Bend 3model

Diunggah oleh

Chanakya SharmaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bend 3model

Diunggah oleh

Chanakya SharmaHak Cipta:

Format Tersedia

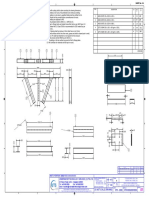

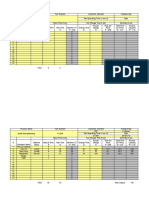

General Notes

1. All dimension are in millimeters unless specified

otherwise.

2. No dimension shall be scaled out,only written

dimension are to

be taken as correct.

3. Before putting into service,all the internal spiders etc.

shall be removed and plate cleaned from inside from

all foreign bodies.

4. On completion of fabrication the unpainted parts

(welded joints) shall be prepared and painted with

specified paints as a protective measure.

5. Welding shall be done by electric arc process as per

IS:816

6. All operations connected with welding and cutting

equipment shall conform to the safety

requirements given in IS:818

7. Electrodes shall conform to IS: 814 part I,II

8. Electrodes should be stored in their original bundles

or carton in a

dry place and adequately protected for weather effects.

Wastage 9. During the entire welding or cooling cycle the joints

and the parts shall not be subjected to any external

forces,shocks or vibrations.

10. Two coat of zinc primer inner side and red oxide

primer outside.

Wastage

11. Epoxy coal tar painting on inner face.

12. Green paint out side.

13.If there is deviation in the elevation, location,

alignment the corresponding changes are required to

be incorporated in the bend Design Cell be intimated

well before undertaking the fabrication .

14.DPT & UT of all the joint shall be conducted before

putting in to service

15.Thickness of the weld shall be kept more than

thickness of plate with proper 3mm Reinforcement.

Welding

Thickness of Plate 20mm

Developer:-

M/S Kapil Mohan &Associates Hydro

Executed By:-

Sai Engineering Foundation

Sai Bhawan, New Shimla

Sector-4 (H.P.)

Project:-

Drawn By:- Beas Kund Hydro Electric Project

Jitendra Bhatt

Design By:- Drg No.

Double "V" Butt Weld Er. Chanakya SEF/Beas kund/Bend-3

Checked By:- Date:-14-4-11 Title:-

Er. Munish Sharma Scale:-NTS Detail of Bend -3

Anda mungkin juga menyukai

- Metro Box Girder Section Scale (1:100) : DETAIL A (1:20) (Plate Anchorage)Dokumen1 halamanMetro Box Girder Section Scale (1:100) : DETAIL A (1:20) (Plate Anchorage)Mridul GaurBelum ada peringkat

- Lift and Retaining Wall DetailsDokumen1 halamanLift and Retaining Wall DetailsKEVIN ASIAGOBelum ada peringkat

- PT5C 08 PHC T12 004 D2Dokumen1 halamanPT5C 08 PHC T12 004 D2ma.shaheBelum ada peringkat

- Metro Proj - 12 MTR Span-1Dokumen3 halamanMetro Proj - 12 MTR Span-1kukadiya127_48673372Belum ada peringkat

- Sign TSDokumen16 halamanSign TSAjay SinghBelum ada peringkat

- Brochure WebDokumen7 halamanBrochure WebOmar Abdel AzizBelum ada peringkat

- Comment - 210906 FACADE SHD For Typ Details-Sliding Door and Top-Hung Window With RFI-F001Dokumen28 halamanComment - 210906 FACADE SHD For Typ Details-Sliding Door and Top-Hung Window With RFI-F001Tuấn Phạm AnhBelum ada peringkat

- Letter ObservationsDokumen2 halamanLetter ObservationsSaurabh PandeyBelum ada peringkat

- Condenser MicrophoneDokumen11 halamanCondenser Microphoneverd leonardBelum ada peringkat

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDokumen1 halamanSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayBelum ada peringkat

