Guaranteed Data

Diunggah oleh

srigirisetty208Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Guaranteed Data

Diunggah oleh

srigirisetty208Hak Cipta:

Format Tersedia

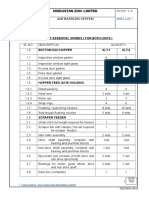

PT.

MADHUCON SRIWIJAYA POWER, INDONESIA

2X150MW MINE MOUTH COAL FIRED TPP

GUARANTEED DATA

SL NO. ITEM

UNIT

SEPCO

(CFD without Coal Drying Plant)

(CFD with Coal Drying Plant)

SDEPCI

(PF with Coal Drying Plant +

(PF without Coal Drying Plant + FGD)

FGD)

GEDI

(CFBC without Coal Drying Plant)

(CFBC without Coal Drying Plant)

Gross Output at the generator terminal at TMCR with excitation

loss deducted

MW

150

150

150

150

2X150

155

Auxiliary Power Consumption at TMCR

MW

17.79

Not furnished

17.98

Not furnished

29.34(9.78%)

14.95

2469

2025.0 (0% make-up)

2X457.5

485 (0% make-up)

2X505

525

2008.8 (Turbine heat rate),

KCal/ KWH 2465.8 (Gross Plant heat

rate)

2008.8 (Turbine heat rate), 2466

(Gross Plant heat rate)

Gross Plant Heat Rate at TMCR

Steam Consumption at TMCR Condition

T/HR

457.5

Not furnished

457.5 Not furnished

Steam Generator Maximum Continuous Rating (SGMCR)

T/HR

510

Not furnished

510 Not furnished

MW

158.128

Not furnished

158.128 Not furnished

VWO output at the generator terminal with excitation loss

deducted

Not furnished

Not furnished

2X157.5

161

Gaseous Emission

SO2 : 750 mg/Nm

Nox: 750 mg/Nm3 ,

SO2 : 750 mg/Nm

Nox: 750 mg/Nm3 ,

SO2 : 750 mg/Nm

Nox: 750 mg/Nm3 ,

SO2 : 750 mg/Nm

Nox: 750 mg/Nm3 ,

Particulate Emission

50 mg/Nm3

50 mg/Nm3

50 mg/Nm3

50 mg/Nm3

Noise Level

85dB(A) (1m from

equipment)

85dB(A) (1m from

equipment)

85dB(A) (1m from equipment)

85dB(A) (1m from

equipment)

Compliance with EPC Bid specification

The max. surface noise level of these

enclosures shall not exceed 85 dB(A)

10

Effluent discharge quality from the Plant

Not furnished

Not furnished

Not furnished

Not furnished

Compliance with EPC Bid specification

Meet the water discharge requirement

11

Coal Handling Plant Performance

660 T/Hr

660 T/Hr

660 T/Hr

660 T/Hr

Compliance with EPC Bid specification

CHP is designed for 8 hrs daily

operation.

SO2 : 650 mg/Nm ,

Nox: 420 mg/Nm3 ,

SO2= 750mg/m3, NOx= 750mg/m3

50 mg/Nm3

50 mg/m3

12

Ash Handling Plant Performance

Fly ash handling: 20 T/hr

Fly ash handling: 20 T/hr

Fly ash handling: 20 T/hr (one

(one unit), Bed ash handling: (one unit), Bed ash handling: unit), Bed ash handling: 20 T/hr

20 T/hr (one unit),

20 T/hr (one unit),

(one unit),

Fly ash handling: 20 T/hr

Compliance with EPC Bid specification

(one unit), Bed ash

handling: 20 T/hr (one unit),

Quantity of ash will be based on firing

worst coal with 100% BMCR operation

of boiler and worst expected ash

distribution in different ash hoppers/

discharge points. Above these, a

margine of 15% will be provided for

each item.

13

Water Pretreatment Plant Performance

1100m3/hr.

1100m3/hr.

1100m3/hr.

1100m3/hr.

