High-Rise Water Systems Design

Diunggah oleh

htosar2Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

High-Rise Water Systems Design

Diunggah oleh

htosar2Hak Cipta:

Format Tersedia

Continuing Education

High-Rise Domestic Water Systems

Alfred Steele, PE CIPE

The primary objectives in the design of water supply systems for buildings are to ensure an adequate supply of water at

the required pressure to all fixtures, outlets, and equipment at all times and to achieve an economical, efficient, and energy-

conserving installation.

Excessive Pressure from the riser and serve three floors from each branch with

Excessive pressure causes operational difficulties and a PRV in each branch. The number of PRVs was reduced

greatly increases the cost of maintenance. Unless a piece of by two-thirds, but the branch piping became very compli-

equipment or an operation requires a specified high pres- cated in many installations. This method never became

sure, it is economic folly to design a system with outlet very popular. In recent years the method of zoning the

pressures that exceed a maximum of 70 psi, and it would building vertically and utilizing master PRV stations for each

be desirable, if possible, to limit the maximum to 60 psi. zone was introduced and has proven to be an outstanding

When pressures are above 70 psi, it is difficult to maintain success. By the use of zones not only is the number of

flow velocities (a function of pressure) below the critical PRVs drastically reduced, but the design of the hot water

velocity of 10 fps. Velocities of 10 fps or higher will result distribution system is greatly simplified.

in noises throughout the piping system. Although noise Determining the number of zones for any building is a

itself may not be objectionable in certain areas or cause straightforward procedure. Assume the pressure at fixtures

damage, excessive pressures and velocities do present is to be 20 psi. The type of water closet will determine the

some very real problems: actual minimum pressure required. Pressure required for

• Excessive wear or erosion of piping proper flushing action of water closets varies from 12 psi to

• Wire drawing of valve seats with resultant maintenance 25 psi. With the assumed 20 psi pressure, there is now an

problems and faulty operation allowable additional pressure of 50 psi that can be accom-

• Hydraulic shock (water hammer) and the resulting stress- modated before reaching the maximum pressure criterion

es that could rupture pipes or damage equipment of 70 psi. Fifty psi is equivalent to a static pressure of 115.5

• Damage to fixtures or equipment that are not designed ft (50 x 2.31). To obtain the maximum zone heights, a

for high pressure or velocity downfeed system should be employed so that gravity is

• Wasted water at outlets due to high rates of flow in working with the system instead of against it. With a PRV

excess of required flow set for an outlet pressure of 20 psi the piping can now be

• The nuisance of water splashing on walls, floors, or the run down for 115.5 ft before reaching 70 psi. If the floor-

user to-floor height is 12 ft, each zone can then be either 9 or

• Reduced life expectancy of the system and equipment 10 stories each (115.5 ÷ 12 = 9.6). The top zone of any sys-

• Increased costs of equipment, which requires special tem would never require a PRV. If an up-feed system is

construction for operation at the higher working used for each zone, the PRV outlet pressure would be set

pressures. at 70 psi.

To avoid the dangers attributable to excessive pressure,

some means must be provided to reduce the pressures to Actual Installations

below the maximum of 70 psi. Pressure-regulating valves A brief description of the domestic water system

(PRVs) and vertical zoning have proven to be the best designed by the author for an office building that has been

methods of maintaining pressures within desired limits. built and has been operating very satisfactorily should clar-

ify some high-rise design principles.

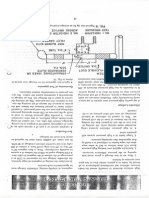

PRVs and Zoning Figure 1 is a schematic flow diagram of the cold water

Various schemes have been proposed and utilized distribution system, and Figure 2 shows the cold and hot

throughout the years to minimize the number of PRVs water piping in a typical zone.

required in a high-rise building. The earliest method was to A gravity tank system was selected after a complete and

install a PRV in every branch from a riser where the pres- thorough analysis of all the factors. A 10,000-gallon tank

sure was excessive. This resulted in hundreds of PRVs for was located at the top of the building, and a 15,000-gallon

every job. Access had to be provided to service these tank was located on the 40th floor. Two pumps located in

valves. The cost of the valves and the additional cost for the lowest level pump up to the 40th-floor tank. This tank

providing access was a decided disadvantage. The earliest serves as the water supply for the 34th floor down to the

attempt to eliminate some of the PRVs was to take a branch lowest level and at the same time acts as a suction tank to

Reprinted from Steele, Alfred (1984), Advanced Plumbing Technology, Elmhurst, IL: Construction Industry Press.

