PQR Form

Diunggah oleh

pokok assamDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PQR Form

Diunggah oleh

pokok assamHak Cipta:

Format Tersedia

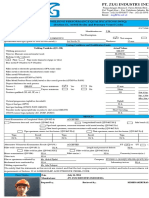

FACULTY PROCEDURE

OF QUALIFICATION

MECHANICAL ENGINEERING RECORD

(PQR)

GENERAL

Company : Date : October 15 2010

Welding process : Gas Metal Arc Welding Welding code : ASME BPVC Section 9

(GTAW)

JOINT CONFIGURATION FOR TEST ASSEMBLY

JOINT DESIGN USED

WELDING POSITION : Vertical Up (1G) FILLER METAL : ER 70S-G

BASE METAL : ASME SA-333 ELECTRODE SIZE : 2.4mm

BACKGOUGING : Yes No CURRENT : AC DCEP DCEN

PREHEAT TEMP. : none (ambient temperature ) VOLTAGE : 9 – 15 V AMPERAGE : 90 - 200

INTERPASS TEMP. : 200o C ARC TRAVEL SPEED : 80 mm/min

POSTWELLHEAT TREATMENT : N/A STRINGER or WEAVE BEED : string or weave

bead

INTERPASS CLEANING : Brushing or Grinding MULTI PASS or SINGLE PASS : Multi - pass

WELDER’S NAME : BADRUL HISYAM PEENING :

WELDER’S SOCIAL SECURITY NAME : - TEST DATE :

TEST RESULTS

VISUAL INSPECTION

Appearance : _______ Undercut : _________ Piping Porosity : _________ Convexity :

_________

FILLET WELD TEST

Result Satisfactory Penetration into parent metal

Yes Yes

No No

TENSILE TESTS

Specimen Width, Thickness, Area, Ultimate Ultimate Fracture

No. in in sq. in. Tensile Tensile Location

Load, lbs Stress, psi

Macro – Result : __________________________________ Remark :

___________________________

TEST CONDUCTED BY ________________ LAB NO ______________________

We the undersigned, certify that the information in this record is correct, and that the test weld was prepared, welded and

tested in accordance with the requirements of ASME BPVC Section 9

Signed by ______________________

Anda mungkin juga menyukai

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDokumen1 halamanWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityBelum ada peringkat

- BS en 14399-9-2018 - (2019-07-15 - 10-31-27 Am)Dokumen32 halamanBS en 14399-9-2018 - (2019-07-15 - 10-31-27 Am)DEEPAK SHARMABelum ada peringkat

- Wps 15614 TemplateDokumen2 halamanWps 15614 Template0502raviBelum ada peringkat

- S235JR PDFDokumen3 halamanS235JR PDFRv Vaghasia100% (1)

- Dic Pps Weld StrengthDokumen1 halamanDic Pps Weld StrengthWoong KimBelum ada peringkat

- RDSO Manual Flash Butt Welding 2012-ACS2Dokumen9 halamanRDSO Manual Flash Butt Welding 2012-ACS2Fredrick JeraldinBelum ada peringkat

- Solvent Removable Dye Penetrant AnalysisDokumen1 halamanSolvent Removable Dye Penetrant AnalysisAries MarteBelum ada peringkat

- Sampling Procedure For Impact Testing of Structural SteelDokumen4 halamanSampling Procedure For Impact Testing of Structural Steeljoy gultom100% (1)

- 3580Dokumen1 halaman3580milamiroslavaBelum ada peringkat

- DS W9Dokumen3 halamanDS W9Dar FallBelum ada peringkat

- Automatic Weld Size GaugeDokumen1 halamanAutomatic Weld Size GaugeLucioBelum ada peringkat

- Iso 6259 3 2015Dokumen9 halamanIso 6259 3 2015ayaanhaddiBelum ada peringkat

- Gantrex Mk20 Pad Data Sheet MetricDokumen2 halamanGantrex Mk20 Pad Data Sheet Metricjhon jairo arangoBelum ada peringkat

- Laboratory Testing of Polyethylene (PE) Butt Fusion Joints Using Tensile-Impact MethodDokumen11 halamanLaboratory Testing of Polyethylene (PE) Butt Fusion Joints Using Tensile-Impact Methodastewayb_964354182Belum ada peringkat

- Calibrate Coating Thickness GagesDokumen5 halamanCalibrate Coating Thickness GagesJose OcañaBelum ada peringkat

- Aws 5.36Dokumen2 halamanAws 5.36ManikandanBelum ada peringkat

- Geomet 500bDokumen1 halamanGeomet 500bellisforheroesBelum ada peringkat

- Specification For Bridge Construction (England)Dokumen35 halamanSpecification For Bridge Construction (England)Roy GuoBelum ada peringkat

- Astm D2729 PDFDokumen2 halamanAstm D2729 PDFShan Adrias100% (1)

- BS Steel Bar Connection Technology Profile Method StatementDokumen48 halamanBS Steel Bar Connection Technology Profile Method StatementRuwan Sampath Wickramathilaka100% (1)