- Proposed Residential Development at Ohaohia in Amano-Anara Isiala Mbano L.G.A Imo StateDokumen1 halamanProposed Residential Development at Ohaohia in Amano-Anara Isiala Mbano L.G.A Imo StateAmadi HenryBelum ada peringkat

- Column GwaliorDokumen1 halamanColumn Gwaliorvs consultantBelum ada peringkat

- Design Details Canopy Ground FloorDokumen1 halamanDesign Details Canopy Ground FloorAditya K100% (1)

- SECTION 07 21 13 Thermal InsulationDokumen10 halamanSECTION 07 21 13 Thermal Insulationtaghreed shabanBelum ada peringkat

- Backfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersDokumen1 halamanBackfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersRVNLPKG6B VBL-GTLMBelum ada peringkat

- Construction Bored Pile (A4)Dokumen14 halamanConstruction Bored Pile (A4)Ratha Men100% (1)

- 5.SCHEDLE OF FOOTINGS 150 200 250 - SI - East - ZII - AppdDokumen1 halaman5.SCHEDLE OF FOOTINGS 150 200 250 - SI - East - ZII - AppdMusini Rajesh KumarBelum ada peringkat

- Decorative Metals (r1)Dokumen23 halamanDecorative Metals (r1)irshad khanBelum ada peringkat

- RLFLTT: 25luly20l9 DayDokumen2 halamanRLFLTT: 25luly20l9 DayHui ShanBelum ada peringkat

- Sheet MetalDokumen6 halamanSheet Metalajrio1785Belum ada peringkat

- Conduit PDFDokumen1 halamanConduit PDFPraveen KumarBelum ada peringkat

- North West View 1 North East View 2: ClientDokumen1 halamanNorth West View 1 North East View 2: ClientCSEC Uganda Ltd.Belum ada peringkat

- INSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVDokumen7 halamanINSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanBelum ada peringkat

- Backfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersDokumen1 halamanBackfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersRVNLPKG6B VBL-GTLMBelum ada peringkat

- Corrected 2door LatrineDokumen1 halamanCorrected 2door LatrineJoseph MugoBelum ada peringkat

- Symbology Legend: Ministry of Transport & CommunicationsDokumen1 halamanSymbology Legend: Ministry of Transport & CommunicationsAbid AyubBelum ada peringkat

- Culvert Drawing BinderDokumen5 halamanCulvert Drawing BinderAhmed Nader KhurshidBelum ada peringkat

- DPLN-CULVERT, SUPPORT & PLATFORM DETAILS. Rev.00Dokumen3 halamanDPLN-CULVERT, SUPPORT & PLATFORM DETAILS. Rev.00Cihan YasarBelum ada peringkat

- MI Tube Skin Thermocouple AssembliesDokumen6 halamanMI Tube Skin Thermocouple AssembliesAlonso MooriBelum ada peringkat

- SOQ Railway Hospital 205kwDokumen3 halamanSOQ Railway Hospital 205kwDebabrata GhoshBelum ada peringkat

- Work Procedure For Steel Fab & ErectionDokumen5 halamanWork Procedure For Steel Fab & ErectionHiren Thakkar100% (1)

- Mobile Generater: Sheet No: Sheet NoDokumen2 halamanMobile Generater: Sheet No: Sheet NoMdWarisKhanBelum ada peringkat

- 146 Mrs Vijayalakshmi Remaining Details 11102021-2Dokumen13 halaman146 Mrs Vijayalakshmi Remaining Details 11102021-2Gorky Structural ConsultantBelum ada peringkat

- Ref FRP Arch Guideline SpecDokumen8 halamanRef FRP Arch Guideline SpecgeorgeBelum ada peringkat

- Cam & Groove Couplings: Standard Federal Mil A-A-59326ADokumen42 halamanCam & Groove Couplings: Standard Federal Mil A-A-59326ADar FallBelum ada peringkat