26 Plumbing Systems & Design • Jan/Feb 2003

Figure 1. Schematic Flow Diagram: Cold Water Distribution Figure 2. Schematic Flow Diagram: Typical Zone

System

Only pertinent features are shown; other required valves and piping are

deleted for clarity.

the pressure will now be approximately 70 psi. For this and

every zone below, the pressure must be reduced to

approximately 25 psi so as not to exceed 70 psi at the base

of each riser. PRVs are utilized for this purpose. After the

PRV, a connection is taken off for the water heater for that

zone. System pressure at the heaters is always below 30 psi,

and the same is true for the hot water circulating pumps.

The beauty of this system is that no special materials or

extra heavy construction is required (for which a premium

is always paid). The only piping in the entire job that is

Standard Oil Building, Chicago 1,136 ft high subjected to pressures greater than 70 psi is the pump dis-

charge lines and the main riser from the tanks.

supply two pumps on the same 40th floor to pump water The hot water distribution system is the epitome of econ-

to the top tank. This tank supplies water from the 80th floor omy. From the heater a riser feeds down in one vertical

down to the 35th floor, inclusive. The capacity of the two bank of toilet rooms, and at the base runs over to and up

basement pumps is sized for the total building demand, the other vertical bank of toilet rooms back to the heater for

and the two 40th-floor pumps are sized only for the upper a closed loop. No additional circulating risers are required,

section of the building. Each pump is sized for two-thirds and there are no problems of balancing the system. This

of the load, so if one pump fails in the duplex set-up the ideal set-up can probably be used for many office buildings.

other pump is capable of keeping the system in operation.

By placing gravity tanks at the top and middle of the Multi-Purpose Building

building, we have essentially divided a building of extreme A multi-purpose structure poses interesting problems for

height into two buildings of approximately 500 ft each in the plumbing engineer. The conceptual design of the water

height. One-half of the building will now be discussed distribution system for Water Tower Place in Chicago was

because the other half is designed in exactly the same man- prepared by the author, and thus enough information is

ner. A main downfeed riser runs from the tank down to the available to present the parameters and solutions for this

top of the lowest zone. For the second zone below the tank building.

Jan/Feb 2003 • Plumbing Systems & Design 27

Continuing Education: High-Rise Domestic Water Systems

Figure 3. Schematic Water Flow Diagram: Water Tower Place meter the condominium complex is thus

divorced entirely from the rest of the building

and all costs can be accurately allocated for

the operation and maintenance of that com-

plex.

The hotel complex and each major depart-

ment store tenant are treated in the same

manner as the condominium complex. An

examination of the water flow diagram illus-

trates how each is isolated (Figure 3).

The office complex, other shops, and any

other tenants remain the responsibility of the

owner and are identified as the base building.

The total building then breaks down into

base building, two separate department

stores, hotel, and condominiums.

Water Tower Place is of special interest to

the plumbing engineer because it is a com-

bination of most of the design applications

recommended in Advanced Plumbing

Technology. Both a gravity tank and booster

pump system are utilized in the same job.

The entire building is zoned to isolate vari-

ous complexes and to maintain maximum

pressures within recommended limits. There

are both up-feed and downfeed systems.

This should hopefully emphasize that no one

system is best for every job.

The illustrations (Figure 4 and Figure 5)

of the water distribution systems for other

high-rise jobs are given with no comments.

They are not presented as recommended sys-

tems because, as previously stressed, no two

jobs are identical and each must be thor-

oughly analyzed to select the best design for

that particular job. It is impossible to intelli-

gently critique a system until all the back-

ground information is available and all the

Water Tower Place, Chicago 838 ft high

peculiar and special requirements for the job

The occupancies of the building are divided into four dis- are known. The illustrations are shown to

tinct entities. The owner is obligated to provide only cer- demonstrate the approaches and solutions utilized by vari-

tain basic services to each entity and the responsibility for ous engineers for various jobs.

