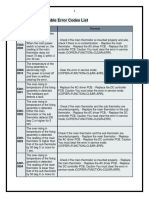

Canon IR3225 Trouble Error Codes

Diunggah oleh

nafeesHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Canon IR3225 Trouble Error Codes

Diunggah oleh

nafeesHak Cipta:

Format Tersedia

1

Canon iR3225 Trouble Error Codes List page 1 (from 16)

Code

Description

Remedy

The temperature of the fixing

assembly is abnormally high.

While startup control is under way, the

reading of the main thermistor is less

than 30 deg C continuously for 200

msec or more 1 sec after the start of

power supply. While startup control is

under way, the reading of the main

E000- thermistor is less than 70 deg C

0001 continuously for 200 msec or more 2

sec after the start of power supply.

While startup control is under way, the

reading of the main thermistor is less

than 120 deg C continuously for 200

msec 6 sec after the start of power

supply. The startup control does not

end 30 sec after the start of power

supply.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the main thermistor. Replace

the DC controller PCB.

The temperature of the fixing

assembly is abnormally high.

E001The reading of the main thermistor is

0000

250 deg C or more continuously for

200 msec.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the main thermistor. Replace

the DC controller PCB.

The temperature of the fixing

assembly is abnormally high.

E001The hardware circuit detects

0001

overheating of the main or sub

thermistor for 200 msec

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the DC controller PCB.

The temperature of the fixing

assembly is abnormally high.

E001The reading of the sub thermistor is

0002

295 deg C or more continuously for

200 msec.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the sub thermistor. Replace the

DC controller PCB.

The rise in temperature of the fixing

assembly is faulty.

While startup control is under way, the

E002- reading of the main thermistor is less

0000 than 115 deg C continuously for 400

msec 1.3 sec after it has indicated 100

deg C. While startup control is under

way, the reading of the main

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the main thermistor. Replace

the DC controller PCB.

thermistor is less than 150 deg C

continuously for 400 msec 1.3 sec

after it has indicated 140 deg C.

The fixing temperature is too low after

a standby state.

E003- While regular temperature control is

0000 under way, the reading of the main

thermistor is less than 140 deg C

continuously for 400 msec or more

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the main thermistor. Replace

the DC controller PCB.

Failure in main/sub thermistor

When disconnection is detected with

E004connector of the main/sub thermistor

0000

for 30 sec continuously while DC

controller is working.

Clear the error in Service Mode:

COPIER > FUNCTION > CLEAR > ERR.

Replace the main thermistor (film unit).

Replace DC controller PCB.

The rotation of the fixing film is faulty.

While the fixing motor is rotating, the

E007marker signal is not detected for 6 sec

0000

with the reading of the main thermistor

indicating 100 deg C or more.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR.

Replace the main thermistor. Replace

the DC controller PCB.

The rotation of the main motor is

faulty.

E010- Detection is executed every 100 msec Replace the main motor. Replace the DC

controller PCB.

0001 after the start of motor rotation;

however, the drive detection signal is

absent for 2 sec.

The rotation of the main motor is

faulty.

E010- During motor rotation, detection is

0002 executed every 100 msec; however,

the drive signal is absent 5 times in

sequence.

Replace the main motor. Replace the DC

controller PCB.

The rotation of the fixing motor is

faulty.

E014- Detection is executed every 100 msec Replace the fixing motor. Replace the

DC controller PCB.

0001 after the start of motor rotation;

however, the drive detection signal is

absent for 2 sec.

The rotation of the fixing motor is

faulty.

E014- During motor rotation, detection is

0002 executed every 100 msec; however,

the drive signal is absent 5 times in

sequence.

Replace the fixing motor. Replace the

DC controller PCB.

The waste toner case is full, or the

waste toner case full sensor is faulty.

When the waste toner case is

E019identified as being full for 2000 prints

0000

continuously, an alert is issued;

thereafter, the case is identified as

being full continuously for 100 prints.

Replace the waste toner sensor.

Replace the DC controller PCB.

The path between the sub hopper and

the developing assembly is clogged

with toner

The developing assembly toner

sensor detects the absence of toner,

Replace the developing assembly toner

E020- while the sub hopper toner sensor

sensor. Replace the sub hopper toner

0000 detects the presence of toner. With

sensor. Replace the DC control PCB

the developing clutch turned on, the

hopper feedscrew motor is rotated for

1 sec intermittently 194 times; still, the

developing assembly toner sensor

does not detect the presence of toner

The developing assembly connector is

disconnected/Disconnection of Toner Replace the developing assembly toner

E024sensor.

sensor. Connect the connector. Replace

0000

The connection detection signal is

the DC controller PCB.

absent continuously for 100 msec

Code

Description

Remedy

The developing assembly connector is

disconnected/Disconnection of Toner sensor.

Disconnection of the wire used for detecting the

connection of the toner level sensor is found. When the

disconnection of the wire used for detecting the connection

of the toner level sensor has been detected for 7.5 min

without interruption (12.5 min in the manual /envelop

cassette feeding). When the disconnection of the wire

Correct the cable.

E024used for detecting the connection of the toner level sensor

Replace the sensor.

0001

has been detected for 12.5 min without interruption.

-iR 3225

When the disconnection of the wire used for detecting the

connection of the toner level sensor has been detected for

7.5 min without interruption (12.5 min in the manual

/envelop cassette feeding).

-iR 3245/3235/3230

When the disconnection of the wire used for detecting the

connection of the toner level sensor has been detected for

12.5 min without interruption.

The hopper motor or the bottle motor is faulty.

E025The sub hopper toner sensor connection detection signal

0000

is absent for 100 msec 10 times in sequence.

Replace the sub

hopper toner

sensor. Connect the

connector. Replace

the detection PCB.

The hopper motor or the bottle motor is faulty.

While the hopper motor is rotating, the motor error lock

E025signal is detected continuously 4 times every 56 msec. Or,

0001

while the bottle motor is rotating, the motor error lock

signal is detected 22 times in sequence every 10 msec.

Replace the hopper

motor. Replace the

bottle motor.

Replace the DC

controller PCB.

E032- The NE controller counter malfunctions.

0001 An open circuit is detected for the count pulse signal.

Turn off the main

power, and check

the cable for an

open circuit; then,

turn the main power

back on.

The voltage of the power supply is faulty (high-voltage

E064- error).

0001 The value read from the EEPORM is outside a specific

range.

Turn off and then

back on the main

power. Replace the

EEPROM.

The voltage of the power supply is faulty (high-voltage

error).

E064- While output is being generated, the AD value of the

0002 primary DC voltage is 230 (DEC) or more for 100 msec 2

times in sequence. (However, after output, it is not

detected for 100 msec.)

Replace the highvoltage power

supply. Replace the

DC controller PCB.

The voltage of the power supply is faulty (high-voltage

error).

E064- While output is being generated, the AD value of the

0003 developing DC voltage is 224 (DEC) or more for 10 msec

2 times in sequence. (However, after output, it is not

detected for 100 msec.)

Replace the highvoltage power

supply. Replace the

DC controller PCB.

The voltage of the power supply is faulty (high-voltage

error).

E064- While output is being generated, the AD value of the

0004 transfer output current is 205 (DEC) or more for 100 msec

2 times in sequence. (However, after output, it is not

detected for 100 msec.)

Replace the highvoltage power

supply. Replace the

controller PCB.

E064- The voltage of the power supply is faulty (high-voltage

0005 error).

