Flow Table

Diunggah oleh

คุณชายธวัชชัย เจริญสุขHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Flow Table

Diunggah oleh

คุณชายธวัชชัย เจริญสุขHak Cipta:

Format Tersedia

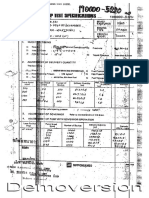

FL-1 00 SERIES, FL-1 10, FL-1 20

Now Available

COMPUTERIZED

FLOW TABLES

FOR OMEGA@ ROTAMETERS

A new R L D project at Omega Instruments has

produced a new computerized procedure for

generating complete Row tables for any suitable

fluid of known viscosity and density.

Tables of flow are available for calibrated and

correlated flowmeters at every scale division from 1 to 100.

Similar tables are available for compact

flowmeters at every direct flow reading of

scale.

condiVolume flow rates are given at the

tions of flow and corrected to volumes

measured at standard conditions.

Each chart for a correlated and calibrated

flowmeter is specific to the actual serialized

meter and float material.

The flow rate can be given in any units

desired including mass flow.

New correlation method uses complex analytical equations programmed to achieve

maximum accuracy.

Resultant accuracy is at least twice as good

as the best previous correlation developed,

namely:

Average error = -t 2% or f 0.5 S.D. whichever is the greater (compared to -+ 4% for

previous best method)

Maximum Error = -t 6% or 2 1.5 SD. whichever is the greater (compared to -+ 12%

for previous best method)

NEW CORRELATION *

he new computerized method is based on

he use of the flow equation given in terms

If q as a function of CR and K, A new more

!xtensive correction is used for

CR and

cf as follows:

1. From the latest available flow data and

flowmeter characteristics ~(10 + log C,) IS

plotted as a function of ~(10 + log K,) with

Parameter Ft. where,

KR IS independent of R and a function of the

physlcal properties of the fluid and the flowmeter only. It is proportional to the square root

of the Archimedes number (a dimensionless

quantity used in fluid dynamics analysis).

division for each particular flowmeter.

2.Two new functions related toy and u are defined as,

a. W = log w. where w = log z log z0

and log z = - log (y, y)

y,=yasu a=

z,=zatSt=5

b.V=logv,wherev=u-u,

and u,=uatSt=5

5. The relationship between C, and St IS simplified in the Stokes region as before to give:

3. The analytical relatlonship between W and

V is given by,

W = n, + n,V + n,V* i n,V3

where St<5

6. The correction factor, K, is defined by:

This polynomial expression is evaluated using the

best values of the four coefficients, n,. n,. n2 and

n3 determined by a graphical least squares analysis of cross plots and derivattve plots These

coefficients In turn are determined by a similar

analysis to yield polynominals In R as follows:

n,=a,+q,R+q2R2

n, =a,,+a,,R+a,,RZ

n2 = aZO + a,,R + a&+

n3 = a, + a,,R + aZ2RZ

Relerence: Gitmont 8 Wechster.

Meas. 8 Control V21, No. 6, P.148 (Dec. 1987).

GB-104350

ingi;98D,

where, R, is a simple function of v; namely,

The coefficients of the linear function above are

again evaluated by a graphical least squares

analysis of cross plots of data to yield:

m,=m,+m,,RJ

and m, = m,, + mrp R2

C,

Substitut-

4-R[A + 21

K ,

yields the volumetnc rate at condltlons of

flow, whfch in turn is converted to the standard rate

by the program. If one attempted these computations with a scientific calculator, it would require

an inordinate amount of time to obtain the complete table produced by the computer program as

illustrated above.

IiOW TO,ORDER

When ordenng your specific computerized table

please supply the following information:

a. At operating conditions of specified

pressure and temperature

b. At standard conditions of 1 atm. and 70F

3. Float material

4. Flowmeter size and serial number where

5. Units of flow desired

Ml 072/0390

DIRECTIONS

OMEGA@ ROTARilETERS

The procedure for calculating the flow of any fluid of known density and

viscosity are based on the new standard correlation curve supplied

with the new serialized flowmeter. NOTE: Owners of old serial num

bers may write for a new chart at no extra charge, by supplying us with

the size and serial number of the flowmeter.

iIGH-ACCURACY, UNSHIELDED

Computer tables are now included at no extra charge

- four tables in ail, air and water at standard conditions using glass and stainless steel floats. For other

fluids and any conditions of flow.

