Trouble Shooting Chart

Diunggah oleh

gustavofx210 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan2 halamanyork comp

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniyork comp

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan2 halamanTrouble Shooting Chart

Diunggah oleh

gustavofx21york comp

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 2

INSTRUCTIONS

SERVICE

Form 220. 10-NMI (Supl. 1)

1066 [esses on

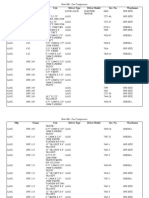

TURBOMASTER COMPRESSORS—SERIES M

TROUBLE SHOOTING CHART

SYMPTOMS ‘CAUSES

1. Compressor Surging: Insufficient load,

Cooling water temperature too high.

Low condensing water flow.

Dirty condenser or evaporator tubes.

Oil in evaporator or condenser tubess

Low relrigerant charge,

Foul gas in system.

Low driver speed.

Excessive oil in the refrigerant.

PRV closed from malfunction.

Discharge check valve stuck ia closed position.

Improper float or intercooler operation.

Recheck controls system.

KPRETEOmppop>

>

2 Fluctuation or loss of oil (Oil sump heaters not energized prior to startup, Sump

pressure during startup: temperature should be 150 F. In cold ambients, sump

should be 90 F above ambient prior to starting.

B, When oil foaming occurs, renew oil charge, prior to

re-starting.

G. Insufficient water flow thru lube oil cooler.

D, Refrigerant condensed in casing, by running hot water

or product thru chiller, while outdoor compressor is,

shutdown,

Outdoor oil lines and lube oil cooler absorbed refrigerant.

Remedy: Circulate hot sump oil, thru lines with auxiliary

oll pump for 15 minutes, to move refrigerant laden oil

back to sump heaters, prior to startup.

3. Low Oil Pressure | A. Diny oit filter.

BL Obstructed jet nozzle.

GC. Oil foaming, due to refrigerant absorbed in the oil.

D. Worn pump volute, seal ring.

E, Worn journal bearings.

F, Wom thrust bearing, ‘The thrust oil outlet pressure

should exceed the ofl supply pressure.

G. Improperly installed pump housing gaskets.

H. Low driver speed.

I. Valves improperly set on auxiliary oil pump.

3. Low oil level,

4. High oil temperature: ‘A. Dirty oil cooler,

(Max. off thrust bearing 185 F) | B, Reduced water (or air) flow.

(Max at filter - 140 F) Cl Extremely high discharge temperature.

D, Thrust bearing failure, if temperature range across the

thrust bearing increases (nominal is 30 F). Check balance

Piston pressure, (see item 5), and oil supply temperature,

E, Low oil flow, indicated by reduced oil pressure differential

across the thrust bearing.

SYMPTOMS ‘CAUSES

5. High Balance Piston Preysure ‘A. Balance piston seal ring worn,

Note: - Pressure should be 2 t0 | By Seal ring svized to balance piston and rotating with it.

5 peig above the pressure at Compression seal ring on oll sump stuck, broken oF

equalized stage (sce aasembly otherwise damaged.

drawings for specific compress- | D, Worn or missing McKim gaskets under bolt heads on

ors) on halocarbon compressors. collection ring (See Instr.

For other gases, refer to Improperly assembled vent tube seals.

Engineering Department-York, Pas| F. Excephonally high discharge pressure,

6. Compressor loses oil into | 1 foaming, heaters not working prior to startup,

system! | insuttictent cooling water to lube ofl cooler, oF Liquid

sslopover.

Balance piston seal ring worn,

Porous casting at suction end.

Porous casting OF leaking plugs on oil sump.

Equalizing tubes improperly installed,

Excessive shait gas seal leakage, worn gas seal

seal end List.

Too high oil level, above sight glass.

7. Compressor vibrates: A. Check and eliminate surging.

Cheek and correct coupling alignment and spacing.

Check

8. Shaft seal oil leakage: | A; Check oit pressure at shat seal

BL Cheek oil temperature.

CL Check alignment,

D. Check thrust bearing axial clearance.

E, Replace shaft seal a8 necessary.

vere ‘pried pont ee York Teterhone 5

Tnrermtional Syeteme on Renmeytvnta, THVT E90

Ecrporation torn Trees

‘YORK has a policy of contnuavs product miprovement, ard reserves he fight lo change specifications and designs without notice

Printed in USA Copyright” by York internavonal Corporation 1991 ALL FIGHTS RESERVED

Fe NM Supt 1 (086) SHUM 49120

“OFM 220.1080 (Suh. 1) BB

Anda mungkin juga menyukai

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Rino KK - Gas CompressorsDokumen20 halamanRino KK - Gas Compressorsgustavofx21Belum ada peringkat

- Ariel-Er-105 1 1Dokumen9 halamanAriel-Er-105 1 1gustavofx21Belum ada peringkat

- Woodward Mechanical TG Governor PDFDokumen52 halamanWoodward Mechanical TG Governor PDFgustavofx21Belum ada peringkat

- Recommended Maintenance Intervals For Continuous Duty Reciprocating CompressorsDokumen7 halamanRecommended Maintenance Intervals For Continuous Duty Reciprocating Compressorsgustavofx21Belum ada peringkat

- Force Feed Lubricator Pump: PrimingDokumen2 halamanForce Feed Lubricator Pump: Priminggustavofx21Belum ada peringkat

- Psu 2 PDFDokumen2 halamanPsu 2 PDFgustavofx21Belum ada peringkat

- Demo 24x3ringDokumen20 halamanDemo 24x3ringgustavofx21Belum ada peringkat

- Proflo Jr. No-Flow SwitchDokumen3 halamanProflo Jr. No-Flow Switchgustavofx21Belum ada peringkat

- CATERPILLAR 3516 TA Parts 1 PrelubricadoraDokumen2 halamanCATERPILLAR 3516 TA Parts 1 Prelubricadoragustavofx21Belum ada peringkat

- P 172Dokumen2 halamanP 172gustavofx21Belum ada peringkat

- 642G Chockfast InstallDokumen6 halaman642G Chockfast Installgustavofx21Belum ada peringkat

- York Centrifugal M PamphletDokumen8 halamanYork Centrifugal M Pamphletgustavofx21Belum ada peringkat

- U 134Dokumen2 halamanU 134gustavofx21Belum ada peringkat

- P 172Dokumen2 halamanP 172gustavofx21Belum ada peringkat

- HG 12 SeriesDokumen2 halamanHG 12 Seriesgustavofx21Belum ada peringkat

- H 276Dokumen46 halamanH 276gustavofx21Belum ada peringkat

- ITW Philadelphia Resins Material Safety Data Sheet: Chockfast Black HardenerDokumen14 halamanITW Philadelphia Resins Material Safety Data Sheet: Chockfast Black Hardenergustavofx21Belum ada peringkat

- 6320 Spare Parts ListDokumen6 halaman6320 Spare Parts Listgustavofx21Belum ada peringkat

- Model 6320/VA: Four Channel Vibration AnalyzerDokumen2 halamanModel 6320/VA: Four Channel Vibration Analyzergustavofx21Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)