Replace the highvoltage power

While output is being generated, the AD value of the

supply. Replace the

transfer output voltage is 0 (DEC) for 100 msec 2 times in DC controller PCB.

sequence. (However, after output, it is not detected for 100

msec.)

The scanner motor is faulty.

E110- The scanner motor speed lock signal does not indicate a

0001 locked state a specific period of time after the scanner

motor has been started.

Replace the laser

unit. Replace the

DC controller PCB.

Check the wiring.

The scanner motor is faulty.

E110- The speed lock signal indicates a deviation 10 times in

0002 sequence at intervals of 10 msec after the signal has

indicated a locked state.

Replace the laser

unit. Replace the

DC controller PCB.

Check the wiring.

With the image clock switched over, the scanner motor

E110- speed lock signal does not indicate a locked state 6.5 sec

0003 after a switchover is made from low to normal speed or 8

sec after a switchover is made from normal to low speed.

Replace the laser

unit. Replace the

DC controller PCB.

Check the wiring.

There is an error in the communication with the highvoltage power supply.

E191The data transmission/reception does not end normally

0000

500 msec after the most recent transmission/reception of

data ended normally.

Replace the highvoltage power

supply. Replace the

DC controller PCB.

E197- Error in communication of laser driver PCB

0000 Communication error with IMG1L (communication data)

- Check routing

(wiring) - Replace

the laser unit Replace DC

controller PCBP

Error in communication of laser driver PCB

E197Communication error with IMG1L. (Serial communication

0001

ENG)

- Check routing

(wiring) - Replace

the laser unit Replace DC

controller PCBP

Code

Description

Remedy

E1970003

Error in communication of laser

driver PCB

Disconnection of laser harness

- Check routing (wiring) - Replace the laser

unit - Replace DC controller PCB

E2020001

There is an error in the detection

of the CCD home position.

The attempt to detect the home

position fails when the CCD is

moved forward.

Disconnect and then connect the harness

connector. Replace the optical HP sensor,

optical motor, and reader controller PCB.

E2020002

There is an error in the detection

of the CCD home position.

The attempt to detect the home

position fails when the CCD is

moved back.

Disconnect and then connect the harness

connector. Replace the optical HP sensor,

optical motor, and reader controller PCB.

E225

The light intensity of the CCD is

faulty.

Disconnect and then connect the flexible

cable. Replace the flexible cable, CCD unit,

and reader controller PCB.

E2270001

The reader unit power supply

(24V) is faulty.

At time of power-on, the 24V port

is off.

Disconnect and then connect the power

supply harness connector. Replace the

power supply.

E2270002

The reader unit power supply

(24V) is faulty.

At the start of a job, the 24V port

is off.

Disconnect and then connect the power

supply harness connector. Replace the

power supply

E2270003

The reader unit power supply

Disconnect and then connect the power

(24V) is faulty.

supply harness connector. Replace the

At the end of a job, the 24V port is

power supply.

off.

E2270004

The reader unit power supply

(24V) is faulty.

When a load is being driven, the

24V port is off.

Disconnect and then connect the power

supply harness connector. Replace the

power supply.

E2480001

EEPROM error

An error has occurred at poweron.

Replace the reader controller PCB.

E2480002

EEPROM error

An error has occurred during write Replace the reader controller PCB.

operation.

E2480003

EEPROM error

An error has occurred during read

Replace the reader controller PCB

operation following write

operation.

E2610000

The zero-cross signal is faulty.

When the relay is on, the zerocross signal is not detected for

500 msec or more.

E2800001

Reading unit communication error Disconnect and then connect the flexible

Reception status error

cable. Replace the flexible cable

E280-

Reading unit communication error Disconnect and then connect the flexible

Replace the AC driver PCB. Replace the

DC controller PCB.

0002

Reception interrupt error

E2800003

Reading unit communication error

Disconnect and then connect the flexible

Insufficient insertion of the

cable. Replace the flexible cable

reading unit connector

Code

Description

cable. Replace the flexible cable

Remedy

E3150007

There is an error in image data.

There is an error in JBIG encoding.

Turn off and then back on the

power.

E315000d

There is an error in image data.

There is an error in JBIG decoding.

Turn off and then back on the

power.

E315000e

There is an error in image data.

Error in decoding of software

Replace the main controller

PCB

E3150025

There is an error in image data.

Error in ROTU hardware

Replace SDRAM. Replace

HDD. Replace the main

controller PCB

E3150027

There is an error in image data.

Error in ROTU timeout

Replace SDRAM. Replace

HDD. Replace the main

controller PCB.

E3150033

There is an error in image data.

Error in MemFill hardware

Replace the main controller

PCB.

E3150035

There is an error in image data.

Error in MemFill timeout

Replace the main controller

PCB.

E3150100

There is an error in image data.

Error in PrcOverRun

Replace the main controller

PCB.

E3150500

There is an error in image data.

Error in device timeout [location to be detected] Check connection with DDI-S

image process module (SCIO) [Detection timing] cable(RCON). Replace the

when there is no interruption 2 min after the

main controller PCB.

operation has been started

E3150501

There is an error in image data.

Device: abnormal termination error [location to

Check connection with DDI-S

be detected] image process module (SCIO)

cable(RCON). Replace the

[Detection timing] When abnormal interruption is main controller PCB.

detected after the operation has been started.

E3150510

There is an error in image data.

Device: timeout error [Location to be detected]

Check connection with DDI-S

image process module (SCIP) [Detection timing] cable(RCON). Replace the

when there is no interruption 2 min after the

main controller PCB.

operation has been started.

E3150511

There is an error in image data.

Device: abnormal termination error [Location to Check connection with DDI-S

be detected] image process module (SCIP)

cable(RCON). Replace the

[Detection timing] when abnormal interruption is main controller PCB.

detected after the operation has been detected

E3150520

There is an error in image data.

Device: timeout error [Location to be detected]

Check connection with DDI-S

image process module (CMIP) [Detection timing] cable(RCON). Replace the

When there is no interruption 2 min after the

main controller PCB.

operation has been started

E3150521

There is an error in image data.

Device: abnormal termination error [Location to Check connection with DDI-S

be detected] image process module (CMIP)

cable(RCON). Replace the

[Detection timing] when abnormal interruption is main controller PCB

detected after the operation has been detected

E3150530

There is an error in image data.

Device: timeout error [Location to be detected]

image process module (JPEN) [Detection

timing] when there is no interruption 2 min after

the operation has been started.

Code

Description

Turn OFF and then ON the

power. Replace the main

controller PCB if this occurs

frequently.

Remedy

There is an error in image data.

Device: abnormal termination error [Location

Turn OFF and then ON the power.

E315- to be detected] image process module

Replace the main controller PCB

0531 (JPEN) [Detection timing] when abnormal

if this occurs frequently.

interruption is detected after the operation

has been started.

There is an error in image data.

Device: timeout error [Location to be

E315- detected] image process module (JPDE)

0540 [Detection timing] when there is no

interruption 2 min after the operation has

been started.

Turn OFF and then ON the power.

Replace the main controller PCB

if this occurs frequently.

There is an error in image data.

Device: abnormal termination error [Location

Turn OFF and then ON the power.

E315- to be detected] image process module

Replace the main controller PCB

0541 (JPDE) [Detection timing] when abnormal

if this occurs frequently.

interruption is detected after the operation

has been started

E315- There is an error in image data.

Check connection with DDI-P

0550

Device: timeout error [Location to be

detected] image process module (PRIP)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

cable(DCON). Replace the main

controller PCB.

There is an error in image data.