?? The standard calibration chart for air and water using

the glass float now contains the values of R for use

with the new generalized correlation.

?? Calibration curves for any fluid and float can be

obtained at the operating conditions of flow using

the new generalized correlation. Only the density and

viscosity of the fluid need be known.

?? Each serialized meter is statistically calibrated with

air at three points (an improvement over the previous

two point calibration) to assure an accuracy of

f 2%

or f 1 Scale division (whichever is the greater).

. Readings are reproducible to f 1% or * 0.5 scale

divisions (whichever is the greater).

?? Other features have been maintained as follows:

1. Specially designed Teflon stops accept cones.

ponding tapered joints and O-Rings to make a

vacuum tight seal.

2. Permanent black ceramic scale and white

background for easy reading.

3. Corrosion resistant-fluid comes in contact with

glass and tefion only (when using glass float and

plain end meter).

4. Glass and stainless steel floats are supplied with

each meter. A conversion chart indicates pressure

drops for each float and converts flow rates with the

glass float to those with stainless steel.

These flowmeters are manufactured from tapered

(-t .OOOlprecision bore tubing to ultimate tolerances

.0002) which give maximum precision attainable

for spherical float rotameters.

The tolerances on

the floats are of comparable magnitude.

The latest generalized correlation is based on a new

dimensionless quantityKi(related to the Archimedes

number). Prediction of fluid flows with an accuracy at

least twice as good as any previous method is now

possible (see page 1). See DIRECTIONS of sample

calculations using graphical and analytical methods.

* U.S. Patent No. 3,183,713

** Reference: Gilmont 8 Maurer. Instr. & Control Sys. V.34.

p.2070 (1941).

??

Reference:

p.148 (Dec.

Gllmont

1987).

8 Wechsler.

Meas.

&Control

V.21, N

GRAPHICAL SOLUTION

Select the desired value of Rat the corresponding value of

scale division from the calibration curve supplied.

2. Calculate the value of KR:

1.

K,= ,.;, [

SIZE NO

Cat. No.

F-2004

F-2005

F-2031

F-1133

F-1134

1 Ring 101 JOl",

S-1105

S~l105-E

I-Ring EPR

-LOAT

Pf FC Fw

;1ass

253

F-2032

;?I

8 02 18 i 1 F-2032 S

rantttt

166 26 32

149 24

3OF-2032.TC

lCttt

pf = density,

ttt suppled

Cat. No.

F-1104

F-1105

F-1131

F-1133

F-1134

S-1105

S-ll05~E

F~ll32

F-1132-S

F-1132-T

Cat. No.

F~l204

C, = .0852K,R5

4.

Determine the value of the correction factor. K,. For gases ant

values of R < 10, the value of K, may be taken as unity. If not

letermine K, as follows:

a. Calculate the value of v:

b. From the Correction Factor Chart on the page following thr

Correlation Chart, obtain the value of

100/k?, correspondin<

to the values of R and Y.

K,:

c. Calculate the value of

PI

R,

Calculate the volumetric rate of flow,

q:

q= CRK4R f. + 2

[

Kq = 59

K,

1PPt

6 D, !%- )

s

[

snd D, = Diam. float in inches from data.

3. The above.value of q is at the conditions of flow which may be

.educed to a volume measured at standard conditions, q :q

= qpfp

Nhere. p0 = density at standard conditions

SAMPLE CALCULATIONS

FL-105

Shown with

resDective ioint

6,

Cat. No.

Flowmeter, Size

#l. FllOO, Glass Float,

W, = .00530 g, p, =

2.53 glee. 0, = .0625 in. Water at 40

C. p = ,653 cp., p = .99i

g/cc. p. = .99d g/cc. Values of R at 5, 10 & 25

F-7032

F-7032-E

F-1232

F-1232~s

F-1232-T

F~l332

2119-S

1332-T

F~l432

F 1432-S

F-1532

F-1532-S

F-2504

F-1505

F-1531

F-1533

F-1534

F 1432.TC

F-1532.TC

F-1x35~

F-1535-E

R

5

10

25

I!

