151 Inste

Diunggah oleh

Taimoor AhmedJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

151 Inste

Diunggah oleh

Taimoor AhmedHak Cipta:

Format Tersedia

DKG-151

MANUAL START UNIT

INSTALLATION AND OPERATING INSTRUCTIONS

DESCRIPTION

The model DKG-151 is a microprocessor controlled

unit used to start and stop the genset manually

using the key switch and pushbuttons on the front

panel.

When the engine is running, the unit monitors fault

conditions and shuts-down the engine automatically

in the occurrence of an alarm. The alarms are

identified by a group of LEDs displaying only the

first occurring one.

The unit has jumper selectable options for 50/60Hz

nominal frequency and the auxiliary relay output

function. The selection is made by the position of a

single jumper situated at the left side panel of the

unit.

If the jumper is placed between:

A & B : 50 Hz nominal, AUX is Preheat output

B & C : 60 Hz nominal, AUX is Preheat output

C & D : 60 Hz nominal, AUX is Stop output

D & A : 50 Hz nominal, AUX is Stop output

In the OFF position, the DC supply is removed from

the module, thus zero power consumption is

achieved.

OPERATION

The unit powers up when the RUN position on the

front panel is selected. If required, the

PREHEAT/STOP (

) button may be depressed

as long as needed. This will activate the

AUXILIARY relay output and the related front panel

led marked (

).

The engine is started using the pushbutton marked

CRANK (I). This will also energize the fuel solenoid

relay. Once the engine is running, the switch should

be released. However the internal logic inhibits

cranking when the engine fires up.

The alarm checking is only enabled after the

protection hold-off timer is expired. This timer

resets to 12 seconds if:

-the unit is powered up,

-or CRANK (I) button is pressed,

-or PREHEAT/STOP (

) button is pressed,

-or the engine gets running.

The occurrence of below fault signals (which are

close on fault) will cause the engine to be stopped

immediately:

-Overspeed,

-Underspeed,

-High engine temperature,

-Low oil pressure,

-Auxiliary shutdown.

If a fault condition occurs, the FUEL solenoid will

be deenergized. If the auxiliary relay output is set to

Stop option, the AUXILIARY relay output will be

energized during stop timeout and the led

associated with this condition will turn on. To reset

the fault condition, turn the switch to the OFF

position for a few seconds.

The Charge Fail input is treated as a warning only

and do not cause the engine to stop. The input

monitors the D+ terminal of the charge alternator.

To shut-down the engine manually:

-if the AUX output is set to Stop option, press the

PREHEAT/STOP (

) button until the engine

comes to rest. Then select the OFF position on the

switch.

-else select the OFF position on the switch.

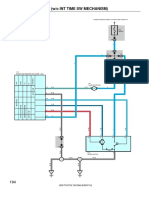

TYPICAL CONNECTION DIAGRAM

INPUTS

OPTIONAL FEATURES:

(SUBJECT TO SPECIAL ORDER)

DC SUPPLY: 12 or 24 volts DC, (+) and (-) terminals.

L1: Generator phase voltage.

NEUTRAL: Generator neutral terminal.

HIGH TEMP SWITCH: Negative closing switch input.

LOW OIL PRESSURE: Negative closing switch input.

AUX: Spare fault input. A negative supply connection

to this input will cause the engine immediately stopped

and an alarm given (independent of the protection

hold-off timer).

CHARGE: Connect the charge alternators D+ end to

this terminal. This terminal will supply the excitation

current and measure the voltage of the charge

alternator.

OUTPUTS

FUEL SOLENOID

START

AUXILIARY

: 10amps@28V-DC.

: 10amps@28V-DC.

: 10amps@28V-DC.

OPTIONS

JUMPER SELECTABLE STANDARD

FEATURES:

Engine control (without alternator),

Remote start input (DKG-152),

Negative pulling semiconductor outputs (DKG-153).

TECHNICAL SPECIFICATIONS

Alternator Voltage: 15 to 300 V-AC

Alternator Frequency: 50 or 60 Hz nominal.

Overspeed: nominal frequency + 14%

(+24% overshoot)

Underspeed: 25Hz

DC Supply Range: 8 to 33 V-DC.

Current consumption: 80mA max. (Relay outputs

open).

Charge fail threshold: 6 V-DC.

Charge excitation current: via 82 ohms resistor

connected to the FUEL output.

Stop Timeout: 30 sec.

Operating temp.: -20C (-4F) to 70 C (158F).

Storage temp.: -30C (-22F) to 80 C (176F).

Maximum humidity: 95% non-condensing.

Dimensions: 72x72x38mm (WxHxD)

Panel cutout dimensions: 68x68 mm

Weight: 140g (approx.)

