Pad Eyes

Diunggah oleh

Rachmad HidayatJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pad Eyes

Diunggah oleh

Rachmad HidayatHak Cipta:

Format Tersedia

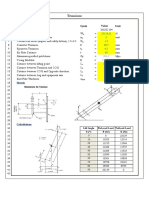

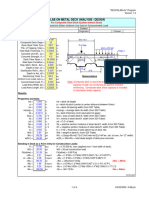

"PAD EYES CALCULATION for TOILET"

Equipment erection weight / loads

Dinamic factor

Number of Lifting Lug

Material of Lifting Lug

W

C

n

Mat'l

:

:

:

:

1070 kg

:

1.070

ton

1.5 ( Assumed for safety )

2 ( When loading or pulling with 2 points )

ASTM A-36

Yield Stress of Lift. Material

Ys

25.3105 kg/mm2

( According to Std. Matl. Properties )

Yield Stress of Welding Electrode

Ye

49.2142 kg/mm2

( Assumed E 70xx electrode are used )

Allowable Stress of Fillet Weld

Lifting / Sling Angle

Side Swing Angle

Diameter of Pin that which pulling

Dp

:

:

:

:

19.6857

45

0

40

kg/mm

Deg.

Deg.

mm

42.18464

A

H

R

d

t

tp

w1

w2

=

=

=

=

=

=

=

=

267

85.9

58

38.01

19

76.2

5

5

802.5 kg

2. Lifting Load per X axis, Fx

Fx = F / tan

Fx

802.5 kg

3. Lifting Load per Y axis, Fy

Fy = Fx * tan

Fy

0.000 kg

4. Resultant Load of Lug, Fz

Fz = Sqrt (F2 + Fx2 + Fy2 )

Fz

1134.906 kg

5. Bending Stress on Lug, Sb

X axis

Sb-x = Fy * H / ( 1/6 * A * t2 )

Sb-x

0.000 kg/mm2

Y axis

Sb-y = Fx * H / ( 1/6 * A2 * t )

Sb-y

0.305 kg/mm2

St

0.524 kg/mm2

LIFTING LUG STRESS CHECK

Checking Stress that working to each lug

1. Load per Lug

F :

F = (C * W) / n

6. Tension Stress on Lug, St

St = Fz / ( t * 2 * R - d )

7. Combined Stress

Sc

= ((Sbx / 0,66 * Ys) + (Sby / 0,66 * Ys) + (St /0,6 * Ys))

< 1,00

mm

mm

mm

mm

mm

mm

mm

mm

Sc

0.0528

<

O.K

8. Shear Stress on Pin Hole of lug, Ss

Ss = Fz / ( 2 * t * ( R - d/2 )

Ss =

0.7659 kg/mm2

>

= 0,4 * Ys

=

10.12420 >

Allowable Shear Stress

Ss

0.7659

O.K

9. Bearing Stress on Pin Area, Sb-p

Sb-p = Fz / ( Dp * t )

Sb-p =

1.4933 kg/mm2

>

= 0,90 * Ys

=

22.77945 >

Allowable Bearing Stress

Sb-p

1.4933

O.K

WELDING CHECK

Checking Fillet Weld Leg on Lug

10. Section Modulus of Fillet Weld, Sw

Sw = A2 / 3

Sw

23763.00 mm2

11. Bending Force on Lug, Fb

Fb = Fz * H / Sw

Fb

4.1025 kg/mm2

12. Tension Force on lug, Ft

Ft = Fz / ( 2 * A )

Ft

2.1253 kg/mm2

13. Combined Force, Fc

Fc = sqrt ( Fb2 + Ft2 )

Fc =

4.6204 kg/mm2

14. Required Fillet Weld Leg on Lug, W reg

Wreg = Fc / f

Wreg =

0.2347 mm

Actual Fillet Weld ( w1 )

Actual Fillet Weld ( w2 )

