Ewsletter O Pril: Eports N This Ssue

Diunggah oleh

Shijo AntonyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ewsletter O Pril: Eports N This Ssue

Diunggah oleh

Shijo AntonyHak Cipta:

Format Tersedia

For an introduction to CROSS see www.structural-safety.org. Email: structures@structural-safety.

org

NEWSLETTER NO 42, APRIL 2016

REPORTS IN THIS ISSUE:

INTRODUCTION

577 BRIDGE WING WALL COLLAPSE ............... 1

530 INCENTIVISING

SAFE BEHAVIOUR THROUGH

STANDARD AGENDAS ....................................

566 SUDDEN HOLE IN PILING MAT ................. 3

533 PV PANEL INSTALLATION ....................... 4

176 LIFTING LARGE DOUBLE GLAZING UNIT .... 4

532 STORED GLAZING PANELS ..................... 5

562 FALLING LATH AND PLASTER CEILING ...... 5

387 IMPORTANCE OF BEARINGS .................... 5

CROSS has launched an additional category of reports to capture

damage to buildings and related infrastructure from the effects of

weather. There appear to be a greater number of storms and

extreme weather events and the question is whether our buildings

are being affected more severely now than was the case

previously. Accordingly, the Department of Communities and Local

Government has sponsored a programme to gather evidence

which could help determine what changes might be required to

future building regulations.

Reports are being requested from all local authorities in England

and, with support from the relevant authorities, also in Scotland,

Wales and Northern Ireland. Reports will be welcome too from

anyone else who observes damage from weather effects. The aim

is to build up a record of evidence, and events of interest include:

extreme rainfall

high winds

flooding (including tidal and surge effects)

freezing temperatures

ground movement (earthquakes, sink holes, subsidence etc)

high temperatures

moisture

snow/sleet/hail/ice

Reports will be submitted through the web site and the usual

confidentiality will apply to reporters but locations will be recorded

so that these can be linked to maps and to the severity of weather

at the time. Categories of damage will be allocated so that the data

can be analysed.

Reports sent to CROSS are de-identified, categorised,

and sometimes edited for clarification, before being

reviewed by the CROSS panel of experts. The panel

makes comments that are intended to assist those

who may be faced with similar issues. In the

Newsletters the reports are shown in black text and

the comments are shown below these in green italics.

Reports and comments are also given on the web site

database.

The programme has started and reports will be welcome. As with

all CROSS material there will be lessons that can be learned by

designers, contractors, regulators, building control officers and

academics. Results will help to improve our knowledge and

participation will help others.

The success of the CROSS programme depends on receiving

reports, and individuals and firms are encouraged to

participate by sending concerns in confidence to StructuralSafety.

CROSS Contact

Director:

Alastair Soane

Email:

structures@structural-safety.org

CROSS Website:

www.structural-safety.org

577 BRIDGE WING WALL COLLAPSE

The masonry wing wall of a bridge fell as a single section and

came to rest against an adjacent pile. Staff had been in the

immediate area prior to the collapse but left following some

observed movement in the previous 30 minutes. The wall

collapsed because adjacent excavations had undermined the

supporting ground.

PAGE 2

What should be reported?

