Stirling 60

Diunggah oleh

Ami JohnstonHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stirling 60

Diunggah oleh

Ami JohnstonHak Cipta:

Format Tersedia

Stirling '60'

page

scale

name

1 of 8

12-06-2010

drawn date

J. Jonkman

size

A4

Stirling '60'

page

scale

name

2 of 8

12-06-2010

drawn date

J. Jonkman

size

A4

2

1

3

1) smooth

2) Loctite

3) pressfit

4) solder

5) pin

* see page 8

Stirling '60'

page

scale

name

3 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

upper platform: wood (scale 1:2)

2

2

3

0

,

8

1

4

,

9

6

1

33

18,2 53,5

89,9

R

3

9

5(countersunk, 2x)

M4(4x)

1

9

,

4

28,6

lower platform: wood (scale 1:2)

3

4

,

6

3

0

,

3

3

0

,

8

9

1

,

4

37,4

100,4 53,5

184,2

1

0

R

3

,5

5(countersunk) 4(countersunk, 4x)

12

10

8

M4

1

0

2

1

3

2

3

7

M4

1

2

platform pillar (4x): brass

20

M4

17

14

11,8

1

0

2

0

3

0

M6

8

1

4

0,8x45(3x)

candle pillar : brass

2

6

M6

candle pillar threaded rod : steel

41

8

,

5

1

3

,

5

4

11,5

45

R5

15(24x)

4

7

candle holder: brass

1x45(2x)

candle pillar top section: brass

11,5

M6

10,5

1

,

5

1

7

1

"O" ring 10x1

(12,5)

Stirling '60'

page

scale

name

4 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

7

,

4

1

0

4

4,2

23

3

7

4

4,2

4

,

8

7

,

4

1

0

1

2

11,5

main shaft bearing housing: brass

1

,

5

20

M5

9

1

8

2

7

3

5

,

5

3

7

3

6,8

11,4

15,7

1

5

main shaft support pillar: brass

1

x

4

5

(

3

x

)

23 5 5

33

M

3

4

main shaft: brass

crank: brass

4,3

0,2

7,4

2

5

3

,

5

2

5,8

18,5

1

2

6

M

3

3

5,4

crank spacer: brass

1

2

6

crank rod: brass

10

2

10

3,2

4

9

,

2

3

9

0

,

8

(

6

x

)

M

3

1

2

0,2

3,6

6,2

1

2

0

(

1

0

,

5

)

3

(

7

,

5

)

flywheel: brass

9

,

2

R

2

,

5

(

1

2

x

)

5

,

8

2

,

5

6

1,3

7

,

5

1

2

,

5

1

8

,

3

2

5

,

5 3

4

,

5

6

9

4

,

8

3

,

8

1

,

1

1

,

1

9,5

2 1

2

R

2

,

5

5

tumbler plate: brass 1.6mm

Stirling '60'

page

scale

name

5 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

central pillar: brass

1,6

4

,

5

10

7

1

4

2

4

6

2

8

9

9

8

3

2

4

8

6,5

(

1

0

,

5

)

1,1

5

M5

4,2

2x45

1x45(4x)

14

17,5

21,5

(

4

2

)

4

(

3

8

)

10,5(2x)

9

power piston: brass

4

5

1

2

2

,

8

8

1

1

,

5

1,1

1

,

5

power piston connection rod : brass

1,6

3

5

5

,

5

3

1x45(2x)

1

4

7

,

5

2

4

,

5

2

7

1

,1

1

1,1

2,5

1,7

power cilinder: brass

1

3

,

5

1

5

9,5

11,5

2

7

,

5

short & long support studs: brass

28,7

4

31,7

4

displacer cap: brass

4

12,4

4

displacer: brass

35,6

1

2

,

4

1

3

R

6

,

5

35,3

displacer bearing: perlitic cast iron

2

6

8

displacer rod: steel

2

35

displacer rod end: brass

1

4,8

1

,

1

R

4

,

8

1,6

5

2

2

,

5

6,5

Stirling '60'

page

scale

name

6 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

test tube: glass

1

4

,

8

1

5

,

6

54,5

54,1

2

,

5

6

4

,

5

2

0

,

5

4

2

11,3

11,5

3

,

5

1

4

,

5

1

6

,

5

1

9

,

5

5

1

8

13

20,5

24

2

1,5

2

1

1

2

3

2

5

main cilinder: brass (scale 2:1)

"O" ring 20x2 (2x)

33

Stirling '60'

page

scale

name

7 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

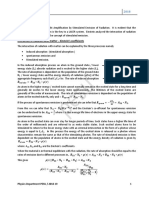

1) The fitting of the displacer rod and the corresponding bearing is critical; make sure they are smooth and straigth. The goal is to get them

as air tight as possible, while keeping the friction to a minimum. The same applies to the power piston and the corresponding cilinder. Never

lubricate these parts.

2) Join these parts with Loctite and wipe off any residue.

3) This part of the assembly must be able to be taken apart, therefore a light pressfit is recommended.

4) As these pieces are likely to get hotter then Loctite resists, soldering is used.

