RBH Innovative Conveyor Solutions Flyer

Diunggah oleh

ajaykrishnaa0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

41 tayangan2 halamanHak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

41 tayangan2 halamanRBH Innovative Conveyor Solutions Flyer

Diunggah oleh

ajaykrishnaaHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 2

jirect Drive

facuum.

are modular in design for fully configurable conveying solutions

+ Compact MotoriGear box mounting

combinations

traditional drive train out of the way

+ Right Hand or Left Hand Drive

+ Used to control product on a

horizontal or inclined conveyor

+ Variety of sizes, shapes

+ Open frame design

+ Good for point contact part

transporting

+ Lighter loads and shorter

distances

Ideal for elevation changes or part

holding

Can be used in upside down

applications

+ Vacuum area required is designed

per application

+A variety of vacuum sources can

be used

ffset Drive

+ Compact MotoriGear box mounting

combinations.

+ Under side mounting for side

cleara

‘+ Chain and Sprocket Drive for Long

Life

+ Left Hand and Right Hand Versions

+ Motor tucked under conveyor for

width restrictive applications

jodular Plastic

+ Sprocket driven for positive belt

engagement

“+ Higher load capacities and longer

ngths.

variety of belt compositi

and styles

+ Modular construction for simple belt

change

+ Conveyor

+ Higher Load Capacities and Longer

Lengths

+ Used to control product on a

horizontal or inclined conveyor

+ Accurate cleat spacing and

+ Highly durabl

+ Variety of sizes, shapes

= on

Automation

Robohand FERGUSON

ide Rails

“Multiple styles and materials of

side rails

-UHMW backing fixed or

adjustable

Round rod

“Heavy duty steel fixed

+Stainless steel fixed and

adjustable

jagnetic Belt Conveyors

“Effective control of ferrous

objects

*High speed horizontal and

inclined to vertical conveyor

belts

*Electromagnetic rail located

beneath the belt surface attracts

the ferrous objects to the belt

ing Belts With Cleats

+Sprocket driven for positive belt

engagement

*Higher load capacities and

longer lengths.

*Wide variety of belt

compositions and styles

+Molded or bolt on fixture

attachments available

SS.

itainless Mesh With Fixtures

*Capable of handling part contact

at high temperatures

“Belt construction allows flow of

ir and liquids throughout the

entire belt

jeavy Duty

+Engineered to elevate and

transfer a broad range of tough

materials

+Available in both Flat Belt and

Modular Plastic Belt

Applications

steel Chain

“Designed for accumulation of

difficult metal parts

ideal for metal cutting

‘environments.

*Cost effective replacement for

inline vibratory tracks

“Sprocket driven for positive

chain engagement

“Multiple options and packages

are available

+Material handling in wash down

or corrosive environments

Applications requiring a more

sanitary design

hain With Cleats

=

ravity Roller

ff

rip Trays

angles available

*Increased load carrying

‘capacity compared to belt

*Cost effective transport solution

to basic product transport

yned for handling multi-sized

packages in low to high-volume

applications

+Available in steel and stainless

*Prevent access to the underside

of the conveyor for safety

*Shield area under conveyor from

particles in clean room

applications

+Can be inclined, to enable the

waste fluid to flow to a drain

outlet

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Catia Interview Question and AnwersDokumen64 halamanCatia Interview Question and AnwersajaykrishnaaBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Standard Holes and Tapping ChartDokumen1 halamanStandard Holes and Tapping ChartajaykrishnaaBelum ada peringkat

- FESTO Basic PLCDokumen180 halamanFESTO Basic PLCapi-3769014100% (25)

- FESTO Basic PnuematicsDokumen115 halamanFESTO Basic Pnuematicsapi-3769014100% (10)

- Delcam Power Mill Roughing and Finishing ProgrammeDokumen27 halamanDelcam Power Mill Roughing and Finishing Programmeajaykrishnaa68% (19)

- 99 Pneumatic ApplicationsDokumen121 halaman99 Pneumatic Applicationsapi-3731420100% (7)

- Conveyor DesignsDokumen34 halamanConveyor Designsajaykrishnaa100% (2)

- Unigraphics NX4 ManualDokumen700 halamanUnigraphics NX4 Manualajaykrishnaa100% (7)

- Guide To Selection: Call Toll Free 800-562-0357Dokumen7 halamanGuide To Selection: Call Toll Free 800-562-0357ajaykrishnaaBelum ada peringkat

- Tool Steel CompositionDokumen5 halamanTool Steel CompositionajaykrishnaaBelum ada peringkat

- Ajay Covering LetterDokumen1 halamanAjay Covering LetterajaykrishnaaBelum ada peringkat

- En 8Dokumen3 halamanEn 8ajaykrishnaaBelum ada peringkat

- Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact UsDokumen3 halamanTechnical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact UsajaykrishnaaBelum ada peringkat

- THK LM Guide en - A01 - 102Dokumen2 halamanTHK LM Guide en - A01 - 102ajaykrishnaaBelum ada peringkat

- Mild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankDokumen2 halamanMild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankajaykrishnaaBelum ada peringkat

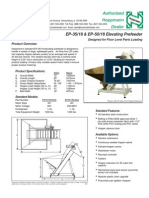

- Ep 35 50Dokumen1 halamanEp 35 50ajaykrishnaaBelum ada peringkat

- Speed and Accuracy Applications: Linear Drive UnitsDokumen31 halamanSpeed and Accuracy Applications: Linear Drive UnitsajaykrishnaaBelum ada peringkat

- Over Cap FeederDokumen1 halamanOver Cap FeederajaykrishnaaBelum ada peringkat

- DSC Modular Conveyor Systems BrochureDokumen32 halamanDSC Modular Conveyor Systems BrochureJuan Manuel LaraBelum ada peringkat

- UG Interview QuestionsDokumen16 halamanUG Interview Questionsharsharg6_8Belum ada peringkat

- Conveyor Chain GuideDokumen59 halamanConveyor Chain GuideajaykrishnaaBelum ada peringkat

- Innovative Designs For Positive Parts TransferDokumen21 halamanInnovative Designs For Positive Parts TransferajaykrishnaaBelum ada peringkat

- Afttp 1Dokumen2 halamanAfttp 1ajaykrishnaaBelum ada peringkat

- Basic Mathematics by Thomas WardDokumen23 halamanBasic Mathematics by Thomas WardazuzardBelum ada peringkat