Wopq Asme Section Ix

Diunggah oleh

kanchanabalajiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Wopq Asme Section Ix

Diunggah oleh

kanchanabalajiHak Cipta:

Format Tersedia

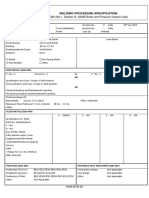

ASME Code Section IX - QW-360

Doc. No.:

AUTOMATIC AND MACHINE - WELDING

Automaten- und Maschinen - Schweien

Rev.

Date

24.01.2013

WELDINGOPERATOR - PERFORMANCE - QUALIFICATION

WOPQ_B1

Maschinen - Schweier - Zeugnis

Info only

Info only

Info only

Info only

Info only

MUSTERMANN

Klaus

B1

Name

First Name(s)

Stamp No.

pipe or plate

base material(s)

P-No to P-No

welding machine

filler metal or electrode classification

Welding Variables

QW

361.1 (a)

361.1 (b)

WPS 24

BASIC INFORMATION

Pipe

SA-312 316

T = 5 [mm]

8

to

8

Master-3000

SFA 5.18

Actual Values from Coupon

or Production Weld

AUTOMATIC - WELDING

automatic

Laser Beam Welding 522

to SA-312 316

(electron beam - EBW or laser beam welding - LBW)

yes

no

without

361.1 (d)

type of laser for LBW (CO2 to YAG)

yes - CO2

no

CO2 laser only

361.1 (e)

continuous drive or inertia welding

yes

no

without

361.1 (f)

vacuum to out of vacuum (EBW)

T = 5 [mm]

automatic

Laser Beam Welding 522

yes

no

without

MACHINE - WELDING

GTAW

361.2 (a)

process(s)

361.2 (b)

direct visual control remote control

direct

remote

direct

361.2 (c)

automatic volt control (GTAW)

yes

no

with / without

361.2 (d)

automatic joint tracking

no

with / without

361.2 (e)

welding position

361.2 (f)

consumable inserts

yes

no

with / without

361.2 (g)

backing

yes

no

with / without

361.2 (h)

single pass multiple pass

single

multiple

single / multiple

yes

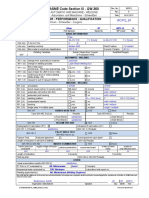

QW-161

Type QW-462.3 (a) (b)

x (Face Bend)

x (Root Bend)

QW-191

Radiographic Examination (RT)

Fracture Test

fractured specimen

None

Type QW-462.2

x (Side Bend)

x (Side Bend)

YES

Results:

None

QW-184 or QW-362

MACRO EXAMINATION

regular shape of fusion

z

QW-191.2.3 Results:

YES

None

bend specimen upon itself

Length of inclusion or percent of defects:

fusion zone size

consistent

OD 73,0 [mm]

Ultrasonic Examination (UT)

satisfactory

FILLET WELD TEST

QW-462.4 (b) or (c)

QW-181.2

YES

Results:

satisfactory

satisfactory

VOLUMETRIC NDE

QW-191.1.2 Results:

GTAW

OD = 100,0 [mm]

GUIDED BEND TEST

Rev.

Weld Position

1G rotated

Current / Polarity

AC (-)

Qualified Ranges

361.1 (c)

1G

WPS used

change from automatic to machine

change in welding process

filler metal used

(friction welding - FW)

WOPQ

uniform penetration

QW-182 Results:

YES

sound weld metal

None

cracks in weld

metal

cracks in

heat-affected zone

yes

yes

Length of indication:

Fillet leg size:

yes

yes

no

no

Concavity:

Convexity:

QW-184 or QW-362 Results:

OTHER

Visual examination results (QW-302.4):

satisfactory

Level

RT Film or UT evaluated by:

Mr. Mustermann

Company:

Mechanical tests conducted by:

TV Thringen

Laboratory test report no.:

/var/www/apps/conversion/tmp/scratch_4/321351385.docx

www.cis-inspector.com

Welding supervised by:

Mr. Mustermann (Welding Engineer)

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in according with the requirements of Section IX ASME Boiler and

Pressure Vessel Code.