anything beyond these basic services belongs to each enti- Hot Water System

ty. The apartments are condominiums, and everything serv- In a high-rise building where the water distribution sys-

ing this complex (piping, pumps, heaters, other equipment, tem is zoned vertically to maintain pressures within the

operation, and maintenance) is the responsibility of the maximum criteria established, it is imperative that certain

condominium owners. It is, therefore, necessary to design precautions be observed in the design of the hot and cir-

the water distribution so that, from the point of service pro- culating water system. Each zone must be considered as a

vided by the building owner, the entire system is absolute- complete system with no interconnection with any other

ly separate and distinct from any other system in the build- zone. Each zone must have its own water heater, hot water

ing. The owner is responsible for tank fill pumps in the distributing piping, circulating hot water piping, and circu-

third basement, piping to the combination gravity and suc- lating pumps.

tion tank, the tank on the 32nd mechanical equipment If no economic penalty is involved, it is always desirable

floor, and the piping from tank to outlet of meter. From the to locate the heater at the top of the system. The pressures

28 Plumbing Systems & Design • Jan/Feb 2003

Figure 4. Schematic Water Flow Diagram: Bank Building Figure 5. Schematic Water Flow Diagram: John Hancock

Building

60-Story Bank Building 840 ft high John Hancock Building, Chicago 1,100 ft high

the heater and circulating pump are subjected to are much strip. The copper wires are not the heating element; their

less in this location than at the base of the system. Many only function is to provide a voltage potential across the

times the pressure at the base of a hot water system will polymer core along the entire length of the heater. The heat

require heaters, tanks, and pumps of special construction generated is due solely to the flow of current through the

to withstand the stresses. Under all circumstances, provi- core from one wire to the other.

sions must be made to relieve the air at any and all high

points of the system. Heater Operation

The strip heater is installed in contact with the piping

One-Pipe Hot Water Distribution System along its entire length. As the polymer core is heated by the

Due to an exciting innovation, it is now possible to elim- pipe, it expands and microscopically reduces its conductive

inate the requirement of separate water heaters for each paths. As thermal expansion of the core continues with

zone and specify a one-pipe hot water distribution system increased pipe temperature, more electrical paths are dis-

with a central water heater for the total project, which connected, thus reducing the heat output of the core until

requires absolutely no circulating system! the system reaches thermal stability. When the pipe tem-

perature drops, this process is reversed; the core responds

Self-Regulating Strip Heater by creating or reconnecting additional paths. As the num-

Researchers have recently developed a strip heater that ber of conductive paths increases, the resistance to current

responds to localized temperature conditions by self- flow decreases and the strip heater produces more heat.

regulating its heat output. The heart of the heater is a semi- This is the self-regulating characteristic of the core’s molec-

conductive polymer, which has been incorporated as the ular memory, which responds to thermal changes inde-

core of a strip heater that consists of the core and two cop- pendently at every point along the length of the pipe. In

per bus wires that run in parallel the length of the heater operation the self-regulating heater replaces the pipe heat

Jan/Feb 2003 • Plumbing Systems & Design 29

Continuing Education: High-Rise Domestic Water Systems

Figure 6. Self-Regulating Heater Construction Figure 8. Heater Positioning and Attachment

Figure 7. Heat Output Versus Water Temperature

source of electricity is installed by the electrical contractor.

The other end of the heater is simply cut to length and ter-

minated with an end seal. The parallel wire circuit design

of the heater permits teeing-off to feed multiple risers from

one horizontal base heater strip. A typical circuit can be a

maximum of 475 ft in length.

One-Pipe System Versus Two-Pipe System

The conventional hot water system is a two-pipe system

composed of a water heater (with a hot water storage tank

when required), supply piping, circulation piping, and cir-

loss at the point it occurs along the pipe and thus maintains culation pump. The system utilizing the self-regulating strip

the temperature of the water from its source (the conven- heater is a one-pipe system composed of only a water

tional water heater) to the end of the hot water supply net- heater (with a hot water storage tank when required), sup-

work. By continuously maintaining the water temperature ply piping, and self-regulating strip heater. In the one-pipe

in the supply piping there is no need for the conventional system the water heater (and storage tank) is exactly the

recirculation system! same as in the two-pipe system and functions to bring the

Although the self-regulating heater is relatively new to cold water supply up to required system temperature.

the commercial construction industry it has been widely Controls for the heater are the same in both systems.

used in industrial applications to maintain the temperature When the cold water has been brought up to system tem-

of fluids in pipes. The reliability, savings in energy, sim- perature the self-regulating heater then maintains the water

plicity of hot water system design, and ease of installation at this temperature throughout the supply piping. The self-

have led to the installation of more than 60 million ft of regulating heater replaces the heat loss at the points along

self-regulating strip heaters during the past 12 years. the supply piping where heat loss occurs, and since the

Construction of the heater is shown in Figure 6. water temperature is continuously maintained there is no

Figure 7 illustrates the relationship between the heat out- need for circulation piping, balancing valves, circulation

put of the heater and the temperature of the water in the pumps, and controls.

pipe.

