Short Columns

Diunggah oleh

srividyaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Short Columns

Diunggah oleh

srividyaHak Cipta:

Format Tersedia

Journal of Advanced Concrete Technology Vol. 3, No.

2, 267-281, June 2005 / Copyright 2005 Japan Concrete Institute

267

Scientific paper

Behavior of Confined High Strength Concrete Columns under Axial

Compression

Umesh K. Sharma1, Pradeep Bhargava2 and S.K.Kaushik3

Received 12 October 2004, accepted 1 February 2005

Abstract

An experimental study was carried out to investigate the behavior of high strength concrete short columns confined by

circular spirals and square ties under monotonically increasing concentric compression. The test variables included

volumetric ratio, spacing and yield strength of transverse reinforcement, longitudinal reinforcement ratio, lateral steel

configuration, shape of cross section and concrete compressive strength. The effects of these variables on the uniaxial

behavior of high strength concrete columns are presented and discussed The results indicate that more confinement is

required in columns of high strength concrete than in columns of low strength concrete to achieve the desired post-peak

deformability. The behavior of high strength concrete columns is characterized by the sudden spalling of concrete cover,

leading to a loss of axial capacity. A comparative study of existing confinement models of high strength concrete columns was also conducted to assess their capabilities of predicting the actual test behavior. To this end, the stress-strain

curves of the specimens tested in the present study were compared with the ones predicted by the various models. It is

shown that Legeron & Paultre (2003) model estimates the actual experimental curves more closely as compared to the

other models employed in the study.

1. Introduction

Inelastic deformability of reinforced concrete columns is

essential for overall stability of structures in order to

sustain strong earthquakes. Deformability of columns

can be achieved through proper confinement of the core

concrete. It is now well documented that the desired ductility can be attained in case of normal strength concrete

columns by providing well-detailed lateral confinement

reinforcement (Richart et al. 1928; Sheikh & Uzmeri

1980; Park et al. 1982; Mander et al. 1988). However,

the gradual development of concrete technology has

promoted the use of high strength concrete owing to its

wide range of advantages over normal strength concrete

and as a result, concrete strengths much higher than

60Mpa have gained acceptance in the construction industry. The high strength concrete is significantly more

brittle than conventional normal strength concrete. While,

existing code provisions for minimum amount of confinement reinforcement are based on experiences with

normal strength concrete, questions have been asked as

to whether similar amount of confinement is suitable for

high strength concrete columns (Razvi & Saatcioglu

1994; Pessiki & Pieroni 1997; Foster 2001).

The few studies carried out on confinement of high

Research Scholar, Department of Civil Engineering,

Indian Institute of Technology, Roorkee, India.

E-mail:umuksdce@iitr.ernet.in

2

Associate Professor , Department of Civil Engineering,

Indian Institute of Technology, Roorkee, India.

3

Professor, Department of Civil Engineering, Indian

Institute of Technology, Roorkee, India.

strength concrete columns in the recent past indicate that

the confinement steel requirements for such columns

have not yet been fully developed (Bjerkli et al. 1990;

Muguruma et al. 1993; Li et al. 1994; Cusson & Paultre

1994; Razvi & Saatciouglu 1996; Foster & Attard 2001).

This is also evidenced by the lack of design provisions in

the current relevant building codes of various countries.

ACI Committee 441 (1997) also emphasized that more

data on the confinement of high strength concrete columns are needed. Therefore, as a part of ongoing combined experimental and analytical study to fully discover

the strength and ductility of high strength concrete columns, this paper reports the results of concentrically

tested circular and square high strength concrete columns. An attempt has also been made to evaluate the

capabilities of existing stress-strain models for high

strength concrete by comparing the experimentally

found curves with the ones estimated by the various

models.

2. Experimental program

2.1 Test specimens

A total of 44 high strength concrete columns, 600 mm in

length, were tested under

concentric compression.

They included 18 tie confined 150 mm square specimens

and equal numbers of spiral confined 150 mm diameter

circular section columns. The remaining 8 columns were

prepared as 4 square and 4 circular plain (unconfined)

concrete specimens to establish the properties of unconfined concrete and thereby to get comparison of in place

strength of concrete with standard cylinder compressive

strength. To properly investigate the behavior of high

strength concrete columns, the specimens were cast and

268

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

faces of the specimens to prevent direct loading of the

bars. In all the specimens, the ratio of gross area of the

section, Ac, to the core area, Acc, measured to the outside

of the lateral reinforcement was 1.33. Longitudinal reinforcement was provided in all the confined column

specimens. The lateral ties of all square specimens had

1350 hooks and a development length as per the ACI 318

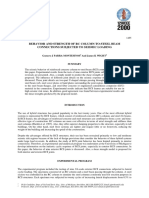

code provisions. Fig.1 and Table1 show the various

properties of longitudinal and transverse reinforcement.

The notation fc shows standard cylinder compressive

strength on the day of testing of columns, l and fy are

respectively longitudinal steel ratio and yield strength of

longitudinal steel, s, s and fyh are respectively spacing,

volumetric ratio and yield strength of lateral steel. Two

different specified concrete strengths, two lateral steel

yield strengths and two longitudinal steel ratios and resulting lateral steel configurations were employed. The

spacing of spirals and ties were varied from approximately one fourth to half of the total lateral dimension of

column in order to give varying volumetric ratios of lateral confining steel.

Failure of the specimens was forced in the test region,

which was equal to 300 mm in the middle of the specimen height by reducing the spacing of the lateral reinforcement out side the test region to half of the specified

spacing in the test region. However, in the case of the

specimens where specified spacing of lateral steel was

30 mm, the spacing in the end zones was reduced to only

three fourth of that in test region to facilitate proper placing of concrete in the cover of columns in these end regions. All the specimens were also externally confined

by 10mm thick mild steel collars in the end regions of

150 mm to further prevent premature failure.

tested in duplicate for each case in order to get the average of two results thus making 22 independent column

designs. All the details regarding the various column

specimens are illustrated in Table 1 and Fig. 1. Most of

the results reported here in this study are the averages of

two tests with a few exceptions of SG, SC, CH and SF

columns where duplicate results could not be taken due

to the following reasons. One of the SG specimens failed

rather more suddenly compared to the other and all the

measuring instruments like LVDTs and strain gauges got

dislodged and further readings after peak could not be

taken. In case of one of the CH specimens the top end

concrete cover of the column got crushed and the loads

came directly on the end steel collars which got damaged and therefore the test was stopped. Whereas one of

the results of each of SC and SF specimens were rejected

due to the reason that in spite of exercising extra care to

avoid any eccentric loading of the specimens, these columns seemed to suffer from this problem as evidenced

by their considerable tilting and entire spalling on one

side only.

The specimens were cast in total eleven sets. Each set

consisted of two duplicate circular and two duplicate

square columns of one design. For example two specimens of CA and SA each were cast in one set. The columns were designed to investigate the parameters of

confinement, including volumetric ratio and spacing of

transverse reinforcement, yield strength of transverse

reinforcement, longitudinal reinforcement ratio, and lateral steel configuration in addition to shape of cross section and concrete compressive strength. Concrete cover

of 10 mm was provided in all the confined specimens. A

concrete cover of 15 mm was also provided between the

ends of the longitudinal bars and the top and bottom sur-

150 mm

End Region

250 mm

LVDT

Gauge Length

600 mm

Square Column

150mm

6 Nos

8mm dia.

6 Nos

12mm dia.

150mm

150 mm

4 Nos

12 mm

dia.

150 mm

150mm

Cover 10mm

Cover 10 mm

600 mm

150 mm

End Region

Cover 10mm

Cover 10mm

8 Nos

12 mm dia.

150 mm

150 mm

150 mm

Strain Gauges - Longitudinal Bar

Lateral Steel

Circular Column

Fig. 1 Details of column specimens, reinforcement arrangement and location of strain gauges.

