Principle of Energy Conservation

Diunggah oleh

Abubakar Ibrahim MusaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Principle of Energy Conservation

Diunggah oleh

Abubakar Ibrahim MusaHak Cipta:

Format Tersedia

Principle of Energy Conservation

Principle of Energy

Conservation

Principle of Energy Conservation

4.1 Energy, Work and Heat

5.1 1

st

Law for Control Mass

5.2 Specific Heats for Ideal Gas

5.3 1

st

Law for Control Volume

5.4 Steady-State, Steady-Flow Process

5.5 Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Energy, Work and Heat

Two major concepts of thermodynamics are energy

and entropy. They are both abstract concepts in

classical thermodynamics, which are derived from

the 1

st

and 2

nd

law of thermodynamics.

Energy, Work and Heat

4.1 Energy, Work and Heat

Principle of Energy Conservation

(Energy)

System

Work

Energy

Flow

Energy

Flow

Heat

Surrounding

Energy, Work and Heat

Principle of Energy Conservation

Energy

Macroscopic view

1

st

Law :

Energy can be transferred in two different forms,

heat and work. Energy is an abstract concept given

as a thermodynamic property, defined in terms of

the 1

st

law of thermodynamics.

Microscopic view

Energy can be stored i n many di fferent forms;

intermolecular potential energy, molecular kinetic

energy and intermolecular energy including rotational

and vibrational energy.

dE Q W o o =

Energy, Work and Heat

Principle of Energy Conservation

Work and Heat

There are only two forms of energy transfer, work and

heat.

Work : a form of energy transfer due to an externally

applied force and resulting displacement of the system

F c a n be a n y g e n e r a l i z e d f o r c e a n d x i s t he

corresponding generalized displacement.

Conventionally work is defined as positive if energy is

transferred from the system to the surrounding.

W Fdx o

Energy, Work and Heat

Principle of Energy Conservation

Heat : a form of energy transfer from a higher temperature

to a lower temperature. Conventionally heat is defined as

positive if energy is transferred to the system from the

surrounding.

The system contains energy, not heat. Heat is identified

at the boundary, as energy transfer occurs across the

boundary due to difference in T.

,

2

1 2

1

Q Q o =

Q

Q

dt

o

&

Energy, Work and Heat

Principle of Energy Conservation

Units for work are same as those for energy.

1 J = 1 Nm

Power:

1 W = 1 J/s

1 hp = 550 lbf ft/s

Specific work: work per unit mass of the system

W

W

dt

o

&

W

w

m

|

Energy, Work and Heat

Principle of Energy Conservation

Units of heat are same as those for work.

1 btu = 1.055056 kJ

1 cal = 4.1868 J

Specific heat transfer; heat transfer per unit mass of

the system

Adiabatic process;

Q=0

Q

q

Energy, Work and Heat

Principle of Energy Conservation

Example of work crossing the boundary of a system

Energy, Work and Heat

Principle of Energy Conservation

Example of work crossing the boundary of a system

because of a flow of an electric current across the

system boundary

Energy, Work and Heat

Principle of Energy Conservation

System

> T

surr

T

sys

Surrounding

Heat

Energy, Work and Heat

Principle of Energy Conservation

Schematic arrangement showing

work done on a surface film

Energy, Work and Heat

Principle of Energy Conservation

Schematic arrangement fir magnetic cooling

Energy, Work and Heat

Principle of Energy Conservation

Work done at the moving boundary in a quasi-

equilibrium process

Quasi-equilibrium process : internally reversible process.

Infinitesimal change to maintain equilibrium throughout

the process.

Non-equilibrium process : the intermediate states can

not be defined. The force exerted by the pressure of

gas does not equal the external force.

W PdV o =

2 2

1 2

1 1

W W d o

ext

W d o

Energy, Work and Heat

Principle of Energy Conservation

Use of pressure-volume diagram to show work done

at the moving boundary of a system in a quasi -

equilibrium process

Energy, Work and Heat

Principle of Energy Conservation

Work done depends not only on the two end

states but also on the path followed.

W :

path function

:

inexact differential

Var i ous quas i -equi l i br i um pr oces s es bet ween t wo

given states, indicating that work is a path function.

1 2 2 1

1 2 1 2 1 2

A B C

W W W X

W W W

=

= =

W o

Energy, Work and Heat

Principle of Energy Conservation

2 1 2 1

1 2 1 2

2 1 2 1

1 2 1 2

2 2 2 2

1 1 1 1

2 2

1 1

A B A B

C B C B

A C A C

A C

Q W

Q Q W W

Q Q W W

Q Q W W

Q W Q W

o o

o o o o

o o o o

o o o o

o o o o

=

+ = +

+ = +

=

=

Energy, Work and Heat

Principle of Energy Conservation

Q W o o

dE Q W o o

1 2 2 1 1 2

2

2

Q E E W

dE dU m dV mgdZ

d mV

Q dU d mgZ W o o

: point function

Energy, Work and Heat

Principle of Energy Conservation

Point Functions

thermodynamic properties

e.g. V, U, H,

The change in volume depends only on the two end

states.

dV : exact differential

2

2 1

1

dV V V =

Energy, Work and Heat

Principle of Energy Conservation

The relationship between P and V is required for

integration.

Polytropic Process

where n=1(isothermal process),

2 2

2 2 1 1

1 1

1

n

n

PV const

dV PV PV

PdV const

V n

=

= =

2

2

1 1

1

1

ln

V

PdV PV

V

=

Energy, Work and Heat

Principle of Energy Conservation

Other Modes of Work

There is only one mode of heat, while there can be

many different modes of work.

0

W PdV dL dA Hd V dZ o p = + M E

Energy, Work and Heat

Principle of Energy Conservation

Non-equilibrium Process; No Work is involved.

Example of a process involving a change

of volume for which work is zero

Energy, Work and Heat

Principle of Energy Conservation

Heat and Work

(1) Both are transient phenomena.

They cross the boundary as the system undergoes a

change in its state.

(2) Both are boundary phenomena.

They represent energy crossing the boundary of the

system.

(3) Both are path functions and inexact differentials.

Thermodynamic properties are state or point functions,

which do not depend on the previous path or history.

Energy, Work and Heat

Principle of Energy Conservation

Identification of works involved is an important

part of many thermodynamic problems.