concerns which may require industry

or regulatory action

lessons learned which will help others

near misses and near hits

trends in failure

Benefits

unique source of information

better quality of design and

construction

possible reductions in deaths and

injuries

lower costs to the industry

improved reliability

Supporters

Association for Consultancy and

Engineering

Bridge Owners Forum

British Parking Association

Communities and Local Government

Construction Industry Council

Department of the Environment

DRD Roads Services in Northern

Ireland

Health and Safety Executive

Highways England

Institution of Civil Engineers

Institution of Structural Engineers

Local Authority Building Control

Network Rail

Scottish Building Standards Agency

Temporary Works Forum

UK Bridges Board

NEWS

ICE Health and Safety 2016

Culture, Leadership, Ownership

13 May 2016 - London, United Kingdom

Register now

Structural-Safety Partner ICE in the 2016

conference

Avoiding Design Errors Workshop

Lessons from forensics and their

application to engineering design by Sean

Brady

24 May 2016 IStructE HQ London,

United Kingdom Register now

CROSS NEWSLETTER

Although the roles and

responsibilities placed on

individuals on site was clear,

there was a lack of direction

on who held ultimate

responsibility for identifying

the need for temporary

works. This action relied on

the recognition of the

Displaced wall resting on pile

requirement by the site

team, the Temporary Works Coordinator and/or the designers. A requirement

for temporary works was identified by the designers but this became diluted

and was not picked up on site. A management issue was that some

responsibilities, which might have been better if handled separately, were

allocated to one individual. Ultimately it was decided that the event was a

caused by a lapse due to lack of foresight.

It was recommended that:

Designers review their risk registers and highlight temporary works

issues.

No one individual should be expected to prepare, review, and authorise

either works control documents or design certificates. Reviews are to

be independent.

Formal documented handover meetings are undertaken between the

design organisation and the project team.

Prior to the commencement of major work or high risk activities a joint

risk review is carried out by designers, contractors, and others as

appropriate at a suitably high level across all disciplines and

organisations.

Comments

When working on congested sites adjacent to existing infrastructure, the risk

of the works affecting the stability of old structures, with low confidence on as

-built condition, is high. Designers should be alert to this and draw attention to

the risks, with a default position in favour of temporary works to remove or

reduce uncertainty. Contractors should be aware and devise appropriate

methods that recognise the uncertainties and associated risks.

Communication between contractor and designer is essential, preferably at

many levels to raise confidence that risks are sufficiently understood.

However, the sole responsibility for temporary works lies with the Contractor.

A capable contractor will have appointed a Temporary Works Co-ordinator

(TWC) who will assess the need for temporary works. BS5975:2008+A1:2011

Code of Practice for Temporary Works sets out the procedures. Reference

should also be made to Regulations 19 and 22 of CDM 2015, which imposes

obligations on contractors in relation to stability of structures and excavation.

On site it is the TWC who has ultimate authority and control, having regard to

advice from the permanent works designers and the temporary works

designers. The Contractor can only assess what is reasonably evident. It is

for the permanent and temporary works designers to ensure that significant

residual risks are communicated to the Contractor via the pre-construction

information pack.

The suggestion that, prior to commencement of high-risk activities, there

should be a joint review is a sensible move and to be welcomed. This should

be chaired by an individual with appropriate technical, contractual and

statutory knowledge of the situation and type of works involved. To

supplement the paper work, it is prudent for those with experience to observe

the works during execution just to be sure nothing has been overlooked. It is

often much easier to see danger in real life than it is by looking at drawings.

PAGE 3

CROSS NEWSLETTER

530 INCENTIVISING SAFE BEHAVIOUR THROUGH STANDARD

AGENDAS

A reporter was investigating a near miss involving concrete construction in which pre-cast and insitu concrete were used in combination (see report 529 Risks from off-site manufacture and hybrid

construction in Newsletter No 41). This type of construction offers efficiencies and, as in this

instance, can reduce the number of man-hours worked at height. It does however bring its own risks,

and these need to be understood. The design had developed from all in-situ construction to a hybrid

pre-cast/in-situ over a series of design meetings. It was the combination of pre-cast and in-situ

construction that led to the near disaster in which multiple fatalities were a real possibility. During the

investigation, the reporter was presented with a document developed from the 2007 CDM

Regulations. This was a CDM Coordinators standard agenda for a design review meeting. One

heading was Significant Risks Identified during Design which then elicited two questions: Q1: Since

the last meeting have any significant hazards been identified that are likely to affect the works? (Yes/

No). Q 2: If yes, please describe and confirm they have been added to the Risk register. Space was

then given to describe the new significant hazards. There was however no Q3 which might have

been. If no how do you justify that no new significant hazard has been introduced? The absence of

this question allowed for a passive negative. Such an approach is complacent. There are also

behavioural implications: without Q3 the CDM-C and the design team has a much simpler life of it

than if their answer to Q1 is Yes. Secondly, if a significant new hazard had been introduced, surely

this would be seen as a sign of failure, as design work should eliminate hazards? Third, the design

team was innovating and it was working outside its area of experience; with no active prompt to seek

out hazards, and the requirement to commit this to record, why would they go seek them out? Whilst

the role of the CDM-C is now behind us, the duties to find hazards are not. Under CDM 2015,

Principal Designers are asked to ensure that potential hazards are sought out diligently, and the

industry is asked to apply a standard of active negative as a part of the process to assure that this is

done.