269

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

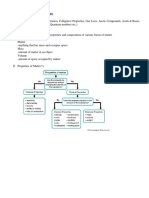

Table 1 Properties of column specimens.

Specimens

Circular

Square

f 'c

Longitudinal Reinforcement

Number &

l

fy

Diameter, mm

%

MPa

6 No 8

1.70 412

Diameter

mm

Transverse Reinforcement

s

Arrangement

s

mm

%

A

50

3.3

f yh

ke s f yh / f 'c

MPa

412

0.186

CA

MPa

62.20

CB

62.80

6 No 8

1.70

412

75

2.2

412

0.107

CC

61.85

6 No 8

1.70

412

50

3.3

520

0.236

CD

63.35

6 No12

3.84

395

50

3.3

412

0.189

CPL

61.90

--

--

--

--

--

--

--

--

--

CE

82.50

6 No 8

1.70

412

30

5.5

412

0.256

CF

81.75

6 No 8

1.70

412

50

3.3

412

0.141

CG

83.15

6 No 8

1.70

412

75

2.2

412

0.081

CH

81.80

6 No 8

1.70

412

50

3.3

520

0.178

CI

82.55

6 No12

3.84

395

50

3.3

412

0.145

CPH

82.25

--

--

--

--

--

--

--

--

--

SA

62.20

4 No12

2.01

395

50

3.3

412

0.0984

SB

62.80

4 No12

2.01

395

75

2.2

412

0.0505

SC

61.85

4 No12

2.01

395

50

3.3

520

0.1248

SD

63.35

8 No12

4.02

395

50

5.62

412

0.2303

SPL

61.90

--

--

--

--

--

--

--

--

--

SE

82.50

4 No12

2.01

395

30

5.5

412

0.1483

SF

81.75

4 No12

2.01

395

50

3.3

412

0.0748

SG

83.15

4 No12

2.01

395

75

2.2

412

0.0381

SH

81.80

4 No12

2.01

395

50

3.3

520

0.0944

SI

82.55

8 No12

4.02

395

50

5.62

412

0.1767

SPH

82.25

--

--

--

--

--

--

--

--

--

The fabricated steel cages were fixed in the steel

moulds and the casting was carried out in the laboratory.

After 24 hours, the specimens were removed from the

moulds and submerged in a water tank for curing. The

water-curing period lasted for 28 days, after which the

specimens were left in the laboratory at ambient temperature until the time of testing. The testing was commenced after 90 days of ageing.

2.2 Material properties

Two high strength concrete mixes were employed in the

study. The materials consisted of Ordinary Portland Cement, natural river sand, crushed stone aggregate of

maximum size 10mm, tap water for mixing and curing,

silica fume and superplasticizer admixture to maintain

adequate workability of mix. To obtain the desired

strength, several preliminary mix designs were practiced

and then optimal mix designs were determined after testing 28 days strength. The final mixes had 28 days average cube (150x150x150mm) compressive strengths of

68.4 & 87.5 MPa and average cylinder (100x200mm)

strengths of 58.03 and 76.80 MPa. Table 2 shows the

mix proportions and 28 days compressive strengths for

both the mixes. The measured tangent elastic moduli

(Ec) were 31645 MPa and 34465 MPa for lower and

higher strength concrete mixes respectively. The slump

value ranging from 100-120mm was maintained to ensure that the concrete could be placed through the dense

reinforcement cages.

Three standard concrete cylinders (100 x 200 mm)

were cast along with each set of four columns. They

were tested at various ages to determine the strength of

concrete fc on the day of testing of columns. The properties of unconfined concrete were obtained by testing

plain unreinforced column specimens (CPL, CPH, SPL

& SPH). It was observed that concrete strength of column specimens were generally lower than the concentric

strength measured on standard cylinders. The average

unreinforced specimen concrete strength was measured

as 88% and 90% of the average concrete cylinder

strength for the lower high strength (CPL & SPL) and

upper high strength (CPH and SPH) concretes respectively. The commonly used ratio of 0.85 was then used

for evaluating the concrete section capacity of the

specimens tested in the present study.

The longitudinal reinforcement consisted of 8 mm and

12mm deformed bars for circular columns and 12 mm

deformed bars for square columns. Two different grades

(412 MPa and 520 MPa) of reinforcing steel with a diameter of 8 mm were used as lateral reinforcement.

270

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

taken to complete each test ranged from 30 minutes to 1

hour depending upon the degree of confinement in the

specimen. To ensure concentric loading, an initial load

of approximately 20% of the total ultimate load was applied and the readings of the four LVDTs were monitored. If the readings of the LVDTs were not approximately equal, this signals that the load is not concentric.

The column was then unloaded and the additional packing was given under the wooden plies unless the load

becomes almost concentric. In spite of the rigorous procedure followed for aligning the specimens, some eccentricities were unavoidable.

Stress-strain relationships, established by performing at

least three coupon tests for each reinforcement, are illustrated in Fig. 2. The yield strength of the lateral reinforcement is defined as an offset strain of 0.2%.

2.3 Instrumentation and testing procedure

Longitudinal and lateral steel strains were measured by

electrical resistance strain gauges glued to the steel bars.

The strain gauges were pasted to the two opposite longitudinal steel bars at their middle lengths. Similarly two

gauges were glued at the two locations on the lateral

steel at approximately middle length of the specimen as

shown in the Fig. 1. The axial displacement of the

specimens was recorded using four linear variable differential transducers (LVDTs). Two LVDTs were attached on the opposite faces to a top and bottom steel

clamps to the specimens to give a gauge length of 250

mm. Whereas, two LVDTs were mounted on the other

two faces of the specimen and were held by the attachments provided to the end steel collars. If a sudden failure occurs or due to spalling, the steel clamps get dislodged, the LVDTs mounted on the end collars could be

used instead of the gauge length over the central 250 mm.

LVDTs were of 50 mm stroke. Loads were recorded

through a 3000 kN load cell. The recorded strain data

from the four LVDTs, four strain gauges and corresponding load data from load cell were fed to a data acquisition system and stored on a computer. Overall view of

the test setup is shown in Fig. 3.

The top and bottom ends of the specimens were

slightly ground by a grinding machine to remove any

surface unevenness. But, at the same time it was ensured

that the excessive grinding is not carried and the required cover is maintained to the longitudinal bars at the

ends. In addition, 6mm wooden ply pieces were put at

the top and bottom ends of the specimens to ensure parallelism of specimen end surfaces and uniform distribution of the load on the specimen. The test specimens

were loaded using a 5000 kN capacity hydraulic universal testing machine with load controlled capabilities. The

monotonic concentric compression was applied at very

slow rate to capture the post-peak part of the measured

load deformation curves by manually controlling the oil

pressure. The load was applied from zero to failure,

which was determined primarily by either rupture of the

lateral reinforcement or excessive crushing of the core,

together with buckling of the longitudinal bars. The time

800

8 m m ( f y h = 5 2 0 M P a , y h = 0 .0 0 2 6 )

700

Stress (MPa)

600

500

8 m m ( f y h = 4 12 M P a , y h = 0 .0 0 2 4 )

400

300

12 m m ( f y = 3 9 5 M P a , y = 0 .0 0 2 3 )

200

100

0

0

0.01

0.02

0.03

0.04

0.05

Strain (m m /m m )

Fig 2 Stress-strain curves for reinforcing bars.

Fig. 3 Experimental setup.

Table 2 Mix proportions.

Mix

Cement

Kg/m3

Water

Kg/m3

Coarse

Aggregate

Kg/m3

Sand

Kg/m3

Silica

Fume

Kg/m3

Superplasticizer

Kg/m3

Mix 1

545

169

1105

700

--

5.45

28 Days

Cylinder

Compressive

Strength*

f c ' , MPa

58.03

Mix 2

600

168

1055

625

50

7.5

76.80

* Average of 5 Specimens.

