Profile Projector

Diunggah oleh

Anand BabuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Profile Projector

Diunggah oleh

Anand BabuHak Cipta:

Format Tersedia

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

MEASUREMENT LINEAR AND ANGULAR DIMENSIONS USING PROFILE PROJECTOR

47

PROFILE PROJECTOR

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

MEASUREMENT OF LINEAR AND ANGULAR DIMENSIONS USING PROFILE PROJECTOR

AIM:

To determine the diameters of the holes and the angle of bevel edge of the given specimen using profile projector.

APPARATUS: Profile projector. THEORY:

Profile projector is a device which displays the magnified image of the object on an appropriate viewing screen. The magnified image serves as an aid to more precise determination of dimension, form etc. The objects like screws, gears used in wrist watches and small templates having holes, bevel edges will not lend them selves to carryout measurements using instruments like Vernier Calipers and micrometers. Measurements of dimensions on such small objects can be accomplished using profile projector.

48

PROFILE PROJECTOR

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

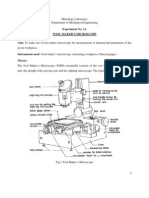

The profile projector consists of a glass table the object to be projects is to be placed on the glass table either directly or with the help of a suitable fixture depending upon the type of job. The table is equipped with two micrometers. With the help of micrometers the movement of the glass table in turn image can be precisely registered. Below the glass table a light source and condensing or collimating lens system exists. It also consists of a screen where the image of the work piece is projected with the help of mirrors and lenses. The optical system of the profile projector is shown in the figure.

PROCEDURE:

The specimen along with the features to be measured is shown in the figure.

B A C

The task is to determine the diameters of the holes A, B, C and to determine angles of beveled edges 1 and 2 To determine the diameters of the holes following steps may be followed. 1. Keep the specimen on the glass table and switch on the bulb 2. Adjust the height of the table until; a sharp image of contour of the specimen appears on the screen. 3. Now arrange the image of the hole tangential to one of the cross lines as shown in the figure image of the hole. Image of the Hole Vertical Cross Wire

4. The above arrangement is to determine the diameter of the hole in x-direction. 5. In this position note down the reading of the micrometer.

49

PROFILE PROJECTOR

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

6. Rotate the micrometer thimble until same Vertical cross line occupies diametrically opposite point as shown below. Vertical Cross Wire

7. In this position again note down the reading of micrometer. 8. Difference of the readings in the steps (7) and (5) gives the diameter of the hole in x direction. 9. To determine the diameter of the hole in y direction horizontal cross line may be made tangential to the image of the hole. 10. Repeat the above procedure for other holes also. To determine the angles of the beveled edges following steps may be followed: 1. First get the sharp images of the specimen. 2. Coincide one of the lines of cross line with one side of the bevel edge image as shown in the figure. In this position note down the reading of the protractor.

3. Rotate screen in such a way that same line coincides with other side of the beveled edge, as shown in the figure. In this position again note down the reading of the protractor.

4. Difference of the readings of the protractor in steps (2) and (3) gives the angle of the beveled edge.

50

PROFILE PROJECTOR

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

5. Same procedure may be implemented for other beveled edge to get the angle.

OBSERVATIONS:

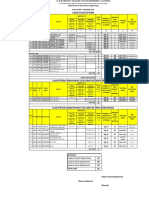

Determination Diameters of Holes:

X Direction

S.No. Initial Reading R1= M.S.R.+L.C x T.R Final Leading R2 = M.S.R. + L.C x T.R Dia of the hole R1-R2

1 2 3 Average Y Direction

S.No. Initial Reading R1= M.S.R.+L.C x T.R Final Leading R2 = M.S.R. + L.C x T.R Dia of the hole R1-R2

1 2 3 Average Determination of Angles of Bevel Edge: Sl No. Initial Reading 1 Final Reading 2 1- 2

PRECAUTIONS:

1. Students are advised to take readings without any parallax error. 2. For each feature atleast two readings must be taken and average is to be presented. 3. Table must be properly adjusted to get a sharp image.