Compliance with EPC Bid specification

Meet the plant water requirement

14

Intake System Performance

1052m3/hr.

1052m3/hr.

1052m3/hr.

1052m3/hr.

Compliance with EPC Bid specification

Meet the plant water requirement

15

Demineralisation Plant Performance

50 T/hr.

50 T/hr.

50 T/hr.

50 T/hr.

Compliance with EPC Bid specification

16

Air Conditioning & Ventilation System Performance

Not furnished

Not furnished

Not furnished

Not furnished

Compliance with EPC Bid specification

Meet the AC & Ventilation System

requirement

17

Emergency D.G. Set Performance

Not furnished

Not furnished

Not furnished

Not furnished

720KVA

Meet the Emergency DG set

requirement

18

Coal Drying Plant Performance

Not furnished

Design capacity: 260 T/hr for

worst coal, Consumption of

Not furnished

steam: 30 T/hr for worst coal

Design capacity: 260 T/hr

for worst coal, Consumption

Not furnished

of steam: 30 T/hr for worst

coal

Not applicable

1 of 2

PT. MADHUCON SRIWIJAYA POWER, INDONESIA

2X150MW MINE MOUTH COAL FIRED TPP

North-West DFPS

Shaanxi North- West Power

(CFBC without Coal Drying Plant)

150

152

14.543

12

2375

2401.86

455.2

443

505

478

157.5

160

SO2 = ~300 mg/m ,

Nox = ~ 200 mg/m3

SOx : 400 mg/Nm3, NOx : 300 mg/Nm3,

<50 mg/Nm3

50 mg/Nm3

85 dB(A), for Steam turbine generator & BFW

Pumps: 90dBA (without acoustic enclosure)

Max. surface noise level of noise source: 80 dBA, In the

control rooms: 60 dBA

Zero discharge

Not furnished

660 T/Hr

Rated capacity of CHP: 400t/h

Storage for 4 days

Capacity of fly ash handling system, bottom ash

handling and lime stone handling system are all not

less than 25t/h

1018 T/Hr.

Treated water output of each inclined Plate/ Tube settler: 600

m3/hr, Suspended solids from each inclined Plate/ Tube

settler at rated and overload condition: 15 and 20 mg/l,

Turbidity from each inclined Plate/ Tube settler at rated and

overload condition: 15 and 20 NTU, Processing capacity of

each Gravity filter: 220m3/hr, Total suspended solids from

Gravity filter: 2mg/l, Turbidity from Gravity filter: 2 NTU.

1107 T/Hr

Flow of Raw Water intake pump: 1650 m3/hr.

40 T/hr

Capacity of each DM chain shall not be less than 50

m3/hr.

Comply with requirement

Temperature of Central Control Room: 241 deg. C,

based on Dry bulb temp. 34.4 deg. C & mean

coincident wet bulb temp. 26.8 deg C (design outdoor

condition of PEAKAN BARU in ASHRAE Handbook)

2X(2X200) kW

800kW, power factor : 0.8, efficiency: 94.4%

2X150 T/Hr

Not used

2 of 2

Anda mungkin juga menyukai

- Arar 33kV Cable Sizing ReportDokumen9 halamanArar 33kV Cable Sizing Reportsrigirisetty208Belum ada peringkat

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDokumen3 halaman4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Belum ada peringkat

- NB O&M Brochure 01sept2020Dokumen10 halamanNB O&M Brochure 01sept2020srigirisetty208Belum ada peringkat

- 5C1. Coal Ash Generation Process and Application FieldsDokumen2 halaman5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208Belum ada peringkat

- 4.5 - Dam and Spillway - ElevatorDokumen2 halaman4.5 - Dam and Spillway - Elevatorsrigirisetty208Belum ada peringkat

- 330MW Shrinagar Project Technical Data SheetDokumen4 halaman330MW Shrinagar Project Technical Data Sheetsrigirisetty208Belum ada peringkat

