B. Design of Substructure

Diunggah oleh

Deepak Kr GuptaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

B. Design of Substructure

Diunggah oleh

Deepak Kr GuptaHak Cipta:

Format Tersedia

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

B. Design of Substructure

1.0 Design Data:

1.1. Materials and its Properties:

Concrete: M20

Reinforcement: Fe415

Basic Permissible Stresses of Concrete as per IRC : 21-2000:

Permissible direct compressive stress, σco = 5.0 Mpa

Permissible flexural compressive stress, σc = 6.67 Mpa

Maximum Permissible shear stress, τmax = 1.8 N/mm2

Basic Permissible Stresses of Reinforcing Bars as per IRC : 21-2000:

Permissible Flexural Tensile stress, σst = 200 N/mm2

Permissible direct compressive stress, σco = 170 N/mm2

Design of Data:

Modular Ratio = 10.98

Neutral axis depth factor, n = (mσc)/( mσc+σst) = 0.268

Lever arm factor, j = (1-n/3) = 0.911

Moment of resistance coefficient, R = ½ x n x j x σc = 0.814

Unit weight of materials as per IRC : 6-2000:

Concrete (cement-Reinforced) = 2.4 t/m3

Macadam (binder premix) = 2.2 t/m4

Water = 1.0 t/m5

Backfill = 1.92 t/m6

1.2. Geometrical Properties:

Effective Span of Bridge Deck = 18.0 m

Total length of each Span = 18.60 m

Angle of internal friction of backfill = 29 degree

Approach slab

Length, L = 3.5 m

Width, B = 7m

Depth, D = 0.26 m

Size of bearing

Length = 400 mm

Width = 250 mm

Thickness = 50 mm

High Flood Level, HFL = 1002.15 m

Mean scour depth from HFL = 3.28 m

Lowest Bed Level = 997 m

Bottom level of abutment = 999.600 m

Clearance above HFL = 0.9 m

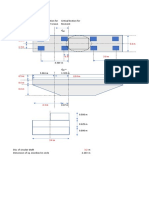

Top level of abutment = 1003.00 m Fig.20

Depth of superstructure = 1.4 m

Total height of abutment = 4.85 m

h1 = 4.59 m b1 = 1m

h2 = 0.26 m b2 = 0m

Unique Engineering Consultancy (P) Ltd Page 1

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

h3 = 1.45 m b3 = 0.25 m

h4 = 0.4 m b4 = 0.55 m

h5 = 3.00 m b5 = 0.9 m

h6 = 0.05 m b6 = 0.35 m

Cap overhang, b7 = 0.15 m

Min. length of cap = 7.2 m

Length of abutment shaft = 6.9 m

1.3. Calculation of weight and C.G. of the abutment stem

Elements Area, Ai Weight (t) Xi (m) Yi (m) AiXi AiYi

(m2)

P1 3.00 49.68 0.5 1.50 1.50 4.50

P2 0.00 0.00 1.00 1.00 0.00 0.00

P3 0.46 7.95 0.58 3.20 0.26 1.47

P4 0.3625 6.00 0.125 4.12 0.05 1.50

3.82 63.63 1.81 7.47

C.G. from back of abutment, x = 0.473 from bottom of abutment, y = 1.954

e= 0.125 m

Moment about back face = 30.13 t-m

1.4. Calculation of Loads and Moments

Due to Dead Load

Dead load from superstructure, = 81.08 t

Weight of bearings, expansion joint etc. = 4.05 t

Total dead load from superstructure on each abutment, PDL = 85.14 t

Distance of bearing center from back of abutment = 0.6 m

Eccentricity of DL & LL from superstructure acting through bearing,

e= 0.125 m

Moment due to DL of superstructure about CG of abutment = 10.64 t-m

Due to Live Load

Live load from superstructure:

Due to IRC Class A wheel load, in longitudinal direction,

11.4 t 11.4 t 6.8 t 6.8 t 6.8 t 6.8 t

Fig. 21

Max. LL on abutment from right side = (11.4*18+11.4*16.8+6.8*12.5+6.8*9.5+6.8*6.5+6.8*3.5)/18

= 68.26 t

impact factor = 1.188

Max LL including Impact, PLL = 81.06 t

Moment due to eccentric load = 10.13 t-m

In transverse direction, eccentricity of load = 0.25 m

Moment due to live load = 20.26 t-m

Unique Engineering Consultancy (P) Ltd Page 2

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Due to IRC Class AA Tracked Vehicle, in longitudinal direction,

70 t

Fig. 22

Max. LL on abutment from right side = 70x(20-1.8)/20

= 63.70 t

impact factor = 1.10

Max LL including Impact, PLL = 70.07 t

Moment due to eccentric load = 8.76 t-m

In transverse direction, eccentricity of load = 0.35 m

Moment due to live load = 24.52 t-m

Due to IRC Class AA Wheeled Vehicle, in longitudinal direction,

20 t 20 t

Fig. 23

Max. LL on abutment from right side = 20+20x14.8/20

= 34.80 t

impact factor = 1.188

Max LL including Impact, PLL = 41.33 t

Moment due to eccentric load = 5.17 t-m

In transverse direction, eccentricity of load = 0.35 m

Moment due to live load = 14.46 t-m

Due to Earth Pressure

= 0.5γs×h1 ×tan2(45o-φ/2)×t

2

Horizontal force due to earth pressure

= 48.42 t

Which acts at a distance from abutment base = 0.42xh1 = 1.93 m

Magnitude of surcharge, q = 1.2xγs = 2.304 t/m2

2

Horizontal force due to surcharge = qxh1xtan (45-φ/2)xt = 25.32 t/m2

Which acts at a distance from abutment base = h1/2 = 2.295 m

Weight of backfill behind the abutment resting on foundation = 0.0 t

Moment due to earth pressure about abutment base = 151.45 t-m

Due to Temperature Variation

o

Maximum temperature variation, T = 25 C

Coefficient of thermal expansion, α = 1.17E-05 /m/oC

Max. Elongation , δ = 4.68 mm

Shear Mdulus of bearing material, G = 1.00 Mpa

Depth of bearing = 50.00 mm

Longitudinal force / bearing = 1.053 t

The total resistance offered by bearing = = 3.159 t

Unbalanced force at the bearing = 3.16 t

This force acts at the bearing level, i.e. at a distance from pier base = 3.45 m

Moment due to temperature variation = 10.90 t-m

Due to Braking Effect

Effect due to class A loading = 0.2x70 = 14 t

Unique Engineering Consultancy (P) Ltd Page 3

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

This acts at distance above deck level = 1.2 m

And at a distance from abutment base = 6.05 m

Moment due to braking about abutment base = 84.70 t-m

Due to Seismic force

Description Total Load Seismic Lever arm (m) Moment (t-m)

