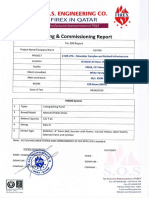

Commissioning Request and Check List (Form 9180)

Diunggah oleh

Sraz MidniteDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Commissioning Request and Check List (Form 9180)

Diunggah oleh

Sraz MidniteHak Cipta:

Format Tersedia

Dunham-Bush Industries Sdn Bhd (166302-K)

Lot 5755-6, Kidamai Industrial Park

Bukit Angkat, 43000 Kajang

Selangor Darul Ehsan, Malaysia

T: +603 89249000

W: www.dunham-bush.com

COMMISSIONING REQUEST AND PRE-START-UP CHECK LIST

Request for start-up and commissioning of Dunham-Bush Air and Water Cooled Chillers

Job Name :

Address & Location :

Unit Model

Unit Serial

Number of Units

Kindly complete, officially stamp, sign and return this form to Dunham-Bush (DB) should you

require DB to dispatch technicians or supervision to jobsite. Failure to complete and check

all the below items may result in additional charges to your company. Additional charges will

result if the start-up and commissioning exercise is delayed, or additional days are

required due to site delays/problems, or if there is in-complete preparations on your scope of

work.

A. Dunham-Bush Unit

1.

Essential electrical power to the Chiller is available

Measured Voltage: L1-L2:

L1-L3:

L2-L3:

1.

Erected on foundation

2.

Spring isolators or Neoprene Rubber pads installed and adjusted to level

unit

3.

Cooler / Chiller vessel insulated

4.

Chiller leveled within 1/16 per foot

5.

Visually check for leaks (oil dripping etc.)

6.

Standing Pressure of each refrigerant circuit Refrigerant

7.

Inspect chillers or condensing units for damage

8.

Check for enough clearance for proper airflow and servicing of unit

Page 1 of 5

DBI/WS/SCPC/17 Rev.1 07/15

B. Air Handling Unit/ Fan Coil / Process System

1.

All units tested, commissioned and operating without problem

2.

All process system ready and completed for Operation

C. Piping

1.

Cleaned , flushed and pressure tested for leaks

2.

Properly supported vibration eliminators installed

3.

Air vents, thermometers and pressure gauges installed

4.

All water balancing and isolating valves installed and tested

5.

All chilled and condenser water flow switches installed, tested and

calibrated

6.

All modulating valves and flow controls checked and calibrated

7.

All modulating valves and flows set at design flow requirement

8.

Water piping system properly purged of air and no air lock in system

D. Units with Cooling Tower

1.

Cleaned, tested and operational

2.

Tower fan tested and balanced

3.

Tower water flow balanced

4.

Water treatment services performed, auto chemical Feed has flow

interlock

E. Water Pump

1.

All condenser and chilled water pump tested operational and balanced

Condenser Pump FLA :

Pump Running Amp:

Chilled Water Pump FLA :

2.

Pump Running Amp:

All pumps properly primed and no air lock in pumping system

Page 2 of 5

DBI/WS/SCPC/17 Rev.1 07/15

3.

Adequate and constant water supply available

4.

Required flow ratio must be maintained prior to start-up the chillers

(Follow water flow curve on I.O.M.)

F. Electrical Wiring

1.

Adequate and constant power supply available

2.

All power wiring and control completed to all of the system components

3.

All circuit breakers and overload relays properly sized and installed

4.

All wiring and grounding conforms to National Electrical Codes

5.

All automatic control devices checked, tested and operational

6.

All field supplied main electrical boards, switch boards, starter boards and

controls checked, tested and operational.

7.

Customer interlocks only as indicated on wiring diagram

(shielded cable as required )

8.

Energize crank case heater for 24 hours prior to start-up of the

compressors

G. Units with Remote Refrigerant Condenser Piping

1.

Required amount of refrigerant for system charging at job site

2.

Entire system properly dehydrated must hold vacuum at 700

microns for a minimum half an hour.

3.

All fan cycling, damper control systems checked and operational

4.

All control wiring installed

H. Remote Evaporator Systems

1.

Liquid line solenoid interlocked with Dunham-Bush unit control panel

2.