CR

.0842

,233

,526

100/R,

1

.097

,693

.0469

.0625

.125

,250

,375

,500

.P64

,962

5.48

-OFI ANALYTICAL SOLUTION see page following the

r:ON CHART.

.%33

,956

5.45

CORRELA.

exer.

sised not to lose the ball, especially for the smaller sizes It is

POSSi.

aru

318 to replace the ball with negligible error because the diameter

density of the ball are held to very close tolerances. Normal method:

3f cleaning are recommended using mild detergents and drying witt

acetone.

JOINT SETS: It is recommended that short lengths of flexible

tubin<

[such as tygon or teflon) be used on each end to hold the joints se

curely to the flowmeter especially with the smaller sizes

(#O and #1)

To protect the tiny teflon stops of these smaller sizes a suitable nee

dle may be inserted in the orifice upon assembly and disassembly

SET OF

FLOAT

DIAM.

4.44

2.30

K,

1

.923

,870

.06836. Kq = .2130

CLEANING: When cleaning the meter, great care should be

FA and Fw are magmfylng

factors far

ar & wakr

wlfh conversion char, for flow and pressure drop

FLOWUETERS, PLAIN ENDS

RANGES MLlMlN tt

AIR

CAT. NO.

WATER

0.2-100

,002-l .l

FL-100

l-280

.Ol-4.0

FL-101

10-1900

0.2-36

FL-102

200s14,000

3-300

FL-103

l OOO-36,000

1 O-850

FL-104

3000-77,000

30-l 900

FL-105

1 =

y = 1.021 .00530(2.53 - .992).992 O5

R

,653 L

2.53

5

Cat. No.

Cat. No.

at low flows, may cause erratic readings due

to electrostatic charge build-up.

[I

K , = ,-- !T2

P

whers,

NOTE: Extremely dry gases,

SIZE

IOQR

F-2404

F-1405

F 1431

F-1433

F 1434

F 1435-v

F-1435E

F-1231

F-l 233

F-i 234

v = IogK, - ,350 t

F-1304

F-1305

F-1331

F-1333

F-1334

S-1205

S 1205-E

F-1205

where, p = viscoscity of fluid in cp

W, = weight of float in g/cc

p, = density of float in g/cc

p = density of fluid in glee

note, W, and P, are given in the calibration curve data.

3. From the correlation chart on the next page obtain the value o

28 corresponding to R and Kn. When C, < .19. use the equation

SPARE IJAR1 rs LIST

Description

.etlan Stop, Top

retIon Stop. Bottom

:lowmeter Tube

klmt, inner

loIni. Outer

W ,(p:j-pipl

the

TUBE

O.D. n

5116

5116

5116

7116

11116

15/16

TUBE

LENGTH w

7 l/2

7 /2

7 /2

7%

JOlNTSt

CAT. NO.

IO%0

10130

12130

14135

19138

24140

FL-J1

FL-J1

FL-J2

FL-J3

FL-J4

FL-J5

Each meter is supplied with complete directions and correlation charts for calculating the calibration curve for any fluid whose density and viscosity are

known. Owners of serialized flowmeter made prior to the new computerized correlation, may order any one of the four computer tables,

specify desired tables.

Just supply us with flowmeter size and serial number and

tconsists of one inner and outer joint plus two O-rings.

ttFlow ranges for glass float stated above may be extended by factors of approx 2 to 3 by using heavier floats. See Spare Parts List.

rt

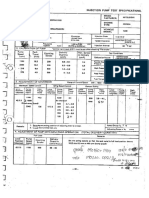

C ORRELA T/ON CHART

10

Density a Viscosity of

Gases at 70F a 1 atm

p in g/Li

GAS

KR

c1 in cp

1.087

1.200

.7155

1.655

2.510

2.481

1.035

1.160

2.989

1.259

1.170

.1657

.0834

1.522

1.429

3.382

.6653

2.139

.035a

1.244

1.161

1.836

1.326

1.075

2.717

5.307

cetylene

.ir

.mmonia

.rgon

utane (n)

utane (iso)

