkat

- Supreme Motors - FusoDokumen61 halamanSupreme Motors - Fusocaidenbourke100% (1)

- Daytona 150cc T-REX Installing Instructions - Chain RollerDokumen5 halamanDaytona 150cc T-REX Installing Instructions - Chain RollerMinibikeTechBelum ada peringkat

- Title: Boom Cylinder Model Number: E42 Serial Number: AG3411001 & AboveDokumen3 halamanTitle: Boom Cylinder Model Number: E42 Serial Number: AG3411001 & AboveJhon EcheverryBelum ada peringkat

- 03 Combustion ChamberDokumen13 halaman03 Combustion ChambernareshBelum ada peringkat

- Internship On KSRTC Central Works PappanamcodeDokumen64 halamanInternship On KSRTC Central Works Pappanamcodeajay.pBelum ada peringkat

- Lab ReportDokumen41 halamanLab Reportharoon100% (1)

- Aba Aeg 2 0 PDFDokumen25 halamanAba Aeg 2 0 PDFVictor100% (1)

- 3408E Industrial Engine Electrical System: Top ViewDokumen2 halaman3408E Industrial Engine Electrical System: Top ViewxuanBelum ada peringkat

- Crankshaft Main Bearing MEDIDASDokumen2 halamanCrankshaft Main Bearing MEDIDASRECTIMANSABelum ada peringkat

- C18 Industrial Engine WRH00001 - Sensor Eg GroupDokumen2 halamanC18 Industrial Engine WRH00001 - Sensor Eg GroupBlog Teknisi100% (1)

- 5303 - 5403 Ind.Dokumen308 halaman5303 - 5403 Ind.Edinaldo GuimaraesBelum ada peringkat

- Sge S Series Gasengines NG LRDokumen6 halamanSge S Series Gasengines NG LRenconBelum ada peringkat