51

PROFILE PROJECTOR

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

RESULT:

Feature Diameter of the hole A Diameter of the hole B Diameter of the hole C

X-Direction

Y-Direction

Angle of the Beveled Edge 1 1 Beveled Edge 22

= =

52

PROFILE PROJECTOR

Anda mungkin juga menyukai

- Experiment 4Dokumen3 halamanExperiment 4Arvind BhosaleBelum ada peringkat

- Measure Straightness with Auto-CollimatorDokumen6 halamanMeasure Straightness with Auto-CollimatorKarikalan Loganathan100% (1)

- Nomenclatures of Single Point Cutting Tool Using Tool Makers MicroscopeDokumen7 halamanNomenclatures of Single Point Cutting Tool Using Tool Makers Microscopeविशाल पुडासैनीBelum ada peringkat

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Dokumen27 halamanLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaBelum ada peringkat

- Experiment Measurement of Lengths, Heights, Diameters, Vernier CaliperDokumen11 halamanExperiment Measurement of Lengths, Heights, Diameters, Vernier Caliperv sharvan kumar asst.prof(mech)Belum ada peringkat

- Force MeasurementDokumen18 halamanForce MeasurementKali DasBelum ada peringkat

- Mechanical Measurement LaboratoryDokumen24 halamanMechanical Measurement LaboratoryMahendra SinghBelum ada peringkat

- Lab ManualDokumen19 halamanLab ManualAjij Mujawar100% (1)

- MILLING LAB EXPERIMENTDokumen12 halamanMILLING LAB EXPERIMENTLuqman HakimBelum ada peringkat

- Roundness ExperimentDokumen8 halamanRoundness ExperimentLanceal TanBelum ada peringkat

- BME UNIT II MeasurementDokumen55 halamanBME UNIT II MeasurementVivek Patel100% (1)

- Introductory Macroeconomics XIIDokumen28 halamanIntroductory Macroeconomics XIISnigdha100% (1)

- Metrology: ME3190 Machine Tools and MetrologyDokumen64 halamanMetrology: ME3190 Machine Tools and MetrologySujit MuleBelum ada peringkat

- Analysis and Modeling of Roundness Error PDFDokumen6 halamanAnalysis and Modeling of Roundness Error PDFCarlosQuelartBelum ada peringkat

- CNC Operator Web-Based Tutorial 545Dokumen20 halamanCNC Operator Web-Based Tutorial 545api-274441692Belum ada peringkat

- Unit 2 MetrologyDokumen32 halamanUnit 2 MetrologyMuthuvel M83% (6)

- Screw Thread MeasurementDokumen55 halamanScrew Thread MeasurementMadhuBelum ada peringkat

- TURNING LAB EXPERIMENTDokumen12 halamanTURNING LAB EXPERIMENTLuqman HakimBelum ada peringkat

- RoundnessDokumen7 halamanRoundnessjacobian1810Belum ada peringkat

- Metrology Lab Manual NewDokumen41 halamanMetrology Lab Manual Newg venkatesh100% (1)

- Gauges and Gauge DesignDokumen12 halamanGauges and Gauge DesignAmir JodeyriBelum ada peringkat

- Sine BarDokumen13 halamanSine BarmaneeshBelum ada peringkat

- Roundness Measuring MachineDokumen19 halamanRoundness Measuring MachineArif SanjidBelum ada peringkat

- Unit 3 MetrologyDokumen38 halamanUnit 3 MetrologyMuthuvel M92% (36)

- Metrology Lab ManualDokumen33 halamanMetrology Lab ManualRachit_Goyal25_10Belum ada peringkat

- A Brief Introduction To The Measurement of Roundness and Spindle Error SeparationDokumen12 halamanA Brief Introduction To The Measurement of Roundness and Spindle Error SeparationaralvoiBelum ada peringkat

- Metrology and Measurements Lab PDFDokumen65 halamanMetrology and Measurements Lab PDFGopal Krishan Sharma0% (1)