Example showing how

selection of the system

determines whether work

is involved in a process

Energy, Work and Heat

Principle of Energy Conservation

An example showing the difference

between heat and work

Energy, Work and Heat

Principle of Energy Conservation

Example 4.1

Consider as a system the gas in the cylinder. The cylinder

is fitted with a piston on which a number of small weights

are placed. The initial pressure is 200kPa, and the initial

volume of the gas is 0.4m

3

.

1. Let a Bunsen burner be placed under the cylinder,

and l et the vol ume of the gas i ncrease to 0. 1m

3

whi l e t he pr es s ur e r emai ns cons t ant . Cal cul at e

the work done by the system during this process.

2 2

1 2 2 1

1 1

12.0 W dV P dV P V V kJ ! ! ! !

Energy, Work and Heat

Principle of Energy Conservation

2. Consider the same system and initial conditions,

but at same time the Bunsen burner is under the

cylinder and the piston is rising, let weights be

removed from the piston at such a rate that, during

the process, the temperature of the gas remains

constant.

n=1

2

2

1 2 1 1

1

1

ln 7.33

V

W PdV PV kJ

V

! ! !

Energy, Work and Heat

Principle of Energy Conservation

3. Consider the same system, but during the heat

transfer let the weights be removed at such a rate

that the expression describes the

relation between pressure and volume during the

pr oces s . Agai n t he fi nal vol ume i s 0. 1m

3

.

Calculate the work.

1.3

2

0.04

200 60.77

0.10

P kPa

! !

1.3

PV const !

2

2 2 1 1

1 2

1

6.41

1 1.3

PV PV

W PdV kJ

! ! !

Energy, Work and Heat

Principle of Energy Conservation

4. Consider the system and initial state in the first

three examples, but let the piston be held by a pin

so that the volume remains constant. In addition,

let heat be transferred from the system until the

pressure drops to 100kPa. Calculate the work.

The work is zero, because there is no change in

volume.

Energy, Work and Heat

Principle of Energy Conservation

Pressure-volume diagram

Energy, Work and Heat

Principle of Energy Conservation

Example 4.2

Consider a slightly different piston cylinder arrangement

as shown in Fig.4.8. In this example the piston is loaded

with a mass, m

p

, the outsi de atmosphere P

0

, a linear

spring and a single point force F

1

. The piston is restricted

in its motion by lower and upper stops trapping the gas

with a pressure P. A force balance on the piston in the

direction of motion yields

with a zero acceleration in a quasi-equilibrium process.

The forces, when the piston between the stops, are

0

p

m a F F

o q

!

;

Energy, Work and Heat

Principle of Energy Conservation

with the linear spring constant, k

s

. The piston position

for a relaxed spring is x

0

, which depends on how the

spring is installed. The force balance then gives the

gas pressure by division with the area, A as

To illustrate the process in a P-V diagram, the distance

x is converted to volume by multiplication with A:

0 0 1 p s

F m g P A k x x F

q

= + + +

F PA

T

=

0 1 0

/

p s

P P m g F k x x A !

1

0 0 1 2

2

p

s

m g

k F

P P V V C C V

A A A

= + + + = +

Energy, Work and Heat

Principle of Energy Conservation

This relation gives the pressure as a linear function of

the volume, with the line having a slope of C

2

=k

s

/A

2

.

With the stops installed, the minimum and maximum

volumes limit the possible states of the system to the

Combination of P and V as shown in Fig.4.9. Regardless

of what substance is inside, any process must proceed

along the lines in the P-V diagram. The work term in a

quasi-equilibrium process then follows as

2

1 2

1

( ) W PdV AREA under process curve ! !

' '

1 2 1 2 2 1

1

2

W P P V V = +

Energy, Work and Heat

Principle of Energy Conservation

with and , subject to the

constraint

that

These limits show that only the part of the process

that follows the sloped line, when the piston moves,

contributes to the work. Any part of the process with

a pressure smaller than P

min

or larger than P

max

does

not involve work as the piston is held in fixed piston

by one of the stops. The maximum work then arises,

when the piston travels the total distance between

the two stops.

'

1 1

P P !

'

2 2

P P !

' '

min 1 2 max

, P P P P e e

Energy, Work and Heat

Principle of Energy Conservation

The process curve showing possible P-V combination

Energy, Work and Heat

Principle of Energy Conservation

The 1

st

Law of Thermodynamics

(Conservation of Energy)

Example of a control mass undergoing a cycle

Q W o o =

5.1 1

st

Law for Control Mass

1

st

Law for Control Mass

Principle of Energy Conservation

Control Mass Undergoing a Process

E :

all energy of

the system

Energy Conservation

The net change of the energy is always equal to the

net transfer of energy across the boundary as heat

and work.

dE

dE Q W

dE

Q W

dt

o o !

!

& &

(work)

System

(heat)

Q o

W o

dE

1

st

Law for Control Mass

Principle of Energy Conservation

Internal Energy

E = U + KE + PE

U : internal energy

E represents all the energy of the system in the given

state.

Kinetic and potential energy(KE and PE) depend on

the coordinate frame that we choose to select. They

can be speci fied by the macroscopic properti es of

mass, velocity and elevation.

Internal energy(U) is a thermodynamic property, which

may be uniquely given from the thermodynamic state

of the system.

1

st

Law for Control Mass

Principle of Energy Conservation

No information about the absolute magnitude of the

internal energy.

U : extensive property

u : intensive property

2 2

2 1

1 2 2 1 2 1 1 2

2

m V V

Q U U mg Z Z W

= + + +

2

2

d mV

Q dU d mgZ W o o = + + +

U

u

m

=

f fg

u u xu = +

1

st

Law for Control Mass

Principle of Energy Conservation

Example 5.2

Consider a stone having a mass of 10kg and a bucket

containing 100kg of liquid water. Initially the stone is

10.2m above the water, and the stone and the water

are at the same temperature, state 1. The stone then

falls into the water.

Determine U, KE, PE, Q, and W for the following

changes of stat e, assumi ng standard gravi tat i onal

acceleration of 9.80665m/s

2

a. The stone is about to enter the water, state 2.

b. The stone has just come to rest in the bucket,

state 3.

1

st

Law for Control Mass

Principle of Energy Conservation

c. Heat has been transferred to the surroundings

in such an amount that the stone and water

are at the temperature, , state 4.