Comments

Report 529 Risks from off-site manufacture and hybrid construction in Newsletter No 41 contains

comments from CROSS on the issues of divided responsibilities and emphasises the fact that

procedures on their own are not enough to provide safety. They are only a part of the process which

demands clear thinking about what might and could go wrong, and the allocation of duties and

responsibilities.

The present report raises some observations on the standard agenda that is quoted.

The heading Significant Risks Identified during Design should really have been Significant

Residual Risks arising from the Design i.e. those where it was not possible to eliminate or

significantly reduce a risk, and on which others would welcome information.

The suggested Q2 should more correctly have been What new Hazards have been identified

which have given rise to significant residual risk.

Q3 as suggested may not be necessary. The emphasis should be on whether the Designer

has implemented an appropriate risk management process. If the Designer has, then this

would have identified any further Hazard.

The above is now thought by some to be complicated by the fact that in CDM2015 HSE has removed

Hazards from the process, concentrating on risk alone. Innovation always requires care, although it

is not to be discouraged needlessly as it can be a driver for safety.

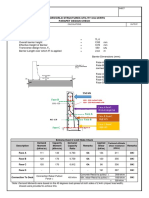

566 SUDDEN HOLE IN PILING MAT

Hole shown to the right of the wall

This concerns a near miss on a site where a piling wall was

being constructed. The reporter says that whilst digging a

trench a 450mm diameter hole appeared in the pile mat about

0.5m from the guide wall. As the grab was being lowered into

the 55m deep trench, bentonite from the wall panel gushed out

from the hole. This was found to be 1.2m deep and went under

the guide wall and into the panel trench. Steel plates were

introduced into the front of the guide wall (piling platform side)

and the opening filled with concrete. The reason for the hole

PAGE 4

CROSS NEWSLETTER

appearing is not known although one possibility is that the bentonite wash from the grab being

continually withdrawn created a vacuum. This pulled in loose granular material from beneath the

guide wall thus causing a cavity which extended into the piling platform. The integrity of the pile mat

was then checked to ensure that work could safely continue. Had there been personnel in the vicinity

of the hole when it appeared the consequences could have been serious.

Comments

Excavations always carry some risk partially because of unknown or unidentified conditions below

the surface. The lesson to be learned from this is that there may be circumstances when holes may

suddenly appear and personnel need to be aware and on the lookout for warning signs.

533 PV PANEL INSTALLATION

A reporter's firm used to carry out design work for installers of PV panels, many on domestic roofs.

Unfortunately, because the market was buoyant, many 'engineers' entered the market and drove the

prices for assessments down by undertaking far less rigorous analysis, and suggesting that far fewer

fixings were adequate. Both the lower cost analysis and cheaper installation were just too attractive a

proposition for the reporters client base and they switched suppliers, despite efforts to advise them

that the short term gain could leave the installations in a dangerous condition. Because of this the

reporter's firm could not do the job properly within the current rates and left the market. The reporter

agrees that the comments in Newsletter 40 on Reports 519 PV panels blown off roof and 528 PV

Panels on Domestic Roof are entirely accurate and believes the issues stem from the use of design

packages. These check that the rails will not be overstressed but, he says, may not properly account

for the fixings and the roof structure itself. Even if the fixings are checked, most of the inspections

that are carried out do not take account of the effect on the roof!