5) Make pins from a staight piece of brass rod, lenght corresponding with joining parts. Use a very small drop of Loctite on one end to lock

the pin in place, but keep the parts moving freely.

The crank spacer is placed over the crank rod, against the crank

If the glass testtube is somewhat different in dimensions, adjust the design of the cilinder holding the testtube and the size of the displacer.

The main concern schould be the air tight seal of the O rings around the test tube. Also make sure the displacer does not come in contact

with any of the parts.

To assemble the testtube in the cilinder, put all parts including the O rings in place and insert a very thin sheet of metal inside the cilinder.

Now gently press the testtube inside, while making sure the sheet metal is between the O rings and the testtube. This way the O rings are

compressed into place and friction between the O rings and the cilinder is low. After complete insertion of the testtube, gently remove the

sheet metal.

Ajust the hight of the candle flame by rotating the candle holder. The tip of the flame should be 3mm clear of the testtube.

Apply a small amount of light machine oil or WD40 on moving parts, except for the displacer rod and power piston.

Use 2 open, degreased and cleaned ball bearings for the main shaft, size 10x4x4.

A video can be found via www.youtube.com/jeroenjonkman

Stirling '60'

page

scale

name

8 of 8

1:1 [mm] 12-06-2010

drawn date

J. Jonkman

size

A4

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Well Stimulation Techniques: Faisal Zainal AbidinDokumen23 halamanWell Stimulation Techniques: Faisal Zainal AbidinDinesh Kanesan100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- 200 E 2 Floating Head Heat Exchanger MaintenanceDokumen16 halaman200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- S60X Embasy Service MDokumen461 halamanS60X Embasy Service MALEJOBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- DCC ChecklistDokumen1 halamanDCC Checklistluci_camBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grid1 - Untitled - gr1S - CompleteRapportDokumen3 halamanGrid1 - Untitled - gr1S - CompleteRapportKhaoula BenBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Well Intervention Manuals Rig LessDokumen2 halamanWell Intervention Manuals Rig LessDhruba Jyoti BuragohainBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Seminar Final ReportDokumen22 halamanSeminar Final ReportVasu Dev Vkm67% (6)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Engine Kontrol 1Dokumen35 halamanEngine Kontrol 1imat ruhimatBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hens FileDokumen22 halamanHens FileIlham DjafarBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Ed 00 (EN) PDFDokumen14 halamanEd 00 (EN) PDFValentin draceaBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Energizer 522: Product DatasheetDokumen1 halamanEnergizer 522: Product DatasheetAli AbdullahBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- 4016TAG2A 1500 RPM ElectropaK PN2181Dokumen5 halaman4016TAG2A 1500 RPM ElectropaK PN2181Mohammed HamzaBelum ada peringkat

- Naya Raipur': A New City Takes RootDokumen34 halamanNaya Raipur': A New City Takes Rootrevati chandakBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- C075 Aq SPC 0006 - 3Dokumen12 halamanC075 Aq SPC 0006 - 3Mingyu SongBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Ge312-1121 Columns - DrumDokumen20 halamanGe312-1121 Columns - DrumDiarista Thoma SaputraBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Kirlosker Pump Selection Models PDFDokumen36 halamanKirlosker Pump Selection Models PDFgarimaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Flyer Symap-Bc, BCG, X, XG, yDokumen11 halamanFlyer Symap-Bc, BCG, X, XG, yanon_123213442Belum ada peringkat

- 1.7 Financial ManagementDokumen26 halaman1.7 Financial ManagementEngr Mohammed UsmaniaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 4.16 Clear Water High Lift Pump HouseDokumen4 halaman4.16 Clear Water High Lift Pump HousePrasenjit DeyBelum ada peringkat

- q22 001 Fat Procedure Mt1 SK 4910 B ADokumen18 halamanq22 001 Fat Procedure Mt1 SK 4910 B APham Thai Tuyen100% (1)

- QSL9 G91Dokumen2 halamanQSL9 G91Obdvietnam ServiceBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsDokumen2 halamanSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXABelum ada peringkat

- Toyota Service Specifications - 2000 To 2002Dokumen44 halamanToyota Service Specifications - 2000 To 2002Marcelo Pchevuzinske100% (1)

- Hyosung Sf50 Prima 2007 Part CatalogueDokumen76 halamanHyosung Sf50 Prima 2007 Part CatalogueRobert 70% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- 4 Lasers 2 PDFDokumen10 halaman4 Lasers 2 PDFDark WolfBelum ada peringkat

- OiLibya Lubricants Guide InteractiveDokumen10 halamanOiLibya Lubricants Guide Interactivehoussem houssem100% (1)

- Manual de Servicio Motores M6 M7 DenisonDokumen24 halamanManual de Servicio Motores M6 M7 DenisonaugustoBelum ada peringkat

- TTHHDokumen4 halamanTTHHHitesh PanigrahiBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- FSD101eng FSG Seals Catalog A4Dokumen64 halamanFSD101eng FSG Seals Catalog A4ASHOKBelum ada peringkat

- STS Finals PDFDokumen40 halamanSTS Finals PDFJanelle TanBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)