Entire system properly dehydrated must hold vacuum at 700 microns

microns for a minimum half an hour.

Page 3 of 5

DBI/WS/SCPC/17 Rev.1 07/15

3.

All expansion valves properly sized and properly installed

4.

All refrigerant piping installed in accordance With standard good practice

and design criteria

5.

All terminal equipment properly sized and properly installed

6.

All automatic control devices checked and operational

I. Condition

1.

Essential electrical power to the equipment is available as designed

2.

Essential water supply for city usage and conditions is available

3.

Full load available for proper test and balance of Dunham-Bush equipment

Services To Be Rendered

Dunham-Bush engineers, supervisors, technicians and service representative will check,

test, start-up and commission the chiller and condensing units in accordance to

standard Dunham-Bush procedures and re-commendation and standard commercial

good practices.

Dunham-Bush Rendered Services Above Do Not Include Any Responsibility For The

Following:1. Installation and operating of the temperature control system external to the chillers

or condensing units - Other wise agreed upon by both parties prior to performance

of works.

a. Balancing of the air distributor side of this system.

b. Balancing of the water side of the system other than the chillers or condensing

units

c. Balancing of refrigerant systems.

2. Electrical wiring performed by others.

We (the dealer/contractor)

request the present of Dunham-Bush personnel at the job site on or about

(date) to check, test start-up and commission the equipment /

system as required.

On receipt of this form, Dunham-Bush will schedule their service personnel to this

job within seven to fourteen days (7-14 days) of the requested date.

Page 4 of 5

DBI/WS/SCPC/17 Rev.1 07/15

It is understood that Dunham-Bush personnel will be at site to perform start- up

and commissioning exercise for a period not exceeding

normal working days.

We the undersigned agree that we will pay a free for such time that is spent on this

over the specific normal working days agreed upon, due to delays and in-complete

preparations on our part and scope of works/responsibilities. To cover this

contingency, our contingency Purchase Order No.

be issued with

the assurance that if no addition time is required, this purchase order will be

cancelled.

An overtime charge will be rendered for work executed on Saturday, Sunday and

Public Holidays

Dealer /

Contractor:

Address:

Authorized

Signatory:

Full Name :

Company

Stamp:

Position:

Page 5 of 5

DBI/WS/SCPC/17 Rev.1 07/15

Anda mungkin juga menyukai

- OMM-Kandis Residences (2019) PDFDokumen38 halamanOMM-Kandis Residences (2019) PDFjo_eli_Belum ada peringkat

- VRF & DX Split Type ACU Testing MethodologyDokumen1 halamanVRF & DX Split Type ACU Testing MethodologydamianBelum ada peringkat

- Fire Alarm System Maintenance 2Dokumen3 halamanFire Alarm System Maintenance 2renvBelum ada peringkat

- Fire Fighting Pipe Sizing UAEDokumen2 halamanFire Fighting Pipe Sizing UAEgiemy george100% (1)

- All Projects - Snag ListDokumen7 halamanAll Projects - Snag ListMohammed Javid HassanBelum ada peringkat

- Preventive Maintenance of FDAS and Sprinkler SystemDokumen6 halamanPreventive Maintenance of FDAS and Sprinkler SystemchocostarfishBelum ada peringkat

- Mr. Slim System Pre-Commissioning and Installation Check ListDokumen4 halamanMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasBelum ada peringkat

- Fcu Method StatementDokumen3 halamanFcu Method StatementBalajiBelum ada peringkat

- SD Qatar Product CatalougeDokumen36 halamanSD Qatar Product CatalougeRichard Beldua50% (2)

- Air Conditioning System: Section 15 / 1Dokumen12 halamanAir Conditioning System: Section 15 / 1Ahmed Yousri AhmedBelum ada peringkat

- Ahu BoqDokumen2 halamanAhu BoqRajesh BMBelum ada peringkat

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Dokumen7 halamanPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffBelum ada peringkat

- Havc Underground Piping MosDokumen5 halamanHavc Underground Piping MosYusuf Ziya DilbazBelum ada peringkat

- Fire Fighting SpecificationsDokumen50 halamanFire Fighting SpecificationsPabbathi VinayBelum ada peringkat