1. The stone has fallen from to , and we assume

no heat transfer as it falls.

; ;

For the process from state 1 to state 2,

and

1

T

Q U KE PE W ! ( ( (

2

Z

1

Z

0 U ( !

1 2

0 Q =

1 2

0 W =

2 1

0

1000 1

KE PE

KE PE mg Z Z J kJ

( + ( =

( = ( = = =

1 KE kJ ( ! 1 PE kJ ( =

1

st

Law for Control Mass

Principle of Energy Conservation

2. For the process from state 2 to state 3 with zero

kinetic energy

; ;

3. In final state,

; ; ;

0 PE ( =

2 3

0 Q =

2 3

0 W !

3 4

0 W =

0 PE ( =

0 KE ( = 1 U kJ ( =

0

1

U KE

U KE kJ

( + ( =

( = ( =

3 4

1 Q U kJ !( !

1

st

Law for Control Mass

Principle of Energy Conservation

Example 5.3

A vessel having a volume of 5m

3

, contains 0.05m

3

of

saturated liquid water and 4.95m

3

of saturated water

vapor at 0.1MPa. Heat is transferred until the vessel is

filled with saturated vapor. Determine the heat transfer

for this process.

Control mass : All the water inside the vessel.

Initial state : Pressure, volume of liquid, volume of

vapor; State 1 is fixed.

Fi nal s t at e : Somewher e al ong t he s at ur at ed-

vapor curve; the water was

h e a t e d ,

so P

2

>P

1

.

1

st

Law for Control Mass

Principle of Energy Conservation

process : constant volume and mass, therefore,

constant specific volume.

1 2 2 1

Q U U !

2 2

2 1

1 2 2 1 2 1 1 2

2

V V

Q U U m mg Z Z W

= + + +

1

1

0.05

47.94

0.001043

4.95

2.92

1.6940

liq

liq

f

vap

vap

g

V

m kg

v

V

m kg

v

! ! !

! ! !

1 1 1 1 1

27326

liq liq vap vap

U m u m u kJ ! !

1

st

Law for Control Mass

Principle of Energy Conservation

Then

1 1

50.86

liq vap

m m m kg ! !

3

2

0.09831 /

V

V m kg

m

= =

2

2 2

1 2 2 1

2600.5 /

132261

104935

u kJ kg

U mu kJ

Q U U kJ

!

! !

! !

1

st

Law for Control Mass

Principle of Energy Conservation

Problem Analysis

(1) Define the system. Control mass or control volume?

(2) Find out the initial and final states.

(3) Description of the process.

(4) Diagram of the process helps.

(5) How to obtain thermodynamic properties.

(6) Analysis of the problem.

1

st

or 2

nd

laws? Relevant work modes?

(7) Solution technique.

Numerical solution? Trial-and-error?

1

st

Law for Control Mass

Principle of Energy Conservation

Enthalpy

H = U + PV

h = u + Pv (h=H/m)

Enthalpy is also a thermodynamic property, which may

be defi ned as ei ther an extensi ve or an i ntensi ve

property. (H or h)

In a constant pressure process;

1 2 2 1 1 2

Q U U W = +

1 2 2 1

W P V V =

1

st

Law for Control Mass

Principle of Energy Conservation

therefore

The combination, U+PV, appears often in control

volume analysis of the 1

st

law of thermodynamics.

1 2 2 2 2 1 1 1 2 1

Q U PV U PV H H = + + =

1

st

Law for Control Mass

Principle of Energy Conservation

Example 5.4

A cylinder fitted with a piston has a volume of 0.1m

3

and cont ai ns 0. 5kg of s t eam at 0. 4MPa. Heat i s

transferred to the steam until the temperature is 300rC,

while the pressure remains constant.

Determine the heat transfer and the work for this process.

Control mass: Water inside cylinder.

Initial state: P

1

, V

1

, m; therefore v

1

is known, state 1 is

fixed(at P

1

, v

1

, check steam table - two-phase region).

Final state: P

2

, T

2

; therefore state 2 is fixed(superheated).

Process: Constant pressure.

Model: Steam tables.

1

st

Law for Control Mass

Principle of Energy Conservation 1

st

Law for Control Mass

Principle of Energy Conservation

No change in kinetic energy, no change in potential

energy. Work is done by movement at the boundary.

Assume the process to be quasi-equilibrium. Since the

pressure is constant,

Therefore , the first law is

2 2

1 2 2 1 2 2 1 1

1 1

W PdV P dV P V V m Pv Pv ! ! ! !

1 2 2 1 1 2 2 1 2 2 1 1 2 1

Q m u u W m u u m Pv Pv m h h ! ! !

1

st

Law for Control Mass

Principle of Energy Conservation

1

1 1

1

1 1

2

1 2

1 2 2 1

2 1 1 2 1 2

0.2 0.001084 0.4614

0.4311

1524.7

3066.8

0.5 3066.8 1524.7 771.1

91.0

680.1

f fg

V

v x

m

x

h h x h

h

Q kJ

W mP v v kJ

U U Q W kJ

! ! !

!

! !

!

! !

! !

! !

1

st

Law for Control Mass

Principle of Energy Conservation

Specific Heats

Specific heat at constant volume :

Specific heat at constant pressure :

The specific heats are thermodynamic properties.

(A function in terms of thermodynamic properties is

itself a thermodynamic property.)

For solid and liquid,

v

v

u

C

T

x

=

x

p

p

h

C

T

x

=

x

2 1 2 1 2 1

p v

dh du CdT C C C

h h u u C T T

} } } }

} }

Specific Heats for Ideal Gas

5.2 Specific Heats for Ideal Gas

Principle of Energy Conservation

Internal Energy, Enthalpy and Specific Heats of

Ideal Gas

For ideal gas the internal energy and enthalpy are the

functions of temperature only.

I deal gas s peci fi c heat s ar e al so cal l ed as zero-

pressure specific heats, , .

from

0 0 p v

C C R =

0 v

C T

0 p

C T

v

p

du

C f T

dT

dh

C f T

dT

! !