=

=

5

5

>

>

0.2347

0.2347

O.K

O.K

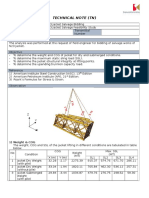

"PAD EYES CALCULATION for SHELTER"

Equipment erection weight / loads

Dinamic factor

Number of Lifting Lug

Material of Lifting Lug

W

C

n

Mat'l

:

:

:

:

588 kg

:

0.588

ton

2 ( Assumed for safety )

1 ( When loading or pulling with 1 points )

ASTM A-36

Yield Stress of Lift. Material

Ys

25.3105 kg/mm2

( According to Std. Matl. Properties )

Yield Stress of Welding Electrode

Ye

49.2142 kg/mm2

( Assumed E 70xx electrode are used )

Allowable Stress of Fillet Weld

Lifting / Sling Angle

Side Swing Angle

Diameter of Pin that which pulling

Dp

:

:

:

:

19.6857

90

0

40

kg/mm

Deg.

Deg.

mm

42.18464

A

H

R

d

t

tp

w1

w2

=

=

=

=

=

=

=

=

200

76.05

58

38.01

19

76.2

5

5

1176 kg

2. Lifting Load per X axis, Fx

Fx = F / tan

Fx

= 7.20E-014 kg

3. Lifting Load per Y axis, Fy

Fy = Fx * tan

Fy

0.000 kg

4. Resultant Load of Lug, Fz

Fz = Sqrt (F2 + Fx2 + Fy2 )

Fz

1176.000 kg

5. Bending Stress on Lug, Sb

X axis

Sb-x = Fy * H / ( 1/6 * A * t2 )

Sb-x

0.000 kg/mm2

Y axis

Sb-y = Fx * H / ( 1/6 * A2 * t )

Sb-y

0.000 kg/mm2

St

0.543 kg/mm2

LIFTING LUG STRESS CHECK

Checking Stress that working to each lug

1. Load per Lug

F :

F = (C * W) / n

6. Tension Stress on Lug, St

St = Fz / ( t * 2 * R - d )

7. Combined Stress

Sc

= ((Sbx / 0,66 * Ys) + (Sby / 0,66 * Ys) + (St /0,6 * Ys))

< 1,00

mm

mm

mm

mm

mm

mm

mm

mm

Sc

0.0358

<

O.K

8. Shear Stress on Pin Hole of lug, Ss

Ss = Fz / ( 2 * t * ( R - d/2 )

Ss =

0.7936 kg/mm2

>

= 0,4 * Ys

=

10.12420 >

Allowable Shear Stress

Ss

0.7936

O.K

9. Bearing Stress on Pin Area, Sb-p

Sb-p = Fz / ( Dp * t )

Sb-p =

1.5474 kg/mm2

>

= 0,90 * Ys

=

22.77945 >

Allowable Bearing Stress

Sb-p

1.5474

O.K

WELDING CHECK

Checking Fillet Weld Leg on Lug

10. Section Modulus of Fillet Weld, Sw

Sw = A2 / 3

Sw

13333.33 mm2

11. Bending Force on Lug, Fb

Fb = Fz * H / Sw

Fb

6.7076 kg/mm2

12. Tension Force on lug, Ft

Ft = Fz / ( 2 * A )

Ft

2.9400 kg/mm2

13. Combined Force, Fc

Fc = sqrt ( Fb2 + Ft2 )

Fc =

7.3236 kg/mm2

14. Required Fillet Weld Leg on Lug, W reg

Wreg = Fc / f

Wreg =

0.3720 mm

Actual Fillet Weld ( w1 )

Actual Fillet Weld ( w2 )

=

=

5

5

>

>

0.3720

0.3720

O.K

O.K

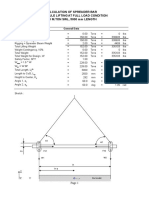

"PAD EYES CALCULATION"

Equipment erection weight / loads

Dinamic factor

Number of Lifting Lug

Material of Lifting Lug

W

C

n

Mat'l

:

:

:

:

3000 kg

:

3.000

ton

2 ( Assumed for safety )

4 ( When loading or pulling with 4 points )

ASTM A-36

Yield Stress of Lift. Material

Ys

25.3105 kg/mm2

( According to Std. Matl. Properties )

Yield Stress of Welding Electrode

Ye

49.2142 kg/mm2

( Assumed E 70xx electrode are used )

Allowable Stress of Fillet Weld

Lifting / Sling Angle

Side Swing Angle

Diameter of Pin that which pulling

Dp

:

:

:

:

19.6857

60

45

42

kg/mm

Deg.

Deg.

mm

42.18464

A

H

R

d

t

tp

w1

w2

=

=

=

=

=

=

=

=

1500 kg

2. Lifting Load per X axis, Fx

Fx = F / tan

Fx

866.0254 kg

3. Lifting Load per Y axis, Fy

Fy = Fx * tan

Fy

866.025 kg

4. Resultant Load of Lug, Fz

Fz = Sqrt (F2 + Fx2 + Fy2 )

Fz

1936.492 kg

5. Bending Stress on Lug, Sb

X axis

Sb-x = Fy * H / ( 1/6 * A * t2 )

Sb-x

4.677 kg/mm2

Y axis

Sb-y = Fx * H / ( 1/6 * A2 * t )

Sb-y

0.748 kg/mm2

St

1.195 kg/mm2

LIFTING LUG STRESS CHECK

Checking Stress that working to each lug

1. Load per Lug

F :

F = (C * W) / n

6. Tension Stress on Lug, St

St = Fz / ( t * 2 * R - d )

7. Combined Stress

Sc

= ((Sbx / 0,66 * Ys) + (Sby / 0,66 * Ys) + (St /0,6 * Ys))

< 1,00

125

45

41

19

20

5

5

5

mm

mm

mm

mm

mm

mm

mm

mm

Sc

0.4034

<

O.K

8. Shear Stress on Pin Hole of lug, Ss

Ss = Fz / ( 2 * t * ( R - d/2 )

Ss =

1.5369 kg/mm2

>

= 0,4 * Ys

=

10.12420 >

Allowable Shear Stress

Ss

1.5369

O.K

9. Bearing Stress on Pin Area, Sb-p

Sb-p = Fz / ( Dp * t )

Sb-p =

2.3053 kg/mm2

>

= 0,90 * Ys

=

22.77945 >

Allowable Bearing Stress

Sb-p

2.3053

O.K

WELDING CHECK

Checking Fillet Weld Leg on Lug

10. Section Modulus of Fillet Weld, Sw

Sw = A2 / 3

Sw

5208.33 mm2

11. Bending Force on Lug, Fb

Fb = Fz * H / Sw

Fb

16.7313 kg/mm2

12. Tension Force on lug, Ft

Ft = Fz / ( 2 * A )

Ft

7.7460 kg/mm2

13. Combined Force, Fc

Fc = sqrt ( Fb2 + Ft2 )

Fc =

18.4374 kg/mm2

14. Required Fillet Weld Leg on Lug, W reg

Wreg = Fc / f

Wreg =

0.9366 mm

Actual Fillet Weld ( w1 )

Actual Fillet Weld ( w2 )

=

=

5

5

>

>

0.9366

0.9366

O.K

O.K

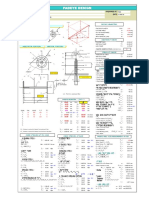

"PAD EYES CALCULATION for SKID"

Equipment erection weight / loads

Dinamic factor

Number of Lifting Lug

Material of Lifting Lug

W

C

n

Mat'l

:

:

:

:

25098 kg

:

25.098 ton

1.5 ( Assumed for safety )

4 ( When loading or pulling with 4 points )

ASTM A-36

Yield Stress of Lift. Material

Ys

25.3105 kg/mm2

( According to Std. Matl. Properties )

Yield Stress of Welding Electrode

Ye

49.2142 kg/mm2

( Assumed E 70xx electrode are used )

Allowable Stress of Fillet Weld

Lifting / Sling Angle

Side Swing Angle

Diameter of Pin that which pulling

Dp

:

:

:

:

19.6857

45

0

80

kg/mm

Deg.