- Visual Defect Standards for Glass-Reinforced LaminatesDokumen18 halamanVisual Defect Standards for Glass-Reinforced Laminatesnaoufel1706Belum ada peringkat

- DrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsDokumen1 halamanDrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsmarcotplBelum ada peringkat

- ASTM A36 Steel plate propertiesDokumen1 halamanASTM A36 Steel plate propertiesStan HonBelum ada peringkat

- ASTZM E1476-97 Metals Sorting Guide PDFDokumen12 halamanASTZM E1476-97 Metals Sorting Guide PDFKewell LimBelum ada peringkat

- Tablas Cf574 - Sika Base AguaDokumen13 halamanTablas Cf574 - Sika Base AguaDaniel PatronBelum ada peringkat

- SSPC CS 36Dokumen5 halamanSSPC CS 36Gaapchu0% (1)

- Astm A 490Dokumen6 halamanAstm A 490Pedro Diaz UzcateguiBelum ada peringkat

- E494-95 Measuring UT VelocityDokumen14 halamanE494-95 Measuring UT VelocityRuiBelum ada peringkat

- Light Meter (Lux) : 840006 Instruction ManualDokumen4 halamanLight Meter (Lux) : 840006 Instruction ManualAlfredo Lopez CordovaBelum ada peringkat

- 610 Series Product BulletinDokumen2 halaman610 Series Product BulletinEran LopezBelum ada peringkat

- FRP Pipe Specification GuideDokumen24 halamanFRP Pipe Specification GuideJUAN PABLO LUCEROBelum ada peringkat

- Astm A254Dokumen4 halamanAstm A254dai.nh100% (2)

- Ford Wa 960-2004Dokumen1 halamanFord Wa 960-2004DanielMa0% (1)

- Bolt Torque Chart: ASTM A307Dokumen5 halamanBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDokumen4 halaman177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraBelum ada peringkat

- Mbg533 09 CoverDokumen1 halamanMbg533 09 CoverwahyuBelum ada peringkat

- Japan SteelDokumen27 halamanJapan SteelVaniya GoelBelum ada peringkat

- Technology Guide 15: SSPC: The Society For Protective CoatingsDokumen16 halamanTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- Welding Procedures Package-Gas Line Replacement JobDokumen11 halamanWelding Procedures Package-Gas Line Replacement JobFeroz KhanBelum ada peringkat

- BS en 01395-1-2007Dokumen12 halamanBS en 01395-1-2007sepehr heidariBelum ada peringkat

- Steel Castings, Carbon, For General ApplicationDokumen4 halamanSteel Castings, Carbon, For General ApplicationVIKAS DAHIYA100% (1)

- Design Standard for FRP StructuresDokumen27 halamanDesign Standard for FRP Structuresjdiaz87Belum ada peringkat

- Iso 1817 2022Dokumen12 halamanIso 1817 2022Henry PedrazaBelum ada peringkat

- Structural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)Dokumen8 halamanStructural Bolts, Steel, Heat Treated 830 Mpa Minimum Tensile Strength (Metric)abohassn72Belum ada peringkat

- Hilti Hit-Re 500-SDDokumen17 halamanHilti Hit-Re 500-SDmon012Belum ada peringkat

- Certification Document - Da200 Contour ProbeDokumen1 halamanCertification Document - Da200 Contour ProbeTonyRiverosBecerraBelum ada peringkat

- Sae J1701Dokumen5 halamanSae J1701Marco NiBelum ada peringkat

- Measure Fresh Concrete TemperaturesDokumen2 halamanMeasure Fresh Concrete TemperaturesLydiaBelum ada peringkat

- 5.1 Sumatane HSDokumen4 halaman5.1 Sumatane HSjnu6mnju6njBelum ada peringkat

- Astm A759Dokumen4 halamanAstm A759Laziz AtmaniBelum ada peringkat

- Manual de Operacion Controlador Digital EstufaDokumen1 halamanManual de Operacion Controlador Digital EstufajosephBelum ada peringkat

- F 1055 - 98 RjewntutotgDokumen9 halamanF 1055 - 98 RjewntutotgMMBelum ada peringkat

- Welding Domex SteelsDokumen16 halamanWelding Domex SteelspozolabBelum ada peringkat

- Iso 7452 2013 en PDFDokumen8 halamanIso 7452 2013 en PDFfahmi aballiBelum ada peringkat

- Installation Instructions C+Dokumen5 halamanInstallation Instructions C+Anonymous m1cSnEavoBelum ada peringkat

- Welder Certificate Akilesh YadavDokumen1 halamanWelder Certificate Akilesh Yadavtripatipankaj023Belum ada peringkat

- Plates and Sheets ToleranceDokumen15 halamanPlates and Sheets ToleranceDimas Hand SulistiyoBelum ada peringkat

- SSPC QP 3Dokumen6 halamanSSPC QP 3anoopkumarBelum ada peringkat

- WPS A36 For PipesDokumen3 halamanWPS A36 For PipesJuan AvellaBelum ada peringkat

- Saudi Pipe System Co. Mold Final Inspection ReportDokumen8 halamanSaudi Pipe System Co. Mold Final Inspection ReportNADEEM AHMEDBelum ada peringkat