! !

u u T !

h h T !

h u RT ! +

Specific Heats for Ideal Gas

Principle of Energy Conservation

The energy in a molecule may be stored in several

forms. Translational and rotational energies increase

l i nearl y wi th temperature. Vi brati onal energy i s

temperature dependent.

monoatomic : Ar, Ne, He (f=3)

diatomic : Air, O

2

, H

2

(f=6)

polyatomic : CO

2

, H

2

O (f=9)

Specific Heats for Ideal Gas

Principle of Energy Conservation

Specific Heats

C o n s t a n t - p r e s s u r e

s p e c i f i c h e a t s f o r a

n u m b e r o f g a s e s a t

zero

pressure

Specific Heats for Ideal Gas

Principle of Energy Conservation

Enthalpy from Specific Heats of Ideal Gas

- constant

less accurate except for monatomic gases

- as an analytical function of T

close empirical approximation

- Gas Table

most accurate

0 p

C

0 p

C

Specific Heats for Ideal Gas

Principle of Energy Conservation

Example 5.6

Calculate the change of enthalpy as 1kg of oxygen is

heated from 300 to 1500K. Assume ideal-gas behavior.

Our most accurate answer for the ideal-gas enthalpy

change for oxygen between 300 and 1500K would be

from the ideal-gas tables, Table A.13.

1500 300

2 1

1267.0 /

h h

h h kJ kg

M

! !

Specific Heats for Ideal Gas

Principle of Energy Conservation

The empirical equation from Table A.11 should give

a good approximation to this result.

2 2

1 1

2

1

2 1 0 0

15

2.5 0.5 1

1500 300

3

1500 300

2 1

100

0.020102 178.57

100 37.432 236.88

2.5 0.5

40525 /

1266.4 /

T

p p

T

h h C dT C d

h h

kJ kmol

h h

h h kJ kg

M

U

U

U

U

U U

U U U U

!

!

! ! v

!

!

! !

Specific Heats for Ideal Gas

Principle of Energy Conservation

I f we as s ume cons t ant s peci fi c heat , we mus t be

concerned about what value we are going to use. If

we use the value at 300K from Table A.10,

On the other hand, suppose we assume that the specific

heat i s constant at i t s val ue at 900K, t he average

temperature. Substituting 900K into the equation for

specific heat from Table A.11,

2 1 0 2 1

1105.9 /

p

h h C T T kJ kg ! !

0

2 1

1.0714 /

1285.7 /

p

C kJ kgK

h h kJ kg

!

!

Specific Heats for Ideal Gas

Principle of Energy Conservation

Example 5.7

A cylinder fitted with a piston has an initial volume of

0. 1m3 and contains ni trogen at 150kPa, 25rC. The

piston is moved, compressing the nitrogen until the

pressure is 1MPa and the temperature is 150rC. During

this compression process heat is transferred from the

nitrogen, and the work done on the nitrogen is 20kJ.

Determine the amount of this heat transfer.

Specific Heats for Ideal Gas

Principle of Energy Conservation

First law:

1 2 2 1 1 2

Q m u u W !

1 2 0 2 1 1 2

150 0.1

0.1695

0.2968 298.15

4.2

v

PV

m kg

RT

Q mC T T W kJ

v

! ! !

v

! !

Control mass: Nitrogen.

Initial state: P

1

, T

1

, V

1

; state 1 fixed.

Final state: P

2

, T

2

; state 2 fixed.

Process: work input known.

Model: Ideal gas, constant specific heat at 300K,

Table A.10

Specific Heats for Ideal Gas

Principle of Energy Conservation

Example 5.8

During the charging of a storage battery, the current

is 20A and the voltage is 12.8V. The rate of heat

transfer from the battery is 10W. At what rate is the

internal energy increasing?

256

246 /

dU

Q W

dt

W Ei W

dU

Q W J s

dt

= +

= =

= =

& &

&

& &

Specific Heats for Ideal Gas

Principle of Energy Conservation

Control Volume Formulation : Mass

5.3 1

st

Law for Control Volume

1

st

Law for Control Volume

Principle of Energy Conservation

Control Volume Formulation : Energy

1

st

Law for Control Volume

Principle of Energy Conservation

Control Volume Formulation

()

1

st

Law for Control Volume

Principle of Energy Conservation

Steady State, Steady Flow(SSSF) Process

1. CV at rest.

2. SS everywhere in the CV.

3. SS for flows across the CS.

SS for heat and work.

where ,

i e

m m m ! !

& & &

2 2

2 2

i e

i i e e

V V

q h gZ h gZ + + + = + + +

. . c v

Q

q

m

!

&

&

. . c v

W

m

=

&

&

Steady-State, Steady-Flow Process

5.4 Steady-State, Steady-Flow Process

Principle of Energy Conservation

Example 5.10

The mass rate of flow into a steam turbine is 1.5kg/s,

and the heat transfer from the turbine is 8.5kW. The

following data are known for the steam entering and

leaving the turbine.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Determine the power output of the turbine.

Control volume: Turbine.

Inlet state: Fixed.

Exit state: Fixed.

Process: SSSF.

Model: Steam tables.

First law

with

. .

8.5

c v

Q kW !

&

2 2

. . . .

2 2

i e

c v i i e e c v

V V

Q m h gZ m h gZ W

!

& &

& &

Steady-State, Steady-Flow Process

Principle of Energy Conservation

h

i

=3137.0kJ/kg

h

e

=2675.5kJ/kg

2

1.25 /

2

0.059 /

i

i

V

kJ kg

gZ kJ kg

!

!

2

20.0 /

2

0.029 /

e

e

V

kJ kg

gZ kJ kg

=

=

. .

655.7

437.11 /

5.667 /

c v

W kW

kJ kg

q kJ kg

=

=

=

&

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Example 5.11

Steam at 0.6MPa, 200rC enters an insulated nozzle

with a velocity of 50m/s. It leaves at a pressure of

0.15MPa and a velocity of 600m/s. Determine the

final temperature if the steam is superheated in the

final state, and the quality if it is saturated.

Control volume: Nozzle.

Inlet state: Fixed.

Exit state: P

e

known.

Process: SSSF.

Model: Steam tables.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

. .

. .

2 2

0

0

2 2

2671.4 /

2671.4 467.1 2226.5

0.99

c v

c v

i e

i e

i e

e

f fg

e

e

Q

W

PE PE

V V

h h

h kJ kg

h h xh

x

x

}

=

=

+ = +

=

= +

= +

=

&

&

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Example 5.12

I n a r efr i ger at i on s ys t em, i n whi ch R-134a i s t he

refrigerant, the R-134a enters the compressor at 200kPa

, -10rC and leaves at 1.0MPa, 70rC. The mass rate of

flow is 0.015kg/s, and the power input to the compressor

is 1kW.