Deg.

mm

A

H

R

d

t

tp

w1

w2

tc

dc

=

=

=

=

=

=

=

=

=

=

176

88

88

76

19

152.4

10

10

10

136

9411.75 kg

2. Lifting Load per X axis, Fx

Fx = F / tan

Fx

9411.75 kg

3. Lifting Load per Y axis, Fy

Fy = Fx * tan

Fy

0.000 kg

4. Resultant Load of Lug, Fz

Fz = Sqrt (F2 + Fx2 + Fy2 )

Fz

= 13310.224 kg

LIFTING LUG STRESS CHECK

Checking Stress that working to each lug

1. Load per Lug

F :

F = (C * W) / n

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

5. Bending Stress on Lug, Sb

X axis

Sb-x = Fy * H / ( 1/6 * A * ( t + 2tc)2 )

Sb-x

0.000 kg/mm2

Y axis

Sb-y = Fx * H / ( 1/6 * A2 * ( t + 2tc) )

Sb-y

4.114 kg/mm2

St

2.370 kg/mm2

6. Tension Stress on Lug, St

St = Fz / ( ( t + 2 tc ) * 2 * (( R - d ) + ( dc - d )) )

7. Combined Stress

Sc

= ((Sbx / 0,66 * Ys) + (Sby / 0,66 * Ys) + (St /0,6 * Ys))

< 1,00

Sc

0.4023

<

O.K

8. Shear Stress on Pin Hole of lug, Ss

Ss = Fz / 2 * ( t * ( R - d/2 )) + ( 2 * tc * ( dc - d/2 ))

Ss =

3.4482 kg/mm2

>

= 0,4 * Ys

=

10.12420 >

Allowable Shear Stress

Ss

3.4482

O.K

9. Bearing Stress on Pin Area, Sb-p

Sb-p = Fz / ( Dp ( t + 2 tc )

Sb-p =

4.2661 kg/mm2

>

= 0,90 * Ys

=

22.77945 >

Allowable Bearing Stress

Sb-p

4.2661

O.K

WELDING CHECK

Checking Fillet Weld Leg on Lug

10. Section Modulus of Fillet Weld, Sw

Sw = A2 / 3

Sw

10325.33 mm2

11. Bending Force on Lug, Fb

Fb = Fz * H / Sw

Fb

113.4394 kg/mm2

12. Tension Force on lug, Ft

Ft = Fz / ( 2 * A )

Ft

37.8131 kg/mm2

13. Combined Force, Fc

Fc = sqrt ( Fb2 + Ft2 )

Fc =

119.5756 kg/mm2

14. Required Fillet Weld Leg on Lug, W reg

Wreg = Fc / f

Wreg =

6.0742 mm

Actual Fillet Weld ( w1 )

Actual Fillet Weld ( w2 )

=

=

10

10

>

>

6.0742

6.0742

O.K

O.K

Anda mungkin juga menyukai

- Lifting Trunnion Calculations On Horizontal Vessel - 1Dokumen1 halamanLifting Trunnion Calculations On Horizontal Vessel - 1miteshpatel191Belum ada peringkat

- Design Calculation 4-PadeyesDokumen4 halamanDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- Lifting Beam DesignDokumen4 halamanLifting Beam DesignAnonymous XAqiBJ100% (4)

- 132kV SAG CalculationDokumen14 halaman132kV SAG CalculationPramod B.Wankhade100% (4)

- TrunnionDokumen7 halamanTrunnionRUDHRA DHANASEKAR100% (1)

- Design of Pad Eye Using Check PlatesDokumen3 halamanDesign of Pad Eye Using Check Plateshyoung65Belum ada peringkat