- Care and Maintenance of CFB Boilers Refractory FailureDokumen6 halamanCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZBelum ada peringkat

- Fire Detection and Alarm System Design Basis DocumentDokumen12 halamanFire Detection and Alarm System Design Basis Documentsrigirisetty208Belum ada peringkat

- Boiler Tube Failures Due To Improper CommissioningDokumen21 halamanBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanBelum ada peringkat

- 4.11 - Bypass Channel - Automatic GateDokumen1 halaman4.11 - Bypass Channel - Automatic Gatesrigirisetty208Belum ada peringkat

- 330MW Shrinagar Project Technical Data SheetDokumen4 halaman330MW Shrinagar Project Technical Data Sheetsrigirisetty208Belum ada peringkat

- HZL Ahs EssentialsparesDokumen8 halamanHZL Ahs Essentialsparessrigirisetty208Belum ada peringkat

- 4.19 - Instrumentation and ControlDokumen2 halaman4.19 - Instrumentation and Controlsrigirisetty208Belum ada peringkat

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDokumen3 halaman4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208Belum ada peringkat

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineDokumen2 halaman4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208Belum ada peringkat

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataDokumen2 halaman330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Belum ada peringkat

- 150 MW Coal Fired Power Plant Construction Equipment ListDokumen2 halaman150 MW Coal Fired Power Plant Construction Equipment Listsrigirisetty208Belum ada peringkat

- HZL Chs EssentialsparesDokumen6 halamanHZL Chs Essentialsparessrigirisetty208Belum ada peringkat

- SCH 3A.17 Q.a.assessmentDokumen1 halamanSCH 3A.17 Q.a.assessmentsrigirisetty208Belum ada peringkat

- SCH 3A.9 Places of Mfg.Dokumen1 halamanSCH 3A.9 Places of Mfg.srigirisetty208Belum ada peringkat

- 4.17 - Powerhouse - Powerhouse CraneDokumen3 halaman4.17 - Powerhouse - Powerhouse Cranesrigirisetty208Belum ada peringkat

- HZL Crane EssentialsparesDokumen2 halamanHZL Crane Essentialsparessrigirisetty208Belum ada peringkat

- SCH 3A.11 SparesDokumen3 halamanSCH 3A.11 Sparessrigirisetty208Belum ada peringkat

- Quality Assurance Plan for 2x150 MW Coal Power PlantDokumen1 halamanQuality Assurance Plan for 2x150 MW Coal Power Plantsrigirisetty208Belum ada peringkat

- BFP Drawings PDFDokumen42 halamanBFP Drawings PDFsrigirisetty208Belum ada peringkat

- Sch-3A 14-Perfor GuartDokumen5 halamanSch-3A 14-Perfor Guartsrigirisetty208Belum ada peringkat

- SCH 3A.12 Special Tools &tacklesDokumen3 halamanSCH 3A.12 Special Tools &tacklessrigirisetty208Belum ada peringkat

- Equipment Supply by BidderDokumen6 halamanEquipment Supply by Biddersrigirisetty208100% (2)

- BFP DrawingsDokumen42 halamanBFP Drawingssrigirisetty208Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- EECS Graduate Student Handbook 2009-2010Dokumen33 halamanEECS Graduate Student Handbook 2009-2010Saq IbBelum ada peringkat

- Test Yourself C - BT MLH 12 - KeyDokumen4 halamanTest Yourself C - BT MLH 12 - KeyThao NguyenBelum ada peringkat

- ABB Circit Breaker Trip CurveDokumen1 halamanABB Circit Breaker Trip CurvebjeserviceBelum ada peringkat

- Mep UscgDokumen120 halamanMep UscgAdwaith KrishnanBelum ada peringkat

- Dwa 125RDokumen35 halamanDwa 125RGuillermo HernandezBelum ada peringkat

- Thesis Statement For Fossil Fuel EmissionsDokumen5 halamanThesis Statement For Fossil Fuel Emissionschristinajohnsonanchorage100% (2)