:arbon dioxide

:arbon monoxide

:hlorine

thane

thylene

leiium

lydrogen

lydrogen chloride

lydrogen sulfide

.rypton

lethane

lethyl chloride

leon

litric oxide

litrogen

litrous oxide

)xygen

ropane

iulfur dioxide

:enon

.OlOl

.0181

.00986

.0221

.0076

.0076

.0148

.0174

.0133

.00913

.OlOl

.0194

.0087

.0144

.0126

.02 514

.0109

.0107

.0312

.0188

.0175

.0144

.0203

.00803

.0125

.0226

TABLE II

Density a Viscosity of

Liquids at 70F 8 1 atm

LIOUID

p In g/ml

Acetic Acid

Acetone

Anilme

Benzene

Butyl Acetate

n-butanol

CCI 4

Chlorobenzene

Chloroform

Diethyl Ether

Ethyl Acetate

Ethanol

Ethylene Br

Ethylene Cl

Ethylene Glycol

Fluorobenzene

Heptane

Methyl Acetate

Methanol

Nitrobenzene

n-octane

Propanol

Toluene

o-xylene

m-xylene

p-xylene

Aqueous Solutions

10% HCI

30% HCI

10% HNO,

40% HNO3

10% HzSO~

60% HsSOa

0.2

0.3

0.4

0.5

0.7

1.049

,790

1.022

,879

,083

,610

1.594

1.106

1.483

,714

,900

,709

1.460

898

1.109

1.023

,684

,933

791

1.204

,703

,804

867

,880

.864

861

p in cp

1.221

.32

4.40

,652

,732

2 946

,969

,799

.58

,233

,455

1 20

1.72

.79

19.90

.598

409

381

,597

2 03

,542

2 256

,590

,810

,620

,648

(% by weight)

1.048

1 149

1.054

1.247

1.066

1.499

1.15<

1.70;

1.04;

1 55E

1 22E

5 90:

1.0 1.

CR-

FOR CR < 0.19, CR = .0852 KRR.~

CORRECT/ON FACTOR CHART

SAMPLE CALCULATIONS FORANALyrCAL SOLUTION

ANALYTICAL SOLUTION OF FLUID FLOW

1. Same as step 1 of GRAPHICAL SOLUTION on previous page

2. Same as step 2 of GRAPHICAL SOLUTION

3. Calculate the following:

a) St = KR2R3

b) St,, = 5 + .777R

4. Determine the region of flow as follows:

a) If St < 5 region is Stokes, skip to step 9

b) If .Sb 5 St F 5 region is transitional, skip to step 6

c) If St > St0 region is turbulent, proceed to step 5

5. For the turbulent region, calculate the following:

a) V = log[log Kn - ,350 + 1.5 IogR] (KRfrom step 2)

b) W ,=no+n,V+n2V2+~V3

where, no = -.197 t .00418R- .000155R2

n, = 1.065

- .0189R + 001375R*

n2 = ,929 - .1510R+ .004025R2

n3 = ,542 - .06185R. skip to step 7

6. For the transitional region calculate the following:

a) V, = log[O.5 log S10 - .350] (St,, from step

3b)

b) W, = n,, + n,V, + n2V02 + n3V03 (coeff. the same as in 5b)

c) W, = W0 - V, + V (Vas calculated in Step

5a)

7. Calculate the followino:

a) WC = log-

W,

b) zc = log- (w,+ 0.1193)

C) yc = 10.040 -(l/z,)

d) CR= log-

(y,- 10)

Determine the value of K,as follows: (K, = 1 for gases)

a) v = log- V ( V from step 5a)

8.

1.

R:

af R

7.61

12.77

transitional

5. a) v:

b) W,:

0

:

n, :

2 :

3 :

6. a) V, :

b)

;

c) w,:

7.

a) w,:

b) zc:

c) Yc:

d) C,:

8. a)

Y:

b) R,:

100

c)

where, m, = 4.81 - .138

25

Kn = .08836 for all values

St = .00781 R3

,975

a) sr:

b) St,:

6.805

4.

Region:

Stokes

2.

3.