28 Days

Cube Compressive

Strength*

f ck , MPa

68.40

87.50

0.06

271

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

3. Observed behavior

velopment of strains associated with the failure of unconfined concrete specimens.

The cover spalling often resulted in a sudden drop in

load, which was also more pronounced in higher concrete strength columns. Load resistance of columns

again increased to a second peak normally for wellconfined specimens only. This behavior indicates that

the passive confinement becomes active only after the

cover has spalled and post-spalling behavior depended

solely upon the confinement level of specimens. Figures

5 and 6 show the total column axial load normalized to

unconfined column capacity versus longitudinal strain

curves for circular and square specimens respectively.

All columns initially behaved in a similar manner and

exhibited relatively linear load deformation behavior in

the ascending part, which is typical of high strength concretes. The plain concrete specimens CPL, CPH, SPL &

SPH, had a sudden explosive type of failure at the

maximum axial load. The complete load deflection

curves for these specimens could not be obtained with

the present testing facility, and no readings could be

taken after their brittle failure. The strains corresponding

to the peak loads were 0.00232, 0.00256, 0.00237 and

0.0026 for CPL, CPH, SPL and SPH specimens respectively.

The general behavior of confined specimens was comparatively ductile and complex unlike plain unconfined

columns. These columns were characterized sequentially

by the development of surface cracks, cover spalling,

yielding of longitudinal steel, yielding of lateral steel,

fracture of spiral or ties, buckling of longitudinal bars

and crushing of core concrete. The vertical longitudinal

cracks were noticed invariably first of all for almost all

the columns just before the cover spalling. These cracks

thereafter eventually led to the spalling of cover concrete,

which was marked by the separation of large pieces of

cover from core concrete. Figuer 4 illustrates the appearance of a typical specimen at various stages of loading. The spalling was comparatively more sudden and

explosive for columns with higher strength concrete mix.

The beginning of cover spalling was carefully observed

and marked during testing. The strain data (Table 3)

indicated that spalling of cover occurred prior to the de-

(a)

(a)

(b(b))

(c)

(c)

Fig. 4 Appearance of specimen CC at various

stages:(a) initial vertical cracking, (b) cover spalling,

and (c) ultimate failure.

Table 3 Test results.

Specimens

Pmax,

kN

CA 1109

CB 1059

CC 1148

CD 1241

CPL 963

Circular CE 1381

CF

1294

CG 1352

CH 1321

CI

1379

CPH 1312

SA 1334

SB

1364

SC

1308

SD 1626

Square SPL 1239

SE

1641

SF

1604

SG 1730

SH 1621

SI

1819

SPH 1684

Axial Loads

Pmax/Po Pc,

Pc/Poc

kN

1.063 986 1.074

1.006 947 1.021

1.106 1024 1.115

1.049 973 1.063

1.035 --1.03

1263 1.04

0.972 1175 0.973

0.980 1206 0.982

0.992 1202 0.995

0.956 1111 0.932

1.062 --0.992 1155 0.990

1.005 1185 1.006

0.977 1133 0.977

1.069 1268 1.090

1.046

--0.951 1463 0.946

0.937 1433 0.935

0.995 1551 0.995

0.946 1446 0.943

0.971 1461 0.964

1.070

---

-- Not applicable, * Could not be measured.

Pcc,

kN

978

796

1011

967

-1262

1069

964

1117

1032

-985

917

1042

1268

-1399

1220

1122

1304

1403

--

Pcc/Pocc

1.624

1.309

1.687

1.630

-1.581

1.351

1.199

1.410

1.335

-1.290

1.189

1.372

1.683

-1.382

1.216

1.10

1.30

1.43

--

c

0.00248

0.00236

0.00241

0.00235

0.00232

0.00228

0.00231

0.00250

0.00240

0.00235

0.00256

0.00232

0.00235

0.00224

0.00263

0.00237

0.00228

0.0022

0.0025

0.00232

0.00252

0.00260

Axial Strains

cc/co c50c

c/co

cc

1.068

1.017

1.038

1.013

1.00

0.890

0.902

0.976

0.937

0.917

1.00

0.978

0.991

0.945

1.109

1.00

0.876

0.846

0.961

0.892

0.969

1.00

0.00596

0.00357

0.00813

0.00638

-0.0074

0.0046

0.0034

0.0050

0.00564

-0.00386

0.00312

0.00427

0.00713

-0.0051

0.00344

0.00285

0.00361

0.0063

--

2.568

1.538

3.504

2.75

-2.891

1.797

1.328

1.953

2.203

-1.628

1.316

1.801

3.008

-1.961

1.323

1.096

1.388

2.423

--

0.0278

0.0110

0.0323

0.0291

-0.0298

0.0148

0.0080

0.0155

0.018

-0.011

0.0055

0.014

0.032

-0.014

0.0064

0.0042

0.0098

0.021

--

c50c/co

11.98

4.741

13.92

12.54

-11.65

5.781

3.12

6.051

7.031

-4.641

2.320

5.907

13.50

-5.384

2.461

1.615

3.769

8.076

--

I10

fhcc

MPa

7.8

7.2

8.58

8.3

-8.8

7.6

5.56

7.64

8.4

-6.63

4.32

6.72

8.4

-6.44

4.54

3.38

5.05

7.86

--

412

*

520

412

-412

*

274

458

394

-394

*

420

412

-395

336

*

*

412

--

272

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

Relative Column Load (P/P o)

The second peak was observed for many circular columns CA, CC, CD, CE, CH and CI, and a few square

columns SA, SD, SE and SI which have better efficiently

1.2

1

CB

0.8

CD

CC

CA

0.6

0.4

0.2

0

0

0.03

0.06

0.09

0.12

0.15

Colum n Axial Strain (m m /mm )

(a)

Relative Column Load (P/P o)

1.2

1

CF

0.8

CH

CG

CI

CE

0.6

0.4

0.2

0

0

0.03

0.06

0.09

0.12

0.15

Colum n Axial Strain (mm /m m )

(b)

Relative Column Load (P/P o)

Fig. 5 (a) & (b) Column axial load versus axial strain

curves (circular columns).

1.2

1

SA

SD

SC

SB

0.8

0.6

0.4

0.2

0

0

0.02

0.04

0.06

0.08

0.1

Relative Column Load (P/P o)

Colum n Axial Strain (mm /m m)

(a)

1.2

1

SE

SG

SF

0.8

SI

SH

0.6

0.4

0.2

0

0

0.02

0.04

0.06

0.08

0.1

0.12

Colum n Axial Strain (mm /m m )

(b)

Fig.6 (a) and (b) Column axial load versus axial strain

curves (square columns).

confined core than the other specimens of the study as

implied by their respective volumetric ratios, spacing

and distribution of lateral steel. In the case of CE and SD

specimens the load values at second peak were in fact

more than those at respective first peaks. This may be

attributed due to the fact that CE specimen has a very

high volumetric ratio and closer spacing of spirals.

Square column SD had also high volumetric ratio and

the lateral tie arrangement of eight bars, which provided

better confinement than an arrangement of four bars.

However, the SG, CG and SB specimens failed immediately after the first maximum load was reached, indicating that the spacing of the lateral steel was too wide to

provide lateral confinement. Overall, it was observed

that for the similar confinement circular columns had a

better post peak behavior than the square tie confined

columns and the lower high strength mix columns failed

slowly in a better ductile fashion than the similarly confined higher concrete strength mix columns.