Mustermann GmbH

Organization / Manufacturer

20

Signature

Day

06

2013

Month

Year

Anda mungkin juga menyukai

- PQR 014 (Qualified Sa 106 GR BDokumen5 halamanPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDokumen1 halamanAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityBelum ada peringkat

- WPS-PQR (Er309l Mo)Dokumen4 halamanWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS Resrvoire Sous Pression Smaw SawDokumen6 halamanWPS Resrvoire Sous Pression Smaw SawDanem HalasBelum ada peringkat

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDokumen4 halamanWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidBelum ada peringkat

- LBW WOPQ REV. 2010a Interactive FormDokumen1 halamanLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPS Sitelca S002Dokumen2 halamanWPS Sitelca S002Jose Antonio GomezBelum ada peringkat

- Pwps Jo Wps Asme 016 Rev.001Dokumen2 halamanPwps Jo Wps Asme 016 Rev.001Bagandi ManurungBelum ada peringkat

- Welding Procedure Qualification Record: Shipyard LogoDokumen4 halamanWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- STT Pipe Welding Reduces Spatter & SmokeDokumen3 halamanSTT Pipe Welding Reduces Spatter & SmokeahmedBelum ada peringkat

- Proposed WPSDokumen2 halamanProposed WPSChisom Ikengwu100% (2)

- Wps Format Asme Sec - IxDokumen2 halamanWps Format Asme Sec - IxDeepu ChandranBelum ada peringkat

- Intro To Basic UTDokumen41 halamanIntro To Basic UTgirish310100% (1)

- Asme PQR DemoDokumen3 halamanAsme PQR DemoMuthusamy AyyanapillaiBelum ada peringkat

- Fermi Lab Orbital Welding ProcedureDokumen2 halamanFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDokumen1 halaman193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- CSM-QR-02-2, Medical Gas BPS TablesDokumen8 halamanCSM-QR-02-2, Medical Gas BPS TablesaadmaadmBelum ada peringkat

- 004 Gtaw P5aDokumen16 halaman004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDokumen4 halaman163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen8 halamanQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanBelum ada peringkat

- QW-484A (WPQ) GTAW 4MM FilletDokumen2 halamanQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- SMAW DuniDokumen4 halamanSMAW DuniMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- WOPQ Form English1Dokumen2 halamanWOPQ Form English1oaperuchenaBelum ada peringkat

- PQR TipsDokumen4 halamanPQR TipsWaqas WaqasBelum ada peringkat

- Gmaw Complete Aws d1.6Dokumen1 halamanGmaw Complete Aws d1.6Hamza Nouman100% (1)

- Gtaw 106Dokumen2 halamanGtaw 106ganeshkumarg_1Belum ada peringkat

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDokumen11 halamanEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaBelum ada peringkat

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- TopCorbelco - WPS FCAW Sa 516 GR 70Dokumen6 halamanTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisBelum ada peringkat

- Fillet Weid Break and Macroetch Test PlateDokumen1 halamanFillet Weid Break and Macroetch Test PlatewijiestBelum ada peringkat

- Welding Procedure SpecificationDokumen3 halamanWelding Procedure SpecificationAhmed saber100% (2)

- PT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTDokumen4 halamanPT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- AWS Classification System SAWDokumen5 halamanAWS Classification System SAWperungguBelum ada peringkat

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- WPQ Template (Asme Ix) No LogoDokumen4 halamanWPQ Template (Asme Ix) No LogorcpretoriusBelum ada peringkat

- Wps 1010 IfrDokumen28 halamanWps 1010 IfrSyed Mahmud Habibur RahmanBelum ada peringkat

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDokumen2 halamanTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- Wps Aws d1.1 NEWDokumen2 halamanWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Dokumen1 halamanWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS Api 1104Dokumen3 halamanWPS Api 1104miguelBelum ada peringkat

- Wps 15614 TemplateDokumen2 halamanWps 15614 Template0502raviBelum ada peringkat

- PQR 01 PDFDokumen2 halamanPQR 01 PDFVijay BhaleraoBelum ada peringkat

- WPS - PQR (Sa516 GR.70)Dokumen4 halamanWPS - PQR (Sa516 GR.70)miltonangulomorrisBelum ada peringkat

- WPS for FCAW Welding of SteelDokumen2 halamanWPS for FCAW Welding of SteelHamid MansouriBelum ada peringkat

- WELDER QUALIFICATION REPORTDokumen2 halamanWELDER QUALIFICATION REPORTAkash Singh TomarBelum ada peringkat

- BPV IX-16-3 QW-283 - ButteringDokumen1 halamanBPV IX-16-3 QW-283 - ButteringyutweldingBelum ada peringkat

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Dokumen2 halamanWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhBelum ada peringkat

- All Position Stainless Steel Welding ProcedureDokumen6 halamanAll Position Stainless Steel Welding ProcedureJaime PatrónBelum ada peringkat