On leaving the compressor the refrigerant enter a water-

cooled condenser at 1.0MPa, 60rC and leaves as a liquid

at 0.95MPa, 35rC. Water enters the condenser at 10rC

and leaves at 20rC. Determine:

1. The heat transfer rate from the compressor.

2. The rate at which cooling water flows through the

condenser.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

First control volume: Compressor.

Inlet state: P

i

, T

i

; state fixed.

Exit state: P

e

, T

e

; state fixed.

Process: SSSF.

Model: R-134a tables.

. .

66.67 /

392.34 /

452.35 /

6.66 /

0.10

i e

i

e

c v

q h h w

w kJ kg

h kJ kg

h kJ kg

q kJ kg

Q kW

!

!

!

!

!

!

&

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Second control volume: Condenser.

Inlet states: R-134a-fixed; water-fixed.

Exit states: R-134a-fixed; water-fixed.

Process: SSSF.

Model: R-134a tables; steam tables.

441.89 / 42.00 /

249.10 / 83.95 /

i i e e

r i w i r e w e

r w r w

i i

r w

e e

r w

mh m h

m h m h m h m h

h kJ kg h kJ kg

h kJ kg h kJ kg

=

+ = +

= =

= =

& &

& & & &

Steady-State, Steady-Flow Process

Principle of Energy Conservation

. .

. .

0.0689 /

2.892

0.0689 /

w

c v r e i

r

c v w e i

w

w

m kg s

Q m h h kW

Q m h h

m kg s

=

= =

=

=

&

&

&

&

&

&

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Example 5.13

Consider the simple steam power plant. The following

data are for such a power plant.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Simple steam power plant

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Determine the following quantities per kilogram flowing

through the unit.

1. Heat transfer in line between boiler and turbine.

2. Turbine work.

3. Heat transfer in condenser.

4. Heat transfer in boiler.

All processes: SSSF.

Model: Steam tables.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

From the steam tables:

1. Control volume: Pipe line between the boiler and the

turbine.

1

2

3

4

3023.5 /

3002.5 /

2361.8 /

188.5 /

h kJ kg

h kJ kg

h kJ kg

h kJ kg

=

=

=

=

1 2 1 2

1 2

21.0 /

q h h

q kJ kg

+ =

=

Steady-State, Steady-Flow Process

Principle of Energy Conservation

2. Control volume: Turbine.

3. Control volume: Condenser.

4. Control volume: Boiler.

2 3 2 3

2 3

640.7 /

h h w

w kJ kg

!

!

3 4 3 4

3 4

2173.3 /

q h h

q kJ kg

!

!

5 1 5 1

4 5 4 5

5

5 1

192.5 /

2831 /

q h h

h h w

h kJ kg

q kJ kg

!

!

!

!

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Example 5.14

The centrifugal air compressor of a gas turbine receives

air from the ambient atmosphere where the pressure is

1bar and the temperature 300K. At the discharge of the

compressor the pressure is 4bar, the temperature is 480

K, and the velocity is 100m/s. The mass rate of flow

into the compressor is 15 kg/s. Determine the power

required to drive the compressor.

We consider a control volume around the compressor,

and locate the control volume at some distance from

the compressor so that the ai r crossi ng the control

surface has a very low velocity and is essentially at

ambient conditions.

Steady-State, Steady-Flow Process

Principle of Energy Conservation

If we located our control volume directly across the

inlet section, i t would be necessary to know the

temperature and velocity at the compressor inlet.

Inlet and exit states: Both states fixed.

Process: SSSF.

Model: Ideal gas with constant specific heat, value

from Table A.10(300K)

Steady-State, Steady-Flow Process

Principle of Energy Conservation Steady-State, Steady-Flow Process

Principle of Energy Conservation

A more accurate model for the behavior of the air in

this process would be the ideal gas and air tables,

A.12.

2

2 2

0

. .

2

185.6 /

2 2

2784

e

i e

e e

e i p e i

c v

V

h h w

V V

w h h C T T kJ kg

W kW

!

! ! !

!

&

2

. .

300.19 /

482.48 /

187.3 /

2

2810

i

e

e

e i

c v

h kJ kg

h kJ kg

V

w h h kJ kg

W kW

!

!

! !

!

&

Steady-State, Steady-Flow Process

Principle of Energy Conservation

Uniform State, Uniform Flow(USUF) Process

1. CVat rest.

2. Uniform state in CV. May change with time.

3. SS for the state of mass across the CS.

Mass flow rates may change with time.

2 1

. .

0

e i

c v

m m m m + =

2 2

. .

2 2

2 1

2 2 2 1 1 1 . .

. .

2 2

2 2

i e

c v i i i e e e

c v

c v

V V

Q m h gz m h gz

V V

m u gz m u gz W

+ + + = + + +

+ + + + +

5.4 Uniform-State, Uniform-Flow Process

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Example 5.15

Steam at 800kPa, 300rC is throttled to 200kPa. Changes

i n ki net i c ener gy ar e negl i gi bl e for t hi s pr oces s .

Determine the final temperature of the steam, and the

average Joule-Thomson coefficient.

Control volume: Throttle valve.

Inlet state: P

i

, T

i

known; state fixed.

Exit state: P

e

known.

Process: SSSF.

Model: Steam tables.

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

3056.5 /

200

292.4

0.0127 /

i e

e

o

e

J av

h

h h kJ kg

P kPa

T C

T

K kPa

P

p

= =

=

=

(

= =

(

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Example 5.16

Consider the throttling process across the expansion valve

or through the capi l l ary tube i n a vapor-compressi on

refrigeration cycle. In this process the pressure of the

refrigerant drops from the high pressure in the condenser

to the low pressure in the evaporator, and during this

process some of t he l i qui d fl ashes i nto vapor. I f we

consider this process to be adiabatic, the quality of the

refri gerant enteri ng the evaporator can be cal cul ated.

Consider the following process, in which ammonia is the

refrigerant. The ammonia enters the expansion valve at a

pressure of 1. 50MPa and a temperature of 32rC. I t s

pr es s ur e on l eavi ng t he expans i on val ve i s 268kPa.

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Cal cul ate the qual i ty of the ammoni a l eavi ng the

expansion valve.