At the stage of cover spalling, in all the specimens

longitudinal steel yielded but, the level of stress in lateral

confining steel was considerably less than their respective yield strengths. Similar observations were made in

some earlier studies also (Cusson & Paultre 1994; Foster

1999). Lateral steel yielded either at the second peak or

even after that in the descending part of loaddeformation behavior. In fact yielding of lateral steel at

second peak was noticed only for well-confined columns

and mostly for lower high strength mix specimens. They

were CA, CC, CD, and CE circular columns and SD and

SI square column. Fracture of transverse reinforcement

was observed only for the specimens with closer spacing

of spirals or ties i.e. 30 and 50 mm. The stage of spiral or

tie fracture was invariably at the moment when the load

dropped to approximately 40-50% of the maximum

value in the descending segment. It was observed that

the fracture of lateral steel caused a sudden drop in load.

In the case of columns with 75 mm spacing of transverse

steel, buckling of longitudinal steel was observed prior

to the fracture of lateral steel, which ultimately lead to

the fracture of ties and crushing of core.

4. Test results

The columns were analyzed to obtain the stress-strain

curves of confined concrete, as suggested by Sheikh &

Uzumeri (1980) and Cusson & Paultre (1994). The concrete contribution Pc at a certain deformation was determined by subtracting the contribution of longitudinal

steel from the applied load P. The load carried by the

longitudinal steel was determined from the stress-strain

curves obtained from the tension test. In computing the

load carried by the longitudinal steel, the strain hardening regions of the curves were assumed to be a straight

line that resulted in a maximum error of less than 5% in

the computed concrete force. The concrete contribution

curves were nondimensionalized with respect to gross

concrete area force Poc and core concrete area force Pocc

273

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

(Fig. 7), where

(1)

Pocc = 0.85 f ' c Acc

(2)

While the gross concrete area Ac represented column

behavior before the cover started spalling, only the core

area Acc resisted the applied load after concrete cover

was completely spalled. A smooth transition was assumed to take place from the lower curve to the upper

curve. In Fig. 7, dark line shows the behavior of confined concrete. The load sustained by the confined core

concrete Pcc was calculated by subtracting the load carried by the cover concrete from Pc. The maximum loads

Pmax, Pc and Pcc were normalized by Po, Poc and Pocc respectively and these values were compared with each

other as shown in Table 3, where

Po = 0.85 f ' c ( Ag Ast ) + f y Ast

(3)

The ratio Pmax/ Po ranges from 0.95 to 1.10 for circular

columns and 0.93 to 1.07 for square columns. The lower

ratios are observed for specimens with higher strength

concrete and closer spacing of lateral steel indicating

loss in column capacity due to spalling. Similarly Pc/

Poc varies from 0.93 to 1.11 for circular columns and

0.93 to 1.09 for square columns. The strain ratio c/co,

ranges from 0.89 to 1.07 for circular columns and 0.84

to 1.10 for square columns indicating premature failure

of cover for higher strength concrete columns with dense

lateral steel spacing. Here c stands for axial strain corresponding to the first peak i.e. beginning of spalling and

co is peak strain of unconfined concrete column. The

load ratio Pcc/ Pocc ranges from 1.19 to 1.68 for circular

columns and 1.10 to 1.68 for square columns. The ratio

of peak confined strain cc to co varies from 1.32 to 3.5

for circular columns and 1.09 to 3.0 for square columns.

The strain ratio c50c/co ranges from 3.12 to 13.92 for

circular columns and 1.61 to 13.50 for square columns.

Where, c50c is axial strain corresponding to 0.5 Pcc in the

descending part. The values of ratios Pcc/Pocc, cc /co and

c50c/co prove that the important gains in deformability

of core concrete can be achieved following the spalling

of the cover concrete depending upon the level of confinement.

To quantify the effect of test variables on the postpeak deformability of confined high strength concrete

columns more effectively I10 ductility index can be used

(Foster 1999; Foster & Attard 2001). The definition of

I10 ductility index is adopted from ASTM C1018 (26) for

the measurement of toughness. The I10 index is the ratio

of the area under the load versus strain curve up to a

strain of 5.5 times the yield strain to the area under the

curve for a strain equal to the yield strain. The yield

strain is taken as 1.33 times the strain corresponding to a

load of 0.75 times the maximum load on the ascending

side. The significance of taking area under the curve up

to 5.5 times the yield strain is that for a perfectly elasto-

P c/P oc, P c/P occ

Poc = 0.85 f ' c Ac

P c /P occ

1.8

1.6

1.4

Behavior of

confined concrete

1.2

P c /P oc

0.8

A : B eginning o f spalling

B : A fter spalling o f co ver

C : M aximum co nfined stress and beginning o f

0.6

0.4

0.2

co re crushing.

0

0

0.01

0.02

0.03

Concrete axial strain, c

Fig.7 Nondimensionalized concrete contribution curve.

plastic material I10 = 10, while for a perfectly elasticbrittle material I10 = 1. The I10 values were computed for

all the specimens of the study and the same are given in

Table 3.

5. Effect of test variables

5.1 Concrete compressive strength

The concrete compressive strength was the most important and one of the primary variables investigated extensively in the test program. The behavior of specimens

with same volumetric ratio, spacing, configuration and

yield strength of lateral steel but with different concrete

strengths was compared to quantify the effects of this

parameter. Fig. 8 shows comparisons of both circular

and square columns with different strength concretes.

The post peak curves of the higher strength concrete mix

columns are steeper indicating faster rate of strength

decay as compared to the lower strength concrete specimens. The decreasing trend of strength enhancement

(Pcc/ Pocc) and I10 ductility values for both circular and

square columns from lower strength concrete mix

specimens to higher strength mix specimens show that

effectiveness of confinement decreases as the concrete

strength increases (Table 3). For example, if similarly

confined CC (61.85 MPa) and CH (81.80 MPa) specimens are compared, the percentage increase in strength

reduced from 68 to 41% and I10 ductility decreased from

8.58 to 7.64 from former to latter. Therefore, if the same

levels of strength and ductility enhancements are desired,

higher strength concrete columns shall require more confinement than lower strength concrete columns.

5.2 Volumetric ratios and spacing of lateral steel

The importance of the amount of lateral confining steel

as a factor that affects the behavior of confined concrete

is well recognized. An increase in the volumetric ratio of

confinement steel may be directly translated into a proportional increase in lateral confining pressure. Also, the

spacing of transverse reinforcement is an important parameter that affects the distribution of confinement pressure on the confined core in addition to the stability of

274

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

longitudinal bars. Fig. 9 demonstrates the effect of the

volumetric ratio of confining reinforcement on the behavior of a few confined high strength concrete columns

of the study. These columns also have different spacing

of lateral steel spirals or ties. As expected, the larger the

volumetric ratio or closer the spacing of lateral steel, the

more ductile is the behavior of columns. The columns

with low volumetric ratio or increased spacing of lateral

steel exhibit brittle behavior, showing faster rate of

CA

62.20 MPa

1.6

1.4

Pc/Poc, Pc/Pocc

Relative Concrete Load ,

1.8

CD

63.35 MPa

CB

62.80 MPa

1.2

1

0.8

0.6

CF

81.75 MPa

0.4

0.2

CI

82.55 MPa

CG

83.15 MPa

0

0

0.02

0.04

0.06

0.08

0.1

Axial Strain

Axial

Strain (mm/mm)

(m m /m m )

(a)

(a)

1.8

Relative Concrete Load ,

P c/P oc, P c/P occ

1.6

SD

63.35 M Pa

1.4

SA

62.20 M Pa

1.2

SB

62.80 M Pa

1

0.8

SI

82.55 M Pa

0.6

0.4

SF

81.75 M Pa

0.2

0

0

S G 8 3 .15 M P a

0.02

0.04

0.06

0.08

0.1

Axial Strain (m m /m m )

(b)

Fig. 8 Effect of concrete strength on the behavior of confined concrete: (a) Circular columns & (b) Square columns.

strength decay after the peak. An increase of 32 % in

strength, 270% in strain ductility (c50c/co) and 58.27 %

in I10 ductility was noticed for the higher concrete

strength mix circular columns as the volumetric ratio of

spirals increased from 2.2% to 5.5%. Similarly 25% gain

in strength, 236% enhancement in strain ductility and

90% increase in I10 ductility were observed for higher

strength concrete mix square columns due to the increase

in volumetric ratio of lateral ties from 2.2% to 5.5%.