1

--.1707

1.0315

-.1785

- 0765

-.1592

-.4249

-.1894

1.4519

-.3304

-1.004 3

-.6923

-.9325

-1.061 3

-1.256 5

.0554

1.495

9.371

,235

1

.3760

3.128

9.72

,525

.09632

22.54

IQ:

m,

K,:

::

122.0

24.4

turbulent

23

931

E4

138

71

R3

1000

m,= -2.62+

,369

[I

R2

100

c) K, = 1 - R * Skip to step

R,

PI

9. For the Stokes region calculate:

a) c, = .0852(St)05

10

(m, from step

10.

q = C,K,R

R1

9. a) c,:

b) ~; i

.0842

4.79

,977

8b)

flow at the conditions of flow:

10.

K, = .2130 for all values of

,180

4:

+2 K,

[ 100

11. The above flow (q) mky be

conditions (q) as follows:

red&d to a volume measured at standard

q = q p where, p. = density at std.

PO

11.

q :

* NOTE:

cond

.179

,964

5.45

For size x0 and S.S. Float multiply by an addatonal facior K,

K,: = [l-(k)]

(1 -9

Where: R,I 700 for gases

R;-3.55-51.5R+2.37R2 forfiquiis

Anda mungkin juga menyukai

- YOKOGAWA - Low Flow Transmitters With Integral Flow Orifice - TI01C20K00-01EDokumen10 halamanYOKOGAWA - Low Flow Transmitters With Integral Flow Orifice - TI01C20K00-01EChoochart ThongnarkBelum ada peringkat

- Vortex Meters For GasDokumen5 halamanVortex Meters For GasRicardo Zárate GodinezBelum ada peringkat

- Flow in Circular Pipes: ObjectiveDokumen35 halamanFlow in Circular Pipes: ObjectivemamunruetBelum ada peringkat

- Balancing & Flow Control Valves PDFDokumen47 halamanBalancing & Flow Control Valves PDFNoushad P Hamsa100% (1)

- Diff PR Flo MeterDokumen19 halamanDiff PR Flo MeterShoeb ShaikhBelum ada peringkat

- Steady-State Analyses of Fluid Flow Characteristics For AFWS in PWR Using Simplified CFD MethodsDokumen4 halamanSteady-State Analyses of Fluid Flow Characteristics For AFWS in PWR Using Simplified CFD MethodsViswanathan DamodaranBelum ada peringkat

- TB8102 Rupture Disc SizingDokumen9 halamanTB8102 Rupture Disc Sizingbabis1980Belum ada peringkat

- Lockhart&Martinelli ImprovedDokumen12 halamanLockhart&Martinelli Improvedrui_filho_12Belum ada peringkat

- HydraulicsDokumen65 halamanHydraulicsMohsin EhsanBelum ada peringkat

- Compressible FlowDokumen35 halamanCompressible FlowAngelica KartikaBelum ada peringkat

- Pipe Systems DesignDokumen31 halamanPipe Systems DesignAvinash VasudeoBelum ada peringkat

- 03 VacSysCalculationsDokumen24 halaman03 VacSysCalculationssajjad_naghdi241Belum ada peringkat

- Fluid Engineering - Flow in PipesDokumen6 halamanFluid Engineering - Flow in PipesSherif Abdel Hamid FakhryBelum ada peringkat

- Models - Cfd.pipe Elbow PDFDokumen22 halamanModels - Cfd.pipe Elbow PDFacharya_s89Belum ada peringkat

- Balancing Flow Control Valves PDFDokumen47 halamanBalancing Flow Control Valves PDFRami ReddyBelum ada peringkat

- Z G+P V V U Q+W Z G+ P V V U: Basic Concepts of Fluid TransportDokumen6 halamanZ G+P V V U Q+W Z G+ P V V U: Basic Concepts of Fluid TransportBernard BaluyotBelum ada peringkat

- Arts Fluid FlowDokumen142 halamanArts Fluid Flowchem.tahirBelum ada peringkat

- Art's Fluid Flow 1Dokumen64 halamanArt's Fluid Flow 1Jagadeesh UnnamBelum ada peringkat

- Head Loss in Pipe - Lab Report MannualDokumen4 halamanHead Loss in Pipe - Lab Report MannualRampukar SahBelum ada peringkat

- VXD Old SMC 0900766b8094a5b0Dokumen32 halamanVXD Old SMC 0900766b8094a5b0FranzKafkaBelum ada peringkat