Control volume: Expansion valve or capillary tube.

Inlet state: P

i

, T

i

known; state fixed.

Exit state: P

e

known.

Process: SSSF.

Model: Ammonia tables.

332.6 /

0.1585 15.85%

i e

e

h h kJ kg

x

! !

! !

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Example 5.17

Steam at a pressure of 1.4MPa, 300rC is flowing in a pipe

. Connected to this pipe through a valve is an evacuated

tank. The valve is opened and the tank fills with steam

until the pressure is 1.4MPa, and then the valve is closed.

The process takes place adiabatically and kinetic energies

and potential energies are negligible. Determine the final

temperature of the steam.

Control volume: Tank.

Initial state(in tank): Evacuated, mass m

1

=0.

Final state: P

2

known.

Inlet state: P

i

, T

i

(in tank) known.

Process: USUF.

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Flow into an evacuated vessel-control volume analysis

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

The t emper at ur e corr es pondi ng t o a pr es sure of

1.4MPa and an internal energy of 3040.4kJ/kg is found

to be 452rC.

2 2

2

2

3040.4 /

i i

i

i

mh m u

m m

h u kJ kg

=

=

= =

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Example 5.18

Let the tank of the previous example have a volume 0.4

m

3

and initially contain saturated vapor at 350kPa. The

valve is then opened and steam from the line at 1.4MPa,

300rC flows into the tank until the pressure is 1.4MPa.

Calculate the mass of steam that flows into the tank.

Control volume: Tank.

Initial state: P

1

, saturated vapor; state fixed.

Final state: P

2

.

Inlet state: P

i

, T

i

; state fixed.

Process: USUF.

Model: Steam tables.

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

2 2 1 1

2 1

2 1 2 2 1 1

2 2 1 1

3

2 2

2 1 1

2

0.4

0

i i

i

i

i i

i i

mh m u mu

m m m

m m h m u mu

m h u m h u

m v V m

V

h u m h u

v

=

=

=

=

= =

=

3

1

1

1

0.5243 /

0.763

3040.4 /

2548.9 /

i

v m kg

m kg

h kJ kg

u kJ kg

=

=

=

=

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

2

3

2

2

2

2 1

342

0.1974 /

2855.8 /

2.026

1.263

o

i

T C

v m kg

u kJ kg

m kg

m m m kg

=

=

=

=

= =

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Example 5.19

A tank of 2m

3

volume contains saturated ammonia at a

temperature of 40rC. Initially the tank contains 50% liquid

and 50% vapor by volume. Vapor is withdrawn from the

top of the tank until the temperature is 10rC. Assuming

that only vapor(i.e., no liquid) leaves and that the process

i s adi abat i c, cal cul at e t he mass of ammoni a t hat i s

withdrawn.

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Control volume: Tank.

Initial state: T

1

, V

liq

, V

vap

; state fixed.

Final state: T

2

.

Exit state: Saturated vapor(temperature changing).

Process: USUF.

Model: Ammonia tables.

2 2 1 1

2 1

. .

2 2 1 1 1

1462.8 /

0

0

e

av

e e

e

c v

e e

h kJ kg

m h m u mu

m m m

m h u mh mu

=

+ =

+ =

=

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

3

1

3

1

3

2

3

2

1

1

2

2

2

0.001726 /

0.0833 /

0.001601 /

0.2040 /

369.0 /

1342.7 /

226.6 /

1326.9 /

1100.3 /

f

g

f

fg

f

g

f

g

fg

v m kg

v m kg

v m kg

v m kg

u kJ kg

u kJ kg

u kJ kg

u kJ kg

u kJ kg

=

=

=

=

=

=

=

=

=

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

1

1

1

1

1 1

1 1

2 2 1 1 1

2

2 2

2 2

2

3

2

1 2

579.4

12.0

591.4

865100

229910

635190

2.0

0.001601 0.2040

226.6 1100.3

0.01104

0.003854 /

72.5

f

g

e

f g

e e

e

m kg

m kg

m kg

mh kJ

mu mu mu kJ

m h u mh mu kJ

V

m

v x

u x

x

v m kg

m m m kg

!

!

!

!

! !

! !

! !

!

!

!

! !

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

For ideal gas the internal energy is a function of the

temperature only.

0

T T

v

v

T

P

du T P dv

T

Pv RT

P R P

T v T

du

u f T

x

=

x

=

x

= =

x

@ =

@ =

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

from specific heats.

0

2 1

2 1 0 2 1

0

2 1

p

T

T p

T

T T

h h C T T

h C dT

h h h h

=

=

=

Uniform-State, Uniform-Flow Process

Principle of Energy Conservation

Throttling Process

SS, no work, no heat transfer, no change in PE and KE.

Joule-Thomson coefficient

T drops during throttling.

T drops during throttling.

J

h

T

P

Q

x

|

x

i e

h h =

0

J

Q

0

J

p >

Uniform-State, Uniform-Flow Process

Anda mungkin juga menyukai

- Energy Conservation in IndustriesDokumen31 halamanEnergy Conservation in IndustriesAmit AnandBelum ada peringkat

- Energy Conservation TechniquesDokumen35 halamanEnergy Conservation TechniquesSagar GuptaBelum ada peringkat

- Guideline Energy ManagerDokumen17 halamanGuideline Energy ManagerakanuruddhaBelum ada peringkat

- FinalDokumen21 halamanFinalMohammed Arshad AliBelum ada peringkat

- Energy Conservation TechniquesDokumen2 halamanEnergy Conservation Techniqueskaushik9595Belum ada peringkat

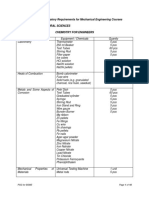

- ANNEX IV ME Laboratories SpecsDokumen16 halamanANNEX IV ME Laboratories SpecsSherwin MosomosBelum ada peringkat

- Blade Less Wind TurbineDokumen6 halamanBlade Less Wind TurbinePavan ReddyBelum ada peringkat

- Thermal Physics ModuleDokumen96 halamanThermal Physics Module3334333Belum ada peringkat

- Bottle Blow Down AnalysisDokumen45 halamanBottle Blow Down AnalysisDoctorOberman100% (2)

- Obrador Activity1 ME-3205Dokumen4 halamanObrador Activity1 ME-3205Leslie Jean ObradorBelum ada peringkat