5.3 Yield strength of transverse steel

The effect of yield strength of transverse confining steel

was investigated by comparing results of two pairs each

of circular and square columns. The compared specimens of each pair had the same concrete strength as well

as the same volumetric ratio, arrangement, and spacing

of lateral steel but different yield strengths (Fig. 10). In

general, it is observed that as the yield strength is increased from 412 MPa to 520 MPa, the strength and

deformability of confined concrete get improved. However, for the range of steel grades used in this study, the

results show that the effect of increasing yield strength

of lateral steel has not very significant effect on the behavior of high strength concrete columns. The maximum

enhancements of 5% in strength and 10% in I10 ductility

were observed. This may be due to the reason and as

mentioned in the earlier section also, that the transverse

steel of only well confined specimens reached its yield

value at peak-confined stress of concrete and that too for

mostly lower concrete strength circular columns only.

The values of stress, fhcc, in lateral steel at peak confined

stress of different specimens are given in Table 3. The

passive confinement pressure is generated from the tensile forces that develop in the lateral confining steel.

However, tensile stress in transverse steel is generated as

a result of lateral expansion of the core concrete, which

in turn is dependent upon the characteristics of concrete.

The higher strength concrete exhibits less lateral expansion than lower strength concrete under axial loads due

to its higher modulus of elasticity and its lower internal

micro cracking. Therefore, the advantages of providing

higher yield strength lateral steel in high strength concrete columns can be realized only if considerably higher

2

1.6

SE

s = 30 mm

s = 5 .5 %

1.4

1.2

1

Relative Concrete Load

P c/P oc, P c/P occ

Relative Concrete Load

P c/P oc, P c/P occ

CE

s = 30 mm

s = 5 .5 %

1.8

SF

s = 50 mm

s = 3 .3 %

0.8

0.6

0.4

CG

s = 75 mm

s = 2 .2 %

0.2

0

0

0.01

CF

s = 50 mm

s = 3 .3 %

0.02

SG, s = 75 mm

s = 2 .2 %

0.03

0.04

0.05

0.06

1.8

CC

1.6

f yh = 520 MPa

1.2

0.07

Fig. 9 Effect of volumetric ratio and spacing of lateral steel.

SC

SH

f y h = 520 MPa

f yh = 520 MPa

1

0.8

CA

f yh = 412 MPa

0.6

0.4

SA

CF

0.2

Axial Strain (m m/mm )

CH

f yh = 520 M Pa

1.4

f y h = 412 MPa

f y h = 412 MPa

0.01

0.02

0.03

0.04

0.05

SF

f yh = 412 MPa

0

0.06

0.07

0.08

0.09

0.1

0.11

Axial Strain (m m /m m )

Fig. 10 Effect of yield strength of lateral steel.

0.12

275

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

5.5 Amount of longitudinal reinforcement

Fig. 12 shows the two different pairs of circular specimens, and for each matched pair, two specimens varying

only in their ratios of longitudinal reinforcement are

compared. It may be mentioned here that this type of

comparison was not possible in case of square columns

because, in addition to amount of longitudinal steel,

volumetric ratios of lateral ties were also varying for any

two comparable specimens. The results show (Table 3)

that the strength and deformability gains are equal to

0.4% and 6.4% for the pair CA-CD and 1.2% and 11%

for the pair CF-CI, respectively. Therefore, based upon

the results it can be said that the amount of longitudinal

steel has only little effect on the behavior of confined

concrete, which might be because of the reason that larger longitudinal bar diameters prevent their premature

buckling.

5.6 Section geometry

It is well established now that circular spirals are more

effective in confining concrete than rectilinear ties owing

to their better uniform distribution of lateral confining

pressure around the core compared to the case of square

or rectangular ties (Mander 1988; Razvi & Saatcioglu

1996). In the present study this variable was investigated

extensively to quantify its effect in case of confinement

1.6

Relative Concrete Load

Pc/Poc, Pc/Pocc

1.4

1.2

SI

1

0.8

SE

0.6

0.4

0.2

0

0

0.01

0.02

0.03

0.04

Axial Strain (m m /m m )

Fig. 11 Effect of configuration of lateral ties.

1.8

Relative Concrete Load

P c/P oc, P c/P occ

5.4 Configuration of lateral steel

The transverse steel configuration and the resulting distribution of the longitudinal steel play a significant role

in the confinement of concrete. If the lateral confining

pressure applied by the transverse reinforcement on concrete is well distributed around the perimeter of the core

concrete, the efficiency of confinement is improved. In

this study it was possible to observe the effect of varying

the lateral steel configuration by comparing the behavior

of square column specimens SE and SI, which have almost, equal volumetric ratio of lateral steel (Fig.11). The

specimen SE was constructed using single perimeter tie

(4 bar arrangement), and SI specimen had double tie

configuration (8 bar arrangement). The ductility indices

(I10) of the specimens SE and SI were 6.44 and 7.86,

respectively indicating a 22% improvement in ductility

of specimen SI which has better steel configuration.

However, the ratio Pcc/Pocc is equal to 1.382 and 1.43 for

specimens SE and SI respectively showing strength enhancement of only 3.5%. This indicates that the improvements in deformability are more marked than in

strength due to better configuration of transverse steel.

Therefore, according to the test results, transverse steel

configuration and the resulting distribution of longitudinal steel has a considerable effect on the ductility of the

confined concrete but insignificant effect on its strength.

of high strength concrete columns. However, only a few

representative comparisons are shown in Fig. 13 with

respect to this parameter. The specimens of each

matched pair have similar concrete strength and volumetric ratios of lateral steel. It is clear from this figure

that circular confinement is substantially more effective

than rectilinear confinement in case of high strength concrete also as evidenced by the margin of increase in

1.6

CD

l = 3.84

1.4

1.2

CI

l = 3.84 %

CA

l = 1.7 %

0.8

0.6

0.4

CF

0.2

l = 1.7 %

0

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Axial Strain (m m /m m )

Fig. 12 Effect of amount of longitudinal steel.

2

1.8

Relative Concrete Load

P c/P oc, P c/P occ

amount of confinement is provided to generate enough

lateral expansion of core so that yield strength of high

yield strength lateral steel is fully developed prior to

appreciable post-peak strength decay.

1.6

1.4

CC

1.2

CE

1

0.8

SC

0.6

SE

0.4

0.2

0

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Axial Strain (m m /m m )

Fig. 13 Effect of section geometry on confined concrete.

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

strength and ductility from square to circular columns.

The square columns SC and SE failed in a comparatively

brittle fashion at 0.0042 and 0.0051 axial strains respectively, while the matched circular columns CC and CE

were able to develop axial strains of 0.0081 and 0.0074

respectively without any strength decay. The maximum

gains of 28% in confined strength (CC vs SC) and 66%

in I10 ductility (CB vs SB) were noticed due to the

change in section geometry. Therefore, if the same percentages of strength and ductility enhancements are desired, square or rectilinearly confined columns are required to be confined more vigorously than circular columns.

6. Design implications for ductility

As a result of some field observations regarding the performance of columns after major earthquakes, it is now

well established that despite following the strongcolumn weak-beam concept in design, damage could

occur at ends of the columns. Therefore, ductile detailing

of these potential plastic hinge regions of columns becomes even more important when high strength concrete

is employed. One of the ways in which most of the

building codes of various countries ensure ductility in

concrete columns, is by specifying the amount of confining transverse reinforcement in critical regions of columns. However, these code equations specifying the

minimum amount of transverse steel for columns are

empirical and have been developed based upon the experimental data obtained from the testing of normal

strength concrete columns. An attempt has been made in

the present study to work out the confinement requirements of high strength concrete columns, based upon the

present test results. Ideally, the behavior of columns

should be studied under combined axial compression

and bending to assess the ductility performance of confined reinforced concrete and the effect of cyclic loading

should be taken in to account. But, in this study uniaxial

load-strain data of confined concrete column sections

under monotonic loading has been analyzed, and this

should give a reasonable assessment in the first instance

considering it to be an extreme case.