Device: abnormal termination error [Location

Check connection with DDI-P

E315- to be detected] image process module

cable(DCON). Replace the main

0551 (PRIP) [Detection timing] when abnormal

controller PCB.

interruption is detected after the operation

has been started.

There is an error in image data.

Device: timeout error [Location to be

E315- detected] image process module (PRIO)

0560 [Detection timing] when there is no

interruption 2 min after the operation has

been started.

Check connection with DDI-P

cable(DCON). Replace the main

controller PCB.

There is an error in image data.

Device: abnormal termination error [Location

Check connection with DDI-P

E315- to be detected] image process module

cable(DCON). Replace the main

0561 (PRIO) [Detection timing] when abnormal

controller PCB.

interruption is detected after the operation

has been started.

Fault in communication with the ADF driver

PCB

E400The checksum values of data from the ADF

0001

driver PCB are inconsistent 14 times

consecutively.

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

The statuses of data from the ADF driver

E400PCB are inconsistent 14 times

0002

consecutively.

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

E400- SCI serial communication error interrupt is

0003 detected 14 times consecutively.

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

The level of the pressure HP sensor does

not change in a specified period of time.

Replace the pressure motor.

E413When the pressure motor is activated, the

Replace the pressure HP sensor.

0001

level of the pressure HP sensor does not

change in a specified period of time with the

10

lead roller opened.

The level of the pressure HP sensor does

not change in a specified period of time.

Replace the pressure motor.

E413- When the pressure motor is activated, the

Replace the pressure HP sensor.

0002 level of the pressure HP sensor does not

change in a specified period of time with the

lead roller closed.

E490- The ADF installed is not supported.

0001 Error with an incorrect ADF model

The ADF installed is not

supported. Replace the DC

controller PCB.

E500- fault in communication with the finisher

0001 (common among all finishers)

Replace the finisher controller

PCB. Replace the DC controller

PCB.

fault in communication

Replace the finisher controller

E503fault in communication between finisher and PCB. Replace the saddle

0002

saddle unit

controller PCB. Check the cable.

Code

Description

Remedy

with the finisher (External finisher)

E503fault in communication between finisher

0003

and punch unit

Replace the finisher controller PCB.

Replace the punch drive PCB. Check

the cable.

fault in the backup memory of the

E505- finisher (common among all finishers)

0001 fault in the data stored in backup

memory

Turn off the main power. Check the

wiring of the DC controller PCB and

the finisher controller, and check the

fuse of the 24-V power supply.

Thereafter, turn the main power back

on.

E505- fault in the EEPROM data of the punch

0002 unit

Replace the punch driver PCB.

Replace the finisher controller PCB.

fault in stack delivery motor (FinisherS1)

E514- When the stack retaining spacer is

0001 returned to home position, the belt

escape home position sensor does not

go on within 1.5 sec.

Replace the finisher controller PCB.

Replace the stack delivery motor.

Check the stack delivery drive

mechanism.

fault in trailing edge assist motor

(External finisher)

Replace the finisher control PCB.

E514The home position sensor does not go

Replace the trailing edge assist motor

0001

off even when the trailing edge assist

motor has rotated for a specific period of

11

time.

fault in stack delivery motor (FinisherS1)

E514- When the stack retaining spacer is

0002 shifted from home position, the belt

escape home position sensor does not

go off within 1.5 sec.

Replace the finisher controller PCB.

Replace the stack delivery motor.

Check the stack delivery drive

mechanism.

fault in trailing edge assist motor

(External finisher)

Replace the finisher control PCB.

E514- The home position sensor does not go

Replace the trailing edge assist motor

0002 on even after the trailing edge assist

motor has rotated for a specific period of

time.

Gear change motor error (External

finisher)

E519The home position sensor does not go

0001

off even when the gear change motor

has rotated for a specific period of time.

Replace the finisher controller PCB.

Replace the gear change motor.

Check the gear change mechanism.

Gear change motor error (External

finisher)

E519The home position sensor does not go

0002

on even when the gear change motor

has rotated for a specific period of time.

Replace the finisher controller PCB.

Replace the gear change motor.

Check the gear change mechanism.

The offset motor or the finisher controller

PCB is faulty. The offset home position

sensor is faulty (Finisher-S1).

Replace the offset motor. Replace the

E520- While the offset motor is in operation,

offset home position sensor. Replace

0001 drive was applied for 1000 msec for

the finisher controller PCB.

movement toward the home position

sensor; however, the offset home

position sensor does not go on.

The offset motor or the finisher controller

PCB is faulty. The offset home position

sensor is faulty (Finisher-S1).

Replace the offset motor. Replace the

E520- While the offset motor is in operation,

offset home position sensor. Replace

0002 drive was applied for 1000 msec for

the finisher controller PCB.

movement away from the home position

sensor; however, the offset home

position sensor does not go off.

Front alignment error (External finisher)

E530- The home position sensor does not go

0001 off even when the front alignment motor

has been rotated for a specific period of

Replace the finisher controller PCB.

Replace the front alignment motor.

Check the front aligning plate drive

mechanism. Check the front

12

time.

alignment home position sensor.

Front alignment error (External finisher)

The home position sensor does not go

E530on even when the front alignment motor

0002

has been rotated for a specific period of

time.

Replace the finisher controller PCB.

Replace the front alignment motor.

Check the front aligning plate drive

mechanism. Check the front

alignment home position sensor.

Rear alignment error (Finisher-S1)

The home position sensor does not go

E530on within 2000 msec after the start of

8001

operation when the rear aligning plate is

shifted to home position.

Replace the finisher controlled PCB.

Replace the rear alignment motor.

Check the rear aligning plate drive

mechanism. Check the rear alignment

home position sensor.

Rear alignment error (Finisher-S1)

The home position sensor does not go

E530off within 1000 msec after the start of

8002

operation when the rear aligning plate is

shifted from home position.

Replace the finisher controlled PCB.

Replace the rear alignment motor.

Check the rear aligning plate drive

mechanism. Check the rear alignment

home position sensor.

Code

Description

Remedy

E5310001

Stapler error (External finisher)

The home position sensor does not

go off even when the stapler motor

has rotated for a specific period of

time.

Replace the finisher controller PCB.

Replace the stapler. Check the harness.

E5310002

Stapler error (External finisher)

The home position sensor does not

go on even when the stapler motor

has rotated for a specific period of

time.

Replace the finisher controller PCB.

Replace the stapler. Check the harness.

E5318001

Stapler error (Finisher-S1)

At time of staple jam recovery, the

Replace the finisher controller PCB.

home position sensor does not go on

Replace the stapler. Check the harness.

with 500 msec after the start of

reverse rotation of the stapler motor.

E5318002

Stapler error (Finisher-S1)

The home position sensor does not

go off within 500 msec after the

stapler motor has been started.

Replace the finisher controller PCB.

Replace the stapler. Check the harness.

E5320001

Stapler shift error (External finisher)

The home position sensor does not

go off even after the stapler shift

motor has rotated for a specific

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness.

13

period of time.

E5320002

Stapler shift error (External finisher)

The home position sensor does not

go on even when the stapler shift

motor has rotated for a specific

period of time.

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness.

E5328001

Stapler shift error (Finisher-S1)

The stapler slide home position

sensor does not go on within 11 sec

when the stapler is shifted to home

position.

Replace the finisher controller PCB.

Replace the stapler shift motor. Check

the stapler shift home position sensor.

Check the harness.

E5328002

Stapler shift error (Finisher-S1)

The stapler slide home position

sensor does not go off within 1.0 sec

when the stapler is shifted from

home position.