- Burj Dubai - The Residences Emaar PropertiesDokumen4 halamanBurj Dubai - The Residences Emaar PropertiesAhmedBelum ada peringkat

- Subject: Method Statement For The Constructio NOF Chimney RaftDokumen10 halamanSubject: Method Statement For The Constructio NOF Chimney RaftSandip PaulBelum ada peringkat

- Installation 4.5M Motorised Antenna-NEWDokumen11 halamanInstallation 4.5M Motorised Antenna-NEWPardomuan SinagaBelum ada peringkat

- عمار الانشائي - compressedDokumen36 halamanعمار الانشائي - compressedzakariaBelum ada peringkat

- PD 0158 SM 01Dokumen1 halamanPD 0158 SM 01FAIZAN AHMEDBelum ada peringkat

- General: Workmanship/Construction Specification: ConcreteDokumen1 halamanGeneral: Workmanship/Construction Specification: ConcreteNabendu KARMAKARBelum ada peringkat

- PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1Dokumen1 halamanPARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1irshad khanBelum ada peringkat

- Material Submittal - GRP Sectional Panel TanksDokumen204 halamanMaterial Submittal - GRP Sectional Panel Tanksmohamed kamalBelum ada peringkat

- Pressure GaugeDokumen1 halamanPressure GaugesrinivasanBelum ada peringkat

- Backfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersDokumen1 halamanBackfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersRVNLPKG6B VBL-GTLMBelum ada peringkat

- Service Manual: GR-D93US, GR-D94USDokumen22 halamanService Manual: GR-D93US, GR-D94USsilictronicBelum ada peringkat

- Structural For TenderDokumen18 halamanStructural For Tenderrimshabatoool72Belum ada peringkat

- San Pedro Central Elementary School Electrical Tech SpecsDokumen9 halamanSan Pedro Central Elementary School Electrical Tech SpecsenginearswebBelum ada peringkat

- Abutment Details River Bharja D2001 R0Dokumen1 halamanAbutment Details River Bharja D2001 R0borkarsd007Belum ada peringkat

- Notes PDFDokumen1 halamanNotes PDFVemajala GaneshBelum ada peringkat

- 14-FEB - JSA - NR - GHWP - Fabrication Shop EXTDokumen2 halaman14-FEB - JSA - NR - GHWP - Fabrication Shop EXTosama sheikhBelum ada peringkat

- Epoxy Installation Procedures For ST II+: Fiber Optic Connectors (Multimode and Singlemode)Dokumen19 halamanEpoxy Installation Procedures For ST II+: Fiber Optic Connectors (Multimode and Singlemode)german12Belum ada peringkat

- Joska Muchelle WambuaDokumen2 halamanJoska Muchelle Wambuamutisoshadrack082Belum ada peringkat

- RUBENDokumen1 halamanRUBENmaeglin_elendilBelum ada peringkat

- A Continuous Wall Insulation SystemDokumen16 halamanA Continuous Wall Insulation SystemGary ChestersBelum ada peringkat

- Staircase DetailDokumen1 halamanStaircase Detailyash mistry100% (1)

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDokumen4 halamanNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocBelum ada peringkat

- And This.: Wemer Fix ScrewsDokumen1 halamanAnd This.: Wemer Fix ScrewsvbgiriBelum ada peringkat

- ZXMW NR8961 (V2.04.04A2) Hardware Installation Guide 2Dokumen57 halamanZXMW NR8961 (V2.04.04A2) Hardware Installation Guide 2Esmail FathyBelum ada peringkat

- Forming and Shaping Plastics & Composite Materials: Chapter - 18Dokumen35 halamanForming and Shaping Plastics & Composite Materials: Chapter - 18Muddu AlaparthiBelum ada peringkat

- Mig Welding Mastery PDFDokumen31 halamanMig Welding Mastery PDFCarlos SosaBelum ada peringkat

- Pacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelDokumen1 halamanPacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelJojo CalimlimBelum ada peringkat