A number of past studies (Sheikh & Uzmeri 1980;

Mander et al 1988, Razvi & Saatcioglu 1994, Foster &

Attard 2001) have indicated that ductility is a function of

effective confinement index k e s f yh / f ' c , where ke is a

confinement effectiveness parameter, which accounts for

configuration of lateral steel and resulting longitudinal

steel distribution. However, the coefficient ke has been

ignored by the present seismic code requirements as indicated by the following relevant expressions of ACI 318

code for rectilinearly confined columns:

s f yh / f ' c 0.18

s f yh / f ' c 0.6(

(4)

Ag

Ac

1)

(5)

In Fig. 14, the I10 ductility index for all the specimens

is plotted against the effective confinement parameter k e s f yh / f ' c . The ke for both spirally confined circular columns and tie confined square columns was

computed using the procedure suggested by Mander et al

(1988). The computed values of confinement index

k e s f yh / f ' c for the various confined specimens are

given in Table 1. In a few columns (CG, SB, SF and SG)

tested in this study, a faster rate of strength decay was

observed after peak. For these columns, an actual value

of I10 ductility could not be obtained. Therefore, for such

cases average values of I10 were calculated by obtaining

the upper and lower bounds (Foster & Attard 2001). A

best fit relationship between I10 and k e s f yh / f ' c was

found from the plot and is given by:

I 10 = 2.89 ln(1000k e s f yh / f ' c ) 0.45

(6)

Foster & Attard (2001) analyzed the test data of 40

concentrically loaded columns tested by Razvi & Saatcioglu (1996) and computed I10 values for all the specimens. For the specimens with I10 < 8 sudden changes in

the load strain data and faster rate of post-peak strength

decay were recorded. However, columns with I10 > 8

exhibited ductile post-peak curves. Therefore, the authors based upon the evaluation of data concluded that

for the regions of moderate seismicity desirable ductility

could be achieved if I10 is more than 8. An analysis of

present test data also reveals that the columns with I10 >

8 showed ductile post-peak load-strain curves with

slower rate of strength decay. So if the same yardstick is

applied on the present test data to achieve a moderate

seismic resistance in terms of ductility, the following

relationship could be derived after substituting the value

of I10 as 8 in equation (6):

k e s f yh / f ' c 0.136

(7)

The equation (7) can be used to design the critical

10

9

8

Ductlity Index I 10

276

7

6

5

4

3

2

1

0

1

10

30

100

Effective Confinem ent Index, k e s f yh /f' c (%)

Fig. 14 I10 ductility index versus effective confinement index.

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

hinge regions of high strength concrete columns. It may

be mentioned here that equation (7) specifies the minimum effective confinement index or ratio for high

strength concrete columns, which includes confinement

effectiveness coefficient (ke <1) unlike equations (4) and

(5) of ACI 318 provisions.

7. Assessment of existing stress-strain

confinement models

The analysis of structural members requires an analytical

model for the full stress-strain relationship of concrete in

compression both in confined and unconfined states. The

analytical models for confined normal strength concrete

based on extensive experimental data are well established. These models, based on the test results of normal

strength concrete columns, might be inadequate for high

strength concrete columns, which possess a less ductile

stress-strain behavior. So the normal strength concrete

models if applied to high strength concrete shall overestimate the ductility. As a result a number of such models

specifically for high strength concrete columns have also

been proposed in the recent past. The following section

provides an overview of these analytical confinement

models that cover high strength concrete with strengths

more than 60 MPa.

Yong, Nour and Nawy (1988)

Yong, Nour and Nawy proposed a model for rectilinearly confined high strength concrete columns. They

tested 24 square prisms that were made of high strength

concrete with compressive strength ranging from 83.6 to

93.5 MPa, confined with square ties with yield strength

of 496 MPa. The variables considered were volumetric

ratio of lateral ties, concrete cover and distribution of

lateral steel. A three-part stress-strain relation was proposed to predict the constitutive behavior of confined

high strength concrete.

Bjerkli, Tomaszewicz and Jansen (1990)

Bjerkli, Tomaszewicz and Jansen proposed a threepart stress-strain curve for high strength concrete columns for both circular and rectilinear cross sectional

shapes based upon their test results. They tested a large

number of plain and confined high strength concrete

columns with compressive strength ranging from 65 to

115 MPa. Both cross sectional shapes i.e. cylinders (150

mm diameter and 500 mm high) and prisms

(150x150x500mm and 300x500x2000mm) were included. The test specimens contained longitudinal steel

but no concrete cover.

Nagashima, Sugano, Kimura and Ichikawa (1992)

Twenty-six prism specimens (225x716mm) of high

strength concrete of strengths 59 and 118 Mpa and laterally reinforced with ties of yield strengths 784 and 1374

MPa were tested by Nagashima, Sugano, Kimura and

Ichikawa. Based on the test results a two-part stressstrain relationship was proposed for confined high

strength concrete columns. The variables taken in to

account were concrete strength, yield strength of lateral

277

steel, tie configuration and spacing of lateral steel.

Muguruma, Nishiyama and Watanabe (1993)

Muguruma, Nishiyama and Watanabe proposed a

three-part stress-strain model for confined concrete

based on their own previous studies. A wide range of

concrete strength ranging from 40 to 130 MPa was covered. They tested small square specimens confined laterally by square helix hoops of different yield strengths

and with various volumetric ratios. The yield strengths

of the hoops ranged from 161 to 1353 MPa.

Li, Park and Tanaka (1994)

Li, Park and Tanaka proposed a three-part stress-strain

model for confined high strength concrete based on their

experimental results. Forty reinforced concrete short

columns of both cylindrical (240x720 mm) and square

(240x240x720mm) cross sectional shapes were tested.

The main parameters were in place concrete strength

(35.2 to 82.5 MPa) and lateral steel grade (445 and 1318

MPa) in addition to other parameters like spacing, volumetric ratio and configuration of lateral steel.

Cusson and Paultre (1995)

Cusson and Paultre developed a confinement model

for high strength concrete on the basis of test results of

50 large-scale high strength concrete tied columns tested

under concentric loading. Out of them, 30 HSC tied columns (235x235x1400 mm) were tested by authors themselves and 20 HSC tied columns (225x225x715 mm)

were tested by Nagashima et al. (1992). The concrete

compressive strengths of the specimens ranged from 60120 MPa. The ties with yield strength from 400 to 800

MPa were used. The proposed model takes in to account

tie yield strength, tie configuration, transverse reinforcement ratio, tie spacing, and longitudinal reinforcement ratio. The two-part stress-strain relationship included separate expressions for ascending and descending parts.

Razvi and Saatcioglu (1999)

Razvi and Saatcioglu proposed a model for confined

normal and high strength concrete columns using extensive test data of authors own test results as well as the

experimental results of other research studies. This included the test results of nearly full size specimens of

different shapes, sizes, reinforcement configurations, tie

yield strength (400 to 1387 MPa) and concrete strengths

(30 to 130 MPa). The parameters incorporated in the

model were type, volumetric ratio, spacing, yield

strength, and arrangement of transverse reinforcement,

distribution and amount of longitudinal steel as well as

concrete strength and section geometry. The two part

stress-strain model proposed by the authors was in the

form of the ascending parabolic branch up to peak and a

linear descending branch up to 20% of the peak stress.