- Lifting Sets Calculation - API RP 2ADokumen11 halamanLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Padeye Calculation For Lifting AnalysisDokumen3 halamanPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- Spreader Bar CalculationDokumen1 halamanSpreader Bar Calculationjirrsama100% (1)

- Lifting Lug CalculationDokumen4 halamanLifting Lug CalculationLokesh PatelBelum ada peringkat

- Padeye CalculationDokumen6 halamanPadeye CalculationKarun DasBelum ada peringkat

- Toaz - Info Lifting Beam Design PRDokumen4 halamanToaz - Info Lifting Beam Design PRHari Kiran100% (1)

- PROBLEM 13.14: SolutionDokumen1 halamanPROBLEM 13.14: SolutionNattamon PetchkeawBelum ada peringkat

- Spreader BarDokumen5 halamanSpreader Barmramico100% (1)

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokumen1 halaman2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanBelum ada peringkat

- 17 TonsDokumen8 halaman17 TonsFernando Humberto100% (1)

- Calculations: M 0 M 1 c1 c1 0 c2 c2 1 2Dokumen6 halamanCalculations: M 0 M 1 c1 c1 0 c2 c2 1 2shadab521100% (1)

- 6a Padeye Aisc 360 2005Dokumen6 halaman6a Padeye Aisc 360 2005mjlazoBelum ada peringkat

- Padeye Check SttandardDokumen36 halamanPadeye Check SttandardRiandi HartartoBelum ada peringkat

- Calculation Lifting LugDokumen4 halamanCalculation Lifting Lugelang purbayaBelum ada peringkat

- Standard Pad Eye 10T SWL-modifDokumen8 halamanStandard Pad Eye 10T SWL-modifrustamriyadiBelum ada peringkat

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDokumen5 halamanCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaBelum ada peringkat

- Calculation of Trunnions Rev3Dokumen3 halamanCalculation of Trunnions Rev3Bilel MahjoubBelum ada peringkat

- Design of Lifting LugsDokumen3 halamanDesign of Lifting LugsSaravan KumarBelum ada peringkat

- Horizontal Lifting LugDokumen1 halamanHorizontal Lifting LugTushar MangratiBelum ada peringkat

- Skid LiftDokumen2 halamanSkid LiftAmi PutraBelum ada peringkat

- DANA-Technical Note (TN)Dokumen8 halamanDANA-Technical Note (TN)Samsul Imran BahromBelum ada peringkat

- Spreader 150T - PL100 A36Dokumen8 halamanSpreader 150T - PL100 A36rustamriyadiBelum ada peringkat

- Lifting Trunnion AnalysisDokumen1 halamanLifting Trunnion Analysisprajwal86Belum ada peringkat

- LiftingLug TrunnionDokumen22 halamanLiftingLug Trunnionrichardchiam100% (2)

- Spreader Beam (Planning)Dokumen28 halamanSpreader Beam (Planning)AKSHAY BHATKARBelum ada peringkat

- Pad Eye DesignFDokumen8 halamanPad Eye DesignFRajasekar MeghanadhBelum ada peringkat

- Cover Plate CalculationDokumen1 halamanCover Plate CalculationSachin5586Belum ada peringkat

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Dokumen7 halamanLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonBelum ada peringkat

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDokumen3 halaman8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshBelum ada peringkat

- 吊耳计算Dokumen4 halaman吊耳计算huangjlBelum ada peringkat

- LIFTING LUG Weld Check KGDokumen4 halamanLIFTING LUG Weld Check KGjoerijiBelum ada peringkat

- SWI PadeyeDokumen11 halamanSWI PadeyeFian ArdiyanaBelum ada peringkat

- Section Properties: Design of Padeye As Per Aisc 360-2005Dokumen6 halamanSection Properties: Design of Padeye As Per Aisc 360-2005Enrique BarajasBelum ada peringkat