Advantages

Installation The advantages of the one-pipe system can be divided

The installation of the self-regulating heater on the hot into four basic categories:

water supply piping is extremely simple. The heater is run 1. Lower installed cost

linearly on the pipe (for most sizes) and fastened with 2. Lower energy consumption (lower operating cost)

adhesive glass tape every 12 in. Pipe insulation fits around 3. Ease of system design

the pipe and heater (see Figure 8). 4. Improved system performance

One end of the heater terminates inside a pipe-mounted

junction box, and the wiring from the junction box to the

30 Plumbing Systems & Design • Jan/Feb 2003

Figure 9. Schematic Diagram of One-Pipe System with Figure 10. Heater Spiraling Installation

Central Water Heater

two-pipe system all the cold water must be heated to a

temperature 10°–20° higher than the required temperature

at the fixtures. This overheating represents a significant

expenditure of energy.

Cost studies of annual operating costs for a typical high-

rise hotel indicated a potential savings of 50% with the one-

pipe system.

Ease of System Design

Only pertinent features are shown; other required valves and piping are At long last we have an innovation that makes life a lit-

deleted for clarity. tle easier for the design engineer. The one-pipe system is

easier to design than the conventional two-pipe system. It

Lower Installed Cost means fewer pipe runs to size, fewer pipe runs to lay out,

Lower installed cost is probably the most obvious advan- no pumps to size and select, and no worries about balanc-

tage of the one-pipe system because of the elimination of ing the system.

all circulation piping, circulation pipe insulation, circulation

riser control valves and balancing valves, and circulation High-Rise Design

pump with its valving, bypass, and controls. Only the cost The self-regulating strip heater probably offers the great-

of the self-regulating heater is added back. An installed cost est benefits when it is applied in the design of hot water sys-

comparison (using Means Mechanical and Electrical Cost tems for high-rise buildings. Consider a high-rise building

Data Book) of more than 100 buildings indicated savings of that has three vertical zones in order to eliminate exces-

more than 40%. sively high pressures. Conventional design dictates that a

separate water heater must be installed in each zone and the

Lower Energy Consumption (Lower Operating Cost) hot water system in each zone must be treated as a self-con-

The one-pipe system requires significantly less energy tained system that is separate from the systems in all other

than the conventional circulation system. In the circulation zones. With a conventional hot water system it is impossi-

system the water in the circulation piping is continuously ble to design a central system due to the unequal pressures

losing heat that must be made up by the heater. Since there of the water that would return to the central water heater

is no circulation piping in the one-pipe system, this source from each zone. With the elimination of the circulation sys-

of heat loss is eliminated and the need for additional ener- tem in the one-pipe design it is now possible to design a

gy is also eliminated. The elimination of the circulation high-rise hot water system using a central water heater, as

pump also contributes to a significant saving of energy. illustrated in Figure 9. The water heater should be located

To obtain a 105° F delivered water temperature at fixtures at the top of the building. If located at the bottom of the

the temperature of the hot water leaving the heater in the building the heater would be subjected to excessively high

conventional circulation system must range from 115° F to pressures.

125° F. In the one-pipe system the water temperature is

continuously maintained at the required temperature and Residential Buildings

as a result the water heater discharge temperature can be Practically all hot water systems for single-residence

set at 105° F. With lower water temperature throughout the homes do not have circulation systems. It is a particular

system there will be considerably less heat loss from stor- annoyance to the homeowner to have to wait a seemingly

age tanks and piping. long time for the hot water at the required temperature to

In the one-pipe system all the cold water supply to the reach the fixtures that are remote from the water heater.

heater is heated to the desired temperature only. In the This annoyance can now be eliminated by the installation

Jan/Feb 2003 • Plumbing Systems & Design 31

Continuing Education: High-Rise Domestic Water Systems

of the self-regulating strip heater. Not only will hot water Codes

be available instantaneously at every fixture, but the There is a very serious roadblock to the complete accept-

wastage of water will be eliminated. ance of the self-regulating strip heater and the resultant

elimination of the circulation system. Practically every code

Expansion of Facilities specifically requires that the hot water be circulated when

When additional fixtures are located in new areas of an the building is more than three stories in height or the run

existing building or a new addition is added to a building of supply piping exceeds 100 ft. It is important that code-

the one-pipe system offers decided advantages. All that is writing authorities be made aware of this breakthrough so

required is a connection to the existing hot water supply that they can make their evaluation and modify the code

piping and running the temperature-maintained piping to requirements as expeditiously as possible.

the new fixture areas.