Legeron and Paultre (2003)

Legeron and Paultre proposed a stress-strain confinement model for normal and high strength concrete columns based on the large number of test results of circular,

square and rectangular columns tested under various

research studies that included the studies undertaken by

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

cular specimens. In the case of square columns Razvi &

Saatcioglu (1999); Li et al. (1994); Bjerkli et al. (1990)

and Yong et al. (1988) models always overestimated the

experimental stress-strain curves by a considerable margin for all the specimens. The model proposed by Muguruma et al. (1993) produced considerably steeper stressstrain curves for all the specimens that were far below

the actual test curves. Whereas, the models proposed by

Cusson & Paultre (1995) and Nagashima et al. (1992)

continuously underestimated the test curves though; the

predictions were quite close in the latter case for few

specimens. As in the case of circular columns, Legeron

& Paultre (2003) model was also able to produce close

predictions of stress-strain behavior for almost all the

square columns except for few cases like SH specimen

where it slightly overestimated the experimental stressstrain curve. The ability of Legeron & Paultre (2003)

model to consistently follow the actual test behavior for

both circular and square columns undoubtedly proves its

superiority over the other models of the study. Therefore,

the present study concludes that this model can be employed to predict the uniaxial response of high strength

concrete columns with a reasonable degree of accuracy.

120

Razvi

Legero n

B jerkli

100

Experimental.

Li

80

Stress (MPa)

themselves and a number of other researchers. The concrete compressive strengths ranged from 20 to 140 MPa

and tie yield strengths ranged from 300 to 1400 MPa.

The model incorporates almost all the parameters of confinement. The stress strain relationship was basically

same as proposed by Cusson and Paultre (1995), but the

parameters of the model were recalibrated on the basis

of large number of test data collected by the authors.

A critical review of the above models indicate that

most of them have limited validity in terms of concrete

strengths, column geometry, transverse reinforcement

yield strength and loading conditions. With the exception

of the models proposed by Razvi & Saatcioglu (1999);

Legeron & Paultre (2003); Li et al. (1994) and Bjerkli et

al. (1990), which cover both circular and rectilinear sections, all other models are applicable to only square or

rectilinear shapes. The models proposed by Yong et al.

(1988); Nagashima et al. (1992); Li et al. (1994) have

limited applicability for wide concrete strength ranges. It

has been proved experimentally in the present study and

in many earlier studies (Cusson & Paultre 1994; Razvi &

Saatcioglu 1996; Foster 1999) that for high strength concrete columns, lateral-confining ties may not yield when

peak of confined concrete stress-strain is reached. But,

most of the models use lateral steel yield strength to calculate lateral confining pressure at peak-confined

strength. Only Cusson & Paultre (1995); Razvi & Saatcioglu (1999) and Legeron & Paultre (2003) have incorporated this fact into their respective models by proposing procedures to calculate actual tie stress at peak of

confined stress-strain response. Li et al. (1994) has also

accounted for this indirectly by suggesting different expression for confined strength when higher grades of

lateral steel are to be used, but no explicit expression for

finding the actual tie stress at peak was proposed. There

is hardly any one model, which takes into account all the

loading conditions namely monotonic, cyclic, strain rates

and eccentric loading into account.

To investigate the relative performance of the various

proposed analytical models (as listed above) with regards to their capabilities of predicting the experimentally observed stress-strain profile, stress-strain curves of

the test specimens of present study were compared with

the ones predicted by the various models. It may again

be mentioned here that all the eight confinement models

of the study are applicable to square sections whereas

only four namely Razvi & Saatcioglu (1999); Legeron &

Paultre (2003); Li et al. (1994) and Bjerkli et al. (1990)

can be applied to circular columns. Figures 15 to 22

illustrate the comparisons of the experimental and predicted stress-strain curves of a few representative test

specimens only. The comparisons for circular columns

indicate that Razvi & Saatciouglu (1999) and Li et al.

(1994) models consistently overestimate the actual test

behavior, while Bjerkli et al. (1990) model underestimates the test curves. Legeron & Paultre (2003) model

closely follows the experimental stress-strain curves

though, with a slight overestimation, for most of the cir-

60

40

20

CA

0

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

Strain (m m /m m )

Fig. 15 Comparison of confined axial stress- strain

curves for CA specimen.

Razvi

Legero n

B jerkli

120

Experimental.

Li

100

Stress (MPa)

278

80

60

40

CC

20

0

0

0.01

0.02

0.03

0.04

Strain (m m /m m )

Fig. 16 Comparison of confined axial stress-strain curves

for CC specimen.

279

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

120

160

Razvi

Legero n

B jerkli

140

Experimental

Li

120

Cusso n

Experimental

Li

M uguruma

80

Stress (MPa)

Stress (MPa)

Nagashima

Razvi

Legero n

B jerkli

100

100

80

60

60

40

40

20

SC

CE

20

0

0

0.01

0.02

0.03

0.04

0.005

0.01

Fig. 17 Comparison of confined axial stress-strain curves

for CE specimen.

120

120

0.02

0.025

0.03

Fig. 20 Comparison of confined axial stress-strain curves

for SC specimen.

140

Razvi

Legeron

B jerkli

0.015

Strain (m m /m m )

Strain (m m /m m )

Experimental

Li

100

Nagashima

Cusson

Razvi

Experimental

Legeron

Li

Bjerkli

M uguruma

Yong

80

Stress (MPa)

Stress (MPa)

100

80

60

40

60

40

20

20

SD

CI

0.01

0.02

0.03

0.04

0.01

Strain (m m /m m )

0.02

0.03

0.04

Strain (m m /mm )

Fig. 18 Comparison of confined axial stress-strain curves

for CI specimen.

Fig. 21 Comparison of confined axial stress-strain curves

for SD specimen.

120

100

Nagashima

Razvi

Legero n

B jerkli

80

Cusso n

Experimental

Li

M uguruma

100

Nagashima

Cusson

Razvi

Experiment al

Bjerkli

Legeron

M uguruma

Li

Yong

Stress (MPa)

Stress (MPa)

80

60

40

20

60

40

20

SA

SH

0

0

0.005

0.01

0.015

0.02

0.025

Strain (m m /m m )

0.005

0.01

0.015

0.02

0.025

Strain (m m /m m )

Fig. 19 Comparison of confined axial stress-strain curves

for SA specimen.

Fig. 22 Comparison of confined axial stress-strain curves

for SH specimen.

8. Conclusions

umns subjected to concentric axial compression. The test

variables are volumetric ratio and spacing of transverse

reinforcement, yield strength of transverse reinforcement,

longitudinal reinforcement ratio, lateral steel configura-

This paper presents the results of spirally confined circular and tie confined square high strength concrete col-

280

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

tion, shape of cross section and concrete compressive

strength. A comparative study of existing stress-strain

models for high strength concrete columns is also reported. The following conclusions can be made based

upon this study.

1. High strength concrete columns show brittle behavior

unless the columns are confined with sufficient lateral

reinforcement that can provide adequately high lateral

confining pressure. A consistent decrease in strength

enhancement and deformability of columns is observed with increasing concrete strength. Therefore, a

higher degree of confinement is required in columns

with higher concrete strength than in a column with

lower concrete strength to achieve similar advantages.

2. High strength concrete columns suffer from the problem of premature cover spalling which reduces the

column load carrying capacity to even less than unconfined strength if sufficient confinement is not provided. The post spalling behavior depends very much

on the degree and efficiency of confinement.

3. Among the test variables studied, volumetric ratio and

spacing of lateral steel has a more pronounced effect

on the behavior of confined columns than the other

parameters like yield strength of lateral steel, longitudinal steel ratio and configuration of lateral steel

though, improvement in each of the variables considered, translated into enhancements in strength and

ductility. However, increasing the yield strength of

lateral steel seems to give benefits only when a column has high volumetric ratio and efficient arrangement of lateral steel.