- Padeye 7Dokumen24 halamanPadeye 7Ramesh SelvarajBelum ada peringkat

- Lifting Lug SampleDokumen1 halamanLifting Lug Sampleabdul marpaung0% (1)

- Sfex Pad Eyes Calculations 35T - 32MMDokumen1 halamanSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaBelum ada peringkat

- Lifting PadeyeDokumen16 halamanLifting PadeyeLưu XuânBelum ada peringkat

- Padeye .5MT CHKDokumen12 halamanPadeye .5MT CHKDhanraj VasanthBelum ada peringkat

- Lifting LugDokumen39 halamanLifting LugSasikumar JothiBelum ada peringkat

- API RP 1102 SpreadsheetDokumen5 halamanAPI RP 1102 SpreadsheetMuhammad Farid TaufikBelum ada peringkat

- Lifting Lug Calculation Rev - 1Dokumen2 halamanLifting Lug Calculation Rev - 1WijayantoBelum ada peringkat

- Pad Eye Calculation For Separator 40 TonDokumen2 halamanPad Eye Calculation For Separator 40 TonDhanraj VasanthBelum ada peringkat

- DNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDokumen2 halamanDNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDhanraj VasanthBelum ada peringkat

- Lifting Lug AnalysisDokumen3 halamanLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Pveng: Pressure Vessel Engineering LTDDokumen5 halamanPveng: Pressure Vessel Engineering LTDBruno TrujilloBelum ada peringkat

- Tail Lifting Lug Calculation MS WordDokumen11 halamanTail Lifting Lug Calculation MS WordWijayanto BekasiBelum ada peringkat

- API 650 RF Pad Calculation PDFDokumen1 halamanAPI 650 RF Pad Calculation PDFRakeshBelum ada peringkat

- Lifting Lug CalculationsDokumen6 halamanLifting Lug CalculationsYash RamiBelum ada peringkat

- Saddle Reaction Summary - For Empty CaseDokumen12 halamanSaddle Reaction Summary - For Empty CasesridharBelum ada peringkat

- Wind Seismic Calculation DataDokumen8 halamanWind Seismic Calculation Dataaknauriyal2013Belum ada peringkat

- Monorail-DesignDokumen8 halamanMonorail-Designdicktracy11Belum ada peringkat

- General Criteria For Design Steel StructureDokumen12 halamanGeneral Criteria For Design Steel StructureSurat WaritBelum ada peringkat

- DECKSLABDokumen4 halamanDECKSLABjustjeff4bpiBelum ada peringkat

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDokumen29 halamanMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDari EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationBelum ada peringkat

- Preview FA Brocure DaiChen InggrisDokumen7 halamanPreview FA Brocure DaiChen InggrisRachmad HidayatBelum ada peringkat

- ILO 152 Lifting GearDokumen18 halamanILO 152 Lifting GearADL123100% (1)

- MD PV Asme v0.1Dokumen35 halamanMD PV Asme v0.1Kamlesh LuharBelum ada peringkat

- Pipe Wall Thickness (ASME B31.3)Dokumen12 halamanPipe Wall Thickness (ASME B31.3)Rachmad HidayatBelum ada peringkat

- Areas ClasificadasDokumen8 halamanAreas Clasificadasedin64Belum ada peringkat

- Design Analysis and Optimization of Offshore ModuleDokumen116 halamanDesign Analysis and Optimization of Offshore Modulerfvz6s100% (1)

- Introduction To Finite Element MethodsDokumen31 halamanIntroduction To Finite Element Methodsaap1Belum ada peringkat

- EED2014 Lab2n3 Tensile Brinell 2Dokumen11 halamanEED2014 Lab2n3 Tensile Brinell 2Pavitra Rajaveloo50% (2)

- P13ME51 BN AjanaDokumen3 halamanP13ME51 BN AjanaRocky FxBelum ada peringkat

- Annual Exam - Physics Answer KeyDokumen13 halamanAnnual Exam - Physics Answer KeyBhavesh AsapureBelum ada peringkat