Conclusion

Electrical Characteristics The design options available to the engineer when faced

The self-regulating strip heaters are suitable for installa- with the design of the plumbing systems for a new project

tion with 120-V or 208-V electrical supply. A typical heater generally involve trade-offs between installed cost advan-

for a 105° F hot water system under maximum demand tages and operating cost advantages. The self-regulating

conditions has a current flow of 0.021 amps per ft at 120V strip heater concept is unique in that it offers both lower

and 0.012 amps per ft at 208 V. installed cost and lower operating cost. It is the combina-

When a greater heat output is required to balance the tion of these benefits that makes the one-pipe system such

heat loss from the pipe, then two parallel heater strips must an attractive alternative to the conventional two-pipe hot

be installed (Figure 8) or the heater strip can be spiraled water system. ■

on the pipe as illustrated in Figure 10.

Continuing Education from Plumbing Systems & Design

Kenneth G. Wentink, PE* CPD, and Robert D. Jackson, Chicago Chapter Vice President, Technical

Do you find it difficult to obtain continuing education waived). If you earn a grade of 90% or higher on the test,

units (CEUs)? Is it hard for you to attend technical semi- you will be notified by return mail that you have logged

nars? ASPE has a new program to help you accumulate 0.1 CEU, which can be applied toward the CPD renewal

the CEUs required for maintaining your Certified in requirement or numerous regulatory-agency continuing

Plumbing Design (CPD) status. education programs. (Please note that it is your responsi-

ASPE features a technical article in Plumbing Systems & bility to determine the acceptance policy of a particular

Design (PSD), excerpted from its own publications. Each agency.) CEU information will be kept on file at the ASPE

article is followed by a multiple-choice test and a simple office for 3 years.

reporting form. No certificates will be issued in addition to the notifi-

Reading the article and completing the form will allow cation letter. You can apply for CEUs on any technical

you to apply to ASPE for CEU credit. For most people, article that has appeared in PSD within the past 12

this process will require approximately 1 hour. A nominal months. However, CEUs only can be obtained on a total

processing fee is charged—$5 for ASPE members and $25 of eight PSD articles in a 12-month period.

for nonmembers (until further notice, the member fee is

*Ken Wentink is licensed as a professional engineer in Massachusetts.

32 Plumbing Systems & Design • Jan/Feb 2003

Anda mungkin juga menyukai

- ASPE Greas Interceptor Sizing-2017EDDokumen11 halamanASPE Greas Interceptor Sizing-2017EDEhab MohamedBelum ada peringkat

- ASPE Cleveland Chapter Plumbing Handbook 2011-2012Dokumen133 halamanASPE Cleveland Chapter Plumbing Handbook 2011-2012Edward Garcia100% (1)

- Elements of PlumbingDokumen70 halamanElements of Plumbinglad odie0% (1)

- ASPE Hot Water System-2015EDDokumen19 halamanASPE Hot Water System-2015EDEhab MohamedBelum ada peringkat

- Air Distribution Engg GuideDokumen8 halamanAir Distribution Engg GuideNiong DavidBelum ada peringkat

- Design Considerations For Hot Water Plumbing PDFDokumen105 halamanDesign Considerations For Hot Water Plumbing PDFdorukbakirBelum ada peringkat

- High Rise StructuresPlumbing Design GuidelinesDokumen6 halamanHigh Rise StructuresPlumbing Design GuidelinesjituplanojrBelum ada peringkat

- Life Safety SystemsDokumen15 halamanLife Safety SystemsmpwasaBelum ada peringkat

- Supply Air Grille SizingDokumen12 halamanSupply Air Grille Sizingdynamitedragon100% (1)

- Energy Impacts of Chiller Water Piping ArrangementDokumen8 halamanEnergy Impacts of Chiller Water Piping ArrangementYazBelum ada peringkat