Comments

This emphasises the need for improved regulation and control in relation to PV panels and SCOSS is

undertaking work to publish guidance. In the meantime it would be expected that any member of a

professional institution would resist requests to undertake an incomplete design. There are many

incidents of items falling off buildings or being blown off building and its clear from this and other

reports that there are uncertainties in the overall fixing capability both short and long term. Safety

requires robust solutions rather than refined analysis based on spurious assumptions. The Scottish

Government published Low carbon equipment and building regulations; A guide to safe and

sustainable construction Photovoltaics in 2012 which contains advice on installation.

176 LIFTING LARGE DOUBLE GLAZING UNIT

Inadequate instructions were provided by a double glazing pane supplier, who was also the designer,

on how to lift and move their product, supplied on a flatbed truck, off the truck and onto the works.

This was a large sheet measuring 3m x 2m with a weight of about 270kg

and initial attempts were made to lift it with a 6 suction lifter 500mm x

750mm in size acting on a small central area of the panel. However, the

complex operation had to be abandoned due to excessive bow and likely

failure in the top of the sheet (as its central area deflected away from the

lower sheet increasing the gap between the two sheets forming the unit).

After half a day during which the truck partially blocked the road, a much

larger 14 suction assembly (as shown in the photo) was obtained and

used to lift the unit from a flat position, turn it through 90 degrees, and

Lifting mechanism

then lift it into position. A phone call to the supplier during the aborted lift

provided no information and in a later call they were advised to provide adequate guidance on the

suction area needed to lift these large panels.

Comments

The designer has the responsibility to consider erection issues from a safety perspective. The

construction process always requires items to be delivered to site then lifted into position. In all cases

there should be clear instructions on what to lift and how to lift the item. This should include

PAGE 5

CROSS NEWSLETTER

information on weight, centre of gravity, and a check that the item is strong and stable enough under

self weight (perhaps with wind) when supported at designated lifting points. The case also illustrates

how lack of due consideration leads to additional cost and delay.

532 STORED GLAZING PANELS

A reporter has been undertaking facade inspections for insurers

across many buildings in the UK and the same issue keeps

appearing on every site; glazing is not individually tied back to

storage frames or to a secure place when being stored. Some of

the panels seen have been 3m by 5m. When a panel is moved

from temporary storage to be installed, a suction force can be

induced onto the panel behind, which could cause the panels to

fall onto workers. This is not something that the managers on

site take seriously as the storage of the panels appears to be

done in a safe way. However, there are hidden dangers.

Stacked glazing panels

Comments

The provision of safe storage is the responsibility of the relevant sub-contractor and the Principal

Contractor. A simple lack of care can lead to devastating consequences which have included death

from toppling panels. Heavy glazing units, mirrors, and cement based sheets that have toppled have

led to fatalities.

562 FALLING LATH AND PLASTER CEILING

A 100 year old lath and plaster ceiling in a shop unit collapsed in part, injuring the shop keeper.

There were signs of distress (cracking) shortly before collapse. Upon inspection, says the reporter, it

appeared that the 35-40mm thick plaster had become de-bonded from the laths. At the time some

'soft' demolition was being carried out on the floors above. This included removal of heavy computer

cabinets and it is contended that vibrations contributed to the collapse.

Comments

Old plasterwork ceilings represent a hazard and collapses are not uncommon. The worst known case

of this occurred at a London theatre (see London Apollo Theatre ceiling collapse) when 70 persons

were injured. All structures degrade with time and ceilings are a cause of particular concern as a)

they can be heavy and fall from height and b) various reports to CROSS suggest cascade type global

collapses can occur from a minor initiating event. Guidance on the subject is being considered by

SCOSS.

387 IMPORTANCE OF BEARINGS

Bearings are an important component of the superstructure. A reporter says that they are often

underestimated in their long term characteristics and behaviour. This includes strength, space for

inspection, types of connection and anchorages, and ease of replacement. It is vitally important to

have regular inspections of bearings and seatings with maintenance as required and the facility to

replace faulty components. The reporter wonders whether any systematic study on the overall issues

of bearing assembly and associated requirements has been done.