- WPSDokumen2 halamanWPSAlam MD Sazid100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokumen2 halamanASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaBelum ada peringkat

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDokumen2 halamanREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZBelum ada peringkat

- WPS API1104 A516 GR 70Dokumen1 halamanWPS API1104 A516 GR 70Erick HoganBelum ada peringkat

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDokumen3 halamanWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniBelum ada peringkat

- Hardox 450Dokumen3 halamanHardox 450Marko RisticBelum ada peringkat

- WPS SampleDokumen182 halamanWPS Sampleaymenfr23Belum ada peringkat

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDokumen2 halamanWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanBelum ada peringkat

- Weldspec ASME PQRDokumen2 halamanWeldspec ASME PQRSunil KumarBelum ada peringkat

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDokumen1 halamanWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0Belum ada peringkat

- WOPQ - ASME Sec - IXDokumen1 halamanWOPQ - ASME Sec - IXEsley H.Belum ada peringkat

- WPQ WELDER PERFORMANCE QUALIFICATIONDokumen2 halamanWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasBelum ada peringkat

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Dokumen1 halamanForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojBelum ada peringkat

- FE Mec CBT Specs PDFDokumen4 halamanFE Mec CBT Specs PDFVictor VerdanBelum ada peringkat

- The Institution of Engineers (India) : IntpeDokumen8 halamanThe Institution of Engineers (India) : IntpekanchanabalajiBelum ada peringkat

- Api Purchasing Guide 2015-08-29 PDFDokumen20 halamanApi Purchasing Guide 2015-08-29 PDFQaiser HafeezBelum ada peringkat

- Pipe 1.25 SCH - XxsDokumen5 halamanPipe 1.25 SCH - XxskanchanabalajiBelum ada peringkat

- PE Mech Machine Apr 2017Dokumen2 halamanPE Mech Machine Apr 2017flounder33Belum ada peringkat

- Seamless Api Pipes PDFDokumen14 halamanSeamless Api Pipes PDFsreeBelum ada peringkat

- TTD - FAQs dt.4-6-2016Dokumen6 halamanTTD - FAQs dt.4-6-2016Srinivas KrishnaBelum ada peringkat

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDokumen1 halamanNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiBelum ada peringkat

- Reference Data - : Metric Conversion ChartDokumen29 halamanReference Data - : Metric Conversion ChartkanchanabalajiBelum ada peringkat

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDokumen1 halamanNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiBelum ada peringkat

- Design For Horizontal Atomization 2Dokumen1 halamanDesign For Horizontal Atomization 2kanchanabalajiBelum ada peringkat

- Off Shore TankDokumen1 halamanOff Shore TankkanchanabalajiBelum ada peringkat

- Guide To Professional Registration With The Engineering CouncilDokumen2 halamanGuide To Professional Registration With The Engineering CouncilRonald GeorgeBelum ada peringkat

- Color Green RecognitionDokumen1 halamanColor Green RecognitionkanchanabalajiBelum ada peringkat

- ASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEDokumen11 halamanASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEKarthik AnandanBelum ada peringkat

- Vehicle DrawingDokumen4 halamanVehicle DrawingkanchanabalajiBelum ada peringkat

- DIPRA DesignofDuctileIronPipeOnSupportsDokumen10 halamanDIPRA DesignofDuctileIronPipeOnSupportskanchanabalajiBelum ada peringkat

- FS2 Learning Journey: Expressive Art & DesignDokumen2 halamanFS2 Learning Journey: Expressive Art & DesignkanchanabalajiBelum ada peringkat

- Early Writing For Little Hands PDFDokumen63 halamanEarly Writing For Little Hands PDFNHIMMALAY100% (1)

- Gems Winchester - Karama Boys PDFDokumen1 halamanGems Winchester - Karama Boys PDFkanchanabalajiBelum ada peringkat

- DB 200 SLDokumen2 halamanDB 200 SLkanchanabalajiBelum ada peringkat

- Ns Edp Mut Hoot Form 1095101137Dokumen12 halamanNs Edp Mut Hoot Form 1095101137kanchanabalajiBelum ada peringkat

- Wireless Broadband Contract SME Izwi ConnectixDokumen6 halamanWireless Broadband Contract SME Izwi ConnectixkanchanabalajiBelum ada peringkat

- Desalination Plant - Resilience Modelling - CSDokumen2 halamanDesalination Plant - Resilience Modelling - CSkanchanabalajiBelum ada peringkat