- Pressure Loss in PipeDokumen8 halamanPressure Loss in PipesaeidianBelum ada peringkat

- Cav03 OS 4 010Dokumen7 halamanCav03 OS 4 010Emad ElsaidBelum ada peringkat

- Pipe Contraction Pressure LossDokumen8 halamanPipe Contraction Pressure LossblumunchieBelum ada peringkat

- Heat ExchangerDokumen27 halamanHeat ExchangerKashish Mehta75% (4)

- Calculation of Flow Rate From Differential Pressure Devices - Orifice PlatesDokumen26 halamanCalculation of Flow Rate From Differential Pressure Devices - Orifice Platesamirreza_eng3411Belum ada peringkat

- Vortex Flowmeter ManualDokumen31 halamanVortex Flowmeter ManualRoLopBelum ada peringkat

- PCV SizingDokumen8 halamanPCV SizingKhanh PhamBelum ada peringkat

- Quick Choice Of: Temperature ControlsDokumen5 halamanQuick Choice Of: Temperature ControlsFlorian DraguBelum ada peringkat

- Pipe Flow Calculations PDFDokumen12 halamanPipe Flow Calculations PDFharrypop418Belum ada peringkat

- Models - Heat.turbulent Heat ExchangerDokumen18 halamanModels - Heat.turbulent Heat ExchangerMaximiliano FaríaBelum ada peringkat

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDokumen16 halamanTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuBelum ada peringkat

- Losses in PipeDokumen9 halamanLosses in PipeNiroexBelum ada peringkat

- OCW Drilling Hydraulics LectureDokumen59 halamanOCW Drilling Hydraulics Lecturefreelancer2earn100% (1)

- Lab 5: Linear Momentum Experiments PurposeDokumen5 halamanLab 5: Linear Momentum Experiments Purposenil_008Belum ada peringkat

- Choose Cast-Iron, Bronze, or Stainless Steel Construction.: Self-Priming PumpsDokumen12 halamanChoose Cast-Iron, Bronze, or Stainless Steel Construction.: Self-Priming PumpscarlofilippinBelum ada peringkat

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Dokumen3 halamanQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliBelum ada peringkat

- Man-Arian Flow Cad SoftwareDokumen27 halamanMan-Arian Flow Cad Softwaresyahmi1337Belum ada peringkat

- 505 - Lec 01 PDFDokumen33 halaman505 - Lec 01 PDFUdara DissanayakeBelum ada peringkat

- Offshore Pipeline Hydraulic and Mechanical AnalysesDokumen25 halamanOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaBelum ada peringkat

- Aerothermal Performance Measurements and AnalysisDokumen8 halamanAerothermal Performance Measurements and Analysisraul19rsBelum ada peringkat

- Basic Concepts of Fluid TransportDokumen14 halamanBasic Concepts of Fluid TransportBernard BaluyotBelum ada peringkat

- Laminar & Turbulent Flow in PipesDokumen5 halamanLaminar & Turbulent Flow in PipesDhananjay KadamBelum ada peringkat

- Op Tim IzationDokumen8 halamanOp Tim IzationJulia Turpo SuarezBelum ada peringkat

- Major No. 2 - Design Problems For The Acetone Production FacilityDokumen15 halamanMajor No. 2 - Design Problems For The Acetone Production FacilityJimmy Velarde RodriguezBelum ada peringkat

- Lab 5Dokumen9 halamanLab 5Cem UsmangilBelum ada peringkat

- Lab 4-Friction Losses and Minor LossesDokumen7 halamanLab 4-Friction Losses and Minor LossesJJ Sean CruzBelum ada peringkat

- Flow in Circular Pipes: ObjectiveDokumen25 halamanFlow in Circular Pipes: ObjectivePatrickAndradeBelum ada peringkat

- Vortex FlowmeterDokumen16 halamanVortex FlowmeterBiswajit DebnathBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Dari EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- Southern Marine Engineering Desk Reference: Second Edition Volume IDari EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IBelum ada peringkat

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsDari EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsBelum ada peringkat

- Cummins Engine Company, Inc M-9720 6BTA5.9-M2Dokumen2 halamanCummins Engine Company, Inc M-9720 6BTA5.9-M2คุณชายธวัชชัย เจริญสุข100% (1)