(t) Load (t)

Superstructure DL 85.14 8.51 4.15 35.33

Abutment shaft P1 49.68 4.97 1.50 7.45

Abutment shaft P2 0.00 0.00 1.00 0.00

Abutment shaft P3 7.95 0.79 3.00 2.38

Abutment shaft P4 6.00 0.60 4.12 2.48

Approach slab 15.288 1.53 4.72 7.22

Backfill 0 0.00 2.29 0.00

Total 164.06 16.41 54.86

Summary of Loads and Moments

The summary of loads and moments are tabulated below. The transverse forces and moments are

not considered, since it would not be critical due to high moment of inertia of abutment. Therefore

stresses are checked in longitudinal direction only.

Description Vertical load (t) Horizontal force (t) Moment (t-m)

Superstructure DL 85.14 10.64

LL including Impact 81.06 10.13

Self wt. of abutment 63.63 0.00

Braking effect 14 84.70

Temperature 3.16 10.90

Earth Pressure 73.74 151.45

Sub Total 229.82 90.90 267.83

Seismic Force 16.41 54.86

Total 229.82 107.31 322.69

As per standard design practice, design of abutment would be carried out for case A, and checked

for case B, as given below.

Case A: (N+T) B: (N+T+S)

Vertical load (t) 229.82 229.82

Horizontal force (t) 90.90 107.31

Moment (t-m) 267.83 322.69

Design of abutment stem section

Abutment section will be designed for case A and the section adequacy will be checked for case B.

Design vertical load = 229.82 t

Design moment = 267.83 t-m

M

Depth of section required = = 691 mm < 910 O.K.

Rb

Clear cover to reinforcement = 75 mm

Effective depth provided = 910 mm

M

=

σ st × j× d

Unique Engineering Consultancy (P) Ltd Page 4

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

M

Area of steel required for tension, Ast = = 16160 mm2

σ st × j× d

Provide 38 nos. of 25 mm φ bars giving area of steel = 18653

mm2 and spacing 182 mm c/c.

Provide 16 mm φ bars @ 150 mm c/c at the front side of the abutment, giving

area of steel, Ast = 9651 mm2. Provided nos of bars = 48

Design horizontal force = 90.90 t

Corresponding shear stress, τv = 0.14 N/mm2

Percentage area of tension steel, 100Ast/bd = 0.30 %

Shear strength increment factor = 1+5P/(Agxfck) = 1.083 < 1.5 O.K.

Design shear strength of concrete, τc = 0.26 > τv O.K.

Check for shear at the bottom of the abutment cap.

Total horizontal force at the bottom of the cap = 17.16 t

Depth of abutment = 1000 mm

Effective depth, d = 893 mm

Corresponding shear stress, τv = 0.03 < tc O.K.

Tension reinforcement required at different level along the height of abutments.

At 1.93 m above base of abutment

Load Type Load (t) Lever arm (m) Moment

DL of Superstructure 85.14 0.125 10.64

Live load (LL) 81.06 0.125 10.13

Breaking load 14 4.12 57.68

Temperature load 3.16 1.52 4.80

Earth Pressure 16.26 1.12 18.17

Surcharge 14.67 1.33 19.51

Total 120.94

Overall depth of abutment = 1000 mm

Effective depth of abutment = 893 mm

Area of tension reinforcement req. = 7436 mm2

Provide 23 numbers 25 mm φ bars and 0 numbers

20 mm φ bars, giving area of steel = 11290 mm2

Actual point of curtailment = 3.08 m from base of abutment.

NO CURTAILMENT IS DONE

Rear side Reinforcement

Provide 16 mm φ bars @ 150 mm c/c at rear side of the abutment.

Check for stresses for case B

Bending Moment = 322.69 t-m

Stress in steel = 208.75 N/mm2 < 300 O.K.

Horizontal force = 107.31 t

Corresponding shear stress = 0.17 N/mm2 < 0.45 O.K.

Design of abutment cap:

Vertical reaction due to

Unique Engineering Consultancy (P) Ltd Page 5

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Dead load, PDL/3 = 28.38 t

Live load including impact, PLL/3 = 27.02 t

Total vertical reaction = 55.40 t

Providing minimum area of steel @ 1% assuming cap thickness 225 mm, area of steel required /m

of cap = 2250 mm2 (for both top and bottom layer).

Provide 16 mm φ bars @ 150 mm c/c, at both top and bottom layers in both ways, giving area of

steel, Ast = 2680 mm2.

As per IRC:78-2000, clause 710.10.4 the two layers of mesh reinforcement, one at 20 mm from

top and the other at 100 mm from top of abutment cap each consisting of 8 mm φ bars @ 100 mm

c/c in both directions, shall be provided directly under the bearings.

Check for bearing stresses

The allowable bearing pressure with nearly uniform distribution on the loaded area of a footing or

base under a bearing or column shall be given by following equation,

A1

C= C 0 ×

A2

C0 = 6.25 MPa, permissible direct compressive stress in concrete

A1 = 0.52 m2, dispersed largest concentric area similar to A2

A2 = 0.1 m2, loaded area

Therefore, Α1/Α2 = 5.2 >2

And, C = 8.84 Mpa

Actual compressive stress = 5.54 < C O.K.