Comments

The reporter is correct that bearings are important components of bridges and buildings and they

may well be neglected. It is important that designers leave sufficient room around bearings for

inspection and replacement and that maintenance regimes specify how often inspection should take

place. Seized bearings can result in unknown loads being generated and affecting serviceability and

ultimate performance. Failure of the bearings under the Thelwall viaduct on the M62 in 2004 resulted

in reported replacement costs of 52 million. There have been other cases where is has been

PAGE 6

CROSS NEWSLETTER

necessary to partially dismantle a structure to maintain or replace bearings. Statements such as

designed for life or maintenance free have to treated with considerable caution.

A useful reference in this regard is Safe access for maintenance and repair Guidance for designers,

second edition 2009, published by CIRIA.

Whilst CROSS and Structural-Safety has taken every care in compiling this Newsletter, it does not

constitute commercial or professional advice. Readers should seek appropriate professional advice

before acting (or not acting) in reliance on any information contained in or accessed through this

Newsletter. So far as permissible by law, neither CROSS nor Structural-Safety will accept any

liability to any person relating to the use of any such information.

Scan the QR code on the right for access to Structural Safety

HOW TO REPORT

DATES FOR PUBLICATION OF CROSS NEWSLETTERS

Please visit the website www.structuralsafety.org for more information.

Issue No 43

July 2016

Issue No 44

October 2016

If you want to submit a report by post

send an email to the address below

asking for instructions.

Issue No 45

January 2017

Comments either on the scheme, or

non-confidential reports, can be sent

to structures@structural-safety.org

Issue No 46

April 2017

When reading this Newsletter online

click here to go straight to the reporting page.

Anda mungkin juga menyukai

- ACR Black Book Rev. 3 - Guidance Note For Competence & General Fitness Requirements To Work On RoofsDokumen9 halamanACR Black Book Rev. 3 - Guidance Note For Competence & General Fitness Requirements To Work On RoofsjesoneliteBelum ada peringkat

- SP04 2008 Update On Tunnelling CoP 2Dokumen6 halamanSP04 2008 Update On Tunnelling CoP 2Rajat DeshmukhBelum ada peringkat

- The Race For More OilDokumen10 halamanThe Race For More Oilk1m1mak1Belum ada peringkat

- Ita Imia 2023 BDDokumen28 halamanIta Imia 2023 BDKishor YenepalliBelum ada peringkat

- N N 48, October 2017 I: Ewsletter O NtroductionDokumen6 halamanN N 48, October 2017 I: Ewsletter O NtroductionShamaBelum ada peringkat

- Chair Safety in Design Tool 0976Dokumen104 halamanChair Safety in Design Tool 0976jeffconnorBelum ada peringkat

- Chair Safety in Design ToolDokumen104 halamanChair Safety in Design ToolS BhoopalBelum ada peringkat

- Liquidated and Ascertained DamagesDokumen12 halamanLiquidated and Ascertained DamagesHaz DagenBelum ada peringkat

- EP62 A CODE OF PRACTICE FOR RISK MANAGEMENT OF TUNNEL WORKS 3rd Edition Feb 2023Dokumen28 halamanEP62 A CODE OF PRACTICE FOR RISK MANAGEMENT OF TUNNEL WORKS 3rd Edition Feb 2023Tiago ConeglianBelum ada peringkat

- Dissertation On CDM RegulationsDokumen4 halamanDissertation On CDM RegulationsWhereToBuyPapersCanada100% (1)

- Contractorsrisk Paras 0003 File PDFDokumen57 halamanContractorsrisk Paras 0003 File PDFMauro MLRBelum ada peringkat

- Collapse of The NATM Tunnels at Heathrow AirportDokumen3 halamanCollapse of The NATM Tunnels at Heathrow AirportOana Mihaela BanuBelum ada peringkat

- Design Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsDokumen4 halamanDesign Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsKhalid Abdel Naser Abdel RahimBelum ada peringkat

- Feasibility Study ReportDokumen13 halamanFeasibility Study Reportwaseem_pakBelum ada peringkat

- Project Finance For Offshore Wind A Practitioner's View: EWEC 2010Dokumen9 halamanProject Finance For Offshore Wind A Practitioner's View: EWEC 2010Joseph FrereBelum ada peringkat