- MEng 198 Proposal FormatDokumen12 halamanMEng 198 Proposal FormatBilly JhunBelum ada peringkat

- Electrical MaterialsDokumen2 halamanElectrical MaterialsDarshan Thakar0% (1)

- Solar Power PlantDokumen6 halamanSolar Power Plantsurafel amareBelum ada peringkat

- Optimal Rotor Tip Speed RatioDokumen10 halamanOptimal Rotor Tip Speed RatioHaposan YogaBelum ada peringkat

- Power Plant EconomicsDokumen27 halamanPower Plant EconomicsAyman Esa0% (1)

- Energy Efficiency in Hospitals Maxi Brochure 5 CADDETDokumen24 halamanEnergy Efficiency in Hospitals Maxi Brochure 5 CADDETAlexandr Rosca100% (1)

- Case Study 7 Load CharacteristicsDokumen3 halamanCase Study 7 Load CharacteristicsMark John ChavezBelum ada peringkat

- Solar Power in IndiaDokumen9 halamanSolar Power in IndiaIAS EXAM PORTAL100% (1)

- Geothermal Power Plants: A Clean Energy SourceDokumen20 halamanGeothermal Power Plants: A Clean Energy SourcePao CastillonBelum ada peringkat

- FDASDokumen22 halamanFDASJunrey EgunaBelum ada peringkat

- Design of 12MW Power System Interconnecting Negros Siquijor and CebuDokumen26 halamanDesign of 12MW Power System Interconnecting Negros Siquijor and CebuRonn AlbertBelum ada peringkat

- Institutional Assessment NC IIDokumen7 halamanInstitutional Assessment NC IIDonnald YambaBelum ada peringkat

- Solar angle tracking systemDokumen21 halamanSolar angle tracking systemTirumalarao PechettyBelum ada peringkat

- Proposed Power Plant Design for Barangay Lalakay, Los BañosDokumen21 halamanProposed Power Plant Design for Barangay Lalakay, Los Bañosjonas pauloBelum ada peringkat

- Cebu Private Power Corporation's 70 MW Power PlantDokumen34 halamanCebu Private Power Corporation's 70 MW Power PlantJChris EsguerraBelum ada peringkat

- Interest and Depreciation For Electrical Power GenerationDokumen7 halamanInterest and Depreciation For Electrical Power GenerationKopi Brisbane100% (1)

- Renewable Energy Sources PresentationDokumen8 halamanRenewable Energy Sources PresentationRushikesh NawaleBelum ada peringkat

- TMPC 632 - Mechanical Engineering Lab 1Dokumen7 halamanTMPC 632 - Mechanical Engineering Lab 1JOHNPAUL DURANOBelum ada peringkat

- Solar Panel: Disputed DiscussDokumen2 halamanSolar Panel: Disputed DiscussTina MatiușencoBelum ada peringkat

- Geo Thermal Energy - MCQs With AnswersDokumen2 halamanGeo Thermal Energy - MCQs With AnswersIsmat33% (3)

- Class I Locations GuideDokumen230 halamanClass I Locations GuideVea ValcorzaBelum ada peringkat

- Lecture 1 Fluid PropertiesDokumen40 halamanLecture 1 Fluid PropertiesRIZWAN KHANBelum ada peringkat

- Design and Development of DC Motor Boat Powered by Solar PanelsDokumen9 halamanDesign and Development of DC Motor Boat Powered by Solar PanelsDeveen SolisBelum ada peringkat

- ME432 Power Plant Engineering May Jun 2007 PDFDokumen3 halamanME432 Power Plant Engineering May Jun 2007 PDFBala MuruganBelum ada peringkat

- EE8703 Renewable Energy Systems 01 - by LearnEngineering - inDokumen27 halamanEE8703 Renewable Energy Systems 01 - by LearnEngineering - inpriya dharshiniBelum ada peringkat

- 41 Self ConsumptionDokumen2 halaman41 Self Consumptioncrico1535Belum ada peringkat

- E-644 - Electrical Codes and StandardsDokumen8 halamanE-644 - Electrical Codes and StandardsLAYTHMUNAFBelum ada peringkat

- Combined Cycle Power PlantDokumen5 halamanCombined Cycle Power PlantarhamBelum ada peringkat

- Research1 5Dokumen44 halamanResearch1 5izzeah ramodBelum ada peringkat

- Hybrid Street LightDokumen8 halamanHybrid Street LightStephanie MarquezBelum ada peringkat

- Calibu Diesel-Electric Power PlantDokumen8 halamanCalibu Diesel-Electric Power PlantCharm100% (2)

- Nuclear ProblemsDokumen9 halamanNuclear ProblemsAzhar AliBelum ada peringkat

- Full ThesisDokumen174 halamanFull Thesishasan noahBelum ada peringkat

- Tutorial Thermodynamic Chapter 2: Properties of Pure SubstanceDokumen3 halamanTutorial Thermodynamic Chapter 2: Properties of Pure SubstanceNaim ZulkifliBelum ada peringkat

- Pico Power: A Boon For Rural Electrification: Rajat KapoorDokumen8 halamanPico Power: A Boon For Rural Electrification: Rajat KapoorBamBelum ada peringkat

- ME Lab 2 Module No. 5 PDFDokumen24 halamanME Lab 2 Module No. 5 PDFIsmaeli KielBelum ada peringkat

- Engineering Chemistry Module 1: An IntroductionDokumen35 halamanEngineering Chemistry Module 1: An IntroductionAudrey MendozaBelum ada peringkat

- Programmable Logic Controller Hardware and Software ArchitectureDokumen10 halamanProgrammable Logic Controller Hardware and Software ArchitectureKantharaj ChinnappaBelum ada peringkat

- Bladeless Wind Energy GenerationDokumen29 halamanBladeless Wind Energy GenerationAnshul KhandelwalBelum ada peringkat

- 10m703 Power Plant EngineeringDokumen2 halaman10m703 Power Plant EngineeringERKATHIR100% (1)

- Solar Energy CompendiumfDokumen86 halamanSolar Energy Compendiumfjchavez3221Belum ada peringkat

- MCE12Lab - Material Science Laboratory ManualDokumen62 halamanMCE12Lab - Material Science Laboratory ManualJaloyd MacalalagBelum ada peringkat