Installation: Front panel mounted. Retaining steel

spring provided.

Genset control,

Activate to Start,

Energize to Stop,

50Hz nominal,

60Hz nominal.

DATAKOM Electronics Ltd.

Tel: +90-216-466 84 60 Fax: +90-216-364 65 65 e-mail: datakom@datakom.com.tr http: www.datakom.com.tr

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- New Wiring Diagram Electric EMS2-tad1640ge PDFDokumen2 halamanNew Wiring Diagram Electric EMS2-tad1640ge PDFVanHoang95% (22)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Toyota B EngineDokumen26 halamanToyota B EngineTaimoor Ahmed100% (2)

- 1ktze Pinin-PinoutDokumen11 halaman1ktze Pinin-PinoutKooked100% (9)

- Toyota 1KZ-TE EngineDokumen2 halamanToyota 1KZ-TE EngineJia Sajeel75% (12)

- Volvo Penta 16 Manual PDFDokumen76 halamanVolvo Penta 16 Manual PDFtonyeld100% (2)

- Renault K-Type EngineDokumen24 halamanRenault K-Type EngineTaimoor AhmedBelum ada peringkat

- Renault K-Type EngineDokumen24 halamanRenault K-Type EngineTaimoor AhmedBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- System Analysis and Design - Chapters 1-7 Study GuideDokumen21 halamanSystem Analysis and Design - Chapters 1-7 Study GuideLoretta Lynn Altmayer75% (4)

- 2011 ESedan WagonDokumen22 halaman2011 ESedan WagonlsybounBelum ada peringkat

- Turn Signal and Hazard Warning Light: 2003 Toyota Tacoma (Ewd517U)Dokumen2 halamanTurn Signal and Hazard Warning Light: 2003 Toyota Tacoma (Ewd517U)Taimoor AhmedBelum ada peringkat

- Design of Digitally Controlled Solid State Soft Starter For Induction MotorDokumen6 halamanDesign of Digitally Controlled Solid State Soft Starter For Induction MotorDesign Department AEMBelum ada peringkat

- WIPER AND WASHER SYSTEM OVERVIEWDokumen2 halamanWIPER AND WASHER SYSTEM OVERVIEWTaimoor AhmedBelum ada peringkat

- Gen2 Brochure WHQ EN 0518 USLetter Final Lowres PDFDokumen15 halamanGen2 Brochure WHQ EN 0518 USLetter Final Lowres PDFTaimoor AhmedBelum ada peringkat

- 2010 E Class PDFDokumen14 halaman2010 E Class PDFTaimoor AhmedBelum ada peringkat

- Tad1641ge PDFDokumen2 halamanTad1641ge PDFjuanBelum ada peringkat

- BMW - US 5series - 2010 PDFDokumen36 halamanBMW - US 5series - 2010 PDFTaimoor AhmedBelum ada peringkat

- Creating a new history with machine room-less elevatorsDokumen20 halamanCreating a new history with machine room-less elevatorsTaimoor Ahmed100% (1)

- VFI-II (Revised 2018.12.20)Dokumen28 halamanVFI-II (Revised 2018.12.20)Taimoor AhmedBelum ada peringkat

- Depmrlwline019aff PDFDokumen15 halamanDepmrlwline019aff PDFTaimoor AhmedBelum ada peringkat

- Renault K-Type Engine - WikipediaDokumen1 halamanRenault K-Type Engine - WikipediaTaimoor AhmedBelum ada peringkat

- 1306C E87tag6 PDFDokumen2 halaman1306C E87tag6 PDFMarran Almarrani100% (1)

- 1300 PerkinsDokumen40 halaman1300 PerkinsTony Apps93% (14)

- Cliafkd Allo: Instruction Handbook Car DoorsDokumen44 halamanCliafkd Allo: Instruction Handbook Car DoorsTaimoor AhmedBelum ada peringkat

- Perkins 20 KvaDokumen1 halamanPerkins 20 KvaTaimoor AhmedBelum ada peringkat

- Alt16installinstruct PDFDokumen12 halamanAlt16installinstruct PDFTaimoor AhmedBelum ada peringkat

- Cliafkd Allo: Instruction Handbook Car DoorsDokumen44 halamanCliafkd Allo: Instruction Handbook Car DoorsTaimoor AhmedBelum ada peringkat

- Eco+ Augusta: Instruction HandbookDokumen48 halamanEco+ Augusta: Instruction HandbookTaimoor AhmedBelum ada peringkat

- 5L-E Engine: DescriptionDokumen2 halaman5L-E Engine: DescriptionTaimoor AhmedBelum ada peringkat

- DKG-154 Remote Start Unit: Installation and Operating InstructionsDokumen2 halamanDKG-154 Remote Start Unit: Installation and Operating InstructionsTaimoor AhmedBelum ada peringkat