Replace the finisher controller PCB.

Replace the stapler shift motor. Check

the stapler shift home position sensor.

Check the harness.

E5350001

Swing cam error (Finisher-S1)

The home position sensor does not

go off within 1000 msec after the

start of operation when the swing

arm is shifted from home position.

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness

E5350001

Swing cam error (External finisher)

The home position sensor does not

go off even when the swing motor

has rotated for a specific period of

time.

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness.

E5350002

Swing cam error (Finisher-S1)

The home position sensor does not

go off within 1.0 sec when the stack

delivery roller swing arm is moved

from home position.

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness

E5350002

Swing cam error (External finisher)

The home position sensor does not

go on even when the swing motor

has rotated for a specific period of

time.

Replace the finisher controller PCB.

Replace the swing cam motor. Check the

swing cam home position sensor. Check

the harness.

E5370001

Rear alignment error (External

finisher)

The home position sensor does not

go on within 2000 msec after the

start of operation when the read

aligning plate is moved to home

Replace the finisher controller PCB.

Replace the rear alignment motor. Check

the rear aligning plate drive mechanism.

Check the rear alignment home position

sensor

14

position.

E5370002

Rear alignment error (External

finisher)

The home position sensor does not

go off within 1000 msec after the

start of operation when the rear

aligning plate is moved form home

position.

Replace the finisher controller PCB.

Replace the rear alignment motor. Check

the rear aligning plate drive mechanism.

Check the rear alignment home position

sensor

E5378001

Front alignment error (Finisher-S1)

The home position sensor does not

go on within 2.0 sec when the front

aligning plate is moved to home

position.

Replace the finisher controller PCB.

Replace the front alignment motor. Check

the front aligning plate drive mechanism.

Check the front alignment home position

sensor.

Code

Description

Remedy

Front alignment error (FinisherS1)

E537- The home position sensor dos

8002 not go off within 1.0 sec when

the front aligning plate is shifted

from home position.

Replace the finisher controller PCB. Replace

the front alignment motor. Check the front

aligning plate drive mechanism. Check the

front alignment home position sensor.

Upper tray ascent/descent

E540- motor error (External finisher)

0002 Upper tray ascent/descent

motor clock error

Replace the No. 1 tray shift motor. Replace the

finisher controller PCB. Check the tray

ascent/descent mechanism.

E540Area error

0003

Replace the No. 1 tray area sensor PCB.

Replace the finisher controller PCB.

E540Safety switch activation

0004

Check the No. 1 tray closed detecting switch.

Replace the finisher controller PCB.

Stack tray motor error

(FinisherS1)

E540The operation to detect the

8002

paper surface of the stack tray

does not end within 1.0 sec.

Replace the finisher controller PCB. Replace

the tray ascent/descent motor. Check the stack

tray drive mechanism. Check the paper

surface sensor.

Stack tray motor error

(FinisherS1)

E540An abnormal combination of

8003

sensor states has been

detected.

Replace the finisher controller PCB. Check the

stack tray upper limit sensor. Check the stack

tray lower limit sensor. Check the stack tray

upper paper surface sensor. Check the stack

tray lower paper surface sensor.

E542- Lower tray ascent/descent

Replace the No. 2 tray shift motor. Replace the

15

0002

motor error (External finisher)

Lower tray ascent/descent

motor clock error

finisher controller PCB. Check the tray

ascent/descent mechanism

Lower tray ascent/descent

E542motor error (External finisher)

0003

Area error

Replace the No. 2 tray shift area sensor PCB.

Replace the finisher controller PCB.

Paddle error (Finisher-S1)

The paddle home position

E577sensor does not go on within

8001

1.5 sec when the paddle is

shifted to home position.

Check the paddle motor. Check the paddle

home position sensor. Replace the finisher

controller PCB

The paddle home position

E577- sensor does not go off within

8002 1.0 sec when the paddle is

moved to home position.

Check the paddle motor. Check the paddle

home position sensor. Replace the finisher

controller PCB

Shutter unit error (External

finisher)

E584The shutter open sensor does

0001

not go off (i.e., the shutter does

not close).

Check the stack edging motor. Check the

open/close clutch. Check the shutter home

position sensor. Replace the finisher controller

PCB.

Shutter unit error (External

finisher)

E584The shutter open sensor does

0002

not go on (i.e., the shutter does

not open).

Check the stack edging motor. Check the

open/close clutch. Check the shutter home

position sensor. Replace the finisher controller

PCB.

Punch motor error

The punching home position is Check the punch motor. Check the punch

E590not detected even when the

motor clock sensor. Check the punch driver

0001

puncher motor has been driven PCB. Replace the finisher controller PCB.

for 20 msec.

Punch motor error

The punch home position

E590- sensor is not defected even

0002 after the motor has stopped at

time of punch motor initial

operation.

Check the punch motor. Check the punch

motor clock sensor. Check the punch driver

PCB. Replace the finisher controller PCB.

Punch dust sensor error

E591Error in light-receiving voltage

0001

while light is emitted

Check the waste paper case full sensor. Check

the punch driver PCB. Replace the finisher

controller PCB.

Code

Description

Remedy

16

Punch dust sensor error

E591Error in light-receiving voltage while light

0002

is not emitted

Check the waste paper case full

sensor. Check the punch driver PCB.

Replace the finisher controller PCB.

Paper trailing edge sensor/ horizontal

E592- sensor error

0001 Error in light-receiving voltage when light

is emitted (trailing edge sensor)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch driver PCB.

Replace the finisher controller PCB.

paper trailing edge sensor/ registration

E592- sensor error

0002 Error in light-receiving voltage when light

is not emitted (trailing edge sensor)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch drive PCB.

Replace the finisher controller PCB.

paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0003

is emitted (horizontal registration sensor

1)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch driver PCB.

Replace the finisher controller PCB.

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0004

is not emitted (horizontal registration

sensor 1)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch driver PCB.

Replace the finisher controller PCB.

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0005

is emitted (horizontal registration sensor

2)

Check the paper training edge

sensor. Check the horizontal

registration sensor. Check the punch

driver PCB. Replace the finisher

controller PCB.

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0006

is not emitted (horizontal registration

sensor 2)

Check the paper training edge

sensor. Check the horizontal

registration sensor. Check the punch

driver PCB. Replace the finisher

controller.

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0007

is emitted (horizontal registration sensor

3)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch driver PCB.

Replace the finisher controller PCB.

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

0008

is not emitted (horizontal registration

sensor 3)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch drive PCB.

Replace the finisher controller PCB.

E592- Paper trailing edge sensor/ registration

Check the paper trailing edge sensor.

17

0009

sensor error

Check the horizontal registration

Error in light-receiving voltage when light sensor. Check the punch driver PCB.

is not emitted (horizontal registration

Replace the finisher controller PCB.

sensor 4)

Paper trailing edge sensor/ registration

sensor error

E592Error in light-receiving voltage when light

000A

is not emitted (horizontal registration

sensor 4)

Check the paper trailing edge sensor.

Check the horizontal registration

sensor. Check the punch drive PCB.

Replace the finisher controller PCB.

Check the horizontal registration

Punch shift motor error

motor. Check the horizontal

E593- The light-receiving voltage home position registration home position sensor.

Check the punch driver PCB.

0001 sensor does not go off when light is

emitted.

Replace the finisher controller PCB.

Check the punch shift mechanism.

Punch shift motor error

E593- The light-receiving voltage home position

0002 sensor does not go on when light is not

emitted.