- 3 Blast Effects On Buildings and People: A Primer For Users of The ISC Security Design CriteriaDokumen22 halaman3 Blast Effects On Buildings and People: A Primer For Users of The ISC Security Design CriteriaVulebg VukoicBelum ada peringkat

- Vol 2 Onshore Pipelines The Road To Success 3rd EditionDokumen418 halamanVol 2 Onshore Pipelines The Road To Success 3rd EditionAli Hammouda100% (1)

- HAZID Wells and Reservoir: Project Title: Page 1 of 12 Document TitleDokumen12 halamanHAZID Wells and Reservoir: Project Title: Page 1 of 12 Document TitleAshwin KumarBelum ada peringkat

- Dissertation Sahil Arora 28 AprilDokumen80 halamanDissertation Sahil Arora 28 AprilSahil Arora100% (1)

- Nec3 DissertationDokumen4 halamanNec3 DissertationOrderPaperOnlineSaintPetersburg100% (2)

- Discuss What Advice You Would Give To Those Reviewing The CDM Regulations, Including Your Recommendations On What Should Be Changed (With Your Reasons)Dokumen9 halamanDiscuss What Advice You Would Give To Those Reviewing The CDM Regulations, Including Your Recommendations On What Should Be Changed (With Your Reasons)wordssmithBelum ada peringkat

- ContractualRisksinFast TrackProjectsDokumen7 halamanContractualRisksinFast TrackProjectsHakimi kaminiBelum ada peringkat

- Off Shore Drilling NotesDokumen15 halamanOff Shore Drilling NotesAamir LokhandwalaBelum ada peringkat

- Report 6 - 216716973 FINAALDokumen11 halamanReport 6 - 216716973 FINAALGerhard vd WesthuizenBelum ada peringkat

- Artificial Intelligence Innovation Report PDFDokumen24 halamanArtificial Intelligence Innovation Report PDFrehmanzidBelum ada peringkat

- CDM Guidance For DesignersDokumen47 halamanCDM Guidance For DesignersAlan Beech100% (1)

- The Factors Affecting The Trenchless ProjectsDokumen5 halamanThe Factors Affecting The Trenchless ProjectsKOKKONDA VENKATESHWARBelum ada peringkat

- Jmse 09 00034 v2Dokumen13 halamanJmse 09 00034 v2VokramBelum ada peringkat

- Contractorsrisk Paras 0003 File PDFDokumen57 halamanContractorsrisk Paras 0003 File PDFRiyasBelum ada peringkat

- Confront The RFI Problem: Addressing The Information GapDokumen6 halamanConfront The RFI Problem: Addressing The Information GapekaciptaBelum ada peringkat

- Construct Ability GuideDokumen33 halamanConstruct Ability Guidejvillar236Belum ada peringkat

- Asuc Underpinning and Mini Piling Guidelines 2015Dokumen98 halamanAsuc Underpinning and Mini Piling Guidelines 2015Xe CohBelum ada peringkat

- An Approach To Quantify The Current Level of Safety Achieved by The BuildingDokumen14 halamanAn Approach To Quantify The Current Level of Safety Achieved by The BuildingjessqiuBelum ada peringkat

- Action Plan: FOR Performance Based Seismic DesignDokumen9 halamanAction Plan: FOR Performance Based Seismic DesignCristian BlanaruBelum ada peringkat

- The Attraction of BIM Solutions Using RevitDokumen9 halamanThe Attraction of BIM Solutions Using RevitDr Hector C Sikazwe100% (1)

- Safety Case BridgingDokumen3 halamanSafety Case Bridginglooking99Belum ada peringkat

- Terry MellersDokumen5 halamanTerry MellersAhmed AyadBelum ada peringkat

- N N 36, O 2014 I: Ewsletter O Ctober NtroductionDokumen7 halamanN N 36, O 2014 I: Ewsletter O Ctober NtroductionponjoveBelum ada peringkat