- Workshop ManualDokumen13 halamanWorkshop ManualAgnivesh SharmaBelum ada peringkat

- Lathe MachineDokumen6 halamanLathe MachineJuno Eron TalamayanBelum ada peringkat

- ME2308 Metrology and Measurements Lab ManualDokumen48 halamanME2308 Metrology and Measurements Lab ManualratchagarajaBelum ada peringkat

- ME232Geometric Tolerancing Classnotes: An Introduction to Geometric Dimensioning and Tolerancing ConceptsDokumen6 halamanME232Geometric Tolerancing Classnotes: An Introduction to Geometric Dimensioning and Tolerancing ConceptsEngineernadeemshahidBelum ada peringkat

- Milling MachineDokumen17 halamanMilling MachineAbhimanyu SinghBelum ada peringkat

- Roundness - GD&TDokumen23 halamanRoundness - GD&TKishor kumar Bhatia100% (3)

- CYLINDRICITYDokumen10 halamanCYLINDRICITYKumar ChowdaryBelum ada peringkat

- To Measure The Angles of Given Specimen Using Bevel ProtractorDokumen3 halamanTo Measure The Angles of Given Specimen Using Bevel ProtractorelavarasanBelum ada peringkat

- Measuring Angles Using Sine BarDokumen4 halamanMeasuring Angles Using Sine Barsameerkhan_mhsscoe0% (1)

- Study of Profile ProjectorDokumen5 halamanStudy of Profile ProjectorSulficker Ali100% (1)

- Measure diameters and thicknesses with Vernier calipers and micrometersDokumen12 halamanMeasure diameters and thicknesses with Vernier calipers and micrometersvdnsitBelum ada peringkat

- Measuring Diameters of Pins Using Vernier CalipersDokumen21 halamanMeasuring Diameters of Pins Using Vernier CalipersNavneet PAnde100% (3)

- JJ104 Workshop Technology Chapter7 Grinding MachineDokumen19 halamanJJ104 Workshop Technology Chapter7 Grinding MachineAh Tiang100% (1)

- Cylindricity Definition and MeasurementDokumen3 halamanCylindricity Definition and MeasurementMuhd Rifdi Che AbRahimBelum ada peringkat

- Methods of Mounting of Jobs and Cutting ToolsDokumen19 halamanMethods of Mounting of Jobs and Cutting ToolsRaghav L NaikBelum ada peringkat

- Murali - Metrology & Measurements Lab ManualDokumen30 halamanMurali - Metrology & Measurements Lab ManualsubhashBelum ada peringkat

- Machine Tool Metrology: Introduction: - Stiffness & Rigidity of The Machine Tool & Its Components PartsDokumen30 halamanMachine Tool Metrology: Introduction: - Stiffness & Rigidity of The Machine Tool & Its Components Partsmohd mansoor100% (1)

- Drill Press Function, Safety and Operation GuideDokumen3 halamanDrill Press Function, Safety and Operation GuideKhairuleIdhamBelum ada peringkat

- Tool Makers Microscope PPT - Siddhant SinghDokumen15 halamanTool Makers Microscope PPT - Siddhant SinghSiddhant Singh100% (1)

- Profile ProjectorDokumen25 halamanProfile Projectorrummanomar0% (2)

- Profile ProjectorDokumen17 halamanProfile ProjectorMukeshChoudhry100% (2)

- Metrology and MeasurmentDokumen36 halamanMetrology and Measurmentdrsahuja100% (7)

- Failure of Cutting Tools and Tool LifeDokumen9 halamanFailure of Cutting Tools and Tool LifeAmanpreet SinghBelum ada peringkat

- Tool Makers MicroscopeDokumen7 halamanTool Makers MicroscopeAnand Babu100% (2)

- 5.EMM Lab ManualDokumen38 halaman5.EMM Lab ManualRakeshkumarcegBelum ada peringkat

- 1.tool Makers MicroscopeDokumen7 halaman1.tool Makers MicroscopeelavarasanBelum ada peringkat