Check the horizontal registration

motor. Check the horizontal

registration home position sensor.

Check the punch driver PCB.

Replace the finisher controller PCB.

Check the punch shift mechanism.

Saddle paper positioning plate error

The paper positioning plate home

position sensor does to go on when the

E5F0paper positioning motor has been driven

0001

for 1.33 sec. Paper positioning plate

motor (M4S)/paper positioning plate

home position sensor (P17S)

Check the paper positioning plate

motor. Check the paper positioning

plate home position sensor. Replace

the finisher controller PCB. Check the

paper positioning plate drive

mechanism

Saddle paper positioning plate error

The paper positioning plate home

position sensor doest not go off when the

E5F0paper positioning plate motor has been

0002

driven for 1 sec. Paper positioning plate

motor (M4S)/paper positioning plate

home position sensor (P17S)

Check the paper positioning plate

motor. Check the paper positioning

plate home position sensor. Replace

the finisher controller PCB. Check the

paper positioning plate drive

mechanism

Code

Description

Saddle paper folding error

The number of detection pulses of the paper

E5F1folding motor clock sensor has dropped

0001

below a specific value. Paper folding motor

(M2S)/paper folding motor clock sensor

Remedy

Check the paper folding motor.

Check the paper folding motor

clock sensor. Replace the finisher

controller PCB. Check the paper

folding plate drive mechanism.

18

(P14S)

Saddle paper folding error

The state of the paper folding home position

E5F1- sensor doest not change when the paper

0002 folding motor has been driven for 3 sec.

Paper folding motor (M2S)/paper folding

motor clock sensor (P14S)

Check the paper folding motor.

Check the paper folding motor

clock sensor. Replace the finisher

controller PCB. Check the paper

folding plate drive mechanism.

Saddle guide error

The guide home position sensor does not go

E5F2on when the guide motor has been driven for

0001

0.455 sec. Guide motor (M3S)/guide home

position sensor (PI13S)

Check the guide motor. Check the

guide home position sensor.

Replace the finisher controller

PCB. Check the guide drive

mechanism.

Saddle guide error

The guide home position sensor does not go

E5F2off when the guide motor has been driven for

0002

1 sec. Guide motor (M3S)/guide home

position sensor (PI13S)

Check the guide motor. Check the

guide home position sensor.

Replace the finisher controller

PCB. Check the guide drive

mechanism.

Saddle alignment error

The aligning plate home position sensor

does not go on when the alignment motor

E5F3has been driven for 0.5 sec. (at time of

0001

initialization, 1.67 sec.) Alignment motor

(M5S)/aligning plate home position sensor

(PI5S)

Check the alignment motor.

Check the alignment home

position sensor. Check the

aligning plate drive mechanism.

Replace the finisher controller

PCB.

Saddle alignment error

The aligning plate home position sensor

E5F3- does not go off when the alignment motor

0002 has been driven for 1 sec. Alignment motor

(M5S)/aligning plate home position sensor

(PI5S)

Check the alignment motor.

Check the alignment home

position sensor. Check the

aligning plate drive mechanism.

Replace the finisher controller

PCB.

Saddle rear stapling error

The stitching home position sensor does not

Replace the stitcher (rear). Check

E5F4- go on when the stitch motor (rear) has been

the harness. Replace the finisher

0001 rotated in reverse for 0.5 sec or more. Stitch

controller PCB.

motor (rear; M6S)/stitching home position

sensor (rear; MS5S)

Saddle rear stapling error

The stitching home position sensor does not

Replace the stitcher (rear). Check

E5F4- go off when the stitch motor (rear) has been

the harness. Replace the finisher

0002 rotated in normal direction for 0.5 sec or

controller PCB.

more. Stitch motor (rear; MS)/stitching home

position sensor (rear; MS5S)

19

Saddle front stapling error

The stitching home position sensor does not

Replace the stitcher (front). Check

E5F5- go on when the stitch motor (front) has been

the harness. Replace the finisher

0001 rotated in reverse for 0.5 sec or more. Stitch

controller PCB.

motor (front; M7S)/stitching home position

sensor (front; MS7S)

Saddle front stapling error

The stitching home position sensor does not

Replace the stitcher (front). Check

E5F5- go off when the switch motor (front) has

the harness. Replace the finisher

0002 been rotated in normal direction for 0.5 sec

controller PCB.

or more. Stitch motor (front; M7S)/stitching

home position sensor (front; MS7S)

Saddle butting error

The paper butting plate home position

E5F6- sensor does not go on when the paper

0001 butting plate motor has been driven for 0.3

sec. Paper butting plate motor (M8S)/paper

butting plate home position sensor (PI14S)

Check the paper butting plate

motor. Check the paper butting

plate home position sensor.

Replace the finisher controller

PCB.

Saddle butting error

The paper butting plate home position

sensor does not go off when the paper

E5F6butting plate motor has been driven for 80

0002

msec or more. Paper butting plate motor

(M8S)/paper butting plate home position

sensor (PI14S)

Check the paper butting plate

motor. Check the paper butting

plate home position sensor.

Replace the finisher controller

PCB.

Saddle butting error

The number of detection pulses of the paper

E5F6- butting plate motor has dropped below a

0003 specific value. paper butting plate motor

(M8S)/paper butting plate motor clock

sensor (PI1S)

Check the paper butting plate

motor. Check the paper butting

plate motor clock sensor. Replace

the finisher controller PCB.

Saddle butting error

The paper butting plate leading edge sensor

E5F6- does not go off when the paper butting plate

0004 motor has been driven for 80 msec. Paper

butting plate motor (M8S)/paper butting plate

leading edge sensor (PI15S)

Check the paper butting plate

motor. Check the paper butting

plate leading edge sensor.

Replace the finisher controller

PCB.

Saddle butting error

The paper butting plate leading edge sensor

E5F6- does not go on when the paper butting plate

0005 motor has been driven for 0.3 sec. Paper

butting plate more (M8S)/paper butting plate

leading edge sensor (PI15S)

Check the paper butting plate

motor. Check the paper butting

plate leading edge sensor.

Replace the finisher controller

PCB.

20

Code

Description

Remedy

Saddle connector error

The connector of the paper butting plate home

E5F8position sensor has been identified as being

0001

disconnected. Connector of guide home

position sensor (PI13S)

Connect the connector of the

guide home position sensor.

Check the harness. Replace

the finisher controller PCB.

Saddle connector error

The connector of the paper butting plate home

E5F8position sensor has been identified as being

0002

disconnected. Connector of paper butting plate

home position sensor (PI14S)

Connect the connector of the

paper butting plate home

position sensor. Check the

harness. Replace the finisher

controller PCB.

Saddle connector error

The connector of the paper butting plate

E5F8leading edge sensor has been identified as

0003

being disconnected. Connector of paper butting

plate leading edge sensor (PI15S)

Connect the connector of the

paper butting plate leading

edge sensor. Check the

harness. Replace the finisher

controller PCB.

Saddle switch error

The inlet cover switch has been identified as

being open for 1 sec or more after the start of

printing or the start of initial rotation with the

following sensors identifying their respective

E5F9- covers as being closed: -inlet cover sensor

0001 (PI9S) -nt cover open/closed sensor (PI2S) delivery cover sensor (PI3S) Or, the front over

switch (MS2S) or the delivery cover switch

(MS3S) is open. Inlet cover switch

(MS1S)/front cover switch (MS2S)/delivery

cover switch (MS3S)

Check the inlet cover switch.

Check the inlet cover sensor.