- Childcare Level 1 Course WorkDokumen7 halamanChildcare Level 1 Course Workiyldyzadf100% (2)

- Heavy-Duty Plate Rolling - Flat Bar Rolling Sheet Metal FormingDokumen3 halamanHeavy-Duty Plate Rolling - Flat Bar Rolling Sheet Metal FormingruddydheeBelum ada peringkat

- Welding Procedure Specification (WPS)Dokumen2 halamanWelding Procedure Specification (WPS)Ramadhan AdityaBelum ada peringkat

- Basic Knowledge of Sheet MetalDokumen36 halamanBasic Knowledge of Sheet MetalHemang Shah33% (3)

- Mechanical Plating and GalvanizingDokumen2 halamanMechanical Plating and GalvanizingUntung Ari WibowoBelum ada peringkat

- Jharkhand IndustriesDokumen18 halamanJharkhand IndustriesDeepak Kumar JhaBelum ada peringkat

- Stamping Design GuidelineDokumen13 halamanStamping Design GuidelineVikram Borkhediya100% (1)

- Process Capacity TableDokumen2 halamanProcess Capacity TablePauline KangBelum ada peringkat

- Select Subjetcts of MetallurgyDokumen3 halamanSelect Subjetcts of MetallurgyRenato BarretoBelum ada peringkat

- Slide 15 - 2. Atomic Layer DepositionDokumen20 halamanSlide 15 - 2. Atomic Layer DepositionMuhammad RezaBelum ada peringkat

- FP - EN - GreenFlux 200 - BB - 1014 - 1Dokumen1 halamanFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- Standard: Title: Boeing Process Specification Index AuthorDokumen9 halamanStandard: Title: Boeing Process Specification Index AuthorHoang TanBelum ada peringkat

- Steel PDFDokumen82 halamanSteel PDFGloremay Ann AlemanBelum ada peringkat

- Introduction To Tool DesignDokumen24 halamanIntroduction To Tool DesignBagus Bramantya bagusbramantya.2019Belum ada peringkat

- Ms For Repair of LR TankDokumen6 halamanMs For Repair of LR Tankdadz mingiBelum ada peringkat

- Standar Undercut PorosDokumen5 halamanStandar Undercut PorosRiska DamayantiBelum ada peringkat

- High Tensile Steel 4140Dokumen2 halamanHigh Tensile Steel 4140Lazzarus Az GunawanBelum ada peringkat

- Welding SymbolDokumen57 halamanWelding SymbolGanesh Sridhar100% (2)

- Smith ForgingDokumen7 halamanSmith Forgingsenel pereraBelum ada peringkat

- Forging Notes PDFDokumen16 halamanForging Notes PDFkumarnpccBelum ada peringkat

- Proposal Pekerjaan Painting PT Linde Indonesia - GresikDokumen16 halamanProposal Pekerjaan Painting PT Linde Indonesia - GresikDicky ArdiansyahBelum ada peringkat

- List of Fabrication and Test Facilities of CCLPEC: No. Name Model Qty. Remark I Fabrication FacilitiesDokumen3 halamanList of Fabrication and Test Facilities of CCLPEC: No. Name Model Qty. Remark I Fabrication Facilitieslemuel bacsaBelum ada peringkat

- PPC Master MarchDokumen148 halamanPPC Master MarchSandip JadhavBelum ada peringkat

- Press Working OperationsDokumen2 halamanPress Working OperationsJermane Delos SantosBelum ada peringkat

- Blow MouldingDokumen40 halamanBlow MouldingDINO FANBelum ada peringkat

- Work-Sheet-6g-Pipe Alloy PDFDokumen4 halamanWork-Sheet-6g-Pipe Alloy PDFRyanM.PradelBelum ada peringkat

- Neis RT Offer List-04.12.2022Dokumen1 halamanNeis RT Offer List-04.12.2022Eswar Enterprises QcBelum ada peringkat