- 5-Corrective Maintenance FahuDokumen2 halaman5-Corrective Maintenance FahuUmair LiaqatBelum ada peringkat

- External Building DrainageDokumen11 halamanExternal Building Drainagevelayuthan_s9168Belum ada peringkat

- Preaction System ManualDokumen64 halamanPreaction System ManualAhmed Mohamed Rashed100% (1)

- Deepak Patil: Fire Fighting Description and WmsDokumen5 halamanDeepak Patil: Fire Fighting Description and WmsDeepak PatilBelum ada peringkat

- Sprinkler and SystmesDokumen4 halamanSprinkler and SystmesridwanBelum ada peringkat

- Project Name: Al Ruwais Housing Complex 663 Villas: ElectricalDokumen3 halamanProject Name: Al Ruwais Housing Complex 663 Villas: Electricalabdallah salama100% (1)

- Methodology Mechanicalr02Dokumen20 halamanMethodology Mechanicalr02damianBelum ada peringkat

- Method Statement For Installation of Electric Water Heater - Method Statement HQDokumen5 halamanMethod Statement For Installation of Electric Water Heater - Method Statement HQGwenn AsprerBelum ada peringkat

- Combined Sprinkler and Standpipe AssemblyDokumen1 halamanCombined Sprinkler and Standpipe Assemblydesign sseBelum ada peringkat

- Boq Hvac Works: Item RefDokumen7 halamanBoq Hvac Works: Item RefMohamed TallyBelum ada peringkat

- DD Electric Driven Fire Pump SpecificationDokumen16 halamanDD Electric Driven Fire Pump SpecificationNurcahyo Djati WBelum ada peringkat

- Heat Loss and Gain CalculationDokumen84 halamanHeat Loss and Gain Calculationafraz_xecBelum ada peringkat

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDokumen25 halamanInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonBelum ada peringkat

- Domestic - MTD SilentDokumen6 halamanDomestic - MTD SilentVan Vinh NguyenBelum ada peringkat

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDokumen1 halaman200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajBelum ada peringkat

- FM-PX - Ca-Pw-00017 - 02 - C PDFDokumen47 halamanFM-PX - Ca-Pw-00017 - 02 - C PDFBaha ShehadehBelum ada peringkat

- Preventative Maintenance Task Sheet: Plant/Equipment: Job IDDokumen29 halamanPreventative Maintenance Task Sheet: Plant/Equipment: Job IDJaveria KhanBelum ada peringkat

- Distancia Soportes PVCDokumen1 halamanDistancia Soportes PVCEduardo ArrietaBelum ada peringkat

- Section 16200 Electrical, GeneralDokumen6 halamanSection 16200 Electrical, GeneralctoujagueBelum ada peringkat

- Bilt Middle East LLC: Inspections and Testing PlanDokumen1 halamanBilt Middle East LLC: Inspections and Testing Plansarmad009Belum ada peringkat

- Snag List Tower D & EDokumen38 halamanSnag List Tower D & EAnushri TaleBelum ada peringkat

- 7-BOQ & Estimate Fire ProtectionDokumen26 halaman7-BOQ & Estimate Fire ProtectionTransitpoint Holiday BungalowBelum ada peringkat

- Chilled Water Buffer TankDokumen4 halamanChilled Water Buffer TankThiraviam Ayyappan100% (1)

- Mep Questionnaire HospitalDokumen7 halamanMep Questionnaire HospitalRaju KsnBelum ada peringkat

- HVAC - BOQ, Cost Estimate & ProcurementDokumen6 halamanHVAC - BOQ, Cost Estimate & Procurementsunkk0369Belum ada peringkat

- Fire Pump Idiot Proofing1Dokumen32 halamanFire Pump Idiot Proofing1Kenneth100% (1)

- Methodology in Dismantling of DX and CHW Type Aircon UnitDokumen2 halamanMethodology in Dismantling of DX and CHW Type Aircon UnitAJ Jarillas100% (1)

- 2 Plumbing and Drainage Tender DocumentDokumen195 halaman2 Plumbing and Drainage Tender DocumentlewisBelum ada peringkat