Check the front cover open/

closed sensor. Check the

delivery cover sensor. Replace

the finisher controller PCB.

Saddle switch error

The front cover switch has been identified as

being open from the start of printing or the start

of initial rotation with the following sensors

E5F9identifying their respective covers as being

0002

closed. -inlet cover sensor (PI9S) -front cover

open/closed sensor (PI2S) -delivery cover

sensor (PI3S) -front cover switch

(MS2S)/delivery cover switch (MS3S)

Check the front cover switch.

Check the inlet cover sensor.

Check the front cover open/

closed sensor. Check the

delivery cover sensor. Replace

the finisher controller PCB.

Saddle switch error

E5F9- The delivery cover switch has been identified

0003 as being open after the start of printing or the

start of initial rotation of the host machine with

Check the delivery cover

switch. Check the inlet cover

sensor. Check the inlet cover

sensor. Check the front cover

21

the following sensors identifying their

respective covers as being closed: -inlet cover

sensor (PI9S) -front cover open/closed sensor

(PI2S) -delivery cover sensor (PI3S) - delivery

cover switch (MS3S)

There is an error on the hard disk.

[Cause] An HDD detection error has occurred.

The HDD cannot be detected. The HDD does

E602not become ready. The HDD returns an error.

0001

[Detection] while boot ROM is in session

BARSAC startup, mounting (usrIde) [Timing of

Detection] once at startup

There is an error on the hard disk.

[Cause] There is no startup file. The program

for the main CPU does not exist on the HDD or

E602in BOOTDEV/BOOT, and so on. [Detection]

0002

while boot ROM is in use at time of system file

loading (usrIde) [Timing of Detection] once at

startup

There is an error on the hard disk.

[Cause] An HD write abort error has occurred.

E602- The sectors for BOOTDEV on the HD cannot

0003 be read. [Detection] BARSAC (all; at time of

bootable startup) [Timing of Detection] once at

startup

There is an error on the hard disk.

[Cause] A subbootable that matches the PDL

E602- type does not exit in BOOTDEV/BOOT.

0006 [Detection] during loading of sub boot in

oclibroot [Timing of Detection] once at bootable

startup

There is an error on the hard disk.

[Cause] An ICC profile that matches the PDL

type does not exist in BOOTDEV/PDL.

E602[Detection] beginning of oclibroot; judgment

0007

based on functions of PDL team that are called

in [Timing of Detection] once at bootable

startup

E602- There is an error on the hard disk.

01XX /DOSDEV is faulty

E602- There is an error on the hard disk.

02XX /FSTDEV is faulty.

open/closed sensor. Check the

delivery cover sensor. Replace

the finisher controller PCB.

22

E602- There is an error on the hard disk.

03XX /DOSDEV2 is faulty.

E602- There is an error on the hard disk.

04XX /FSTPDEV is faulty.

Code

Description

Remedy

E60205XX

There is an error on the hard disk.

/DOSDEV3 is faulty.

E60206XX

There is an error on the hard disk.

/PDLDEV is faulty.

E60207XX

There is an error on the hard disk.

/DOSDEV4 is faulty.

E60208XX

There is an error on the hard disk.

/BOOTDEV is faulty.

E60209XX

There is an error on the hard disk.

/DOSDEV5 is faulty.

E602FFXX

There is an error on the hard disk.

There is an error in a partition that cannot be

identified.

E6040000

The image memory is faulty or is inadequate.

Increase the memory.

The memory size does not match the model.

E6090008

There is an error on the HDD.

At startup, the HDD fails to reach a specific

temperature level within a specific period of

time.

Replace the hard disk. Replace

the DC controller PCB.

E6090009

There is an error on the HDD.

At time of sleep recovery, the temperature

fails to reach a specific level.

Replace the hard disk. Replace

the DC controller PCB.

E610

The HDD coding key is faulty.

E6770001

Failure in PS Printer Kit-AA1

Failure in exhaust fan of PS Printer Kit-AA1

E6770003

Failure in PS Printer Kit-AA1

- Check cable connection Abnormal detection with configuration check Reinstall system of PS Printer

when PS Printer Kit-AA1 is started

Kit-AA1

E6770004

Failure in PS Printer Kit-AA1

Failure in CPU cooling fan of PS Printer KitAA1

- Check connection of the

exhaust fan connector - Replace

the exhaust fan

- Check connection of the

connector for cooling CPU Replace CPU cooling fan

23

E6770010

Failure in PS Printer Kit-AA1

In the case that other type of controller is

connected

E6770080

Failure in PS Printer Kit-AA1

- After checking connection, turn

Communication error between PS Printer KitON the power again. - Reinstall

AA1 and the main controller of the host

system of PS Printer Kit-AA1.

machine after PS Printer Kit-AA1 is started

Code

- Check connection of controller

that supports this machine

Description

Remedy

There is an error in the

initialization of the IPC.

E710The machine fails to become Check the cable.

0001

ready 3 sec or less after the

IPC chip startup

There is an error in the IPC

communication.

The occurrence of an error

E711has been recorded in the

0001

error register of the IPC chip

4 times or more within 1.5

sec.

Check the cable.

There is an error in the

communication with the

finisher or 3 Way Unit-A1.

Check the cable. Replace the DC controller PCB.

E713The communication with the

Replace the finisher controller PCB.

0000

finisher does not resume

within 5 sec after it has been

disrupted.

There is an error in the

communication with the

pedestal.

Check the cable. Replace the DC controller PCB.

E716After the presence of a

Replace the pedestal drive PCB.

0000

pedestal has been detected,

the communication fails to be

normal for 5 sec.

There is an error in the

communication with the

pedestal.

E716When the communication

0010

with the 3 Way Unit-A1 is

faulty after detecting the

connection with the finisher.

Install the 3 Way Unit-A1. Replace the DC

controller PCB after checking the cable

24

There is an error in the

communication with the NE

controller.

Check the cable; thereafter, reset the condition in

E717- The NE controller is not

service mode:

0001 connected at power on,

COPIER>FUNCTION>CLEAR>ERR.

although it was connected

before the power was turned

off because of an error.

There is an error in the

communication with the NE

controller.

An IPC error has occurred

E717- while the NE controller is in

0002 operation. There is an open

circuit for the IPC. An error

has occurred, and the IPC

communication remains

disabled.

Check the cable; thereafter, reset the condition in

service mode:

COPIER>FUNCTION>CLEAR>ERR.

There is a coin vendor error.

The coin vendor is not

connected when the power is Check the cable; thereafter, reset the condition in

E719turned on, although it was

service mode:

0001

connected before the power COPIER>FUNCTION>CLEAR>ERR.

was turned off because of an

error.

There is a coin vendor error.

While the coin vendor is in

operation, an IPC error has

occurred, IPC has developed

an open circuit, or an error

Check the cable; thereafter, reset the condition in

E719- preventing recovery of IPC

service mode:

0002 communication has occurred.

COPIER>FUNCTION>CLEAR>ERR.

An open circuit has been

detected in the line for the

pickup/delivery signal. An

illegal signal has been

detected.

There is a coin vendor error.

While the unit price is being Check the cable; thereafter, reset the condition in

E719checked at startup, an error service mode:

0003

occurs in the communication COPIER>FUNCTION>CLEAR>ERR.

with the coin vendor.

E719- There is a coin vendor error. Check the cable; thereafter, reset the condition in

0011 An error has occurred at new service mode:

25

card reader startup. The new COPIER>FUNCTION>CLEAR>ERR.

card reader is not connected

when the power is turned off,

although it was connected

when the power was turned

off.