Design of Backwall:

Horizontal force due to earth pressure = 0.5γs×(h3- h2) ×tan (45 -φ/2) =

2 2 o

0.47 t/m

Which acts at a distance from backwall base = 0.4998 m

Magnitude of surcharge, q = 2.304 t/m2

Horizontal force due to surcharge = q×(h3-h2)×tan2(45o-φ/2) = 0.95 t/m

Which acts at a distance from backwall base = 0.595 m

Self weight of backwall /m width = 0.714 t/m

Live load on back wall considering class AA loading = 10 t

This acts at a distance from backwall toe = 0.125 m

Moment due to earth pressure about backwall base= 0.80 t-m/m

Moment due to self weight and LL = 1.34 t-m/m

Total Moment = 2.14 t-m/m

Effective depth of backwall = 194 mm

Area of steel required, Ast = 606 mm2

Provide 12 mm φ bars @ 150 mm c/c, giving area of steel, Ast = 753 mm2. And provide 10 mm φ

bars @ 200 mm c/c as distribution bar.

Design of Return wall:

Return wall will be monolithic with the backwall. They are joined together through 30 cm x 30 cm fillets.

The load acting on the wing walls would be earth pressure and is designed to withstand a live load

equivalent to surcharge of 1.2 m height of earth fill according to IRC:78-2000.

Unique Engineering Consultancy (P) Ltd Page 6

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

h1 = 1.65 m

h2 = 1.2 m

h3 = 1.30 m

h4 = 0.4 m

b1 = 2.25 m

Thickness of return wall assumed = 250 mm

Average value of earth pressure = 0.5γs×(h1/2+h2/2+1.2) ×tan (45 -φ/2)

2 2 o

= 1.84 t

Acting at a distance from wing wall bottom = 0.7125 m

Moment due to earth pressure = 3.68 t-m/m

Depth required = 178 mm < Provided O.K.

Effective depth provided = 194 mm

Area of steel required = 1369 mm2

Provide 16 mm f bars @ 150 mm c/c, giving area of steel, Ast = 1910

mm2. And provide 12 mm φ bars @ 150 mm c/c as distribution bar in vertical

direction. In the fillet at the joint provide nominal reinforcement of 10 mm φ bars @ 200 mm c/c.

The wing wall would be properly anchored to the abutment, backwall and cap.

Design of Approach Slab:

The approach slab is resting over the abutment and the other end supported by the soil underneath.

It should be designed on the basis of elastic base theory, which is complicated. Hence the

dimensions and reinforcement is provided as per the standard design practice.

Self weight /m width = 0.624 t/m

Weight of pavement = 0.176 t/m

Maximum live load = 11.44 t/m2

Total udl = 12.24 t/m

Assuming maximum cavitation of 1.2m behind the abutment,

Maximum bending moment = 22.03 kN-m/m

Effective depth of slab required = 164 mm

Effective depth provided = 212 mm

Area of steel required = 751 mm2

Provide 16 mm φ bars @ 150 mm c/c both top and bottom, in both direction

Provided area of steel, Ast = 1340 mm2.

Maximum shear force = 73.4 kN/m

Shear stress = 0.35 N/mm2

Percentage area of steel = 0.63 %

Permissible shear stress = 0.365 N/mm2 > actual shear stress O.K.

Design of RCC Stoppers:

Base width of sttoper, b1 = 0.4 m

Top width of sttoper, b2 = 0.3 m

Height above abutment cap, h1 = 0.45 m

Length of sttoper, l = 0.8 m

Horizontal force acting on the stopper above pier cap @ 10% of vertical load= 7.94 t

Friction resistance = 11.92 t

However as additional factor of safety, assuming an extra lateral force in excess of frictional

resistance taking αR = 0.20 in worst case, Fs = 15.89 t

Difference = 3.97 t

Unique Engineering Consultancy (P) Ltd Page 7

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Moment at the base of stopper = 1.79 t-m

Effective depth required = 166 mm

Effective depth provided = 342 mm

Area of steel required = 287 mm2

Provide 12 mm f bars @ 150 mm c/c. Area of steel provided = 716 mm2

Max. Shear stress, tv = 0.15 N/mm2

Percentage area of steel provided, p = 0.26 %

Permissible minimum shear strength of concrete =0.226 N/mm2 > tv O.K.

Provide nominal shear reinforcement of 8 mm φ bars @ 100 mm c/c.

Design of abutment footing (Piles)

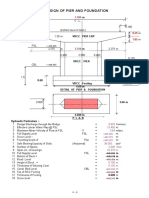

4.2 Geometrical Properties:

High Flood Level, HFL = = 1002.2 m

Maximum depth of scour from HFL = = 3.28 m

Elevation of maximum scour level (MSL) = = 998.87 m

Max. Water depth in the river = = 3.28 m

Water depth near the abutment = = 3.280 m

Proportionate scour depth near the abutment = 3.280 m

Elevation of MSL near abutment = = 998.87 m

Lowest Bed Level = = 997 m

Elevation of top of foundation base = = 999.600 m

Bottom level of foundation = = 998.500 m

h1 = 4.59 m

h2 = 0.26 m

h3 = 1.45 m

h4 = 0.4 m

h5 = 3.00 m

CL of Bearing

4

HFL

MSL

2

LBL

h6 = 0.05 m

HFL above MSL, h7 = 3.28 m

HFL above min. bed level h8 = 5.15 m

MSL below min. bed level, h9 = -1.87 m

Top of foundation base below MSL, h10 = -0.73 m

Depth of pile cap, h11 = 1.1 m

Unique Engineering Consultancy (P) Ltd Page 8

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

b1 = 1.0 m

b3 = 0.25 m

b4 = 0.55 m

b5 = 0.9 m

b6 = 0.35 m

b7 = 0.15 m

b8 = 0.4 m

b9 = 3.5 m

b10 = 3.1 m

b11 = 1 m

b12 = 3.1 m

Foundation base length, b13 = 7.2 m

Abutment base length 6.9 m

Foundation projection beyond abutment stem 0.15 m

Total width of foundation 7.2 m

Angle of internal friction of soil 29 degree

Safe bearing capacity of soil 0 t/m2

Load bearing capacity of pile = 40 t

Numbers of piles along longitudinal dirrection = 4 m

Numbers of piles along transverse dirrection = 4 m

Total numbers of piles = 16

Diameter of piles = 700 mm

Length of piles = 16 m

Soil Type : Clayey Silt

Determination of depth of fixity of piles:

Unconfined compressive strength, S = 0.46 kg/cm2

Modulus of subgrade reaction, K = 13.2 kg/cm2

Therefore, Lf/d = 7 from figure 1 and 2.

and, depth of fixity, Lf = 4.9 m

Calculation of vertical load on foundation base

Due to Dead Load

Superstructure = 85.14 t

Backwall = 6.00 t

Abutment cap = 7.95 t

Abutment shaft = 49.68 t

Soil behind abutment = 196.70 t

Approach slab = 15.29 t

Soil in front of abutment = 0.00 t

Total = 360.76 t

Due to Live Load

Maximum live load including impact = 81.06 t

Due to self weight of foundation base = 136.86 t

Loss in weight due to Buoyancy

Depth of abutment shaft below HFL = 2.55 m

Abutment width at HFL = 1.000 m

Loss in weight of abutment shaft = 17.59 t

Loss in weight of soil behind abutment = 56.92 t

Loss in weight of soil in front of abutment = 0.00 t

Unique Engineering Consultancy (P) Ltd Page 9

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Total buoyant force on abutment = 78.06 t

Buoyant force on foundation base = 57.02 t

Calculation of Moments at Foundation Base Level

Due to superstructure DL+LL

Total superstructure DL+LL = 166.19 t

Eccentricity of load about pile cap transverse axis = 0m

Corresponding moment = 0.00 t-m

Superstructure DL = 85.14 t

Moment at foundation toe due to DL = 0.00 t-m

Due to Abutment + Soil filling DL

A. Maximum Load Condition

i) Due to abutment body

Load = 63.63 t

Lever arm = -0.13 m

Moment = -7.95 t-m

ii) Due to Backfill and approach slab

Load = 196.70 t

Lever arm = -2.1 m

Moment = -413.07 t-m

iii) Due to soil fill in front of abutment

Load = 0.00 t

Lever arm = 2m

Moment = 0.00 t-m

Total moment due to abutment + soil filling DL = -421.03 t-m

B. No LL + Buoyancy Condition

i) Due to abutment body

Load = 85.14 t

Lever arm = -0.13 m

Moment = -10.64 t-m

ii) Due to Backfill and approach slab

Load = 133.93 t

Lever arm = -2.1 m

Moment = -281.25 t-m

iii) Due to soil fill in front of abutment

Load = 0.00

Lever arm = 1.55

Moment = 0.00

Total moment due to abutment + soil filling DL = -291.89 t-m

Due to Earth Pressure

Earth pressure = 48.42 t

Lever arm = 3.03 m

Surcharge = 25.32 t

Lever arm = 3.395 m

Total Moment = 232.57 t-m

Unique Engineering Consultancy (P) Ltd Page 10

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Due to Longitudinal forces:

a) Due to tractive effort or braking = 14 t

Which acts at a distance above foundation bottom = 6.05 m

Moment due to tractive effort or braking about foundation base = 84.70 t-m

b) Force due to resistance in bearings due to temperature = 3.16 t

Which acts at a distance above foundation bottom = 3.4 m

Moment due to tractive effort or braking about foundation base = 10.90 t-m

Due to Seismic Forces:

A. Along longitudinal direction for maximum load condition

Description Load (t) Seismic Load (t) Lever arm Moment (t-m)

Superstructure DL 85.14 8.51 4.15 35.33

Abutment shaft P1 49.68 4.97 1.50 7.45

Abutment shaft P2 0.00 0.00 1.00 0.00

Abutment shaft P3 7.95 0.79 3.00 2.38

Abutment shaft P4 6.00 0.60 4.12 2.48

Approach slab 15.29 1.53 4.72 7.22

Backfill 196.70 19.67 2.1 41.31

Total 360.76 36.08 96.17

B. Case of buoyancy and no live load

The seismic load will be lesser than that for N+T case due to submerged part of the sub structure which

will be under buoyancy.

Moment

Description Load (t) Seismic Load (t) Lever arm (m)

(t-m)

Superstructure DL 85.14 8.51 4.15 35.33

Abutment shaft P1 above HFL 7.45 0.75 3.875 2.89

Abutment shaft P1 below HFL 24.63 2.46 2.375 5.85

Abutment shaft P2 above HFL 3.73 0.37 3.80 1.42

Abutment shaft P2 below HFL 0.00 0.00 #DIV/0! #DIV/0!

Abutment Cap P3 7.95 0.79 3 2.38

Abutment backwall P4 6.26 0.63 4.125 2.58

Approach slab 15.29 1.53 4.72 7.22

Backfill above HFL 109.28 10.93 4.67 51.03

Backfill below HFL 79.68 7.97 2.375 18.92

Total 339.41 33.94 #DIV/0!

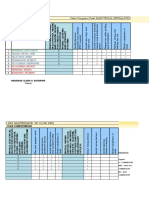

Summary of Moments and Forces

Vertical Loads

Description Case I Case II Case III

Max. Buoyancy+No LL Case I + Seismicity

Load

DL from superstructure + abutment 360.76 282.70 360.76

DL of foundation base 136.86 79.83 136.86

Live load 81.06 - 81.06

Total 578.67 362.53 578.67

Horizontal Forces

Description Case I Case II Case III

Max. Buoyancy+No LL Case I + Seismicity

Load

Earth Pressure 73.74 73.74 73.74

Tractive effort or braking 14 - 14

Unique Engineering Consultancy (P) Ltd Page 11

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Temperature effect 3.16 3.16 3.16

Seismic Force - - 40.41

Total 90.90 76.90 131.31

Resulting Moments

Description Case I Case II Case III

Max. Buoyancy+No LL Case I + Seismicity

Superstructure DL+LL -291.89 0.00 -291.89

Abutment +Soil filling DL -421.03 -291.89 -421.03

Earth pressure 232.57 232.57 232.57

Tractive effort or braking 84.70 - 84.70

Temperature effect 10.90 - 10.90

Seismic force - - 171.28

Total -384.75 -59.32 -213.47

Summary of loads

Cases Unit Case I Case II Case III

Max. Load Buoyancy+No LL Case I + Seismicity

Vertical T 80.37 50.35 80.37

Horizontal T 12.62 10.68 18.24

Moment t-m -53.44 -8.24 -29.65

Case: I

Deducting the bearing capacity of pile cap as a open footing, vertical loads to be taken by piles

= 80.37 t

Loads on each pile due to vertical load = 5.02 t

Axial load on extreme pile due to moment = 12.62 t

Axial load on second row of pile due to moment = 4.02 t

Resultant compressive force on extreme pile = 21.67 t < 40.00 t O.K.