4. The ductility of columns is shown to be dependent on

effective confinement index k e s f yh / f ' c . It is concluded that for regions of moderate seismicity, the

critical hinge regions of high strength concrete columns should have effective confinement index of

more than 0.136 to achieve adequate ductility.

5. A comparative study is undertaken to evaluate the

capabilities of the various confinement models of high

strength concrete columns to predict the actual experimental behavior. The study indicated that almost

all the models are able to estimate correctly ascending

part of stress-strain curve. But, there are wide variations in the prediction of the post-peak part of stressstrain curves, with a few models underestimating and

a few overestimating the test behavior except the

Legeron and Paultre (2003) model, which consistently

predicted experimental results with least amount of

discrepancy. Therefore, the present study concludes

that the Legeron and Paultre (2003) model can be

used to analytically predict the uniaxial response of

high strength concrete columns with a reasonable degree of accuracy.

Notations

Ag = gross area of column cross section including area

of longitudinal steel bars.

Ac = gross area of concrete in the section

Acc = core concrete area

Ast = sectional area of longitudinal reinforcement

Ec = tangent modulus of elasticity of concrete

fc = cylinder compressive strength of concrete

fyh = yield strength of tie steel

fy

= yield strength of longitudinal steel

fhcc = stress in lateral steel at peak stress of confined

concrete

Pmax = maximum applied load on the column

Pc

= concrete load corresponding to first peak

Pcc = peak confined concrete load (corresponding to

second peak)

Po = theoretical load carrying capacity of column including longitudinal bars

Poc = theoretical capacity of concrete in the column

Poc c = theoretical capacity of concrete core

s

= spacing of lateral steel

s = volumetric ratio of lateral steel

l = volumetric ratio of longitudinal steel

co = unconfined strain of concrete column

c50o = axial strain at which the stress drops to 50% of

peak in unconfined concrete

= axial strain corresponding to the first peak, Pc

cc = axial strain at peak confined load, Pcc.

c50c = axial strain at which the stress drops to 50% of

peak in confined concrete

yh = yield strain of reinforcement.

References

Bjerkli, L., Tomaszewicz A. and Jansen J. J. (1990).

Deformation properties and ductility of high strength

concrete. Proceedings of Second International

Symposium on Utilization of High Strength Concrete,

Berkley, California, 215-238.

Cusson, D. and Paultre, P. (1994). High strength

concrete columns confined by rectangular ties. ASCE

Journal of Structural Engineering, 120 (3), 783-804.

Cusson, D. and Paultre, P. (1995). Stress-strain model

for confined high strength concrete. ASCE Journal

of Structural Engineering, 121 (3), 468-477.

Foster, S. J. (1999). Design and detailing of high

strength concrete columns. Research Report No. R375, University of New South Wales, Sydney,

Australia.

Foster, S. J. (2001). On behavior of high strength

concrete columns: cover spalling, steel fibers, and

ductility. ACI Structural Journal, 98 (4), 583-589.

Foster, S. J. and Attard, M. M. (2001). Strength and

ductility of fiber reinforced high strength concrete

columns. ASCE Journal of Structural Engineering,

127 (1), 281-289.

Joint ACI-ASCE Committee (1997). High Strength

Concrete Columns: State of the Art. Report No. ACI441R-96, ACI Structural Journal, 94 (5), 323-335.

Li, B. Park, R. and Tanaka, H. (1994). Strength &

ductility of reinforced concrete members and frames

constructed using high strength concrete. Research

report No. 94-5, University of Canterbury,

U.K. Sharma, P. Bhargava and S.K. Kaushik / Journal of Advanced Concrete Technology Vol. 3, No. 2, 267-281, 2005

Christchurch, New Zealand.

Legeron, F. and Paultre, P. (2003). Uniaxial

confinement model for normal and high strength

concrete columns. ASCE Journal of Structural

Engineering, 29(2), 241-252.

Mander, J. B., Priestly, M. J. N. and Park, R. (1988).

Theoretical stress-strain model for confined

concrete. ASCE Journal of Structural Engineering,

114 (8), 1804-1826.

Muguruma, H., Nishiyama, M. and Watanabe, F. (1993).

Stress strain curve for concrete with a wide range of

compressive strength. Proceedings of Symposium on

High Strength Concrete, California, 314-321.

Nagashima, T., Sugano, S., Kimura, H. and Ichikawa, A.

(1992). Monotonic axial compression test on ultrahigh strength concrete tied columns. Proceedings of

10th World Conference on Earthquake Engineering.

Balkema, Rotterdam , The Netherlands, 2983-2988.

Park, R., Priestly, M. J. N. and Gill, W. D. (1982).

Ductility of square confined concrete columns.

ASCE Journal of Structural Division, 108 (4), 929951.

Pessiki, S. and Pieroni, A. (1997). Axial load behavior

of large scale spirally reinforced high strength

281

concrete column. ACI Structural Journal, 94 (3),

304-314.

Richart, F. E., Brandtzaeg, A. and Brown, R. L. (1928).

A study of failure of concrete under

combined

compressive stresses. Engineering Experiment

Station Bulletin No. 185, University of Illinois,

Urbana.

Razvi, S. and Saaticioglu, M. (1994). Strength and

deformability of confined high strength concrete

columns. ACI Structural Journal, 91 (6), 678-687.

Razvi, S. and Saatcioglu, M. (1996). Tests of high

strength concrete under concentric loading. Report

No.

OCEERC

96-03,

Carleton

Earthquake

Engineering Research Centre, Ottawa, Canada.

Razvi, S. R. and Saatcioglu, M. (1999). Confinement

model for high strength concrete. ASCE Journal of

Structural Engineering, 125 (3), 281-289.

Sheikh, S. A. and Uzmeri, S. M. (1980). Strength and

ductility of tied concrete columns. ASCE Journal of

Structural Division, 106 (5), 1079-1102.

Yong, Y. K., Nour, M. G. and Nawy, E. G. (1988).

Behavior of laterally confined high strength concrete

under axial loads. ASCE Journal of Structural

Engineering, 114 (2), 332-351.

Anda mungkin juga menyukai

- ConcreteFilledSteelTubesSubjectedToAxialCompression Fam QieDokumen41 halamanConcreteFilledSteelTubesSubjectedToAxialCompression Fam QieTejaswini TejuBelum ada peringkat

- 7.ISCA JEngS 2012 026Dokumen5 halaman7.ISCA JEngS 2012 026Turcu Catalin NicolaeBelum ada peringkat

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDokumen6 halamanStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresBelum ada peringkat

- Behavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic LoadingDokumen8 halamanBehavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic Loadingbravo deltafoxBelum ada peringkat

- Sand 4Dokumen17 halamanSand 4Pavan MBelum ada peringkat

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Dokumen16 halamanElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninBelum ada peringkat

- Torsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementDokumen8 halamanTorsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementSuhas Natu100% (1)

- Flexural Behaviour of High-Strength Rectangular Concrete-Filled Steel Hollow SectionsDokumen16 halamanFlexural Behaviour of High-Strength Rectangular Concrete-Filled Steel Hollow SectionsnurhishammBelum ada peringkat

- Camasuire Stalp Cu FerocimentDokumen8 halamanCamasuire Stalp Cu FerocimentChelemen MaryaBelum ada peringkat

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsDokumen10 halamanSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinBelum ada peringkat

- Performance Investigation of Square Concrete-Fi Lled Steel Tube ColumnsDokumen7 halamanPerformance Investigation of Square Concrete-Fi Lled Steel Tube Columnsjoamirhenrique_10316Belum ada peringkat

- Advances in Civil Engineering Tests of Inclined Concrete - Filled Steel Tubular Stub Columns Under Vertical Cyclic LoadingDokumen12 halamanAdvances in Civil Engineering Tests of Inclined Concrete - Filled Steel Tubular Stub Columns Under Vertical Cyclic LoadingChayanon HansapinyoBelum ada peringkat