There is a coin vendor error.

An IPC error has occurred at

new card reader startup.

Check the cable; thereafter, reset the condition in

E719There is an IPC open circuit. service mode:

0012

An error has occurred that

COPIER>FUNCTION>CLEAR>ERR.

prevents recovery of IPC

communication.

1. Check the connection of the cable for the card

reader (connector disconnected, cable cut);

There is a coin vendor error.

thereafter, reset the condition in service mode:

Error in communication at

COPIER > FUNCTION > CLEAR > ERR. 2.

E719- card reader (serial) startup

Execute the following items in service mode after

0031 Communication with the card

removing the card reader, and then install the

reader cannot be started at

card reader again. - COPIER > FUNCTION >

startup.

CLEAR > CARD - COPIER > FUNCTION >

CLEAR > ERR

There is a coin vendor error.

Error in communication after

card reader (serial) startup

E719Communication with the card

0032

reader is available at startup,

and then becomes

unavailable.

Check the connection of the cable for the card

reader (connector disconnected, cable cut);

thereafter, reset the condition in service mode:

COPIER > FUNCTION > CLEAR > ERR.

There is a PDL software

E730- error.

1001 An initialization error has

occurred.

1. Execute PDL resetting. 2. Turn on the power

once again.

Code

Description

Remedy

There is a PDL software error.

1. Execute PDL resetting. 2. Turn on

E730An error that may be critical to the system

the power once again.

100A

(e.g., failed initialization) has occurred.

There is a PDL software error.

E730There is an error in the communication

9004

(PAI) with an external controller.

1. Turn on the power once main. 2.

Check the connection of the open I/F

board and the cable. 3. Replace the

board for the external controller open

26

I/F. 4. Replace the main board.

There is a PDL software error.

E730There is a fault in the connector of the

9005

vide cable to the external controller.

1. Turn on the power once main. 2.

Check the connection of the open I/F

board and the cable. 3. Replace the

board for the external controller open

I/F. 4. Replace the main board.

There is a PDL software error.

E730The PDL board does not respond. A

A006

subbootable is faulty or absent.

1. Execute PDL resetting. 2. Turn on

the power once again. 3. Check the

connection of the SURF board. 4.

Re-install the firmware. 5. Replace

the main board.

There is a PDL software error.

E730- There is a mismatch between the control

A007 software of the machine and the PDL

control software in regard to version.

1. Execute PDL resetting. 2. Turn on

the power once again. 3. Execute

system formatting (all), and reinstall

the system.

E730- There is a PDL software error.

B013 There is corruption in the font data.

1. Turn on the power once again. 2.

Re-install the software. 3. Execute

system formatting (all), and reinstall

the system.

There is an error in the communication

E732with the scanner

0001

There is a DDI-S communication error.

1. Check the connector used to

connect the scanner. 2. Check the

power supply of the scanner (to see if

initialization takes place at startup).

3. Replace the reader controller,

scanner board, or main board as

necessary.

There is an error in the communication

E732with the scanner

0010

Fault in detection of DDI-S Vsync signal

1. Check the connector used to

connect the scanner. 2. Check the

power supply of the scanner (to see if

initialization takes place at startup).

3. Replace the reader controller,

scanner board, or main board as

necessary.

There is an error in the communication

with the scanner

A scanner is first detected from the

E732- printer model. (Not an error code but only

Turn the main power switch off/on

9999 the message 'Turn the main power switch

OFF&ON again' is displayed on the users

screen. The error is recorded in service

mode > DISPLAY > ERR

E733- There is an error in the communication

1. Check the connector used to

27

0000

with the printer

connect to the printer. 2. Check the

At startup, communication with the printer power supply of the printer (to see if

fails

initialization takes place at startup).

3. Replace the DC controller or the

main board.

There is an error in the communication

E733with the printer

0001

There is a DDI-P communication error

1. Check the connection with the

printer. 2. Check the power supply of

the printer (to see if initialization

takes place at startup). 3. Replace

the DC controller or the main board.

There is an error in the communication

E733with the printer

0010

Fault in detection of DDI-P Vsync signal

1. Check the connection with the

printer. 2. Check the power supply of

the printer (to see if initialization

takes place at startup). 3. Replace

the DC controller or the main board.

There is an error in the communication

E733with the printer

0020

Error in DDI-P communication

2. Check the power supply of the

printer (to see if initialization takes

place at startup). 3. Replace the DC

controller or the main board.

There is an error in the communication

E733with the printer

0021

Error in DDI-P communication

1. Check the connection with the

printer. 2. Check the power supply of

the printer (to see if initialization

takes place at startup). 3. Replace

the DC controller or the main board.

E740- There is an error on the Ether board.

0002 The MAC address is illegal.

Replace the LAN card.

Code

Description

Remedy

There is an error in the DDI

communication.

E743- An SCI error has occurred. The

0000 received data is faulty. A reception

timeout condition has occurred. An

SEQ timeout error has occurred.

Disconnect and then connect the flexible

cable used to connect the reader unit and

the printer unit. Replace the following as

necessary: flexible cable, reader

controller PCB, main controller PCB.

There is an error in the language

file/boot ROM.

E744The version of the language file on

0001

the HDD and that of the bootable do

not match.

Download a language file of the correct

version.

E744- There is an error in the language

0002 file/boot ROM.

Download a language file of the correct

version.

28

The size of the language file on the

HDD is too large.

There is an error in the language

file/boot ROM.

Download a language file of the correct

E744There is no language file on the HDD

version.

0003

indicated by config.txt for a

switchover.

There is an error in the language

E744- file/boot ROM.

0004 An attempt to switchover to a

language on the HDD fails.

Download a language file of the correct

version.

There is an error in the language

E744- file/boot ROM.

1000 The boot ROM that is mounted is of

the wrong type

Replace the boot ROM with one of the

model in question.

There is an error in the language

E744- file/boot ROM.

2000 The engine ID indicated by the

software ID is illegal.

Replace it with a software ID of the

correct model.

There is an error in the language

E744- file/boot ROM.

3xxx Disagreement between the installed

memory and the boot ROM

Confirm and correct the installed memory

and the boot ROM.

There is a fault on the TokenRing

E745- board.

0001 An attempt at PCI initialization has

failed.

1. Disconnect and then connect the

TokenRing board. 2. Replace the

TokenRing board.

There is a fault on the TokenRing

E745board.

0002

The MAC address is faulty.

1. Replace the TokenRing board.

There is a fault on the TokenRing

board.

E745There is an error in the

0003

acquisition/setting of board

information.

1. Replace the TokenRing board.

There is a fault on the TokenRing

E745board.

0004

There is a connection error.

1. Check the connection of the cable. 2.

Replace the cable. 3. Check the power

source of the MAU. 4. Replace the MAU.

5. Replace the TokenRing board.

E745- There is a fault on the TokenRing

0005 board.

29

Other Errors

The accessories board is of the

E746- wrong type.

0003 At startup, a board for a different

model has been detected.

Replace the UFR board of the correct

type (model).

There is a mismatch between

E748- controller board and SDRAM size.

2000 An error occurs when accessing the

chip on the main controller PCB.

Replace the main controller PCB.

Code

Description

Remedy

There is an error in the DDI

communication.

E743- An SCI error has occurred. The

0000 received data is faulty. A reception

timeout condition has occurred. An

SEQ timeout error has occurred.

Disconnect and then connect the flexible

cable used to connect the reader unit and

the printer unit. Replace the following as

necessary: flexible cable, reader

controller PCB, main controller PCB.