- Circularity Measurement Using ComparatorsDokumen7 halamanCircularity Measurement Using Comparatorsविशाल पुडासैनीBelum ada peringkat

- Report Experiment ThreadDokumen11 halamanReport Experiment Threadsparklingstars2705Belum ada peringkat

- Experiment No. 1A Tool Maker'S MicroscopeDokumen4 halamanExperiment No. 1A Tool Maker'S MicroscopePraveen KumaarBelum ada peringkat

- Measure Micrometers AccuratelyDokumen10 halamanMeasure Micrometers AccuratelyBhargav DindukurthiBelum ada peringkat

- National Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Dokumen50 halamanNational Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Venu Gopal AnneBelum ada peringkat

- CH 3 Describing DataDokumen25 halamanCH 3 Describing DataATHAYABelum ada peringkat

- Lab Session 2: Figure 1:bevel ProtractorDokumen5 halamanLab Session 2: Figure 1:bevel ProtractorAli RazaBelum ada peringkat

- Dsy Iv Sem Load CalculationsDokumen3 halamanDsy Iv Sem Load CalculationsAnand BabuBelum ada peringkat

- Some Important Terms:: Isometric Axes, Lines and PlanesDokumen10 halamanSome Important Terms:: Isometric Axes, Lines and PlanesAnand BabuBelum ada peringkat

- Final DSY SUMER 21 TIME TABLEDokumen1 halamanFinal DSY SUMER 21 TIME TABLEAnand BabuBelum ada peringkat

- Final M.TECH SUMER 21 TIME TABLEDokumen1 halamanFinal M.TECH SUMER 21 TIME TABLEAnand BabuBelum ada peringkat

- Metro Logy Lab ExperimentDokumen1 halamanMetro Logy Lab ExperimentAnand BabuBelum ada peringkat

- NodeDokumen2 halamanNodeAnand BabuBelum ada peringkat

- Wire EDM: Dielectric Liquid VoltageDokumen12 halamanWire EDM: Dielectric Liquid VoltageAnand BabuBelum ada peringkat

- Dsy M.tech Sumer 21 Time TableDokumen1 halamanDsy M.tech Sumer 21 Time TableAnand BabuBelum ada peringkat

- Tamer Samir Mahmoud Abdul Majeed - 2 - Introduction To CNC PDFDokumen35 halamanTamer Samir Mahmoud Abdul Majeed - 2 - Introduction To CNC PDFdsathiyaBelum ada peringkat

- UntitledDokumen1 halamanUntitledAnand BabuBelum ada peringkat

- Study of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Dokumen38 halamanStudy of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Anand BabuBelum ada peringkat

- Study of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabDokumen9 halamanStudy of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology LabAnand BabuBelum ada peringkat

- Tool Makers MicroscopeDokumen7 halamanTool Makers MicroscopeAnand Babu100% (2)

- Thread MeasurementDokumen5 halamanThread MeasurementAnand BabuBelum ada peringkat

- Rollers and Slip GaugesDokumen6 halamanRollers and Slip GaugesAnand Babu50% (2)

- Measurement of Surface FinishDokumen6 halamanMeasurement of Surface FinishAnand Babu100% (5)

- Gear MeasurementDokumen5 halamanGear MeasurementAnand Babu100% (1)

- Machine Tool TestingDokumen9 halamanMachine Tool TestingAnand Babu70% (10)

- Metrology Lab ManualDokumen1 halamanMetrology Lab ManualAnand BabuBelum ada peringkat

- Castorland Puzzles up to 4000 pieces with nature and animal themesDokumen14 halamanCastorland Puzzles up to 4000 pieces with nature and animal themesEdivaldo VisqueBelum ada peringkat

- ICFES TrainingDokumen2 halamanICFES TrainingJairo Eduardo Cajigas RamirezBelum ada peringkat

- W Quest Cheat SheetDokumen2 halamanW Quest Cheat SheetStuart AlexanderBelum ada peringkat

- The 4Ps of InnovationDokumen9 halamanThe 4Ps of Innovationpavie raja100% (1)