- CD 1 Install InstructDokumen16 halamanCD 1 Install InstructTaimoor AhmedBelum ada peringkat

- Diesel EngineDokumen1 halamanDiesel EngineTaimoor Ahmed100% (1)

- Workshop 4Dokumen4 halamanWorkshop 4Nguyễn LộcBelum ada peringkat

- Verona Manual v1 1x EnglishDokumen46 halamanVerona Manual v1 1x EnglishShameem AhmodBelum ada peringkat

- Hart Chapter 9 SolutionsDokumen23 halamanHart Chapter 9 SolutionsCassio SchefferBelum ada peringkat

- BSC ZeolDokumen17 halamanBSC Zeoladam135Belum ada peringkat

- 27030422-ACOMT2A04 DatasheetDokumen3 halaman27030422-ACOMT2A04 DatasheetJorge VieiraBelum ada peringkat

- Our Presentation On Chapter 3 of CDokumen21 halamanOur Presentation On Chapter 3 of COckouri BarnesBelum ada peringkat

- Bit Stuffing ProgramDokumen3 halamanBit Stuffing ProgramKelvin CooperBelum ada peringkat

- Guide macOS Mojave On Dell Latitude E6x20Dokumen5 halamanGuide macOS Mojave On Dell Latitude E6x20Maurilio MatosBelum ada peringkat

- Cobos V3.0 QuickstartDokumen42 halamanCobos V3.0 QuickstartWellington MarquesBelum ada peringkat

- Sol Midterm 1Dokumen6 halamanSol Midterm 1Mutale Chisanga100% (1)

- Technical Specification For Laptop and Desktop MOEDokumen4 halamanTechnical Specification For Laptop and Desktop MOEbetifeleke1Belum ada peringkat

- List of 7400 Series Integrated CircuitsDokumen13 halamanList of 7400 Series Integrated CircuitsSalvador Flores TorresBelum ada peringkat

- S272 User Manual V2.5Dokumen49 halamanS272 User Manual V2.5Lauren AdolfBelum ada peringkat

- Java Card 222 JC RespecDokumen148 halamanJava Card 222 JC Respecpramendra10Belum ada peringkat

- Ah en Safety Characteristics 105016Dokumen37 halamanAh en Safety Characteristics 105016Dulce Martinez TolentinoBelum ada peringkat

- BGP Flowspec Conceptual ArchitectureDokumen26 halamanBGP Flowspec Conceptual ArchitecturemorpheusnaakBelum ada peringkat

- Cell Phone Detector ProjectDokumen20 halamanCell Phone Detector ProjectRavi Krian100% (1)

- Norton TheoremDokumen5 halamanNorton TheoremShameek PathakBelum ada peringkat

- (Slides Note) 09 ISFT Acquisition and Preservation VE - MHHDokumen40 halaman(Slides Note) 09 ISFT Acquisition and Preservation VE - MHHsdfd84932Belum ada peringkat

- The Circuit Diagram of Three Phase Inverter Given Below. The Circuit Consists of Six Switching Devices Like MOSFETDokumen11 halamanThe Circuit Diagram of Three Phase Inverter Given Below. The Circuit Consists of Six Switching Devices Like MOSFETKhadija HanifBelum ada peringkat

- 2B +RC+Triggering+CircuitDokumen3 halaman2B +RC+Triggering+CircuitklascoolBelum ada peringkat

- 1-Peterson-Computer Science NotesDokumen7 halaman1-Peterson-Computer Science Notesapi-302957605Belum ada peringkat

- Fire Extinguisher Robot Using ArduinoDokumen22 halamanFire Extinguisher Robot Using ArduinoMonica ChakrabortyBelum ada peringkat

- Configuring a DeltaV Batch system in 17 stepsDokumen5 halamanConfiguring a DeltaV Batch system in 17 stepsSd Weds DsBelum ada peringkat

- Structorizer User GuideDokumen177 halamanStructorizer User GuideNicolas Bonacchi33% (3)

- YH Microprocessors-6 Memory ElementsDokumen73 halamanYH Microprocessors-6 Memory ElementsMurad QəhramanovBelum ada peringkat

- CSEE W3827 Fundamentals of Computer Systems Homework Assignment 1Dokumen11 halamanCSEE W3827 Fundamentals of Computer Systems Homework Assignment 1pauline ondisaBelum ada peringkat

- Classes and Data Abstractions Lab ExplainedDokumen8 halamanClasses and Data Abstractions Lab ExplainedHamna BaigBelum ada peringkat

- Tps 65167 ADokumen42 halamanTps 65167 AVikas Deoarshi100% (1)