There is an error in the language

file/boot ROM.

E744The version of the language file on

0001

the HDD and that of the bootable do

not match.

Download a language file of the correct

version.

There is an error in the language

E744- file/boot ROM.

0002 The size of the language file on the

HDD is too large.

Download a language file of the correct

version.

There is an error in the language

file/boot ROM.

Download a language file of the correct

E744There is no language file on the HDD

version.

0003

indicated by config.txt for a

switchover.

There is an error in the language

E744- file/boot ROM.

0004 An attempt to switchover to a

language on the HDD fails.

Download a language file of the correct

version.

There is an error in the language

E744- file/boot ROM.

1000 The boot ROM that is mounted is of

the wrong type

Replace the boot ROM with one of the

model in question.

E744- There is an error in the language

Replace it with a software ID of the

30

2000

file/boot ROM.

The engine ID indicated by the

software ID is illegal.

correct model.

There is an error in the language

E744- file/boot ROM.

3xxx Disagreement between the installed

memory and the boot ROM

Confirm and correct the installed memory

and the boot ROM.

There is a fault on the TokenRing

E745- board.

0001 An attempt at PCI initialization has

failed.

1. Disconnect and then connect the

TokenRing board. 2. Replace the

TokenRing board.

There is a fault on the TokenRing

E745board.

0002

The MAC address is faulty.

1. Replace the TokenRing board.

There is a fault on the TokenRing

board.

E745There is an error in the

0003

acquisition/setting of board

information.

1. Replace the TokenRing board.

There is a fault on the TokenRing

E745board.

0004

There is a connection error.

1. Check the connection of the cable. 2.

Replace the cable. 3. Check the power

source of the MAU. 4. Replace the MAU.

5. Replace the TokenRing board.

There is a fault on the TokenRing

E745board.

0005

Other Errors

The accessories board is of the

E746- wrong type.

0003 At startup, a board for a different

model has been detected.

Replace the UFR board of the correct

type (model).

There is a mismatch between

E748- controller board and SDRAM size.

2000 An error occurs when accessing the

chip on the main controller PCB.

Replace the main controller PCB.

Anda mungkin juga menyukai

- Konica-Minolta Bizhub 423 Error CodesDokumen26 halamanKonica-Minolta Bizhub 423 Error Codesnafees0% (1)

- Error Code For Canon IR4045 AdvanceDokumen30 halamanError Code For Canon IR4045 AdvanceRopsonBelum ada peringkat

- How To Install Android 4Dokumen39 halamanHow To Install Android 4nafeesBelum ada peringkat

- 02 BMWActiveHybridX6Dokumen118 halaman02 BMWActiveHybridX6Damian Creque100% (3)

- Canon IR3245 Error CodesDokumen31 halamanCanon IR3245 Error Codesnafees80% (10)

- Fix Heater Error Codes IR 5075 SeriesDokumen9 halamanFix Heater Error Codes IR 5075 Seriesslavko688% (8)

- Iq4bike PDFDokumen57 halamanIq4bike PDFEd Val100% (1)

- Ir2270 2870 3570 4570-gtc-gcd20041124Dokumen22 halamanIr2270 2870 3570 4570-gtc-gcd20041124utilsc0% (1)

- Ir4570 Service ManualDokumen1.008 halamanIr4570 Service ManualMarco MenaBelum ada peringkat

- How Helicopters WorkDokumen11 halamanHow Helicopters WorknafeesBelum ada peringkat

- ENG ImageRUNNER 1018 1019 1022 1023 Circuit DiagramDokumen30 halamanENG ImageRUNNER 1018 1019 1022 1023 Circuit DiagramNixon8Belum ada peringkat

- Nexans Submarine TechnologyDokumen24 halamanNexans Submarine TechnologyA. HassanBelum ada peringkat

- Ricoh Aficio MPC4000 Trouble Error CodesDokumen25 halamanRicoh Aficio MPC4000 Trouble Error CodesnafeesBelum ada peringkat

- Ir5000, Ir6000 Series Service BulletinsDokumen174 halamanIr5000, Ir6000 Series Service BulletinsAlfonso Sanchez Verduzco100% (1)

- Emerson ECM1500Dokumen34 halamanEmerson ECM1500cristachedinuBelum ada peringkat

- Navy AE 3 & 2Dokumen472 halamanNavy AE 3 & 2Tre Ware100% (1)

- Canon IR Advance 4045 Trouble Error CodesDokumen94 halamanCanon IR Advance 4045 Trouble Error CodesnafeesBelum ada peringkat

- Ricoh Alicia MPC3503SP Trouble Error CodesDokumen46 halamanRicoh Alicia MPC3503SP Trouble Error CodesnafeesBelum ada peringkat

- High Voltage Rules RevisedDokumen9 halamanHigh Voltage Rules Revisedraj KumarBelum ada peringkat

- How The Sun WorksDokumen27 halamanHow The Sun WorksnafeesBelum ada peringkat

- ABB 1HSM 9543 01-10enDokumen16 halamanABB 1HSM 9543 01-10enmrivero1983Belum ada peringkat

- Ricoh Aficio MPC6501 Trouble Error CodesDokumen55 halamanRicoh Aficio MPC6501 Trouble Error Codesnafees100% (1)

- Guide For Preparation of Specifications For Power TransformersDokumen70 halamanGuide For Preparation of Specifications For Power Transformersme_vahabi100% (2)

- Canon Ir8070 Error Codes List PDFDokumen18 halamanCanon Ir8070 Error Codes List PDFGirish KumarBelum ada peringkat

- Canon Ir3225 Error Codes: Code DescriptionDokumen46 halamanCanon Ir3225 Error Codes: Code DescriptionnishaBelum ada peringkat

- Error Code Ir3245 - Series-SmDokumen22 halamanError Code Ir3245 - Series-SmvikramBelum ada peringkat

- Canon IR Advance 500 Trouble Error CodesDokumen30 halamanCanon IR Advance 500 Trouble Error CodesnafeesBelum ada peringkat

- Canon IR4570 Trouble Error CodesDokumen22 halamanCanon IR4570 Trouble Error Codesnafees100% (3)

- ERRor Code IR3245Dokumen7 halamanERRor Code IR3245JatmokoBelum ada peringkat

- Canon IR2535 Trouble Error CodesDokumen36 halamanCanon IR2535 Trouble Error Codesnafees100% (4)

- Canon Ir2525 Trouble Error Codes PDFDokumen11 halamanCanon Ir2525 Trouble Error Codes PDFnafees80% (10)

- Error Codes 7095Dokumen70 halamanError Codes 7095Gerald Aguero PorrasBelum ada peringkat

- Error Code Ir5000Dokumen22 halamanError Code Ir5000Didi ConanBelum ada peringkat

- Canon IR2530 Error CodesDokumen10 halamanCanon IR2530 Error CodesnafeesBelum ada peringkat

- Error Code Details for Canon ImageRunner CopiersDokumen70 halamanError Code Details for Canon ImageRunner CopiersPadiparn Sae HouseBelum ada peringkat

- Resolve E061 Errors and Blank Copies on Canon iR6570Dokumen3 halamanResolve E061 Errors and Blank Copies on Canon iR6570YarnellePinedaAlvaroBelum ada peringkat

- Canon IR2016 Error CodesDokumen7 halamanCanon IR2016 Error CodesnafeesBelum ada peringkat

- Canon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineDokumen94 halamanCanon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineTengkuBelum ada peringkat