- ITPDokumen1 halamanITPmaani7zeroBelum ada peringkat

- TS-02 Ventilation Fans - Toilet & BasementDokumen11 halamanTS-02 Ventilation Fans - Toilet & BasementPraveen KumarBelum ada peringkat

- Hvac Boq-07082014Dokumen17 halamanHvac Boq-07082014eng-ashraf abdullahBelum ada peringkat

- Final Training Manual - SYSTEMDokumen3 halamanFinal Training Manual - SYSTEMsarmad009Belum ada peringkat

- Fire Protection and Suppression SystemDokumen4 halamanFire Protection and Suppression Systemamrit90320Belum ada peringkat

- Refrigerant Piping Work1Dokumen13 halamanRefrigerant Piping Work1Le Manh HieuBelum ada peringkat

- HVAC System: Exhaust FanDokumen4 halamanHVAC System: Exhaust FanAnsari1918Belum ada peringkat

- SECTION 15340 Water Spray Fixed Systems Rev 0Dokumen28 halamanSECTION 15340 Water Spray Fixed Systems Rev 0Basil OguakaBelum ada peringkat

- Specification For Phenolic Duct Works SystemsDokumen2 halamanSpecification For Phenolic Duct Works Systemspsn_kylmBelum ada peringkat

- VRF System Vs Chiller SystemDokumen14 halamanVRF System Vs Chiller Systemgowrish80_bmsBelum ada peringkat

- Method Statement For Duct Smoke DetectorDokumen1 halamanMethod Statement For Duct Smoke DetectorBento BoxBelum ada peringkat

- Air Handling Unit PDFDokumen16 halamanAir Handling Unit PDFizani_idrisBelum ada peringkat

- Diffuser Sizing GuidelinesDokumen1 halamanDiffuser Sizing Guidelinessyed mustafa aliBelum ada peringkat

- Method of Statement FirefightingDokumen10 halamanMethod of Statement FirefightingswamyBelum ada peringkat

- Testing Procedure SprinklerDokumen2 halamanTesting Procedure SprinklerBea RullanBelum ada peringkat

- Burch-Commissioning of HVAC SystemsDokumen9 halamanBurch-Commissioning of HVAC Systemsizzat555Belum ada peringkat

- CV - Tab PDFDokumen66 halamanCV - Tab PDFAhmed HamdiBelum ada peringkat

- Survey Works Rev 1Dokumen12 halamanSurvey Works Rev 1Abraham JyothimonBelum ada peringkat

- PO 46 4429 SITC Emergency Stop AmmendedDokumen3 halamanPO 46 4429 SITC Emergency Stop AmmendedSraz MidniteBelum ada peringkat

- Re - Consultancy Services For Fire Audit of T-1 ...Dokumen5 halamanRe - Consultancy Services For Fire Audit of T-1 ...Sraz MidniteBelum ada peringkat

- BoQ - Supply, Installation, Testing & CommissioningDokumen1 halamanBoQ - Supply, Installation, Testing & CommissioningSraz MidniteBelum ada peringkat

- Mumbai International Airport PVT LTDDokumen3 halamanMumbai International Airport PVT LTDSraz MidniteBelum ada peringkat

- CT Scanner For BaggageDokumen21 halamanCT Scanner For BaggageSraz MidniteBelum ada peringkat

- Commissioning Report-Cer - T&C ReportDokumen2 halamanCommissioning Report-Cer - T&C ReportSraz MidniteBelum ada peringkat

- 7851 Ahu Fahu CHWP Commissioning Report 04-06-16 PDFDokumen66 halaman7851 Ahu Fahu CHWP Commissioning Report 04-06-16 PDFSraz MidniteBelum ada peringkat

- 7851B C17 Storm Water CalculationDokumen56 halaman7851B C17 Storm Water CalculationSraz MidniteBelum ada peringkat

- Oscillating Universe TheoryDokumen1 halamanOscillating Universe TheoryArabella BasilioBelum ada peringkat

- Bergeron Forces&StructureinSoapFilms Review JCondensMatter1999Dokumen25 halamanBergeron Forces&StructureinSoapFilms Review JCondensMatter1999Paul DBelum ada peringkat