- 6BT (180,2500, 2891, MCD, Aug 04, M-09762)Dokumen2 halaman6BT (180,2500, 2891, MCD, Aug 04, M-09762)คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Cummins Mercruiser Diesel Marine Performance Curves 8206 17-Aug-04 5.9 Liter (359 In) 102 MM (4.02 In) 120 MM (4.72 In) 6 220B M-90760 D402013MX02Dokumen2 halamanCummins Mercruiser Diesel Marine Performance Curves 8206 17-Aug-04 5.9 Liter (359 In) 102 MM (4.02 In) 120 MM (4.72 In) 6 220B M-90760 D402013MX02คุณชายธวัชชัย เจริญสุข100% (1)

- HIno Torque SpecDokumen1 halamanHIno Torque Specคุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Cummins Engine Company, Inc M-90196 4BT3.9-MDokumen2 halamanCummins Engine Company, Inc M-90196 4BT3.9-Mคุณชายธวัชชัย เจริญสุข100% (1)

- 4BTA (250,3000,2197, HO, Aug 04, M-90231)Dokumen2 halaman4BTA (250,3000,2197, HO, Aug 04, M-90231)คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- F002 A10 118 PartDokumen2 halamanF002 A10 118 Partคุณชายธวัชชัย เจริญสุขBelum ada peringkat

- F002 A10 118 Product UseDokumen1 halamanF002 A10 118 Product Useคุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Cummins Engine Company, Inc M-90806 270BDokumen2 halamanCummins Engine Company, Inc M-90806 270Bคุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Test ValueDokumen2 halamanTest Valueคุณชายธวัชชัย เจริญสุข100% (2)

- 105833Dokumen2 halaman105833คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Denso 190000-2341Dokumen2 halamanDenso 190000-2341คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Install Notes 1. Install The Game 2. No Cracks Needed.. 3. Have Fun Playing.Dokumen1 halamanInstall Notes 1. Install The Game 2. No Cracks Needed.. 3. Have Fun Playing.คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- 3360Dokumen2 halaman3360คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Denso 196000-6020Dokumen4 halamanDenso 196000-6020คุณชายธวัชชัย เจริญสุข100% (1)

- 0 400 866 208 TestPlanDokumen2 halaman0 400 866 208 TestPlanคุณชายธวัชชัย เจริญสุข100% (2)

- SV 4.20: TV Issue-17: FP A262A902: FV 1.32: RV 1.10: LV 3.00Dokumen1 halamanSV 4.20: TV Issue-17: FP A262A902: FV 1.32: RV 1.10: LV 3.00คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Denso 090000-7632Dokumen1 halamanDenso 090000-7632คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Denso 190000-8920Dokumen2 halamanDenso 190000-8920คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- f2607-#### f2607 20191203 103218Dokumen2 halamanf2607-#### f2607 20191203 103218คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- f2607-#### f2607 20191203 105836Dokumen2 halamanf2607-#### f2607 20191203 105836คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- f2607-#### f2607 20191203 111644Dokumen2 halamanf2607-#### f2607 20191203 111644คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- f2607-#### f2607 20191203 104707Dokumen2 halamanf2607-#### f2607 20191203 104707คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Delphi28236381 20190611 112907Dokumen2 halamanDelphi28236381 20190611 112907คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Chemical Process IndustriesDokumen2 halamanChemical Process Industriessonu mahipalBelum ada peringkat

- Guia de Proveedores de PinturasDokumen28 halamanGuia de Proveedores de PinturasEDGrog100% (1)

- (Dr. Munawir) Environmental and Nutrition PathologyDokumen82 halaman(Dr. Munawir) Environmental and Nutrition Pathologyadidarma58Belum ada peringkat

- Drawback of Plastic Industry Cipet Final Report PDFDokumen32 halamanDrawback of Plastic Industry Cipet Final Report PDFSavi sharmaBelum ada peringkat

- Presentation of Takenate Mar.2017 3Dokumen20 halamanPresentation of Takenate Mar.2017 3huy.dicBelum ada peringkat