- Fees StructureDokumen2 halamanFees StructurekanchanabalajiBelum ada peringkat

- (13630) Literacy - Writing Captions 04052016Dokumen1 halaman(13630) Literacy - Writing Captions 04052016kanchanabalajiBelum ada peringkat

- (13342) Literacy - Captions 28042016Dokumen1 halaman(13342) Literacy - Captions 28042016kanchanabalajiBelum ada peringkat

- Catalogue KingTankDokumen5 halamanCatalogue KingTankkanchanabalajiBelum ada peringkat

- Questions for pictures using 'Is' or 'Can' with Yes/No answersDokumen1 halamanQuestions for pictures using 'Is' or 'Can' with Yes/No answerskanchanabalajiBelum ada peringkat

- IdealGasLawSEDokumen6 halamanIdealGasLawSENada DawoodBelum ada peringkat

- Lec 1 Design of RC Structures For Lateral LoadsDokumen49 halamanLec 1 Design of RC Structures For Lateral Loadsamin alzuraiki100% (1)

- Phy F315 1494Dokumen4 halamanPhy F315 1494pankazspamBelum ada peringkat

- Kinetics of Rectilinear MotionDokumen12 halamanKinetics of Rectilinear MotionAyon SenguptaBelum ada peringkat

- Mensuration R: Pure MathematicsDokumen8 halamanMensuration R: Pure Mathematicsquang hưngBelum ada peringkat

- MechanicsDokumen47 halamanMechanicshitesh81Belum ada peringkat

- PHYSICS 1 Measurements and VectorsDokumen21 halamanPHYSICS 1 Measurements and VectorsIah VergaraBelum ada peringkat

- Formation of ExcitonsDokumen4 halamanFormation of ExcitonsPriyatham KattaBelum ada peringkat

- Nuclear Fission and Fusion ReportDokumen54 halamanNuclear Fission and Fusion ReportHarsh BislaBelum ada peringkat

- Hibbeler, Mechanics of Materials-Deflections 1Dokumen57 halamanHibbeler, Mechanics of Materials-Deflections 1poom2007Belum ada peringkat

- Cosmology Exercises BackgroundDokumen2 halamanCosmology Exercises BackgroundAndra GabrielaBelum ada peringkat

- 2 Drilling PipesDokumen82 halaman2 Drilling Pipesdf_campos3353Belum ada peringkat

- Synthesis of Spinel MgFe2O4 FerriteDokumen9 halamanSynthesis of Spinel MgFe2O4 FerritewillaimBelum ada peringkat

- Physics Paper 1 TZ1 HLDokumen22 halamanPhysics Paper 1 TZ1 HLBrian KwonBelum ada peringkat

- Physics Project-2017-18: Topic: To Determine The Wavelength of Sodium LightDokumen19 halamanPhysics Project-2017-18: Topic: To Determine The Wavelength of Sodium Lightvibhav sharmaBelum ada peringkat

- Shooting Method 6 PDFDokumen11 halamanShooting Method 6 PDFمرتضى عباسBelum ada peringkat

- Sight Distance (Highway Engineering)Dokumen8 halamanSight Distance (Highway Engineering)MAND33P0% (1)

- Slurry PropertiesDokumen5 halamanSlurry PropertiesJuan Pablo ApazaBelum ada peringkat

- Parts of A SubstationDokumen110 halamanParts of A SubstationBrijendra SinghBelum ada peringkat

- ME106 - Casting (2015)Dokumen64 halamanME106 - Casting (2015)just randomBelum ada peringkat

- Describing Magnetic FieldsDokumen19 halamanDescribing Magnetic FieldsFabio LayneBelum ada peringkat

- HV Surge ArresterDokumen15 halamanHV Surge ArrestertwinvbooksBelum ada peringkat

- Part 1Dokumen5 halamanPart 1Snr Berel ShepherdBelum ada peringkat

- A Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013Dokumen146 halamanA Quantum Model About Coherence To Understand Non Ionizing Radiation, Geesink, June 2013marcelogiovaneBelum ada peringkat

- Washburn EquationDokumen2 halamanWashburn EquationZang NguyenBelum ada peringkat

- EMFTDokumen59 halamanEMFTAnshul Bhutani0% (1)

- Neet 2022 GanganagarDokumen30 halamanNeet 2022 GanganagarSarthakBelum ada peringkat

- Short Course Anode Cu EW (Siegmund)Dokumen115 halamanShort Course Anode Cu EW (Siegmund)MaikPortnoy100% (1)

- Hydrostatic ForcesDokumen27 halamanHydrostatic ForcesSumit SahrawatBelum ada peringkat