- Artikel Drama Lysistrata PDFDokumen64 halamanArtikel Drama Lysistrata PDFBala KurawaBelum ada peringkat

- A Strategic Analysis of Apple CorporationDokumen54 halamanA Strategic Analysis of Apple Corporationmahantesh12395% (43)

- The History and Development of the Armenian LanguageDokumen2 halamanThe History and Development of the Armenian Languageetna26Belum ada peringkat

- 02 - Nigeria 100 Years Ago - YorubalandDokumen9 halaman02 - Nigeria 100 Years Ago - YorubalandW MBelum ada peringkat

- List of All Publications With The KRI Seal of Approval: Name of Publication Yoga and Meditation ManualsDokumen3 halamanList of All Publications With The KRI Seal of Approval: Name of Publication Yoga and Meditation ManualsRosely PereiraBelum ada peringkat

- Movie ReviewDokumen3 halamanMovie ReviewArjayBelum ada peringkat

- Guan XiaotongDokumen9 halamanGuan XiaotongHurun AiniBelum ada peringkat

- Gedung Kantor Gubernur Sulut PDFDokumen7 halamanGedung Kantor Gubernur Sulut PDFNJ TVBelum ada peringkat

- BV Doshi: Pioneering Indian ArchitectDokumen9 halamanBV Doshi: Pioneering Indian ArchitectMuskaan ChowdharyBelum ada peringkat

- ADD HOURS MINUTES SECONDSDokumen68 halamanADD HOURS MINUTES SECONDScaje_mac6960Belum ada peringkat

- LC60 70le550ulcdmoduleDokumen8 halamanLC60 70le550ulcdmoduleRosendo PeñaBelum ada peringkat

- TulalerzDokumen2 halamanTulalerzAyiesha PanganBelum ada peringkat

- The Understudy (Fernando Alonso Fanfiction)Dokumen4 halamanThe Understudy (Fernando Alonso Fanfiction)SmallTimeScribeBelum ada peringkat

- Ed-10 Magnetic CompassDokumen7 halamanEd-10 Magnetic CompassBorysBelum ada peringkat

- SReconDokumen4 halamanSReconLesterBelum ada peringkat

- How Many Miles To Babylon Teacher S Pack PDFDokumen30 halamanHow Many Miles To Babylon Teacher S Pack PDFmikecuchulainnBelum ada peringkat

- HALLICHE HOUCINE MIDDLE SCHOOL SECOND ENGLISH EXAMDokumen2 halamanHALLICHE HOUCINE MIDDLE SCHOOL SECOND ENGLISH EXAMfonfaron0% (1)

- King Explicitly Invokes Aristotle's Theoretical Statements On Poetics. To Argue, As Does Chinua AchebeDokumen20 halamanKing Explicitly Invokes Aristotle's Theoretical Statements On Poetics. To Argue, As Does Chinua AchebeSuhrab Khan JamaliBelum ada peringkat

- Revolution The BeatlesDokumen2 halamanRevolution The BeatlesJhordy Barreda SalasBelum ada peringkat

- Ayahuasca DiariesDokumen2 halamanAyahuasca DiariesJoanne RichardsonBelum ada peringkat

- Textile Design: An IntroductionDokumen96 halamanTextile Design: An Introductiondplpthk1502100% (1)

- Age of Sigmar Silver Tower Warscrolls Errata enDokumen1 halamanAge of Sigmar Silver Tower Warscrolls Errata enGareth McKnightBelum ada peringkat

- Douglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Dokumen6 halamanDouglas Aircraft Co., Inc. Structural Repair Manual: Mar l/T0Luis Omar AmundarayBelum ada peringkat

- I Shall See Him by and by - Frank E. Graeff PDFDokumen1 halamanI Shall See Him by and by - Frank E. Graeff PDFEducational PurposesBelum ada peringkat

- The Hunger Game Book - EditedDokumen6 halamanThe Hunger Game Book - Editedjoseph mainaBelum ada peringkat

- Cub & BulBulDokumen9 halamanCub & BulBulProud Indian100% (1)