- Aquanet PLUS AC/DC: Reliable Remote Valve OperationDokumen4 halamanAquanet PLUS AC/DC: Reliable Remote Valve OperationCarlos Rovello GandoBelum ada peringkat

- Light Duty Commercial Electric Water Heaters: Junior, Tall & Short Models - 6 To 120 GallonsDokumen2 halamanLight Duty Commercial Electric Water Heaters: Junior, Tall & Short Models - 6 To 120 GallonssasikalaBelum ada peringkat

- Phase 2 PPT FinalDokumen15 halamanPhase 2 PPT FinalRohith Bhanuprakash100% (2)

- Assemble and Disassemble Powersupply 01Dokumen7 halamanAssemble and Disassemble Powersupply 01Lance Axel Husana100% (1)

- 7.two Stage CompressionDokumen22 halaman7.two Stage CompressionAyesha Sarwar100% (1)

- Colicraft Power Transformer DesignDokumen4 halamanColicraft Power Transformer DesignPablo KuziwBelum ada peringkat

- Systems: Lubrication & Filtration, Turbine FoundationsDokumen52 halamanSystems: Lubrication & Filtration, Turbine FoundationsSuriya KJBelum ada peringkat

- 48V Charger DrawingsDokumen13 halaman48V Charger DrawingsMandeep Singh100% (1)

- Thesis Statement For Wind TurbinesDokumen8 halamanThesis Statement For Wind Turbinesdw9x1bxb100% (1)

- Photoelectric PyrometerDokumen13 halamanPhotoelectric PyrometerAvinash Garikapati100% (1)

- Daikinskyairgar 22Dokumen2 halamanDaikinskyairgar 22adehakBelum ada peringkat

- VSP Final ReportDokumen53 halamanVSP Final ReportAnand GautamBelum ada peringkat

- MFB TrainingDokumen19 halamanMFB Trainingragdapattice100% (6)

- Presentation Sharing of ISTS Charges Regulations 2020Dokumen28 halamanPresentation Sharing of ISTS Charges Regulations 2020koinsuriBelum ada peringkat

- The Water CycleDokumen34 halamanThe Water Cycleapi-192449107Belum ada peringkat

- Fluid Mechanics NotesDokumen12 halamanFluid Mechanics Notessubha_aeroBelum ada peringkat

- Eu Energy Security in The Gas SectorDokumen192 halamanEu Energy Security in The Gas Sectorandreadoumaria5Belum ada peringkat

- WBJEE 2014 Chemistry Question Paper With SolutionsDokumen15 halamanWBJEE 2014 Chemistry Question Paper With SolutionsLokesh Kumar50% (2)

- Steady and Unsteady Flow Simulation of A Combined Jet Flap and Coanda Jet Effects On A 2D Airfoil Aerodynamic PerformanceDokumen6 halamanSteady and Unsteady Flow Simulation of A Combined Jet Flap and Coanda Jet Effects On A 2D Airfoil Aerodynamic PerformancefasterBelum ada peringkat

- Natural Gas Liquids (NGL) Recovery in The Liquefied Natural Gas ProductionDokumen6 halamanNatural Gas Liquids (NGL) Recovery in The Liquefied Natural Gas ProductionMary Grace VelitarioBelum ada peringkat

- M Tech I Sem II Mid TDDokumen4 halamanM Tech I Sem II Mid TDMir Mustafa AliBelum ada peringkat

- Biofuels (Studiu de Caz)Dokumen7 halamanBiofuels (Studiu de Caz)Liviu TimothyBelum ada peringkat

- Solar Success Stories: Learn How Cooperatives Are Embracing Renewable EnergyDokumen55 halamanSolar Success Stories: Learn How Cooperatives Are Embracing Renewable EnergyHoangBelum ada peringkat

- Q3 LAW Science 9 WEEKS 3 4 1Dokumen9 halamanQ3 LAW Science 9 WEEKS 3 4 1reynaldo antonioBelum ada peringkat