- Report Manu PresentDokumen5 halamanReport Manu Presentpokok assamBelum ada peringkat

- Intro HydroDokumen3 halamanIntro Hydropokok assamBelum ada peringkat

- Industrial ManagementDokumen9 halamanIndustrial Managementpokok assamBelum ada peringkat

- Hydraulic Lab Conveyor TensioningDokumen11 halamanHydraulic Lab Conveyor Tensioningpokok assam100% (1)

- IpdDokumen3 halamanIpdpokok assamBelum ada peringkat

- Evaluation of PROSPER For Modeling Long Lateral Gas Well Productivity PDFDokumen178 halamanEvaluation of PROSPER For Modeling Long Lateral Gas Well Productivity PDFJanetRamirezZambranoBelum ada peringkat

- CH 10Dokumen27 halamanCH 10FaisalTahirRambeBelum ada peringkat

- Flanged Bolt Couplings Strength of Materials ReviewDokumen4 halamanFlanged Bolt Couplings Strength of Materials Reviewmark cuananBelum ada peringkat

- THE CORROSION RATE OF Pb-Ca ALLOYS IN SULFURIC ACID SOLUTIONSDokumen7 halamanTHE CORROSION RATE OF Pb-Ca ALLOYS IN SULFURIC ACID SOLUTIONScekmilanBelum ada peringkat

- What Is Buoyancy and Stability of Submerged Bodies.Dokumen14 halamanWhat Is Buoyancy and Stability of Submerged Bodies.Odama KhanBelum ada peringkat

- Diesel Engine For Fire Pump-Fm ApprovedDokumen8 halamanDiesel Engine For Fire Pump-Fm Approvedazul julianBelum ada peringkat

- Coupling and Constraint EquationsDokumen19 halamanCoupling and Constraint EquationsZachary EllisBelum ada peringkat

- Telescope Equations Guide for Exploring the Night SkyDokumen97 halamanTelescope Equations Guide for Exploring the Night SkyAnimalesProtegidosAhora100% (1)

- Shear Wall DesignDokumen33 halamanShear Wall DesignEngrDebashisMallick100% (1)

- Chapter 9Dokumen29 halamanChapter 9Danny TBelum ada peringkat

- 2.Cbs SolutionDokumen14 halaman2.Cbs SolutionHAZARDOUS WIZARDBelum ada peringkat

- C StructDesign Bendapudi Feb10 (1) Part 1Dokumen0 halamanC StructDesign Bendapudi Feb10 (1) Part 1Rubén MenaBelum ada peringkat

- Module 17 Cat A (Jan 18)Dokumen2 halamanModule 17 Cat A (Jan 18)Shaheed ChirayinkeezhuBelum ada peringkat

- Mid-Term IGCSE PhysicsDokumen4 halamanMid-Term IGCSE Physicsgdsuta88% (8)

- 5 ThinFilmSolarDokumen18 halaman5 ThinFilmSolarnomyisBelum ada peringkat

- Biphasic Liquid Dosage FormDokumen18 halamanBiphasic Liquid Dosage FormSai Nath NBelum ada peringkat

- CIV 442 Hydrology: Lecture 4D: Idf TheoryDokumen25 halamanCIV 442 Hydrology: Lecture 4D: Idf TheoryMohammed ZiadBelum ada peringkat

- Atlas Copco Ewd 330 Manual PDFDokumen6 halamanAtlas Copco Ewd 330 Manual PDFMahammadhusain100% (3)

- 2Dokumen13 halaman2VNSAramakiBelum ada peringkat

- Energy Transformations QuizDokumen3 halamanEnergy Transformations QuizAngeli MercedBelum ada peringkat

- 1011 Chapter 3Dokumen38 halaman1011 Chapter 3Eman Sarmiento0% (1)

- Lecture - Week 2 - Introduction To SteelDokumen49 halamanLecture - Week 2 - Introduction To SteelAhmed MaherBelum ada peringkat

- AZ nLOF 2000 Series Technical DatasheetDokumen8 halamanAZ nLOF 2000 Series Technical DatasheetSwarnava SanyalBelum ada peringkat

- High Performance Fiber Reinforced Concrete - OverviewDokumen14 halamanHigh Performance Fiber Reinforced Concrete - Overviewhaoude9Belum ada peringkat

- Design of Gap SlabDokumen15 halamanDesign of Gap Slabvivek100% (1)

- TTVA Fender Data SheetDokumen3 halamanTTVA Fender Data SheetNestor Fernando LagraNaBelum ada peringkat

- AISC 360 - Moment Connection Design ExampleDokumen10 halamanAISC 360 - Moment Connection Design ExamplegireeshaBelum ada peringkat

- retention volumes chromatographyDokumen2 halamanretention volumes chromatographyMohd Sukri DaudBelum ada peringkat

- Taisox 8001Dokumen2 halamanTaisox 8001Le Minh TuanBelum ada peringkat

- Seismic Story Shear Calculation StaadDokumen23 halamanSeismic Story Shear Calculation StaadRajendra KambleBelum ada peringkat