Resultant tensile force on extreme pile = 0.00 t < 40.00 t O.K.

Resultant compressive force on second row of pile= 17.34 t

Coefficient of friction between concrete and clay = 0.20

Friction resistance of cap = 0.00 t

Horizontal force on each pile = 11.17 t

Moment on each piles = 54.72 t-m

Design of piles:

Length of pile, L = 16 m

Diameter of pile, D = 0.7 m

L/D = 22.86 > 12 Hence the pile is designed as long column.

Least radious of gyration, r = 17.5 cm

Reduction coefficient for reduction of stress values is given as,

cr = (1.25-L/48B) = 0.774

Safe stress are,

Permissible direct compressive stress, σco = 3.87 N/mm2

Permissible flexural compressive stress, σco = 5.16 N/mm2

Permissible Flexural Tensile stress, σst = 154.76 Mpa (in steel)

Maximum compressive stress in concrete = 1.50 N/mm2 < 3.869 N/mm2

Unique Engineering Consultancy (P) Ltd Page 12

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Provide minimum area of compression steel @ 1.25 %.

Asc = 4811 mm2

Provide 15 nos. of 25 mm φ bars, giving area of steel = 7363

Check for combined stress:

Percentage area of steel provided, pt = 2.400

p/fck = 0.120

d'/D = 0.091

Pu/fckD2 = 0.088

From chart, Mu/fckD3 = 0.12

and Mu = 82.32 t-m

Working moment, M = 54.88 t-m > 54.72 t-m O.K.

Shear stress due to horizontal force = 0.29 N/mm2

Permissible shear strength of concrete = 0.45 N/mm2 O.K.

Case: C

Axial load on extreme pile due to moment = 27.49 t

Resultant compressive force = 65.07 t < 90.00 t O.K.

Resultant tensile force = 0.00 t < 90.00 t O.K.

Horizontal force on each piles = 6.18 t

Moment on each piles = 30.27 t-m

Pu/fckD2 = 0.100

From chart, Mu/fckD3 = 0.106

and Mu = 72.72 t-m

Working moment, M = 48.48 t-m > 30.27 t-m O.K.

Shear stress due to horizontal force = 0.16 N/mm2

Permissible shear strength of concrete = 0.56 N/mm2 O.K.

Lateral Reinforcement:

Lateral reinforcement should be 0.2% of the gross volume. Using dia. 10 mm ties,

we have the volume of one tie = 145577 mm3

If p be the pitch of the ties in mm, then

Volume of pile per pitch length = 384845 p

Hence equating, we get, p = 189 mm

Hence provide dia 10 mm ties at 160 mm c/c in the main body of the pile.

Design of Pile Cap:

Maximum bending moment in the pile cap due to vertical load,

At center of cap = 312.91 t-m

At face of abutment = 375.77 t-m

Bending moment due to moment on steam = 233.3 t-m

Maximum bending moment = 609.0 t-m

The effective depth required is given by,

dreq = 999 mm

Adopt 1030 mm effective depth and overall depth = 1100 mm

Area of steel required along width of cap = 32466 mm2

Using 25 mm dia. bars, spacing would be 113 mm

Provede 25 mm dia bars @ 120 mm c/c, provided area = 33469 mm2

at both top and bottom.

Distribution reinforcement @ 0.12% = 9900 mm2

Provide 20 mm dia bars @ 150 mm c/c, giving area of stee = 15708 mm2.

Unique Engineering Consultancy (P) Ltd Page 13

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com Design

Detailed Engineering Design of Chargahawa River Bridge For evaluation

Calculation only.

VOLUMN-III

Shear force = 413.23 t

Shear stress, tv = 0.53 N/mm2

Percentage area of steel, pt = 0.43 %

Permissible shear strength of concrete, tc = 0.28 N/mm2 < tv

Shear reinforement is required.

Assuming 10 mm dia 20 legged vertical tirrups, then Asv = 1571 mm2

And spacing of stirrups, S = 163 mm

Maximum spacing of stirrups, = 189 mm

Provide 10 mm dia 4 legged vertical tirrups @ 160 mm c/c.

Check for punching shear along pier,

Shear force = 269.49 t

bo = 20.32 m

tv = 0.13 N/mm2

Punching shear strength, tc = 0.716 N/mm2 > tv Safe.

Check for punching shear along pile,

Shear force = 57.69 t

bo = 5435.0 m

tv = 0.10 N/mm2

Punching shear strength, tc = 0.72 N/mm2 > tv Safe.

Unique Engineering Consultancy (P) Ltd Page 14

Anda mungkin juga menyukai

- 4.0 Design of PierDokumen9 halaman4.0 Design of PierDeepak Kr GuptaBelum ada peringkat

- Abutment DesignDokumen112 halamanAbutment Designmasudulamin14Belum ada peringkat

- Design of Abutment Excel SheetDokumen33 halamanDesign of Abutment Excel Sheetbkvs12340% (5)

- Design of Abutment BridgeDokumen51 halamanDesign of Abutment BridgePrakash Singh Rawal92% (13)

- Design of Bridge PierDokumen12 halamanDesign of Bridge PierSunita Chaurasia88% (8)

- Design of BridgeDokumen59 halamanDesign of BridgeMohd Aftab80% (5)

- Class A Loading (Two Lane) Deck SlabDokumen8 halamanClass A Loading (Two Lane) Deck SlabSUPERINTENDING ENGINEERBelum ada peringkat

- Design of Super StructureDokumen30 halamanDesign of Super StructureHemraj Raj100% (16)

- Design of Abutment-ROBDokumen10 halamanDesign of Abutment-ROBNandeesha Ramesh100% (1)

- R.C Bridge Design For NataiDokumen51 halamanR.C Bridge Design For Nataiencikeddy100% (2)

- Abutment DesignDokumen49 halamanAbutment Designhemantkle2u100% (1)