- PGPM 31Dokumen16 halamanPGPM 31Rutuja GameyBelum ada peringkat

- Report 6: Individual Case Study Report: Sustainability and Impact ofDokumen7 halamanReport 6: Individual Case Study Report: Sustainability and Impact ofGerhard vd WesthuizenBelum ada peringkat

- Vetting & Selection of Contractors (All Including Non-Construction)Dokumen35 halamanVetting & Selection of Contractors (All Including Non-Construction)kanakarao1Belum ada peringkat

- The Bridge To NowhereDokumen4 halamanThe Bridge To NowhereMuhammad FarhalBelum ada peringkat

- CPA Good Practice Guide ExcavationDokumen24 halamanCPA Good Practice Guide Excavationlallanasaints100% (1)

- Recommendations For Bridge and Tunnel SecurityDokumen64 halamanRecommendations For Bridge and Tunnel SecurityAhmed Emad AhmedBelum ada peringkat

- Geotechnical DesignDokumen35 halamanGeotechnical DesignTing Sing JuoBelum ada peringkat

- Project ProposalDokumen21 halamanProject ProposalVidushi AmarasingheBelum ada peringkat

- 2013 - 10 Bridges PDFDokumen52 halaman2013 - 10 Bridges PDFFrederick TanBelum ada peringkat

- BSJ Octnov p12 - 13 SCDokumen2 halamanBSJ Octnov p12 - 13 SCSpencer Carroll MRICSBelum ada peringkat

- 1 Web PageAccessRoutesArticleDokumen39 halaman1 Web PageAccessRoutesArticleRoy StuartBelum ada peringkat

- MPL Construction PDFDokumen40 halamanMPL Construction PDFSheraz QamerBelum ada peringkat

- Managing Design Risks and Liabilities in An Integrated WorldDokumen4 halamanManaging Design Risks and Liabilities in An Integrated WorldAnonymous pGodzH4xLBelum ada peringkat

- CDM Awareness - Online SC 280720Dokumen3 halamanCDM Awareness - Online SC 280720Mhd ThrBelum ada peringkat

- Final DissertationDokumen82 halamanFinal DissertationSyed Omer Hussain ShahBelum ada peringkat

- Roles and Responsibilities of Engineers, Architects, and Code Enforcement OfficialsDokumen4 halamanRoles and Responsibilities of Engineers, Architects, and Code Enforcement Officialsrmm99rmm99Belum ada peringkat

- Safety Acceptance Criteria For Existing Structures by Diammantidis and BazzuroDokumen11 halamanSafety Acceptance Criteria For Existing Structures by Diammantidis and BazzuroChristian SesoBelum ada peringkat

- Mega Project Interface ManagementDokumen3 halamanMega Project Interface ManagementLTE002100% (2)

- Methods for Petroleum Well Optimization: Automation and Data SolutionsDari EverandMethods for Petroleum Well Optimization: Automation and Data SolutionsBelum ada peringkat

- ICE Low Carbon Slide PackDokumen39 halamanICE Low Carbon Slide PackShijo AntonyBelum ada peringkat

- AbstractDokumen1 halamanAbstractShijo AntonyBelum ada peringkat

- Ae4131 Abaqus Lecture 4Dokumen23 halamanAe4131 Abaqus Lecture 4Shijo AntonyBelum ada peringkat

- Ae4131 Abaqus Lecture 2Dokumen26 halamanAe4131 Abaqus Lecture 2Shijo AntonyBelum ada peringkat

- Daily Progress Report (DPR) From Proejct Engineer of PHC: S.E. (Mumbai / TNK/ Pune/ AN/ NAG Regional Office)Dokumen1 halamanDaily Progress Report (DPR) From Proejct Engineer of PHC: S.E. (Mumbai / TNK/ Pune/ AN/ NAG Regional Office)Deepak KaushikBelum ada peringkat

- PPI Technical Guide 01 Five LeversDokumen21 halamanPPI Technical Guide 01 Five LeversMilagros PortugalBelum ada peringkat

- Neo Backer RodDokumen2 halamanNeo Backer RodShibin PoulBelum ada peringkat

- AUTOCLAVE - AdapterCouplingDokumen52 halamanAUTOCLAVE - AdapterCouplingAjimKe'enBelum ada peringkat