- Exercise - 1 To 3 PC Circular Motion ResoDokumen15 halamanExercise - 1 To 3 PC Circular Motion ResoZenith xBelum ada peringkat

- Modul Fizik F5 2023 (Answers)Dokumen25 halamanModul Fizik F5 2023 (Answers)nyshahidaBelum ada peringkat

- Cold Formed Steel DesignDokumen2 halamanCold Formed Steel DesignkiplingkipBelum ada peringkat

- Improved Transverse Shear Stresses in Composite Finite Elements Based On First Order Shear Deformation TheoryDokumen10 halamanImproved Transverse Shear Stresses in Composite Finite Elements Based On First Order Shear Deformation TheoryesatecBelum ada peringkat

- 0.25 Marks X 40 MCQ 10 MarksDokumen5 halaman0.25 Marks X 40 MCQ 10 MarksNilBelum ada peringkat

- Calculuc Physics 1Dokumen82 halamanCalculuc Physics 1Mark De GuzmanBelum ada peringkat

- Measurement of Structural Damping and Equivalent Mass of A Vibrating BeamDokumen5 halamanMeasurement of Structural Damping and Equivalent Mass of A Vibrating BeamTRUNG QUOC LEBelum ada peringkat

- مقاومه مواد محاضرات د.فراتDokumen121 halamanمقاومه مواد محاضرات د.فراتlana_salahadinBelum ada peringkat

- Chapter - 4Dokumen37 halamanChapter - 4Barnabas YohannesBelum ada peringkat

- A Survey of Penetration Mechanics For Long Rods PDFDokumen44 halamanA Survey of Penetration Mechanics For Long Rods PDFleiBelum ada peringkat

- ChainDokumen2 halamanChainmyusuf_engineerBelum ada peringkat

- NotesDokumen4 halamanNotesYASHVI MODIBelum ada peringkat

- Theory of Simple Bending - Full1Dokumen62 halamanTheory of Simple Bending - Full1Rahul KasaudhanBelum ada peringkat

- PART 4 Abutment DesignDokumen23 halamanPART 4 Abutment Designshashi rajhansBelum ada peringkat

- A Study of A Skirtless Hovercraft DesignDokumen71 halamanA Study of A Skirtless Hovercraft DesignSunil Kumar P GBelum ada peringkat

- Fib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFDokumen396 halamanFib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFPieter MeulendijksBelum ada peringkat

- Thermal Physics: Raymond A. Serway Chris VuilleDokumen44 halamanThermal Physics: Raymond A. Serway Chris VuilleMark Lorens StaanaBelum ada peringkat

- Practical No-5 (Curvilinear Motion)Dokumen8 halamanPractical No-5 (Curvilinear Motion)Jay V. GoyelBelum ada peringkat

- Spectrum Physics - May 2016Dokumen100 halamanSpectrum Physics - May 2016Popovici DraganBelum ada peringkat

- The Lift Sling Is Used To Hoist A Container Having - Question SolutionsDokumen3 halamanThe Lift Sling Is Used To Hoist A Container Having - Question SolutionsyogihardBelum ada peringkat

- 2directional Drilling3Dokumen6 halaman2directional Drilling3Hugh He0% (1)

- Ancra 1500 Lbs 425 Ksi 430ksi 52100 AllowableDokumen10 halamanAncra 1500 Lbs 425 Ksi 430ksi 52100 Allowableanhntran4850Belum ada peringkat

- MC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Dokumen69 halamanMC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Ruban FernandesBelum ada peringkat

- TOS NotesDokumen27 halamanTOS Notesaustriamylene31Belum ada peringkat

- UT Dallas Syllabus For Phys2325.001.10f Taught by Jason Slinker (jds107020)Dokumen6 halamanUT Dallas Syllabus For Phys2325.001.10f Taught by Jason Slinker (jds107020)UT Dallas Provost's Technology GroupBelum ada peringkat