- Chapter 16 HWDokumen11 halamanChapter 16 HWsarah_choi_21Belum ada peringkat

- Mass BalanceDokumen6 halamanMass BalanceHaziq AzliBelum ada peringkat

- Effect of Natural Zeolite As Substrate Filler On The Properties of NBREPDM BlendDokumen8 halamanEffect of Natural Zeolite As Substrate Filler On The Properties of NBREPDM BlendhesBelum ada peringkat

- Screening and Isolation of The Soil Bacteria For Ability To Produce AntibioticsDokumen5 halamanScreening and Isolation of The Soil Bacteria For Ability To Produce AntibioticssdBelum ada peringkat

- Zeta-Potential Measurements On Micro Bubbles GeneratedDokumen9 halamanZeta-Potential Measurements On Micro Bubbles Generatedggg123789Belum ada peringkat

- Lipid Digestion and AbsorptionDokumen37 halamanLipid Digestion and AbsorptionIMDCBiochem100% (1)

- Mic180 - Chapter 5 - Carbohydrate - EditedDokumen75 halamanMic180 - Chapter 5 - Carbohydrate - EditedfarBelum ada peringkat

- Additives For Flour Standardisation - Part I: EnzymesDokumen11 halamanAdditives For Flour Standardisation - Part I: EnzymesMilling and Grain magazineBelum ada peringkat

- Non-Chemical Methods For Controlling Diseases in The Home Landscape and GardenDokumen2 halamanNon-Chemical Methods For Controlling Diseases in The Home Landscape and GardenSharad BhutoriaBelum ada peringkat

- Adams RogerDokumen47 halamanAdams Rogerp23cc005Belum ada peringkat

- Critical ConstantsDokumen4 halamanCritical ConstantsDavid0% (1)

- METAL WORKS General CatalogueDokumen695 halamanMETAL WORKS General CatalogueSheila BowenBelum ada peringkat

- Acute Respiratory Distress Syndrome (Ards)Dokumen22 halamanAcute Respiratory Distress Syndrome (Ards)Hani ShafiraBelum ada peringkat

- Alkanes: IB Chemistry Topic 10.2Dokumen20 halamanAlkanes: IB Chemistry Topic 10.2Ravi RanjanBelum ada peringkat

- Optimizing Glycol Dehydration System For Maximum Efficiency A Case Study of A Gas Plant in NigeriaDokumen16 halamanOptimizing Glycol Dehydration System For Maximum Efficiency A Case Study of A Gas Plant in Nigeria1412091090Belum ada peringkat

- MCQ Based Questions Grade 10 - Acids, Bases and SaltsDokumen6 halamanMCQ Based Questions Grade 10 - Acids, Bases and SaltsMahi RajneBelum ada peringkat

- U08 CW03 Acid and Base Properties of Salts Worksheet v2Dokumen2 halamanU08 CW03 Acid and Base Properties of Salts Worksheet v2Muyao ChenBelum ada peringkat

- 7873Dokumen8 halaman7873Faisal AbbasBelum ada peringkat

- PORTFOLIO 6 MEJOS ElaineFaithS. BSMLS1JDokumen4 halamanPORTFOLIO 6 MEJOS ElaineFaithS. BSMLS1JELAINE FAITH MEJOSBelum ada peringkat

- Idoc - Pub - Extraction of Caffeine From Tea Lab ReportDokumen11 halamanIdoc - Pub - Extraction of Caffeine From Tea Lab ReportĐoàn NgọcBelum ada peringkat

- BFR 36-English Version 01-01-12Dokumen16 halamanBFR 36-English Version 01-01-12Rafael García BarasoainBelum ada peringkat

- ASTM Biodiesel Specs - Nov08Dokumen1 halamanASTM Biodiesel Specs - Nov08Alejandra RojasBelum ada peringkat

- Preservation of Fruits by WaxingDokumen10 halamanPreservation of Fruits by WaxingKrishna Kotturi100% (6)

- Report Petrochemical Sec BenchmarkingDokumen174 halamanReport Petrochemical Sec BenchmarkingSachin Chavan100% (2)

- Biochem Exam Practice QuestionsDokumen12 halamanBiochem Exam Practice Questionsihack_101Belum ada peringkat