- Abutment DesignDokumen10 halamanAbutment DesigndsureshcivilBelum ada peringkat

- Design of Well FoundationDokumen39 halamanDesign of Well FoundationvasuBelum ada peringkat

- Shambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentDokumen22 halamanShambhavi Techno Solutions, Patna: Project: Subject: Design of Cantilever Type AbutmentRohit Prakash100% (5)

- Abutment A1 With 8 Piles (Working Stress)Dokumen89 halamanAbutment A1 With 8 Piles (Working Stress)Dipti RandiveBelum ada peringkat

- Computation of Reaction Factors Using Courbon's MethodDokumen2 halamanComputation of Reaction Factors Using Courbon's Methodvasu790075% (4)

- Abutment WellDokumen229 halamanAbutment WellGaurav GhaiBelum ada peringkat

- Idge ManagulliDokumen63 halamanIdge ManagulliHemant SonawadekarBelum ada peringkat

- Abutment DesignDokumen3 halamanAbutment DesignMalay Kumar DebBelum ada peringkat

- Counter Fort Retaining WallsDokumen11 halamanCounter Fort Retaining WallsdsureshcivilBelum ada peringkat

- Design of Box CulvertDokumen17 halamanDesign of Box CulvertSanket Diwate100% (12)

- Design of PierDokumen11 halamanDesign of PierNaveen Yadav100% (6)

- Gravity Retaining Wall - VakapalliDokumen10 halamanGravity Retaining Wall - VakapalliD.V.Srinivasa RaoBelum ada peringkat

- Bridge Abutment Pier Design As Per IRCDokumen41 halamanBridge Abutment Pier Design As Per IRCjibendra mishra88% (43)

- Design of Retaining WallDokumen6 halamanDesign of Retaining WallSasidhar KatariBelum ada peringkat

- Design of Abutment For BridgeDokumen28 halamanDesign of Abutment For BridgeMuhammad Wazim Akram100% (1)

- Design of AbutmentDokumen47 halamanDesign of AbutmentRaju Ranjan SinghBelum ada peringkat

- Well FoundationsDokumen87 halamanWell Foundationsfa100% (1)

- Retaining Wall DesignDokumen5 halamanRetaining Wall DesignbharatBelum ada peringkat

- Counterfort Retaining WallDokumen13 halamanCounterfort Retaining Wallyedida viswanadhBelum ada peringkat

- Design Calculation of Pier Cap With 19.330 M Overall Length of Superstructure in Straight Alignment - R1 - DN-D12-09-01-2020Dokumen17 halamanDesign Calculation of Pier Cap With 19.330 M Overall Length of Superstructure in Straight Alignment - R1 - DN-D12-09-01-2020Partha Gangopadhyay100% (1)

- Box Culvert Two BarrelDokumen23 halamanBox Culvert Two BarrelPurnima ArkalgudBelum ada peringkat

- Abutment WellDokumen576 halamanAbutment WellPrakash Singh RawalBelum ada peringkat

- 73M BridgeDokumen285 halaman73M Bridgemanoj_structure100% (1)

- Bridge BookDokumen76 halamanBridge BookSunkara Hemanth KumarBelum ada peringkat

- DLRB DESN PROC Ver.1-5.11.2020Dokumen11 halamanDLRB DESN PROC Ver.1-5.11.2020S N satyanarayanaBelum ada peringkat

- Design Excel Sheet For AbutmentDokumen8 halamanDesign Excel Sheet For AbutmentSubhash SahBelum ada peringkat

- Design of RC AbutmentDokumen15 halamanDesign of RC AbutmentSuman NakarmiBelum ada peringkat

- Return Wall 10mDokumen23 halamanReturn Wall 10mAkhil Singhal100% (2)

- Design of Pier - RevisedDokumen102 halamanDesign of Pier - RevisedAshish PremiBelum ada peringkat

- RCC Detail Design of Abutment and PierDokumen20 halamanRCC Detail Design of Abutment and Piershashibhushan singh100% (1)

- Abutment 91.69Dokumen20 halamanAbutment 91.69ajoshi_150235Belum ada peringkat

- Critical Section For Moment Critical Section For Shear and TorsionDokumen7 halamanCritical Section For Moment Critical Section For Shear and TorsionShashank Srivastava0% (1)

- Design of BridgeDokumen33 halamanDesign of BridgeAnu PathakBelum ada peringkat

- Design of RCC PierDokumen10 halamanDesign of RCC Piervijayunity40% (5)

- Design of 10m Clear Span Slab BridgeDokumen53 halamanDesign of 10m Clear Span Slab BridgeD.V.Srinivasa Rao100% (4)

- Final Bridge Design Report (Berhampur AniDokumen98 halamanFinal Bridge Design Report (Berhampur AniYogesh Indolia100% (6)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDokumen35 halamanCounter Fort Reatining WAll With HORZONTAL Bach FillUlasi IfeanyiBelum ada peringkat

- Retaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Dokumen21 halamanRetaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Shashank Srivastava100% (1)

- Pier DesignDokumen17 halamanPier DesignvinujohnpanickerBelum ada peringkat

- Limit StateDokumen23 halamanLimit StateSubbarao Kakumanu100% (9)

- Slab Bridge DesignDokumen25 halamanSlab Bridge DesignEngineeri TadiyosBelum ada peringkat

- Design of Cantilever Retaining Wall: Preliminary ProportionsDokumen6 halamanDesign of Cantilever Retaining Wall: Preliminary ProportionsMuhammed NaseefBelum ada peringkat

- RCC Voided Slab 4X20Dokumen80 halamanRCC Voided Slab 4X20amir100% (2)

- Check For Correctness of Data: 2.2 Design of Right AbutmentDokumen47 halamanCheck For Correctness of Data: 2.2 Design of Right AbutmentAbhay ThakurBelum ada peringkat

- Footing Design - Studio AoartmentDokumen23 halamanFooting Design - Studio AoartmentMUKESH RAJENDRABelum ada peringkat

- TCDSCo Bridge SampleDokumen79 halamanTCDSCo Bridge SampleEngineeri TadiyosBelum ada peringkat

- Abutment Design For 30mDokumen40 halamanAbutment Design For 30mManvendra NigamBelum ada peringkat