- FLS Report - Burj Dubai - 14 Sept 2005 - Final Rev - 091505Dokumen112 halamanFLS Report - Burj Dubai - 14 Sept 2005 - Final Rev - 091505SubharajkBelum ada peringkat

- High Velocity Duct Design Tips by TraneDokumen50 halamanHigh Velocity Duct Design Tips by TraneInventor SolidworksBelum ada peringkat

- High Rise Mechanical DesignDokumen55 halamanHigh Rise Mechanical DesignTristan Rice100% (2)

- Humidity Control With Chilled BeamsDokumen7 halamanHumidity Control With Chilled BeamsMelanie WilliamsBelum ada peringkat

- Ashrae CKV Design GuideDokumen14 halamanAshrae CKV Design Guidebasha99Belum ada peringkat

- Pressure Boosting PumpsDokumen4 halamanPressure Boosting PumpsmabuhayehBelum ada peringkat

- Plumbing Design in High RIseDokumen2 halamanPlumbing Design in High RIseyugerajd100% (1)

- Stairwell Lift Pressurization CalculationsDokumen31 halamanStairwell Lift Pressurization CalculationsKarthikeyan SankarrajanBelum ada peringkat

- Fire Sprinkler Design-Part1Dokumen2 halamanFire Sprinkler Design-Part1Henry SuarezBelum ada peringkat

- MAPUA INSTITUTE OF TECHNOLOGY BUILDING UTILITIES REVIEWDokumen11 halamanMAPUA INSTITUTE OF TECHNOLOGY BUILDING UTILITIES REVIEWSky JarielBelum ada peringkat

- 004 - High Rise Plumbing DesignDokumen8 halaman004 - High Rise Plumbing DesignsanjeetkarBelum ada peringkat

- Smacna Duct LeakageDokumen3 halamanSmacna Duct Leakageanton7786Belum ada peringkat

- CEU 258 April 2018Dokumen16 halamanCEU 258 April 2018fazyroshanBelum ada peringkat

- High Rise Water DistributionDokumen2 halamanHigh Rise Water DistributionzueklateBelum ada peringkat

- ASPE PSD - Designing and Constructing A Sewage Lift StationDokumen6 halamanASPE PSD - Designing and Constructing A Sewage Lift StationNiong David100% (1)

- Project Electrical Boq Feb 10-1Dokumen40 halamanProject Electrical Boq Feb 10-1Vijaya Sarathi RaviBelum ada peringkat

- HighRiseWaterSupplyDokumen4 halamanHighRiseWaterSupplySonia Dogra0% (1)

- Fcu SizingDokumen12 halamanFcu SizingLloydBelum ada peringkat

- ASPE Design GuideDokumen16 halamanASPE Design GuideJovenal TuplanoBelum ada peringkat

- Staircase PressurizationDokumen8 halamanStaircase PressurizationSimon LawBelum ada peringkat

- A Low-Cost, High Performance Lab HVAC DesignDokumen4 halamanA Low-Cost, High Performance Lab HVAC Designhtosar2Belum ada peringkat

- Ashrae Design Manual For Smoke ControlDokumen6 halamanAshrae Design Manual For Smoke Controlist93993100% (2)

- PSD Ceu 198april13Dokumen16 halamanPSD Ceu 198april13Niong DavidBelum ada peringkat

- Hotel ManualDokumen48 halamanHotel ManualRachel Dollison100% (7)

- MEBS6008 Environmental Services II Air Diffusion PrinciplesDokumen72 halamanMEBS6008 Environmental Services II Air Diffusion Principlesahtin618Belum ada peringkat

- High Rise BLDG Water SupplyDokumen22 halamanHigh Rise BLDG Water Supplykartik chopra64% (11)

- Central Hot Water in HighDokumen5 halamanCentral Hot Water in Highexfireex1Belum ada peringkat

- #392 - How To Size A Fire Pump and The Basics of Performance CurvesDokumen11 halaman#392 - How To Size A Fire Pump and The Basics of Performance CurvesAmar kobitaBelum ada peringkat

- Tutorial - Cold Water SupplyDokumen7 halamanTutorial - Cold Water SupplyyugerajdBelum ada peringkat

- Chilled Water Plant Pumping SchemesDokumen17 halamanChilled Water Plant Pumping Schemeshima007Belum ada peringkat

- Seresco Natatorium Design Guide 2013Dokumen36 halamanSeresco Natatorium Design Guide 2013Luis Giagante100% (1)