- HCSA-Toolkit-v2.0-Module-4-Forest-and-vegetation-stratification-190917-webDokumen44 halamanHCSA-Toolkit-v2.0-Module-4-Forest-and-vegetation-stratification-190917-webzulfikarishak_300660100% (1)

- EliminationDokumen12 halamanEliminationMatthew JohnBelum ada peringkat

- 14 - Part 3 - Ch. 7 - A Lesson With Czerny - Tempo Rubato PDFDokumen21 halaman14 - Part 3 - Ch. 7 - A Lesson With Czerny - Tempo Rubato PDFErduandBelum ada peringkat

- Edge Crush Test-Tappi-2007Dokumen13 halamanEdge Crush Test-Tappi-2007김강형Belum ada peringkat

- Mivec FaultDokumen1 halamanMivec Faultbjr6627Belum ada peringkat

- MTH101 TutorialDokumen2 halamanMTH101 TutorialOnochie EnunwaonyeBelum ada peringkat

- 22-01 Simple Linear Motion 1Dokumen1 halaman22-01 Simple Linear Motion 1David BumbaloughBelum ada peringkat

- Sef 0l6aeDokumen144 halamanSef 0l6aezarni zarniBelum ada peringkat

- Galleon NTS-6002-GPS DatasheetDokumen3 halamanGalleon NTS-6002-GPS DatasheetObdulio SantanaBelum ada peringkat

- SPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideDokumen4 halamanSPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideRoxy RoxaBelum ada peringkat

- The Death of Science.Dokumen1 halamanThe Death of Science.sam iam / Salvatore Gerard MichealBelum ada peringkat

- Must-On Board Diagnostics II PCED PDFDokumen19 halamanMust-On Board Diagnostics II PCED PDFRopama BraBelum ada peringkat

- Guia 4. Mov Aparente SolDokumen4 halamanGuia 4. Mov Aparente SolAlexa ContrerasBelum ada peringkat

- Chem301 Lab3Dokumen5 halamanChem301 Lab3Gobe JamBelum ada peringkat

- The Periodic TableDokumen16 halamanThe Periodic TableKayla HerdsmanBelum ada peringkat

- BUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Dokumen48 halamanBUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Vidya Hitti100% (2)

- Example 3 (Science-Based)Dokumen75 halamanExample 3 (Science-Based)poppygibson1111Belum ada peringkat

- Cat ElcDokumen17 halamanCat ElcJoel Cunha100% (1)

- International Mathematics Olympiad: Sample PaperDokumen4 halamanInternational Mathematics Olympiad: Sample Paperalien zogBelum ada peringkat

- Maths Formula's Pocket BookDokumen113 halamanMaths Formula's Pocket BookPOLUNATI SAHITHI POLUNATI SAHITHI100% (1)

- Macromolecules Study Guide Key 1Dokumen5 halamanMacromolecules Study Guide Key 1api-330218302Belum ada peringkat

- Report Esomeprazole IV Inj (Guide Batch 03)Dokumen60 halamanReport Esomeprazole IV Inj (Guide Batch 03)Sari Widya Astuti SelianBelum ada peringkat

- Robert Bosch Type VE Diesel Injection PumpDokumen5 halamanRobert Bosch Type VE Diesel Injection PumpShahrizan abdul rahman0% (1)

- IIT AIEEE BITS Free Online Help and QuestionsDokumen7 halamanIIT AIEEE BITS Free Online Help and Questionsapi-3846151Belum ada peringkat

- 10.1109 Jproc.2022.3174030Dokumen30 halaman10.1109 Jproc.2022.3174030Sree Krishna DasBelum ada peringkat

- Finite Element Analysis Using MATLAB ANSYS 16 HrsDokumen2 halamanFinite Element Analysis Using MATLAB ANSYS 16 HrsMOHIT PANTBelum ada peringkat

- SK Product HandbookDokumen110 halamanSK Product Handbooksupriyo110Belum ada peringkat

- Poisson Brackets and Constants of The MotionDokumen4 halamanPoisson Brackets and Constants of The MotionPopoBelum ada peringkat