- 15m RC TG Superstructure DesignDokumen22 halaman15m RC TG Superstructure DesignEngineeri TadiyosBelum ada peringkat

- Example 20m Span RCDGDokumen17 halamanExample 20m Span RCDGIyœ Møsisæ100% (2)

- Section 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDokumen48 halamanSection 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDeepak Kr GuptaBelum ada peringkat

- Nonlinear Limit-State PDFDokumen28 halamanNonlinear Limit-State PDFDeepak Kr GuptaBelum ada peringkat

- RCC Bridge and Culvert DesignDokumen113 halamanRCC Bridge and Culvert DesignDeepak Kr GuptaBelum ada peringkat

- Irrigation DesignDokumen7 halamanIrrigation DesignDeepak Kr GuptaBelum ada peringkat

- Manual Bridge PDFDokumen768 halamanManual Bridge PDFDeepak Kr Gupta100% (1)

- 2 Cell Box CulvertDokumen63 halaman2 Cell Box CulvertOscarKonzultBelum ada peringkat

- 2 Cell Box CulvertDokumen63 halaman2 Cell Box CulvertOscarKonzultBelum ada peringkat

- Abutment Pier and WallDokumen29 halamanAbutment Pier and WallDeepak Kr GuptaBelum ada peringkat

- Borehole Log: No. of Blows Total SPT/D CP Value N-ValueDokumen1 halamanBorehole Log: No. of Blows Total SPT/D CP Value N-ValueDeepak Kr GuptaBelum ada peringkat

- Manual Bridge PDFDokumen768 halamanManual Bridge PDFDeepak Kr Gupta100% (1)

- Section 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDokumen48 halamanSection 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDeepak Kr GuptaBelum ada peringkat

- Section 11Dokumen200 halamanSection 11Waheed AhmadBelum ada peringkat

- Two Cell RCC Box CulvertDokumen40 halamanTwo Cell RCC Box Culvertradespino1Belum ada peringkat

- Section 11Dokumen200 halamanSection 11Waheed AhmadBelum ada peringkat

- Retaining Wall DesignDokumen55 halamanRetaining Wall DesignMohit Kohli100% (1)

- Retaining Wall DesignDokumen55 halamanRetaining Wall DesignMohit Kohli100% (1)

- Abutment DesignDokumen38 halamanAbutment DesignDeepak Kr GuptaBelum ada peringkat

- Grain Size Distribution: Project: Ghatte Khola Client: Mopid, Hetauda, MakawanpurDokumen1 halamanGrain Size Distribution: Project: Ghatte Khola Client: Mopid, Hetauda, MakawanpurDeepak Kr GuptaBelum ada peringkat

- Section 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDokumen48 halamanSection 11 Abutment, Piers, and Retaining Walls Section 11 Abutment, Piers, and Retaining WallsDeepak Kr GuptaBelum ada peringkat

- Methodology For Detailed Geotechnical Investigation of Bridge Sites PDFDokumen4 halamanMethodology For Detailed Geotechnical Investigation of Bridge Sites PDFDeepak Kr GuptaBelum ada peringkat

- Civil Geo Lab Pvt. LTD.: Direct Shear TestDokumen1 halamanCivil Geo Lab Pvt. LTD.: Direct Shear TestDeepak Kr GuptaBelum ada peringkat

- Civil Geo Lab Pvt. Ltd. Lalitpur Test Result Summary SheetDokumen1 halamanCivil Geo Lab Pvt. Ltd. Lalitpur Test Result Summary SheetDeepak Kr GuptaBelum ada peringkat

- Methodology For Detailed Geotechnical Investigation of Bridge SitesDokumen11 halamanMethodology For Detailed Geotechnical Investigation of Bridge SitesDeepak Kr GuptaBelum ada peringkat

- NRRS 2055first Revision 2069 DoLIDAR Reduced For WebDokumen32 halamanNRRS 2055first Revision 2069 DoLIDAR Reduced For WebDeepak Kr Gupta100% (1)

- Plate GirderDokumen1 halamanPlate GirderDeepak Kr GuptaBelum ada peringkat

- Methodology For Detailed Geotechnical Investigation of Bridge Sites PDFDokumen4 halamanMethodology For Detailed Geotechnical Investigation of Bridge Sites PDFDeepak Kr GuptaBelum ada peringkat

- Methodology For Detailed Geotechnical Investigation of Bridge Sites PDFDokumen4 halamanMethodology For Detailed Geotechnical Investigation of Bridge Sites PDFDeepak Kr GuptaBelum ada peringkat

- Methodology For Detailed Geotechnical Investigation of Bridge SitesDokumen19 halamanMethodology For Detailed Geotechnical Investigation of Bridge SitesDeepak Kr GuptaBelum ada peringkat

- Rajesh Bhaiya FinalDokumen1 halamanRajesh Bhaiya FinalDeepak Kr GuptaBelum ada peringkat

- Bore HoleDokumen2 halamanBore HoleDeepak Kr GuptaBelum ada peringkat

- Electronic Temperature Switch ETS 1700: User ManualDokumen15 halamanElectronic Temperature Switch ETS 1700: User ManualНикита ЛесюкBelum ada peringkat

- Activity 2 Resultant Vector by Graphical MethodDokumen2 halamanActivity 2 Resultant Vector by Graphical MethodRick Ignacio0% (1)

- A Quick Tutorial On RSLogix Emulator 5000Dokumen9 halamanA Quick Tutorial On RSLogix Emulator 5000slavezerorjBelum ada peringkat

- West Knits Book 3Dokumen56 halamanWest Knits Book 3Alexandr Maxiuta100% (17)

- Analysis and Design of Filament Power Supply With PDFDokumen5 halamanAnalysis and Design of Filament Power Supply With PDFHoracio Dorantes ReyesBelum ada peringkat

- 2-Way Doherty Amplifier With BLF888ADokumen27 halaman2-Way Doherty Amplifier With BLF888AerdemsecenBelum ada peringkat

- Form Cor Eng Pip 002 e R01Dokumen1 halamanForm Cor Eng Pip 002 e R01Uri SanchezBelum ada peringkat