- Automatic Fire Sprinkler SystemDokumen35 halamanAutomatic Fire Sprinkler SystemAnandababuBelum ada peringkat

- Stairwell Pressurization Systems for Smoke Management in Tall BuildingsDokumen19 halamanStairwell Pressurization Systems for Smoke Management in Tall Buildingsofitecnicajg100% (2)

- Hydraulics in High Rise Satnam SinghDokumen10 halamanHydraulics in High Rise Satnam SinghsauroBelum ada peringkat

- Hot Water Circulation - Designers GuideDokumen3 halamanHot Water Circulation - Designers GuideAntonio LebrunBelum ada peringkat

- As Pe High Rise Plumbing DesignDokumen92 halamanAs Pe High Rise Plumbing Designalmira lhee cadores100% (1)

- High Rise PlumbingDokumen6 halamanHigh Rise PlumbingLyrrainne100% (1)

- ASPE PSD - Fire Pump InstallationDokumen4 halamanASPE PSD - Fire Pump InstallationNiong DavidBelum ada peringkat

- Refresher Note BLDG Utilities PDFDokumen6 halamanRefresher Note BLDG Utilities PDFJoyceBelum ada peringkat

- High-Rise Fire Protection System Design - Zoning & Series PumpingDokumen4 halamanHigh-Rise Fire Protection System Design - Zoning & Series PumpingminiongskyBelum ada peringkat

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDokumen23 halamanAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcBelum ada peringkat

- Sizing of Sewer DrainsDokumen46 halamanSizing of Sewer DrainsvictorBelum ada peringkat

- Sanitary Plumbing in High Rise Building PDFDokumen2 halamanSanitary Plumbing in High Rise Building PDFDrew B Mrtnz100% (1)

- High-Rise Plumbing Design - It's All The Same, Right - ConnellyDokumen11 halamanHigh-Rise Plumbing Design - It's All The Same, Right - ConnellyRamonBelum ada peringkat

- Comml Hi Rise PLMBG System DesignDokumen4 halamanComml Hi Rise PLMBG System DesignNestor S. ReEyesBelum ada peringkat

- Smoke Control System CalcDokumen14 halamanSmoke Control System Calckumar123rajuBelum ada peringkat

- Water Supply and Urban Drainage PDFDokumen107 halamanWater Supply and Urban Drainage PDFManiko Maniko100% (1)

- Hot Water Storage Systems GuideDokumen11 halamanHot Water Storage Systems GuideNadeesha BandaraBelum ada peringkat

- Hot Water SupplyDokumen32 halamanHot Water SupplyRishikesh Wadekar100% (1)

- Typical Schematic For Single Hot Water Heat PumpDokumen12 halamanTypical Schematic For Single Hot Water Heat PumpVin Bds100% (1)

- Design Criteria for Hunter Soil and Waste SystemsDokumen25 halamanDesign Criteria for Hunter Soil and Waste SystemsfayasBelum ada peringkat

- Eaching High-Rise Plumbing DesignDokumen19 halamanEaching High-Rise Plumbing Designm_salah20202000Belum ada peringkat

- Fire Sprinkler Design-Part2Dokumen2 halamanFire Sprinkler Design-Part2Henry SuarezBelum ada peringkat

- Storm Drainage Components GuideDokumen2 halamanStorm Drainage Components GuideNiong DavidBelum ada peringkat

- WHA Water Hammer ArrestorsDokumen5 halamanWHA Water Hammer ArrestorsvitgahiBelum ada peringkat

- Chilled Water Distribution SystemDokumen5 halamanChilled Water Distribution SystemThiru AnanthBelum ada peringkat

- BUILDING WATER SYSTEM DESIGN AND SIZINGDokumen28 halamanBUILDING WATER SYSTEM DESIGN AND SIZINGJam MangalinoBelum ada peringkat

- Chilled Water Dist I But I OnDokumen44 halamanChilled Water Dist I But I OnVineeth MuraleedharanBelum ada peringkat

- High-Performance VAV Systems PDFDokumen11 halamanHigh-Performance VAV Systems PDFTonyChuangBelum ada peringkat

- 1e Green Building and LEED Core Concepts GuideDokumen72 halaman1e Green Building and LEED Core Concepts Guidehtosar2Belum ada peringkat

- Infiltration RateDokumen17 halamanInfiltration RateNirupan KumarBelum ada peringkat