- Electricity Distribution Systems TutorialDokumen6 halamanElectricity Distribution Systems TutorialAmir Luqman AminullahBelum ada peringkat

- Don Mariano Marcos Memorial State University Mid La Union Campus College of EngineeringDokumen1 halamanDon Mariano Marcos Memorial State University Mid La Union Campus College of EngineeringCharlyn FloresBelum ada peringkat

- Mbeya Institute of Science and Technology: Power Plant Lecture Seven Hydropower PlantsDokumen125 halamanMbeya Institute of Science and Technology: Power Plant Lecture Seven Hydropower PlantsNyandaMadili MalashiBelum ada peringkat

- Equations Describing Processes of Ideal GasDokumen28 halamanEquations Describing Processes of Ideal GasAnthony Leire MontealtoBelum ada peringkat

- Energy Analysis of Closed Systems: MAE 320-Chapter 4Dokumen9 halamanEnergy Analysis of Closed Systems: MAE 320-Chapter 4Hafizuddin RazakBelum ada peringkat

- Lecture 3 ThermodynamicsDokumen54 halamanLecture 3 Thermodynamicstorawe6575Belum ada peringkat

- Aero 3sem 111302nolDokumen103 halamanAero 3sem 111302nolvaishu1991Belum ada peringkat

- BSL BOX Manual - High Voltage TypeDokumen22 halamanBSL BOX Manual - High Voltage Typea1z403Belum ada peringkat

- ML12121A173 - Emergency Core Cooling System (ECCS) Performance Evaluation Models, 10 CFR II Annual ReportFor Calendar Year 2011Dokumen14 halamanML12121A173 - Emergency Core Cooling System (ECCS) Performance Evaluation Models, 10 CFR II Annual ReportFor Calendar Year 2011EnformableBelum ada peringkat

- Item Checklist No. DescriptionDokumen7 halamanItem Checklist No. DescriptionAdrianBelum ada peringkat

- PDFDokumen253 halamanPDFWilmar ValenzuelaBelum ada peringkat

- Detailed Project Report For Setting Up EV Assembly Facility: Back GroundDokumen8 halamanDetailed Project Report For Setting Up EV Assembly Facility: Back GroundSaurav MitraBelum ada peringkat

- 998 1689 1 SMDokumen6 halaman998 1689 1 SMPheladi MphahleleBelum ada peringkat

- Dual-Pressure Kalina Cycle Improves Power Recovery EfficiencyDokumen9 halamanDual-Pressure Kalina Cycle Improves Power Recovery EfficiencyArvin SohrabiBelum ada peringkat

- IC EnginesDokumen44 halamanIC EnginesIbrahim KhaleelBelum ada peringkat

- CAR BATTERY CHARGER GUIDEDokumen18 halamanCAR BATTERY CHARGER GUIDEAdrian CosteaBelum ada peringkat

- Brochure GFixFlotF VOL 2 Copy 2Dokumen45 halamanBrochure GFixFlotF VOL 2 Copy 2MarcBelum ada peringkat

- Calculate Energy Use and Lower Costs with Our Advisory ServiceDokumen19 halamanCalculate Energy Use and Lower Costs with Our Advisory ServiceYoesof HilabyBelum ada peringkat

- FSRU Vs PipelineDokumen7 halamanFSRU Vs PipelineAnkurSrivastavBelum ada peringkat

- EG-M54-HLV: (Series) Monocrystalline 108-Cell ModuleDokumen2 halamanEG-M54-HLV: (Series) Monocrystalline 108-Cell ModuleTaso GegiaBelum ada peringkat

- Sandrea Mexico Paper July 2019 FINAL 1Dokumen20 halamanSandrea Mexico Paper July 2019 FINAL 1civalerick549Belum ada peringkat

- 221 ThermoDynamics ThermoDynamicsDokumen5 halaman221 ThermoDynamics ThermoDynamicsmozam haqBelum ada peringkat

- Electric Inspector Form-BDokumen11 halamanElectric Inspector Form-BAamirMalikBelum ada peringkat

- MUET Speaking ExerciseDokumen1 halamanMUET Speaking ExerciseZulaikha ZulkifliBelum ada peringkat

- Energy Conversion and Management: Reza Teymourfar, Behzad Asaei, Hossein Iman-Eini, Razieh Nejati FardDokumen9 halamanEnergy Conversion and Management: Reza Teymourfar, Behzad Asaei, Hossein Iman-Eini, Razieh Nejati FardKamenriderBelum ada peringkat

- Sofar 1 3 KTL g3 DatasheetDokumen2 halamanSofar 1 3 KTL g3 Datasheetbasirjan02Belum ada peringkat

- TDEE Variant With BF 3.06Dokumen10 halamanTDEE Variant With BF 3.06Collette PetitBelum ada peringkat

- The complete range of power solutionsDokumen109 halamanThe complete range of power solutionsJose LopezBelum ada peringkat

- G - Short-Circuit Current Impedance SC2500 - 2750 - 3000-EV - V4.0 - ENDokumen6 halamanG - Short-Circuit Current Impedance SC2500 - 2750 - 3000-EV - V4.0 - ENVishnu ShankerBelum ada peringkat

- Advanced Building ScienceDokumen40 halamanAdvanced Building ScienceMujjo SahbBelum ada peringkat

- Datasheet KEC115x 116xDokumen4 halamanDatasheet KEC115x 116xkazishahBelum ada peringkat

- Current Introduction Letter 1Dokumen7 halamanCurrent Introduction Letter 1kishtechenergyBelum ada peringkat

- Markscheme SL Paper3Dokumen78 halamanMarkscheme SL Paper3Boshra NouriBelum ada peringkat

- A Dimensional Analysis For Determining Optimal Discharge and Penstock Diameter in Impulse and Reaction Water TurbinesDokumen22 halamanA Dimensional Analysis For Determining Optimal Discharge and Penstock Diameter in Impulse and Reaction Water TurbinesArmend AvdiuBelum ada peringkat

- Applied Thermodynamics: BITS PilaniDokumen24 halamanApplied Thermodynamics: BITS PilaniAnmol BansalBelum ada peringkat

- Chapter 5Dokumen2 halamanChapter 5JM NoynayBelum ada peringkat

- TECHNICAL PROGRAMME Dec 2021Dokumen131 halamanTECHNICAL PROGRAMME Dec 2021123harsh123Belum ada peringkat