- Transom Analysis ComparisonDokumen38 halamanTransom Analysis ComparisonRifky NetriadyBelum ada peringkat

- Western Dragon V3 Updated PDFDokumen19 halamanWestern Dragon V3 Updated PDFMark Moldez94% (17)

- Intro Adobe Photoshop HandoutDokumen13 halamanIntro Adobe Photoshop Handoutoyindamola ayobamiBelum ada peringkat

- Mv324 Data SheetDokumen17 halamanMv324 Data SheetGianmarco CastilloBelum ada peringkat

- MMM - Unit 1Dokumen133 halamanMMM - Unit 1Ahmed Raza MokashiBelum ada peringkat

- Bsm2300a SeriesDokumen324 halamanBsm2300a SeriesIBRAHIMBelum ada peringkat

- Degree of Kinematic IndeterminacyDokumen8 halamanDegree of Kinematic IndeterminacyshahrukhBelum ada peringkat

- Introduction & BiomoleculesDokumen50 halamanIntroduction & BiomoleculesAshrul NasirBelum ada peringkat

- Online Food Ordering System MiniDokumen11 halamanOnline Food Ordering System Minijwala reddy83% (47)

- Problem in Traffic Flow Theory: Speed-Density Relationships: Lnu LNK Q U KDokumen10 halamanProblem in Traffic Flow Theory: Speed-Density Relationships: Lnu LNK Q U KRomel DecenillaBelum ada peringkat

- GGDokumen8 halamanGGGaurav SharmaBelum ada peringkat

- Ma 2266 - Statistics and Numerical Methods April - May 2011Dokumen5 halamanMa 2266 - Statistics and Numerical Methods April - May 2011Rahul singhBelum ada peringkat

- Geomechanics: Figure 1 Geomechanics in Oil & Gas Industry (Source: Geomechanics Engineering)Dokumen2 halamanGeomechanics: Figure 1 Geomechanics in Oil & Gas Industry (Source: Geomechanics Engineering)ابوالحروف العربي ابوالحروفBelum ada peringkat

- LAN Cabling: Straight ThroughDokumen3 halamanLAN Cabling: Straight ThroughGemma Quiocho-CardenasBelum ada peringkat

- Yuzuru Hanyu - ThesisDokumen6 halamanYuzuru Hanyu - ThesisFatima Esperanza Ortiz Ortiz100% (4)

- Total Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsDokumen14 halamanTotal Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsAhmad HidayahBelum ada peringkat

- Practical 1 PacingDokumen13 halamanPractical 1 PacingFiaz Hussain0% (1)

- Fascial Manipulation For Internal Dysfunctions FMIDDokumen8 halamanFascial Manipulation For Internal Dysfunctions FMIDdavidzhouBelum ada peringkat

- Rockschool Popular Music Theory Syllabus 2015 18Dokumen33 halamanRockschool Popular Music Theory Syllabus 2015 18Archit AnandBelum ada peringkat

- Class Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Dokumen2 halamanClass Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Shairrah Claire Bañares BatangueBelum ada peringkat

- LEC# 15. Vapor Compression, Air ConditioningDokumen31 halamanLEC# 15. Vapor Compression, Air ConditioningAhmer KhanBelum ada peringkat

- Statics and Mechanics of Materials 3Rd Edition Full ChapterDokumen41 halamanStatics and Mechanics of Materials 3Rd Edition Full Chapterjason.rabil982100% (29)

- TransistorDokumen1 halamanTransistorXhaBelum ada peringkat

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyDari EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyPenilaian: 3.5 dari 5 bintang3.5/5 (111)

- Algorithms to Live By: The Computer Science of Human DecisionsDari EverandAlgorithms to Live By: The Computer Science of Human DecisionsPenilaian: 4.5 dari 5 bintang4.5/5 (722)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityDari EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityPenilaian: 5 dari 5 bintang5/5 (1)

- Cyber War: The Next Threat to National Security and What to Do About ItDari EverandCyber War: The Next Threat to National Security and What to Do About ItPenilaian: 3.5 dari 5 bintang3.5/5 (66)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveDari EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveBelum ada peringkat

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldDari EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (55)

- 100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziDari Everand100M Offers Made Easy: Create Your Own Irresistible Offers by Turning ChatGPT into Alex HormoziBelum ada peringkat

- AI Prompting Mastery: Strategies and Techniques for Effective PromptingDari EverandAI Prompting Mastery: Strategies and Techniques for Effective PromptingBelum ada peringkat

- Alibaba: The House That Jack Ma BuiltDari EverandAlibaba: The House That Jack Ma BuiltPenilaian: 3.5 dari 5 bintang3.5/5 (29)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDari EverandChip War: The Quest to Dominate the World's Most Critical TechnologyPenilaian: 4.5 dari 5 bintang4.5/5 (227)

- Generative AI: The Insights You Need from Harvard Business ReviewDari EverandGenerative AI: The Insights You Need from Harvard Business ReviewPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessDari EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessBelum ada peringkat

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldDari EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (107)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewDari EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewPenilaian: 4.5 dari 5 bintang4.5/5 (104)

- Dark Data: Why What You Don’t Know MattersDari EverandDark Data: Why What You Don’t Know MattersPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceDari EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceBelum ada peringkat

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDari EverandFour Battlegrounds: Power in the Age of Artificial IntelligencePenilaian: 5 dari 5 bintang5/5 (5)

- How to Do Nothing: Resisting the Attention EconomyDari EverandHow to Do Nothing: Resisting the Attention EconomyPenilaian: 4 dari 5 bintang4/5 (421)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesDari EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesBelum ada peringkat

- Working with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)Dari EverandWorking with AI: Real Stories of Human-Machine Collaboration (Management on the Cutting Edge)Penilaian: 5 dari 5 bintang5/5 (5)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideDari EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuidePenilaian: 5 dari 5 bintang5/5 (2)

- The AI Advantage: How to Put the Artificial Intelligence Revolution to WorkDari EverandThe AI Advantage: How to Put the Artificial Intelligence Revolution to WorkPenilaian: 4 dari 5 bintang4/5 (7)

- Everybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreDari EverandEverybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really ArePenilaian: 4.5 dari 5 bintang4.5/5 (913)