- Type VMPD/B: Pressure Relief ValvesDokumen4 halamanType VMPD/B: Pressure Relief Valvestommy lapointeBelum ada peringkat

- API 650-Impact TestDokumen4 halamanAPI 650-Impact TestBashu PoudelBelum ada peringkat

- Motorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Dokumen1 halamanMotorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Jemicah YumenaBelum ada peringkat

- It Is Illegal To Use 60/70 and 80/100 Paving Bitumen in Roads !!!Dokumen28 halamanIt Is Illegal To Use 60/70 and 80/100 Paving Bitumen in Roads !!!Vizag Roads89% (9)

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IIDokumen30 halamanProf (1) - Zahid Ahmad Siddiqi Formwork Design-IISantosoBelum ada peringkat

- Concrete Mix Design Calculation - M20, M25, M30 - Procedure & ExampleDokumen10 halamanConcrete Mix Design Calculation - M20, M25, M30 - Procedure & ExampleJustin Musopole100% (1)

- B. Arch. III Semester Syllabus 2017 RegulationDokumen10 halamanB. Arch. III Semester Syllabus 2017 RegulationMoizu fathimaBelum ada peringkat

- Duane Banks Stadium RenovationDokumen3 halamanDuane Banks Stadium RenovationGazetteonlineBelum ada peringkat

- 1.2842 enDokumen2 halaman1.2842 enCosmin IonutBelum ada peringkat

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYDokumen39 halamanMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonBelum ada peringkat

- Ce6452 Solid MechanicsDokumen1 halamanCe6452 Solid MechanicsarravindBelum ada peringkat

- AISC Properties DatabaseDokumen7 halamanAISC Properties DatabaseShekh Muhsen Uddin AhmedBelum ada peringkat

- 4 BMC III (Arch 3171) - Cladding PDFDokumen48 halaman4 BMC III (Arch 3171) - Cladding PDFabel alemuBelum ada peringkat

- PerfilesDokumen16 halamanPerfilesBill MontoyaBelum ada peringkat

- Design For Manufacturability For CNC MachiningDokumen4 halamanDesign For Manufacturability For CNC Machiningviorelu99Belum ada peringkat

- Storage Tank FoundationsDokumen19 halamanStorage Tank Foundationstariq.muhammad.raheelBelum ada peringkat

- Seepage Drainage and Flow NetsDokumen1 halamanSeepage Drainage and Flow NetsDwight AndersonBelum ada peringkat

- Mailing Address/Contact: Present:: S.M. Mohsi-Ul-AnisDokumen3 halamanMailing Address/Contact: Present:: S.M. Mohsi-Ul-AnisAnisBelum ada peringkat

- American Marsh Srem PDFDokumen28 halamanAmerican Marsh Srem PDFdiuska13Belum ada peringkat

- Concrete Bleeding Good or Bad - tcm45-348530Dokumen2 halamanConcrete Bleeding Good or Bad - tcm45-348530Chris YangBelum ada peringkat

- Euclidean ZoningDokumen1 halamanEuclidean Zoningneda1388Belum ada peringkat

- 2e-Aruana 40 Efi 2017Dokumen57 halaman2e-Aruana 40 Efi 2017costinbalca46Belum ada peringkat

- P & ID Review Check List: Chemical Engineering SiteDokumen7 halamanP & ID Review Check List: Chemical Engineering SiteMayur ParmarBelum ada peringkat

- R/S 15F Thru R/S 30F: Air End Model BSA22, BSA21 Air CooledDokumen20 halamanR/S 15F Thru R/S 30F: Air End Model BSA22, BSA21 Air CooledAnonymous ZtXb2RO100% (1)

- HSE-004 - Rev 0 PDFDokumen43 halamanHSE-004 - Rev 0 PDFbaranakinbingolBelum ada peringkat

- BASIX Project CommitmentsDokumen1 halamanBASIX Project CommitmentsMichelle KieraBelum ada peringkat