- Boiler Venting CategoriesDokumen2 halamanBoiler Venting Categorieshtosar2Belum ada peringkat

- GGHN Installation and Maintenance ManualDokumen13 halamanGGHN Installation and Maintenance Manualhtosar2Belum ada peringkat

- HTTP Factsfacts - Com My Home Repair VentilationDokumen6 halamanHTTP Factsfacts - Com My Home Repair Ventilationhtosar2Belum ada peringkat

- Gas Vent Chimney Sizing Application GuideDokumen29 halamanGas Vent Chimney Sizing Application Guidehtosar2Belum ada peringkat

- Bid Form - Munting Tubig - Balayan - Batangas - 062019 PDFDokumen11 halamanBid Form - Munting Tubig - Balayan - Batangas - 062019 PDFPaul Zedric HerreraBelum ada peringkat

- D H Reasi 8 BeddedDokumen30 halamanD H Reasi 8 BeddedPuneet ShailyBelum ada peringkat

- Design of Hydroelectric Power PlantsDokumen54 halamanDesign of Hydroelectric Power Plantsbagus adi saputraBelum ada peringkat

- YSRR LVPEL - Plumbing BOQ (14.03.23)Dokumen7 halamanYSRR LVPEL - Plumbing BOQ (14.03.23)Lse InfraBelum ada peringkat

- Is 10446 1983 PDFDokumen60 halamanIs 10446 1983 PDFJothimanikkam SomasundaramBelum ada peringkat

- NIT SCHEDULE FOR S.D.M. OFFICE BUILDING CONSTRUCTIONDokumen31 halamanNIT SCHEDULE FOR S.D.M. OFFICE BUILDING CONSTRUCTIONDADADADGGGBelum ada peringkat

- Roca contact proposal for Balai Bomba Kuala TahanDokumen7 halamanRoca contact proposal for Balai Bomba Kuala TahanAffendi Hj AriffinBelum ada peringkat

- Proposed Niper Campus at Guwahati, Assam. Admin BlockDokumen7 halamanProposed Niper Campus at Guwahati, Assam. Admin Blockkiran raghukiranBelum ada peringkat

- HCL Tank Venting StudyDokumen17 halamanHCL Tank Venting StudykalaiBelum ada peringkat

- Plumbing ArrangementDokumen6 halamanPlumbing ArrangementNivedetha VedanayagamBelum ada peringkat

- The Portion of The Plumbing System That Receives Discharges of All Soil and Waste Stacks Within The BuildingDokumen4 halamanThe Portion of The Plumbing System That Receives Discharges of All Soil and Waste Stacks Within The BuildingSharryBelum ada peringkat

- Housing StandardsDokumen19 halamanHousing StandardsRashika Kala100% (1)

- Qatar Building Drainage System RequirementsDokumen38 halamanQatar Building Drainage System RequirementsenviroashBelum ada peringkat

- Training Manual: EASA Part-66 38 Level 3Dokumen24 halamanTraining Manual: EASA Part-66 38 Level 3Luis Enrique La Font FrancoBelum ada peringkat

- Practical ProblemsDokumen119 halamanPractical ProblemsGerson PelayoBelum ada peringkat

- Technical Specifications-PlumbingDokumen52 halamanTechnical Specifications-Plumbingpandey71087100% (1)

- Water Supply Fixture Units - I - WSFU - I - PDFDokumen5 halamanWater Supply Fixture Units - I - WSFU - I - PDFEmir KarBelum ada peringkat

- Miki Take OffDokumen52 halamanMiki Take OffMikiyas SeyoumBelum ada peringkat

- Manual 2014 Saniflo CatalogDokumen32 halamanManual 2014 Saniflo CatalogGeorge PetrakosBelum ada peringkat

- Nat. Bldg. CodeDokumen34 halamanNat. Bldg. Codedela rosaBelum ada peringkat

- MODULE 1. Basic Principles of Sanitary DesignDokumen5 halamanMODULE 1. Basic Principles of Sanitary DesignKervin SangalangBelum ada peringkat

- Industrial Training ReportDokumen210 halamanIndustrial Training ReportMozammil HussainBelum ada peringkat

- Site/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Toilet ConstructionDokumen2 halamanSite/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Toilet Constructionbiniyymail.com100% (1)

- What Is The Minimum Slope Requirement For Drains?Dokumen14 halamanWhat Is The Minimum Slope Requirement For Drains?Jerome D. EdullantesBelum ada peringkat